Before shipping, furniture undergoes a rigorous verification process that includes moisture content testing, structural load-bearing assessments, hardware durability cycles, and surface finish consistency checks to ensure compliance with international safety standards.

For many importers, the arrival of a container is met with anxiety rather than excitement. You spend months designing and negotiating, only to find that 15% of the shipment has structural wobbles or finish peel-offs that make them unsellable. This inconsistency erodes your profit margins and damages your brand reputation with retail partners. By implementing a standardized furniture quality control protocol, manufacturers can identify defects at the source, transforming potential liabilities into high-performing assets that satisfy end-users and reduce costly returns.

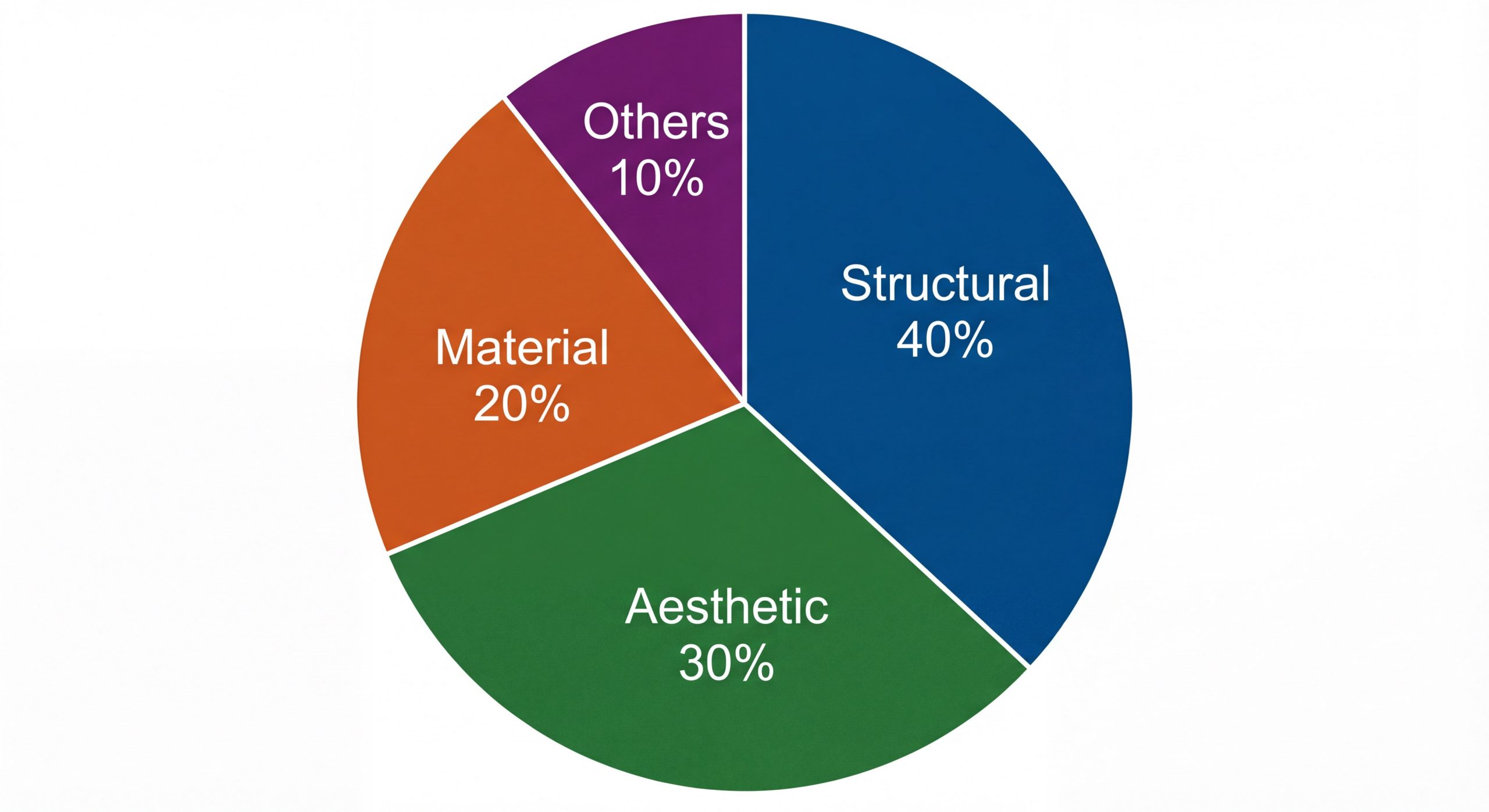

<center>Distribution of common manufacturing defects found during inspection</center>

Ⅰ. Why is furniture quality control essential?

Standardized inspection prevents the shipment of defective goods that could lead to expensive recalls, safety hazards, and the loss of retail contracts. Maintaining a robust furniture quality control system ensures that every piece of wood meets the specifications agreed upon during the sampling phase.

How do defects impact your bottom line?

Poor quality leads to immediate financial loss through replacements and hidden costs like logistics for returns. Think about it: a single faulty chair in a set of six can render the entire unit unsellable.

- High return rates

- Increased shipping costs for replacements

- Negative customer reviews

Key Takeaway: Quality control acts as a financial insurance policy for your inventory.

| Impact Category | Risk Level | Mitigation Strategy |

|---|---|---|

| Customer Trust | Critical | Pre-shipment inspection |

| Profit Margins | High | Batch testing protocols |

| Brand Value | Moderate | Material certification |

Comprehensive oversight ensures that small errors do not escalate into systemic failures.

Ⅱ. Raw material furniture quality control checks

Raw material inspection focuses on verifying the moisture content of the wood and the grade of the timber before any cutting begins. Effective furniture quality control starts in the lumber yard to prevent future issues like warping or cracking caused by unstable wood.

<center>Technician measuring wood moisture content using a digital meter</center>

Why is moisture content the first priority?

Wood is a living material that expands and contracts based on its environment, making moisture stability crucial for long-term durability. Here is why: if the wood is too wet during production, it will shrink and crack once it reaches a dry, heated home in Europe or the US.

- Standard range: 8% to 12%

- Prevents joint separation

- Ensures glue adhesion

Key Takeaway: Stabilizing the material at the start prevents structural failure at the end.

| Material Check | Requirement | Tool Used |

|---|---|---|

| Moisture Content | 8-12% | Digital Moisture Meter |

| Wood Grade | Clear/Selected | Visual Grading Standard |

| FSC Status | Certified | Chain of Custody Audit |

Verifying materials early saves the cost of manufacturing items destined for failure.

Ⅲ. Structural integrity and stability testing

Structural testing involves applying heavy loads to the furniture to ensure it can withstand daily use without collapsing or tipping. While this step is part of furniture quality control, it specifically targets the engineering and joinery of the product.

<center>Automated pressure testing on a wooden chair frame in the lab</center>

Can the furniture pass a load-bearing test?

Testing machines simulate years of use by applying cyclic pressure to seats, backrests, and joints. Look at this: a dining chair must handle at least 100kg to 125kg of static weight to be considered safe for residential use.

- Static load testing

- Impact drop testing

- Joint stress analysis

Key Takeaway: Rigorous load testing guarantees the safety of the end consumer.

| Test Type | Standard Weight | Duration |

|---|---|---|

| Seat Static Load | 125 kg | 10 cycles |

| Back Impact | 25 kg | 1,000 cycles |

| Stability Test | Vertical Pressure | Until failure |

Structural soundness is the non-negotiable foundation of any furniture product line.

Ⅳ. Surface finish furniture quality control

Surface inspection ensures that the paint, lacquer, or oil finish is applied evenly without drips, bubbles, or hazardous chemical off-gassing. Consistent furniture quality control in the finishing department prevents aesthetic complaints that often lead to “open box” returns.

<center>Quality inspector examining the surface finish under high-intensity light</center>

How is finish consistency measured?

Inspectors use gloss meters and cross-hatch adhesion tests to verify that the coating won’t peel or flake off over time. The bottom line: if the finish fails, the premium perception of the wood disappears instantly.

- Cross-hatch adhesion test

- Gloss level verification

- Smoothness “touch” check

Key Takeaway: The finish is the first thing a customer sees and the last thing that should fail.

| Finish Attribute | Quality Goal | Inspection Method |

|---|---|---|

| Adhesion | Grade 0-1 | Cross-cut tape test |

| Color Match | Delta E < 1.0 | Spectrophotometer |

| Odor | Low/No VOC | Sensory/Lab analysis |

A flawless finish distinguishes professional manufacturing from amateur production.

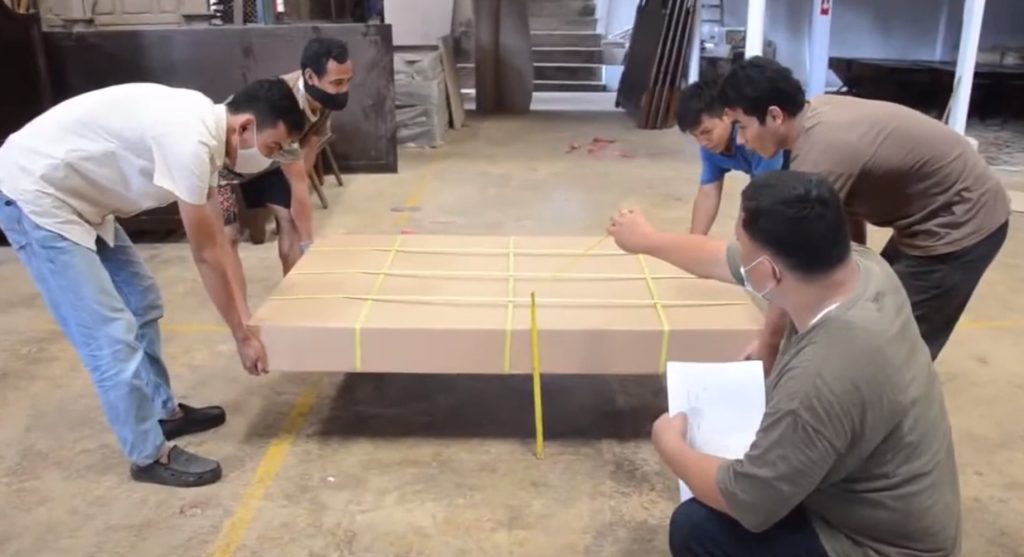

Ⅴ. Precision machining and dimensional accuracy

Dimensional accuracy checks confirm that all components are cut to the exact millimeter specified in the technical drawings. In the world of furniture quality control, precision ensures that flat-pack items can be easily assembled by the customer without frustration.

<center>Macro view of wood grain and precision joinery alignment</center>

Does the furniture fit together perfectly?

Small deviations in drill hole placement can make it impossible to secure a screw or align a drawer front. Think about it: a 2mm error in a table leg can cause a permanent wobble that ruins the user experience.

- Tolerance check (+/- 1mm)

- Hole alignment verification

- Component matching

Key Takeaway: Precise machining is the secret to easy assembly and structural stability.

| Dimension Area | Tolerance | Measurement Tool |

|---|---|---|

| Overall Height | +/- 2mm | Digital Tape |

| Drill Hole Depth | +/- 0.5mm | Caliper |

| Board Thickness | +/- 0.2mm | Micrometer |

Consistent dimensions across thousands of units are the hallmark of advanced CNC manufacturing.

Ⅵ. Hardware durability furniture quality control

Hardware testing focuses on the hinges, drawer slides, and handles to ensure they function smoothly for the life of the product. Integrating hardware checks into furniture quality control is vital because a broken hinge makes a high-end cabinet completely useless.

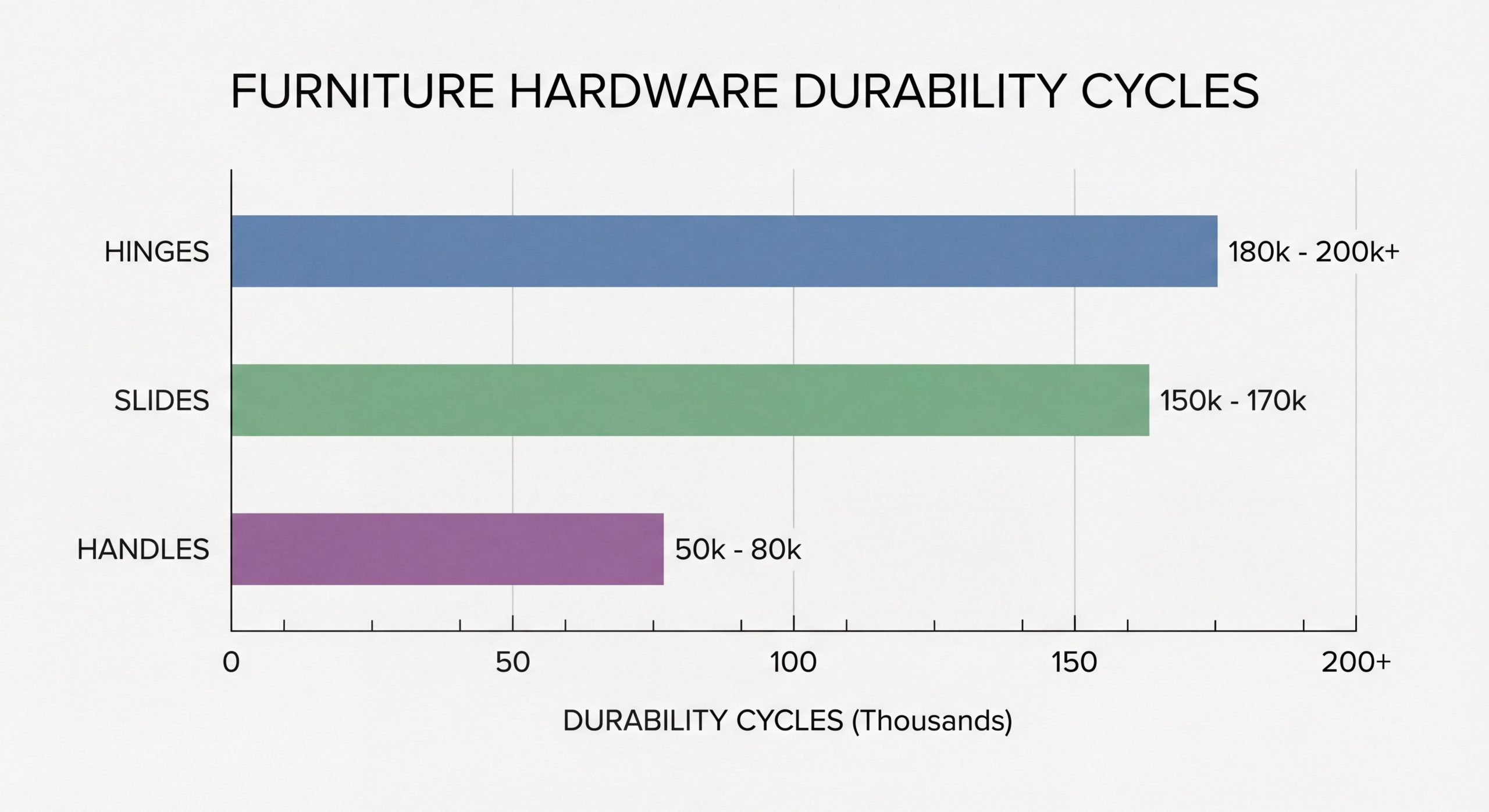

<center>Durability cycle comparison for different furniture hardware components</center>

How long will the hinges and slides last?

Hardware components are subjected to thousands of open-and-close cycles to simulate 10 to 15 years of daily use. Case in point: premium drawer slides should remain silent and smooth even after 50,000 cycles.

- Cycle testing (50k+ reps)

- Salt spray (anti-rust) test

- Weight capacity check

Key Takeaway: High-quality hardware is the engine that keeps furniture functional.

| Hardware Type | Min. Cycles | Common Material |

|---|---|---|

| Door Hinges | 80,000 | Stainless Steel |

| Drawer Slides | 50,000 | Galvanized Steel |

| Magnetic Catches | 20,000 | Rare Earth/Ceramic |

Investing in tested hardware reduces long-term warranty claims significantly.

Ⅶ. Packaging and transit safety protocols

Transit testing verifies that the packaging can protect the wood from the shocks, vibrations, and drops inherent in global shipping. While not part of the physical wood, this phase of furniture quality control is what ensures the product arrives in a sellable condition.

Will the package survive a 1-meter drop?

ISTA-certified drop tests simulate a courier dropping the box from the back of a truck or a warehouse shelf. Here is why: without reinforced corners and internal foam, the heavy weight of wooden furniture will crush the outer carton.

- Edge drop testing

- Vibration simulation

- Burst strength verification

Key Takeaway: Secure packaging is as important as the product inside it.

| Packaging Element | Requirement | Standard |

|---|---|---|

| Carton Grade | 5-Ply / 7-Ply | Double Wall Corrugated |

| Protection | EPE Foam/Corner Guards | 20mm Thickness min. |

| Tape/Seal | H-Seal Pattern | 60mm Reinforced Tape |

Preventing shipping damage is the easiest way to protect your profit margins.

Ⅷ. Compliance and safety furniture quality control

Compliance checks confirm that the furniture meets legal safety standards such as lead-free paint requirements and anti-tip regulations. Strict furniture quality control ensures that your business remains compliant with EU and US customs and consumer protection laws.

<center>Laboratory technician performing chemical safety tests on materials</center>

Is the paint safe for children’s use?

Testing for heavy metals and formaldehyde emissions is mandatory for most international markets. Look at this: certifications like EN71-3 or ASTM F963 are required before any kids furniture can be sold in major retail stores.

- Lead and phthalate testing

- Formaldehyde emission (E1/E0)

- Anti-tip hardware inclusion

Key Takeaway: Legal compliance protects you from lawsuits and customs seizures.

| Certification | Market | Focus Area |

|---|---|---|

| EN71-3 | Europe | Toy/Kids Safety |

| ASTM F963 | USA | Chemical/Physical Safety |

| LFGB | Germany | Food Contact (Trays) |

Documentation of these tests must be archived and ready for inspection at any time.

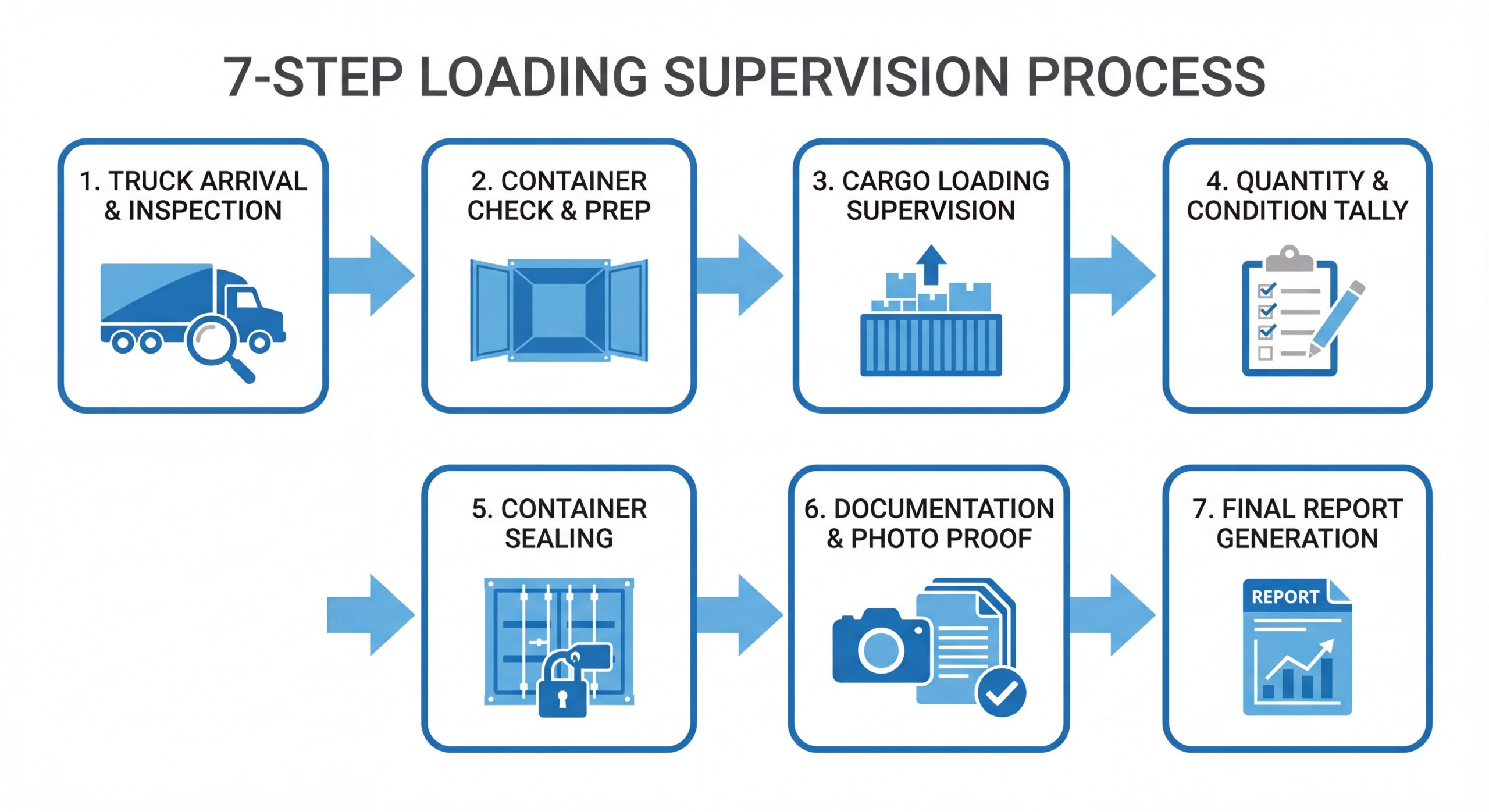

Ⅸ. Final inspection and loading supervision

The final inspection occurs when the goods are packed and ready to be loaded into the shipping container. This stage of furniture quality control acts as the last line of defense, ensuring that the correct quantity and quality of dining furniture is securely stowed.

<center>Standardized seven-step loading supervision flowchart</center>

How is container loading supervised?

Inspectors verify the container’s condition for holes or leaks before supervising the stacking of cartons to prevent crushing. Think about it: if heavy outdoor furniture is stacked on top of light accessories, the bottom boxes will inevitably fail.

- Container seal verification

- Quantity tally check

- Proper weight distribution

Key Takeaway: Professional loading ensures the journey doesn’t destroy the product.

| Loading Step | Verification | Priority |

|---|---|---|

| Container Prep | Clean/Dry/No Holes | High |

| Quantity Check | Scan against PL | Critical |

| Stacking | Heavy on bottom | High |

Supervision at the loading dock prevents theft and transit-related structural damage.

Ⅹ. Data-driven furniture quality control trends

Modern factories now use digital reporting and IoT sensors to track quality metrics in real-time throughout the production cycle. This evolution in furniture quality control allows for “traceable quality,” where every batch has a digital birth certificate detailing its material origin and test results.

What is the future of furniture inspection?

Digital reports with high-resolution photos are replacing paper checklists, providing importers with instant visibility from across the globe. The bottom line: transparency builds the trust necessary for long-term B2B partnerships.

- Cloud-based QC portals

- AI defect recognition

- Batch-level traceability

Key Takeaway: Technology is making quality control more transparent and reliable.

| Trend | Benefit | Implementation |

|---|---|---|

| Live Video QC | Real-time approval | Streaming tools |

| Digital Archiving | 5-year data history | Cloud Databases |

| QR Code Tracking | Individual unit history | Laser marking |

Adopting data-driven methods ensures that quality remains consistent as production scales.

Conclusion

Navigating the complexities of international furniture sourcing requires more than just finding a good price; it requires a partner who understands that quality is a process, not a destination. By insisting on rigorous checks from raw material selection to the final container seal, you eliminate the “quality lottery” and build a resilient brand. We invite you to explore our approach to precision manufacturing and see how our integrated QC systems can protect your next project. Our mission is to transform the standard manufacturing relationship into a transparent, data-backed partnership that delivers excellence to every doorstep.

Frequently Asked Questions

Can I request a third-party inspection?

Yes, professional manufacturers welcome third-party inspectors like SGS or V-Trust at any stage of production to verify quality standards.

How do I know if the wood is properly seasoned?

You should request a moisture content report (MC%) at the raw material stage and again during final inspection to ensure levels are between 8-12%.

What happens if a quality issue is found after arrival?

Reputable suppliers provide an after-sales resolution plan, usually responding within 3 working days with a replacement or credit strategy.

Do all furniture items require drop testing?

While not legally required for all, drop testing is highly recommended for e-commerce items to ensure they survive the “last mile” delivery process.

Can I get a copy of the chemical safety reports?

Absolutely. You should always ask for the EN71 or ASTM test reports for the specific lacquers and paints used on your production batch.