Are your “all-weather” furniture imports cracking after just one season under the sun? Generic labels often hide cheap PVC substitutes that ruin your reputation, but genuine PE rattan offers the ultimate technical solution.

PE rattan, also known as polyethylene rattan or poly-wicker, is a synthetic material designed to mimic natural rattan. It is primarily composed of High-Density Polyethylene (HDPE) infused with UV stabilizers and color pigments. Unlike natural fiber or PVC, PE rattan is 100% recyclable, weatherproof, and resistant to mold.

I. What Is PE Rattan Material?

Understanding the chemical foundation of your inventory is the first step toward reducing customer returns and ensuring long-term structural integrity in varied climates. High-quality PE rattan is specifically engineered from virgin polyethylene resins that provide a balance of tensile strength and environmental resistance that cheaper polymers simply cannot match.

The Chemical Composition of HDPE

The core of premium synthetic wicker lies in High-Density Polyethylene (HDPE), a thermoplastic polymer known for its high strength-to-density ratio and excellent chemical resistance. This material ensures that the furniture remains structurally sound even when subjected to significant weight or repeated mechanical stress over several years of intensive use.

Essential Additives for Outdoor Durability

To transform raw polyethylene into a true all-weather material, manufacturers must integrate a precise cocktail of additives that protect the polymer chains from environmental degradation. These specialized components prevent the material from fading, becoming brittle, or losing its elasticity when exposed to extreme temperature fluctuations.

Consider these critical additives required for high-performance furniture:

- UV Inhibitors: Block ultraviolet radiation to prevent the “chalking” effect and color loss.

- Antioxidants: Protect the material during the high-temperature extrusion process.

- Heat Stabilizers: Ensure the wicker does not soften or deform in tropical heat.

- Light Stabilizers (HALS): Scavenge free radicals created by sunlight to stop molecular breakdown.

Here is the bottom line.

| Component | Function | Industry Standard |

|---|---|---|

| Virgin HDPE Resin | Base structural polymer | >95% purity |

| UV-8/UV-12 Stabilizers | Solar radiation protection | 3000-5000 hours rating |

| Color Masterbatch | Aesthetic pigment consistency | Grade 4-5 color fastness |

| Antioxidant Agents | Thermal processing protection | 0.2% – 0.5% concentration |

Key Takeaway: PE rattan is a sophisticated polymer blend, not just “plastic,” engineered specifically for thermal stability and long-term UV resistance.

II. Common PE Rattan Shapes and Textures

The versatility of PE rattan allows for a wide array of visual profiles that can define the entire character of an outdoor collection. Selecting the right shape is not merely an aesthetic choice; it directly influences the weight, weaving complexity, and perceived value of the finished furniture piece.

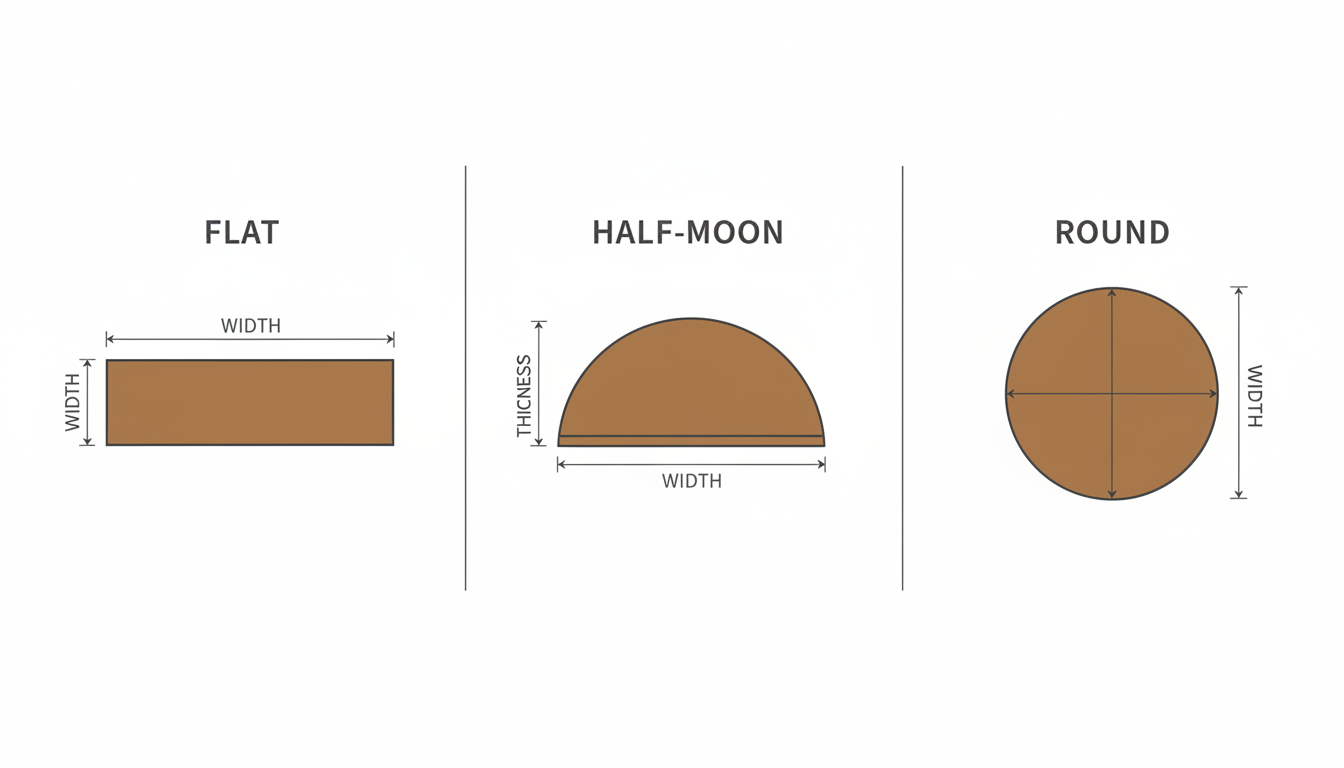

Flat and Halfmoon Profile Differences

Flat rattan is the industry standard for modern, minimalist designs due to its efficient coverage and lower material weight per square meter of weaving. In contrast, the halfmoon profile offers a more robust, three-dimensional look that closely resembles thick natural willow, providing a premium tactile experience for high-end patio sets.

Round and Twist Rattan Varieties

Round rattan represents the pinnacle of synthetic wicker design, offering a heavy, luxurious feel that mimics the structural density of traditional core rattan vines. Twist varieties add an extra layer of artisanal texture by intertwining multiple strands during the extrusion process, creating a unique visual depth that enhances the “organic” appearance of the furniture.

Review the following surface finishes available for modern collections:

- Wood Grain: Embossed patterns that simulate the natural pores of timber.

- Leatherette: A smooth, semi-matte finish that provides a sophisticated indoor-outdoor transition.

- Brushed Texture: A roughened surface that eliminates the “plastic shine” for a matte, natural look.

- Multi-Tone: Co-extruded colors that create a variegated, realistic vine aesthetic.

| Profile Shape | Width Range | Typical Application | Labor Intensity |

|---|---|---|---|

| Flat | 6mm – 12mm | Entry-level dining and lounge sets | Medium |

| Halfmoon | 5mm – 7mm | Mid-to-high range garden sofas | High |

| Round | 2mm – 5mm | Luxury hospitality and boutique sets | Very High |

| Twist | 3mm – 8mm | Accent pieces and textured detailing | High |

Key Takeaway: Profile selection directly impacts both the weaving labor cost and the final aesthetic of the furniture piece, defining its market positioning.

III. Comparing PE Rattan to Other Plastics

Distinguishing between various synthetic polymers is crucial for buyers who need to guarantee a specific lifespan for their commercial or residential projects. While many plastics appear identical at first glance, their molecular behavior under UV stress and mechanical load varies significantly across the manufacturing spectrum.

PE vs. PP: Structural Rigidity Analysis

Polypropylene (PP) is often used as a cheaper alternative because of its high rigidity, but it lacks the essential flexibility required for the tight radii found in intricate hand-weaving. While PP may feel “stronger” initially, its crystalline structure makes it far more susceptible to stress-cracking and environmental fatigue compared to the more resilient polyethylene.

Why PC and PU Are Rarely Used for Weaving

Polycarbonate (PC) and Polyurethane (PU) offer excellent clarity and impact resistance in other industries, yet they remain impractical for mass-market wicker weaving due to their high cost and processing difficulties. These materials are generally reserved for specialized components rather than the primary weaving fiber, as they do not provide the cost-to-performance ratio required for large-scale outdoor furniture.

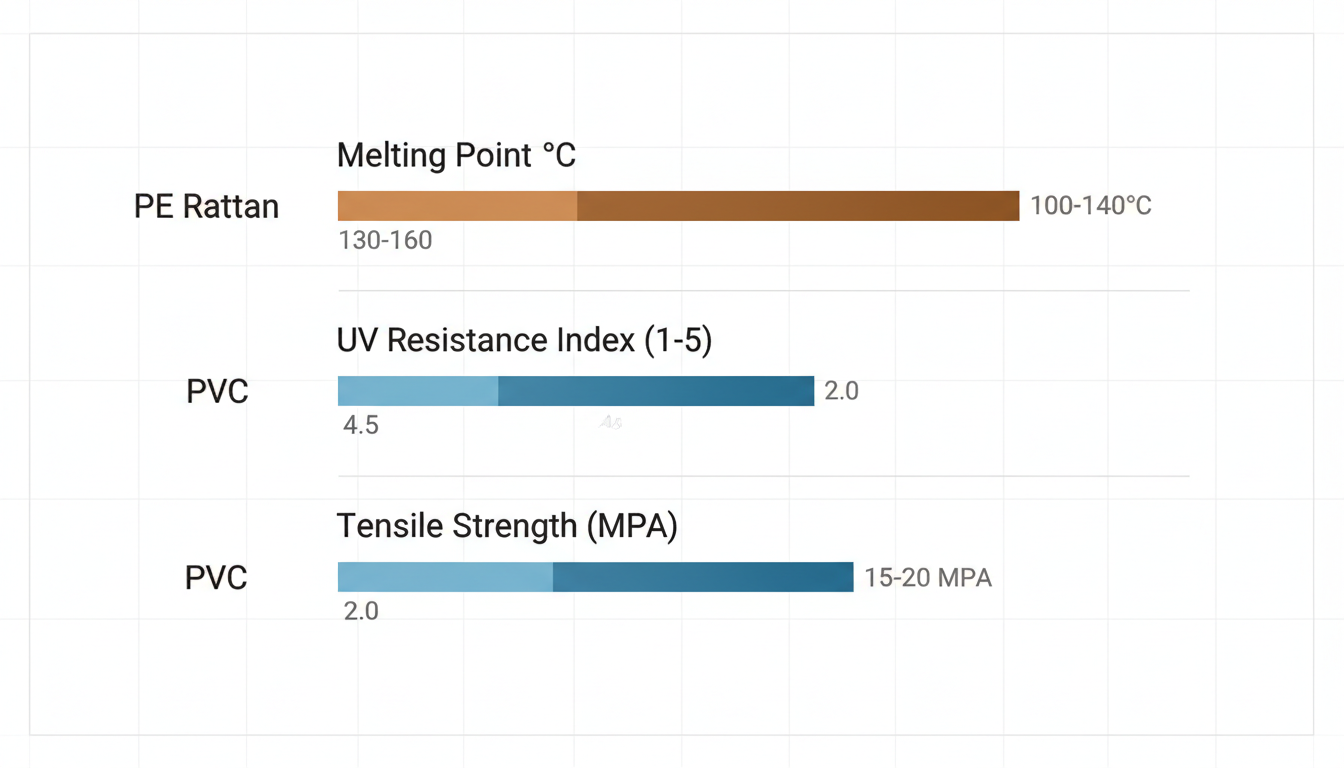

The following technical indicators highlight the performance gaps between common polymers:

- Flexibility: PE maintains its shape without snapping during the weaving of tight corners.

- Melting Point: PE’s thermal window is optimized for stable outdoor use in direct sunlight.

- Chemical Stability: PE does not react with common household cleaners or pool chlorine.

You might be wondering.

| Technical Metric | PE (Polyethylene) | PP (Polypropylene) | PVC (Polyvinyl Chloride) |

|---|---|---|---|

| Melting Point | 115°C – 135°C | 160°C – 170°C | 100°C – 260°C |

| UV Resistance | Excellent (with additives) | Moderate | Poor (yellows/brittles) |

| Flexibility | High (Ideal for weaving) | Low (Prone to snapping) | High (but temperature sensitive) |

| Eco-Friendliness | 100% Recyclable | Recyclable | Non-recyclable/Toxic |

Key Takeaway: While PP is cheaper, PE rattan offers the necessary flexibility required for intricate hand-weaving without the risk of structural cracking over time.

IV. Misleading Labels: PE Rattan vs. PVC

The term “synthetic rattan” is frequently used as a deceptive umbrella for lower-quality materials that fail to meet basic outdoor durability standards. As a professional importer, you must be able to identify when a supplier is substituting high-grade PE with inferior, short-lived alternatives to lower their price point.

The Environmental Impact of PVC Wicker

Polyvinyl Chloride (PVC) is significantly cheaper than PE but poses serious environmental risks and health concerns due to the release of toxic dioxins and phthalates. Furthermore, PVC is nearly impossible to recycle in the context of furniture waste, making it a poor choice for brands focusing on sustainability and corporate responsibility.

Identifying Brittle Low-Cost Substitutes

Low-cost synthetic wicker often incorporates recycled plastics or heavy fillers that compromise the molecular bonds of the material, leading to rapid degradation. These substitutes typically exhibit a characteristic “plastic smell” and a dull surface finish, serving as immediate indicators of a product that will likely fail within 12 to 24 months of outdoor exposure.

Watch for these red flags during your supplier evaluation process:

- Price Disparity: Quotes that are 30% lower than the market average usually indicate PVC usage.

- Odor: A strong chemical or “new car” smell often points to off-gassing PVC.

- Surface Texture: A greasy or overly shiny finish can suggest low-grade recycled content.

- Weight: PVC is generally heavier and more dense than high-quality HDPE.

| Feature | Genuine PE Rattan | Low-Cost PVC Substitute |

|---|---|---|

| Estimated Lifespan | 5 – 10+ Years | 1 – 2 Years |

| Cold Resistance | Remains flexible at -20°C | Becomes brittle and cracks |

| Heat Resistance | Stable up to 60°C+ | Softens and sags |

| Toxic Emissions | None (Chemically inert) | High (Phthalates and Lead) |

Key Takeaway: “Synthetic rattan” is often used as a catch-all term for PVC, which lacks the weather resistance and safety profile of genuine PE rattan.

V. Why PE Rattan Is Superior to Natural Fiber

While the charm of natural organic vine is undeniable, its practical application in outdoor environments is severely limited by biological decay. For commercial applications and high-traffic residential areas, synthetic alternatives provide a level of consistency and longevity that traditional materials simply cannot match.

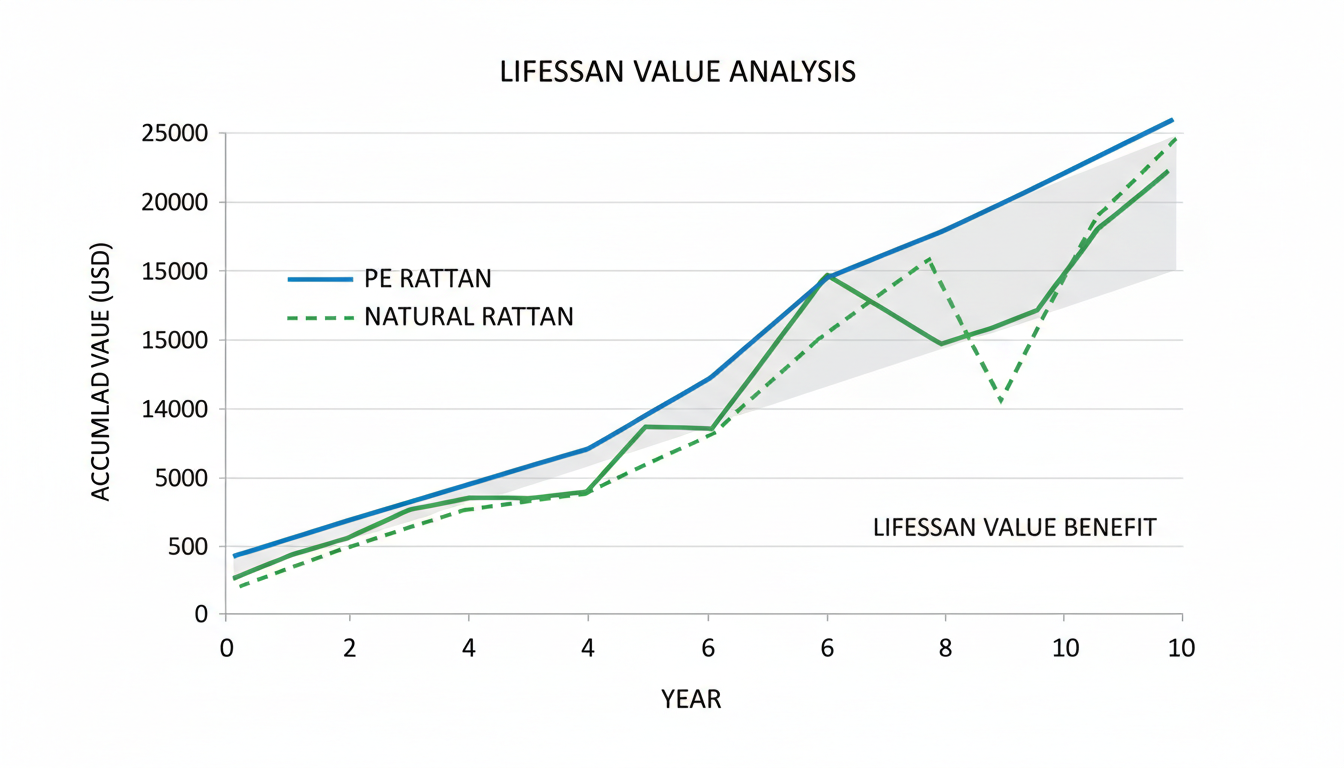

Maintenance and Long-Term Lifespan Data

Natural rattan requires frequent treatment with oils and varnishes to prevent the fibers from drying out or rotting due to moisture absorption. PE rattan, conversely, requires nothing more than an occasional rinse with soapy water, drastically reducing the total cost of ownership and maintenance labor for the end-user.

Environmental Sustainability and Recycling

The sustainability of PE rattan stems from its 100% recyclability and the fact that it does not contribute to the over-harvesting of slow-growing tropical rainforest vines. By choosing high-quality synthetic options, you support a circular economy where old furniture can be ground down and re-processed into new industrial components.

Compare the following benefits of synthetic versus organic materials:

- Mold Resistance: Synthetic fibers are non-porous and do not support fungal growth.

- Color Uniformity: Batch-to-batch consistency is guaranteed through precision extrusion.

- Pest Immunity: Unlike natural wood or vine, PE is not a food source for wood-boring insects.

But that’s not all.

| Performance Area | Natural Rattan | PE Rattan |

|---|---|---|

| Weather Resistance | Low (Indoor/Covered use only) | High (Full outdoor exposure) |

| Cleaning Complexity | High (Specialized products) | Low (Water and mild soap) |

| Initial Cost | Variable (Market dependent) | Predictable (Resin based) |

| 10-Year Value | Poor (Requires replacement) | Excellent (Single investment) |

Key Takeaway: PE rattan provides a 10–15 year outdoor lifespan, significantly outperforming natural vine in high-humidity and direct-sunlight environments.

VI. Step-by-Step Production Process

The quality of the final wicker strand is determined long before it reaches the weaving floor, starting with the precision of the raw material preparation. A standardized manufacturing flow ensures that every meter of rattan has the same tensile strength and color depth, which is vital for large-scale production runs.

Material Mixing and Color Consistency

The process begins with the automated mixing of virgin HDPE pellets with concentrated color masterbatches and UV-protective additives. Maintaining a controlled environment during this phase is essential to prevent contamination, which is one reason why sample approval doesn’t mean responsibility is clear if the factory deviates from these mixing ratios during mass production.

Extrusion and Dual-Cooling Protocols

Once the mixture is liquefied, it is forced through precision dies that determine the rattan’s profile shape and surface texture. Immediate cooling through a dual-stage water bath is then required to “lock in” the molecular structure, preventing internal stresses that could lead to premature snapping or deformation after the furniture is assembled.

The standard manufacturing flow includes these critical steps:

- Resin Inspection: Verifying the purity and moisture content of the HDPE.

- Precision Dosing: Computer-controlled mixing of pigments and stabilizers.

- Melt Extrusion: High-pressure shaping through customized steel dies.

- Surface Embossing: Applying realistic textures while the polymer is semi-malleable.

- Water Quenching: Rapid cooling to stabilize the physical dimensions.

- Spooling: Tension-controlled winding for easy use by the weaving team.

| Stage | Control Parameter | Quality Risk |

|---|---|---|

| Mixing | Additive Percentage | Low UV Resistance |

| Extrusion | Temperature Profile | Internal Voids/Weakness |

| Embossing | Pressure Setting | Loss of Texture Detail |

| Cooling | Water Temperature | Dimensional Instability |

Key Takeaway: Strict temperature control and additive dosing during extrusion prevent the “brittle” effect often found in low-quality or rushed production batches.

VII. Performance Testing for High-Quality Rattan

Relying on a supplier’s word is insufficient in the B2B sector; rigorous, data-driven testing is the only way to verify that a product meets your brand’s standards. Implementing a comprehensive furniture quality control protocol allows you to intercept sub-par materials before they are woven into finished goods and shipped across the globe.

Visual and Sensory Inspection Standards

The first line of defense involves a detailed visual audit to check for color consistency, surface defects, and the absence of the characteristic “plastic sheen” associated with cheap resins. Technicians also perform sensory checks, such as the “smell test,” to ensure that no recycled materials or harmful chemical residues are present in the batch.

Laboratory Tensile and UV Exposure Tests

Advanced quality assurance requires laboratory equipment to simulate years of environmental stress in a matter of weeks using Xenon arc lamps and tensile testers. These tests measure the material’s breaking point and its ability to retain color after thousands of hours of concentrated ultraviolet exposure, ensuring it meets international standards like REACH and RoHS.

You can perform these simple “field tests” to verify material grade on-site:

- Bend Test: Fold the rattan 180 degrees; it should not show white stress marks.

- Pull Test: Stretch the strand; high-quality PE will elongate significantly before snapping.

- Burn Test: PE should smell like candle wax and drip clearly, not produce black, acrid smoke.

- Scrape Test: Use a fingernail to try and peel the color; it should be integrated, not coated.

- Tension Test: Ensure the strand returns to its original length after moderate stretching.

| Test Type | Standard Requirement | Failure Indicator |

|---|---|---|

| UV Weatherometer | 3000+ Hours | Color fading or surface cracking |

| Tensile Strength | >15 MPa | Brittle snapping at low force |

| Heat Aging | 70°C for 168 hours | Significant shrinkage or softening |

| Chemical Resistance | No reaction to 5% NaCl | Pitting or surface degradation |

Key Takeaway: High-quality PE should remain flexible after a 180-degree bend test without showing white stress marks or structural cracks.

VIII. Global Applications for PE Rattan Products

The application of synthetic wicker has expanded far beyond the traditional backyard, finding its way into high-traffic commercial spaces and sophisticated interior designs. As global demand for durable residential furniture continues to rise, the versatility of PE rattan makes it a preferred choice for architects and designers worldwide.

Trends in Residential Outdoor Furniture

Modern homeowners are increasingly looking for “outdoor living rooms” that mirror the comfort and style of their interior spaces while requiring minimal upkeep. PE rattan allows for the creation of oversized sectional sofas, modular daybeds, and ergonomic dining chairs that can withstand the elements without sacrificing the cozy aesthetic of organic textures.

Commercial Hospitality and Garden Design

In the hospitality sector, durability is paramount, as furniture must endure constant use by guests and exposure to pool chemicals or seaside salt air. Hotels and resorts favor PE rattan for its ability to maintain a “like-new” appearance over multiple seasons, providing a higher return on investment than more delicate natural materials.

Think about it.

Consider these diverse applications for modern synthetic weaving:

- Architectural Screens: Weatherproof privacy panels for balconies and terraces.

- Poolside Loungers: High-UV environments where chlorine resistance is mandatory.

- Planter Boxes: Decorative garden elements that must resist constant soil moisture.

- Wall Coverings: Textured interior accents that offer a natural feel with fire-retardant options.

| Market Segment | Primary Requirement | Recommended Rattan Type |

|---|---|---|

| Luxury Resorts | Maximum Durability | Round / High-UV Grade |

| Residential Patio | Aesthetic Variety | Flat / Halfmoon |

| Public Parks | Vandalism Resistance | Thick, high-density profiles |

| Indoor Accents | Soft Tactile Feel | Brushed / Leatherette textures |

Key Takeaway: Beyond standard seating, PE rattan is increasingly utilized for architectural screens and weatherproof wall coverings in diverse global climates.

IX. Sourcing Strategy for Rattan Importers

Building a reliable supply chain requires more than just finding a competitive price; it necessitates a deep dive into the factory’s operational standards and material sourcing. A strategic approach to procurement will protect your business from the risks of sub-standard batches that can lead to costly product recalls and brand damage.

Vetting Factory-Direct Supplier Credentials

When evaluating a manufacturer, you should request a detailed audit of their raw material supply chain and their internal quality testing facilities. Reputable factories will be transparent about their resin sources and will provide documented proof of their extrusion parameters and additive dosing schedules to ensure long-term product consistency.

Interpreting REACH and RoHS Certifications

Compliance with international safety standards like REACH and RoHS is non-negotiable for importers entering the European or North American markets. These certifications ensure that the PE rattan is free from restricted heavy metals and hazardous chemicals, protecting both the end-consumer and your company from legal liabilities.

Best of all.

Ask these critical questions before finalizing any purchase contract:

- What brand of UV stabilizer do you use in your resin mix?

- Can you provide a 3000-hour UV test report from an independent lab?

- What percentage of recycled material is included in this specific grade?

- Do you offer a warranty against cracking and fading for this SKU?

- How do you handle color matching for repeat orders over time?

| Sourcing Criterion | Ideal Standard | Red Flag |

|---|---|---|

| Material Source | 100% Virgin HDPE | “Proprietary Blend” (often recycled) |

| Lab Testing | Third-party (SGS/Intertek) | Internal-only checklists |

| Certification | REACH / RoHS / ISO 9001 | No valid certificates available |

| Warranty | 3 – 5 Years | 6 months or none |

Key Takeaway: Always demand third-party testing reports specifically for UV resistance (3000-hour tests) to ensure export compliance and consumer safety.

X. Future Trends in Synthetic Design

The evolution of synthetic wicker is moving toward “hyper-realism,” where the distinction between man-made polymers and organic fibers becomes nearly impossible to detect. Innovations in extrusion technology and polymer science are opening new doors for creative expressions that combine traditional craftsmanship with modern performance.

Bio-Based Polymers and Green Innovation

Research is currently focused on developing bio-based polyethylene derived from renewable sources like sugarcane to further reduce the carbon footprint of outdoor furniture. These advancements aim to maintain the high performance of HDPE while providing an even more sustainable profile for eco-conscious brands and consumers.

Hybrid Designs Combining Wood and PE

A growing trend in the luxury market is the combination of synthetic weaving with high-quality timber frames, contrasting the sleekness of bedroom furniture wood textures with the durability of all-weather wicker. This hybrid approach allows designers to create sophisticated pieces that feel grounded and organic while possessing the resilience needed for harsh outdoor environments.

Expect to see these color palettes and styles in upcoming seasons:

- Earthy Terracotta: Warm, clay-inspired tones for Mediterranean-style gardens.

- Slate Grey Mix: Multi-tonal greys that mimic weathered stone and driftwood.

- Deep Emerald: Bold, jewel-toned greens that blend seamlessly with lush landscaping.

- Sandstone Matte: Light, neutral tones with a heavy “stone-wash” texture.

| Future Trend | Market Driver | Impact on Manufacturing |

|---|---|---|

| Bio-Polyethylene | Sustainability Demand | Transition to plant-based resins |

| Hyper-Realism | Luxury Aesthetic | Advanced 3D embossing techniques |

| Hybrid Materials | Design Sophistication | Complex assembly and joining methods |

| Smart Weaving | Functional Integration | Inclusion of sensors or lighting elements |

Key Takeaway: The next generation of PE rattan focuses on “hyper-realism,” making it nearly indistinguishable from natural organic fibers while enhancing environmental sustainability.

FAQ

1. Can PE rattan be left outside in winter?

Yes, high-quality PE rattan is engineered to withstand temperatures from -30°C to 120°C, making it frost-resistant and safe for year-round outdoor storage without the risk of cracking or becoming brittle in sub-zero conditions.

2. Is PE rattan eco-friendly?

Unlike PVC, PE rattan is 100% recyclable and made from non-toxic HDPE, which does not release harmful gases when exposed to heat or sun, ensuring a safer footprint for both the environment and the end-user.

3. How can I tell if a supplier is using recycled plastic?

Recycled or low-grade material often has a pungent chemical smell and a duller surface finish compared to virgin PE rattan, and it will often show white stress marks immediately upon being bent or stretched.

Closing Note

Selecting the right material is the foundation of a successful outdoor furniture line. At Everwoody , we prioritize the technical integrity of our PE rattan to ensure our partners avoid the pitfalls of misleading labels and inferior substitutes. Our mission is to provide transparent, factory-direct solutions that elevate the standards of global outdoor living.