Check MOQ & Production Capacity

Confirm real production capacity, sample lead time, and batch lead time. Small mismatches often cause delays in your retail season.

We know the pressure of keeping retail shelves full — unpredictable lead times, inconsistent quality, and rigid MOQs. That's why we built our factory around stability and flexibility.

Most factories demand 500-1000 pieces minimum, tying up your capital in untested inventory.

Flexible MOQ starting from 50-300 pieces to test designs with minimal risk.

Delivery delays hurt your business and customer trust during peak seasons.

Stable production schedule with real-time updates to meet your restocking deadlines.

Inconsistent quality leads to returns and complaints that damage your reputation.

Strict QC system with photo & video reports catches flaws before shipping.

Slow responses waste your time and create uncertainty about order status.

Reply within 6 hours during working days with clear updates and technical support.

Factories refuse small design changes or charge high fees for modifications.

Flexible OEM/ODM service for your unique needs without excessive fees.

Worried about meeting international safety standards and customs clearance.

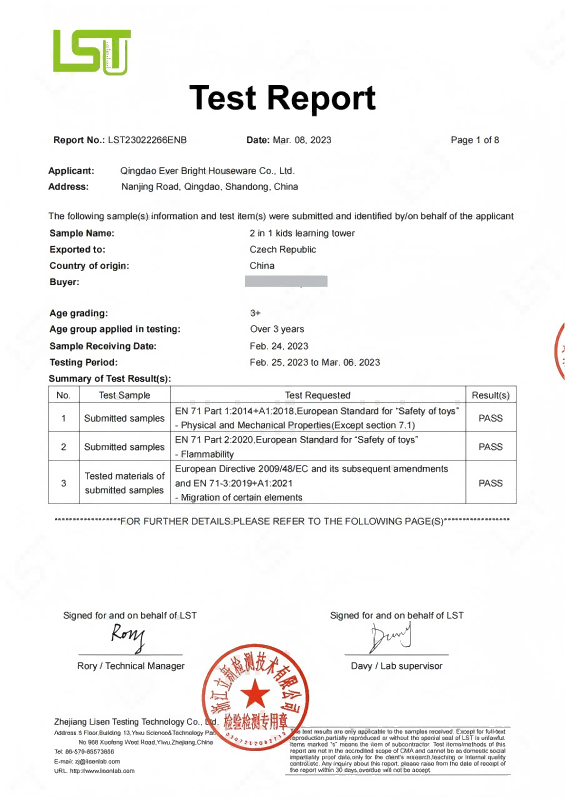

EN71, ASTM, FSC certified materials & processes with full compliance documentation.

Ready to eliminate procurement risks and grow your business with confidence?

Poor material selection leads to cracks, warping, color mismatch, and unstable joints. Here is how we avoid these risks.

We source kiln-dried wood only. Every batch is checked for moisture to reduce warping, cracking, and joint problems during shipping and seasonal changes.

We screen out wood with loose knots, surface defects, inner cracks, or weak grain direction. Higher stability means fewer complaints from end users.

We match wood color, grain pattern, and hardness across batches. This maintains consistency in large orders and reduces the risk of mixed tones.

Fill in your details and we'll respond within 24 hours

Comprehensive furniture systems designed to meet different retail channel requirements

Sofas, coffee tables, TV stands and complementary pieces for cohesive living spaces

Dining tables, chairs, and sideboards designed for durability and style

Beds, nightstands, and wardrobes crafted for comfort and lasting quality

Cabinets, shelving units, and storage benches for organized living

Coat racks, shoe benches, and console tables for welcoming first impressions

Versatile small tables and accent pieces that complete any room setting

Many complaints—loose joints, noise, wobbling—come from structure and craftsmanship, not the design itself.

We use reinforced joints, stable frames, and proper connecting hardware. A good structure reduces wobbling after long-term use.

Smooth surfaces and accurate sizing reduce assembly issues. Poor sanding often causes rough surfaces, unsafe edges, and visible seams.

We apply even coating, proper drying time, and repeated surface checks. Stable finishing avoids peeling and color differences.

Where precision meets patience — small details that make big differences.

Want to feel the texture and see real finish samples?

From cutting to container loading — every step stays on schedule

Our 158 factory staff run 5 production lines that handle woodwork, sanding, painting, and assembly.

Monthly output averages 10–20 containers, depending on product size and mix.

Regular lead time is 25–35 days, and we keep flexible slots for rush orders during peak season.

Want to check lead time for your next order?

Real checkpoints. Real people. Real prevention — so you don't deal with after-sales headaches.

Moisture and wood grade checked before cutting to avoid cracks or warping.

Each piece is measured for a precise fit, ensuring easy assembly and stable structure.

Frames tested for pressure and balance — no loose joints, no wobble.

Checked under different lights to keep color even and touch smooth.

Every order includes labeled hardware kits, tested for fit and durability.

Drop and corner tests ensure protection during transport and delivery.

Final inspection confirms finish, labeling, and quantity accuracy.

Each container loaded under QC supervision with photos recorded.

Want third-party QC reports or inspection videos?

Custom-made options for size, color, and branding — with low MOQ and trial order flexibility.

Modify product length, width, or height based on your market's size standards. Revised sizes are checked to keep good balance and strength.

Color tone, coating type, and material can follow your standard or sample. Each finish is tested for stable appearance and safe contact surface.

Logo can be laser engraved, silk printed, or hot-stamped on furniture or packaging. Private-label packaging available for consistent brand presentation.

MOQ from 50–300 units, depending on item size and packaging requirements. Sample lead time is around 2–3 weeks, with clear progress updates before mass production.

Ready to discuss your new product ideas?

Proven export record across North America, Europe, and Asia-Pacific.

Our furniture reaches major markets across six continents, serving diverse customer needs with consistent quality

Need export compliance support for your market?

Most losses come from small preventable issues—missing parts, unstable finishing, long lead times. Here is a practical checklist.

Confirm real production capacity, sample lead time, and batch lead time. Small mismatches often cause delays in your retail season.

Agree on materials, finishing, edge quality, assembly parts, and packaging details before production. Clear standards reduce disputes.

Confirm carton strength, inner protection, drop-test performance, and palletizing method. Strong packaging reduces sea-freight damage.

Need help verifying your supplier's capabilities?

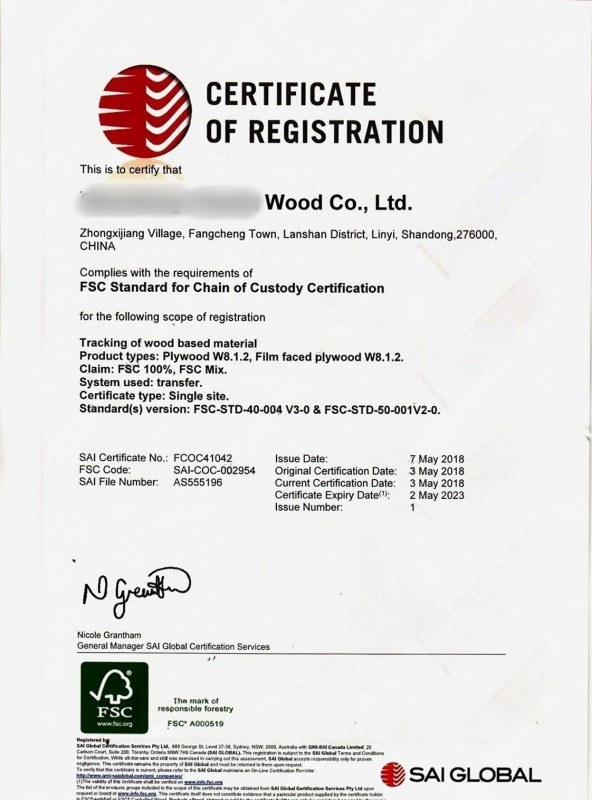

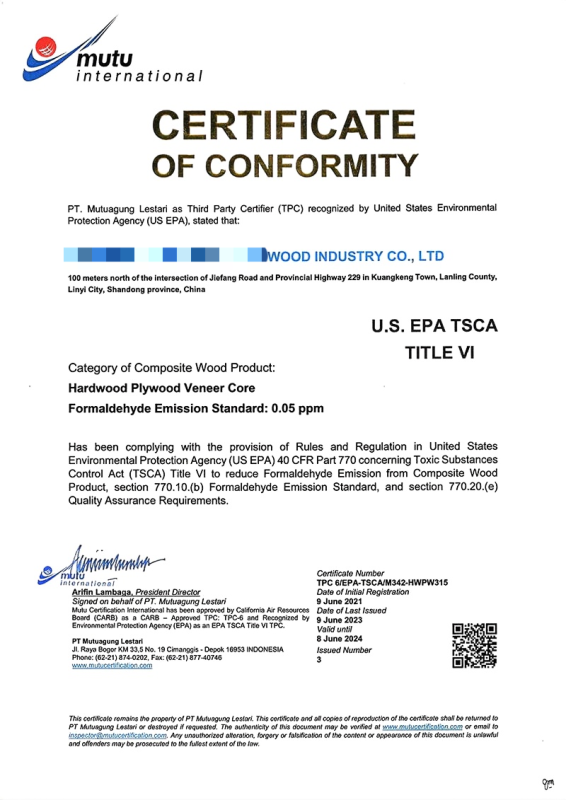

Verified standards reduce import clearance risks and meet market entry requirements

FSC-certified timber available for traceable sustainable orders.

Panels Low-emission MDF and plywood for U.S. markets.

EN, REACH and local tests via independent labs.

Material reports and customs documents prepared on request.

See exactly where your budget goes — and how we make each dollar count.

Want a transparent breakdown for your next order?

Avoid costly complaints and return losses from quality defects before they happen.

Each product goes through reinforced joint testing to prevent wobbling or breakage during use or shipping.

Controlled humidity and multi-layer sealing keep paint from peeling or cracking under dry or humid conditions.

Low-VOC coatings and extended curing times eliminate unpleasant smells and complaint risks.

Pre-shipment verification and photographic records ensure all parts are packed and counted before loading.

Our goal isn't just to meet your specs — it's to protect your after-sales cost and keep your customers coming back.

Concerned about quality risks in your market?

Professional export packaging and global logistics solutions

With long-term partners and stable freight capacity, we manage both small trial orders and large container projects worldwide.

Clear steps, predictable outcomes, no confusion along the way

Submit specs, get detailed pricing with material options and realistic lead times

Approve designs through 3D renderings and physical prototypes before production begins

Receive weekly progress reports with photos documenting milestones and quality checks

Review comprehensive inspection reports confirming order accuracy and quality standards

Complete customs documentation and tracking info provided for seamless import clearance

Direct answers to your most critical procurement concerns

Still have questions about working with our factory?

Get your competitive advantage today with our reliable manufacturing services

Your trusted partner for wooden furniture manufacturing

Fill out the form below and we'll contact you within 6 working hours with your custom proposal.