Approving a furniture sample does not automatically clarify sample approval responsibility in mass production.

You review the prototype, confirm the finish, sign off the sample, and expect bulk production to follow the same standard. Then small differences start showing up — dimensions shift, wood grain varies, finishes feel inconsistent. Nobody acted wrongly. Expectations simply were never written down.

That’s the gray zone most buyers face.

The fix isn’t more inspection. It’s turning visual approval into documented criteria. When tolerances, materials, and QC checkpoints are defined upfront, responsibility stops being assumed and starts being traceable. This article shows how to close that gap before production begins.

Defining sample approval responsibility

Establishing sample approval responsibility involves identifying the specific technical conditions and measurable standards that a prototype must represent before the factory begins mass production. You must understand that a sample is not just a finished product but a living set of acceptance criteria that defines what success looks like for every subsequent unit.

The Role of the Golden Sample

The “Golden Sample” serves as the ultimate physical benchmark for aesthetic and functional expectations in your furniture project. You must ensure this piece is archived in a controlled environment to prevent UV fading or moisture-induced warping, as it remains the primary evidence in any future quality dispute. But here is the catch: a physical sample cannot speak to the internal structural integrity or the chemical composition of the adhesives used unless these are documented alongside the physical object.

Stakeholder Input in Approval

A successful approval process requires input from your design team, the factory’s production engineers, and your quality assurance officers to ensure the prototype is actually manufacturable at scale. By involving these stakeholders early, you align the “user story” of the furniture—how it will be used by the end consumer—with the technical constraints of the Shandong production line.

- Design Team: Verifies aesthetic alignment and brand language.

- Production Engineers: Assess the feasibility of mass-producing complex joints.

- Quality Assurance: Establishes the testing methods for durability and safety.

Verification vs. Validation

Think about it this way: verification confirms that the sample was built according to your initial drawings, while validation ensures that the sample actually fulfills the needs of your market. You might approve a sample that is technically perfect but fails in the real world because the “sample approval responsibility” did not account for the high-humidity environments of your final retail destination.

Key Takeaway: Defining responsibility at the sample stage requires a transition from observing a physical object to documenting a set of repeatable technical requirements.

| Element | Description | Responsibility Holder |

|---|---|---|

| Physical Sign-off | Signature on the actual prototype to confirm visual acceptance. | Client / Product Owner |

| Technical Spec Sheet | Detailed list of materials, dimensions, and finishes. | Factory Engineering Team |

| Testing Protocol | The methods used to verify load-bearing and finish durability. | QA / Third-Party Lab |

This summary highlights the distribution of tasks necessary to move from a subjective “looks good” to an objective “approved for production.”

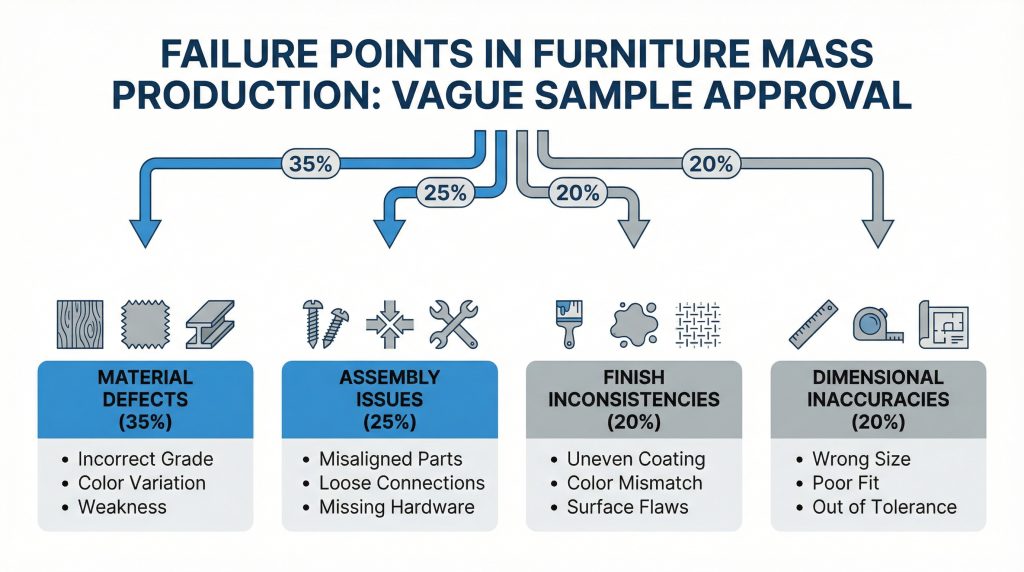

The gray zone of sample approval responsibility

The gray zone of sample approval responsibility refers to the unquantified variables, such as natural wood grain patterns or hand-applied finish depth, that a single sample cannot fully represent. You often encounter friction when the bulk order arrives with “natural variations” that the factory considers acceptable but you perceive as a departure from the approved prototype.

Managing Natural Variability

Wood is a hygroscopic, biological material, meaning no two pieces will ever be identical in grain or mineral streaks. You must define the “range of acceptance” for these natural characteristics during the sample stage to prevent the factory from using low-grade timber that technically meets the “wood” description but fails your aesthetic standard. Look at it this way: if you don’t define the limits of knots and swirls, you are essentially giving the factory a blank check for material selection.

Subjectivity in Hand-Finishing

Many high-end custom furniture pieces require hand-sanding or manual staining, which introduces a level of human variance that a single sample cannot capture. You might approve a sample with a specific “distressed” look, but without a written guide on the density of those distress marks, the bulk production may end up looking over-processed or unfinished.

- Define the number of distress marks per square foot.

- Specify the allowable color deviation using a Pantone or RAL bridge.

- Quantify the gloss level using a gloss meter to ensure consistency.

Environmental Influence on Samples

The factory environment in Shandong, particularly during the dry winters or humid summers, can significantly impact how a sample looks and feels at the moment of approval. The reality is simpler: if a sample is approved in a 60% humidity environment but produced in 20% humidity, the wood will shrink, potentially leading to joint failure that no one took responsibility for during the sign-off phase.

Key Takeaway: Gray zones thrive in the absence of data; therefore, your responsibility is to quantify the “unquantifiable” aesthetic elements of the furniture.

| Criteria | Subjective Approval (Risk) | Objective Acceptance (Clear) |

|---|---|---|

| Wood Grain | “Must look natural and premium.” | “No knots larger than 5mm; mineral streaks < 10%.” |

| Color Match | “Must match the sample provided.” | “Delta E < 2.0 compared to the master swatch.” |

| Surface Feel | “Should be smooth to the touch.” | “No visible sanding marks at 120-grit or higher.” |

This comparison demonstrates how shifting from descriptive adjectives to measurable metrics clarifies responsibility between the buyer and the factory.

Technical specs in sample approval responsibility

Technical specifications serve as the bridge that extends sample approval responsibility from a single prototype to the thousands of units on the production line. You cannot rely on a factory’s memory of a sample; you must provide a comprehensive dossier that includes CAD drawings, material safety data sheets (MSDS), and assembly instructions.

Integrating CAD and 3D Models

While a physical sample is tactile, a 3D CAD model is precise and immutable, providing a “digital twin” that the factory’s CNC machines can follow with sub-millimeter accuracy. You should ensure that your sample approval process includes a final review of the engineering drawings to catch any discrepancies between the handcrafted prototype and the programmed machine paths. Actually, there is more: the CAD model allows you to perform virtual stress tests before a single piece of wood is cut.

Tolerance Mapping for Mass Production

No manufacturing process is perfect, so you must establish “tolerances”—the allowable deviation from the ideal measurement—for every critical dimension of your dining tables or cabinets. If you approve a sample without defining a +/- 1mm tolerance for leg length, you lose the right to complain when a table wobbles due to a minor production variance.

- Critical Dimensions: Tolerances should be tight (e.g., +/- 0.5mm) for joinery.

- Non-Critical Dimensions: Tolerances can be wider (e.g., +/- 3mm) for decorative panels.

- Hole Alignment: Must be exact to ensure ease of assembly for the end-user.

Material Grade and Certification

Your sample approval responsibility includes verifying that the materials used in the prototype—such as FSC-certified oak or E1-grade plywood—are the same ones being staged for the bulk order. You should demand a Bill of Materials (BOM) that lists every screw, glue type, and lacquer brand used in the sample to prevent “specification creep” where cheaper alternatives are substituted during the long production cycle.

Key Takeaway: Technical specifications provide the legal and operational evidence needed to hold a factory accountable when bulk production deviates from the sample.

| Document Type | Purpose | Critical Data Included |

|---|---|---|

| Technical Drawing | Defines geometry and assembly. | Dimensions, angles, joinery types. |

| Finish Schedule | Controls aesthetic consistency. | Stain codes, lacquer type, sheen level. |

| Hardware List | Ensures structural durability. | Screw sizes, hinge brands, metal grades. |

This summary table outlines the essential documentation required to back up a physical sample approval.

Material shifts and sample approval responsibility

Managing material shifts is a critical component of sample approval responsibility, especially when sourcing from the diverse wood markets of Northern China. You must account for the fact that the wood used for your sample may come from a different timber lot than the wood used for your 500-unit bulk order, leading to variations in density, moisture, and color.

Wood Moisture Content Control

The most common cause of post-production failure in wooden furniture is improper moisture content (MC), which can cause the wood to crack or warp as it adjusts to the climate of the export market. You should specify an MC range (typically 8% to 12% for most Western markets) during the sample approval stage and require the factory to use calibrated moisture meters on every batch of timber. Wait, there is a better way: include a “moisture map” in your QC report to show that the sample was tested at multiple points across its surface.

Grain Direction and Stability

The way a board is cut—plain-sawn, quarter-sawn, or rift-sawn—affects its stability and how it looks compared to your sample. If your approved sample uses premium quarter-sawn oak for the tabletop, your sample approval responsibility includes ensuring the factory doesn’t switch to cheaper plain-sawn boards for the bulk run, which are more prone to cupping.

- Specify the “face grade” of the wood for visible surfaces.

- Define the allowable percentage of sapwood versus heartwood.

- Prohibit the use of “dead knots” or filled cracks in structural components.

Adhesive and Chemical Compatibility

The glues and lacquers used in your sample must be identical to those in production to ensure that finishes don’t peel or joints don’t fail over time. You should ask for a “Chemical Compliance Certificate” during the sample phase to confirm that the adhesives are formaldehyde-free and that the lacquers meet the VOC regulations of your target market. Consider this for a moment: a beautiful sample is worthless if the bulk order is rejected at customs due to chemical non-compliance.

Key Takeaway: Material consistency is the foundation of quality; without strict material benchmarks, your sample approval is only a surface-level agreement.

| Material Issue | Potential Risk | Prevention Strategy |

|---|---|---|

| High Moisture | Warping, cracking, mold. | Kiln-drying records and MC testing. |

| Species Substitution | Reduced durability/value. | Microscopic grain analysis or DNA testing. |

| Finish Incompatibility | Bubbling, peeling, discoloration. | Cross-hatch adhesion testing on samples. |

This summary table identifies the primary material risks and the strategies to mitigate them during the approval process.

Quality control meets sample approval responsibility

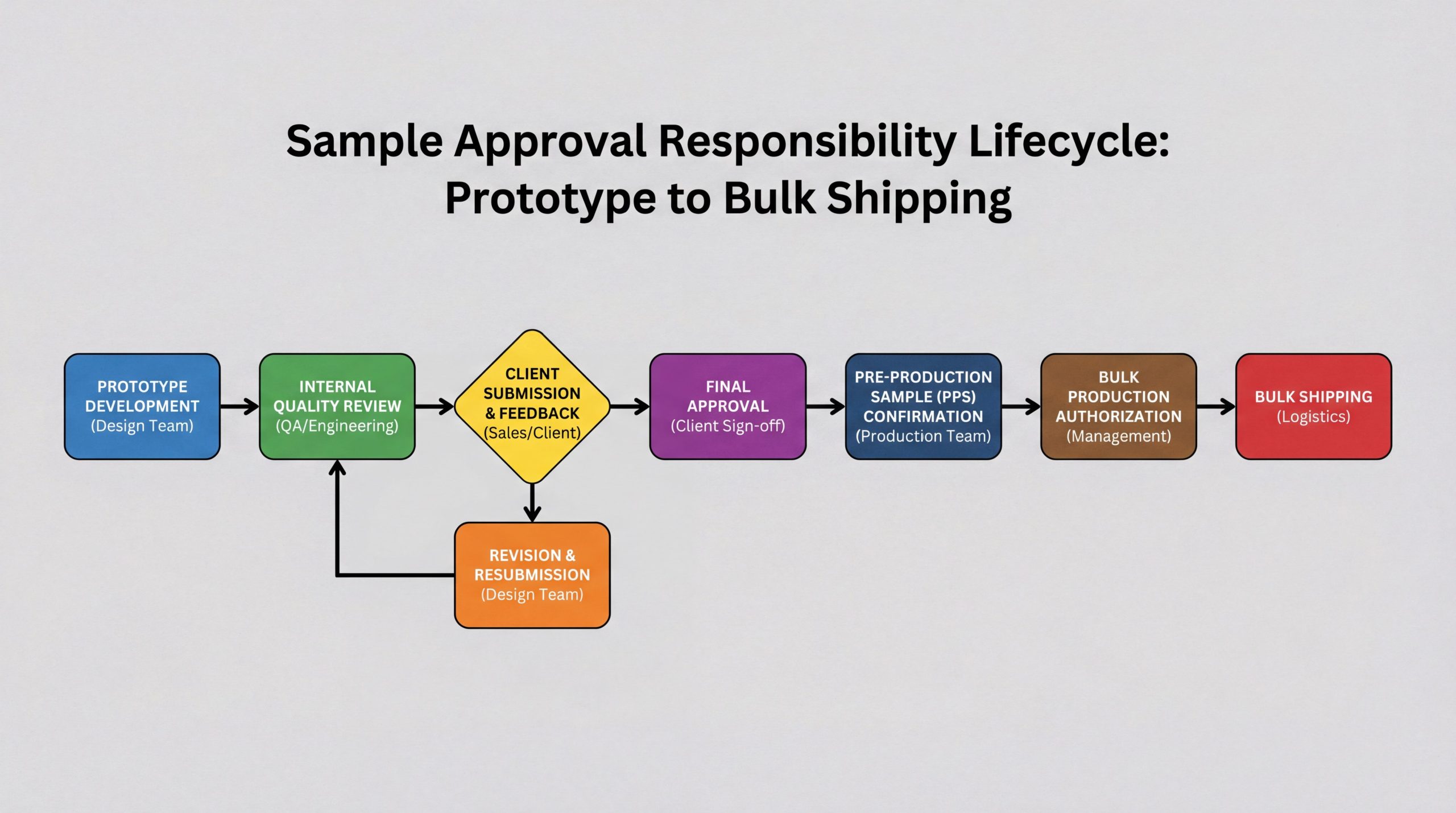

Quality control acts as the enforcement mechanism for sample approval responsibility, ensuring that the factory’s daily output aligns with the benchmarks set by the approved prototype. You must move beyond a “once-and-done” approval and implement a multi-stage inspection process that monitors quality from the raw material stage to the final container loading.

Pre-Production Inspections (PPI)

Before the factory cuts a single board for your order, a PPI should be conducted to verify that the raw materials and components match the approved sample specifications. This is your first opportunity to catch “material shifts” before they become expensive mistakes, allowing you to reject sub-standard timber or incorrect hardware before production labor is invested. The problem lies here: many buyers skip the PPI, assuming the factory will naturally follow the sample, only to find the errors during the final inspection when it’s too late to fix them.

During Production (DUPRO) Checks

A DUPRO inspection occurs when about 20% to 50% of the order is completed, providing a “sanity check” on the assembly line’s adherence to the sample approval responsibility. You should look for consistency in joinery fit, sanding quality, and the application of the first coat of finish.

- Check the fit of tenon and mortise joints for tightness.

- Verify the internal moisture content of semi-finished parts.

- Ensure that the assembly sequence matches the approved structural design.

Final Random Inspection (FRI)

The FRI is your last line of defense, where a statistically significant sample of the finished order is checked against the “Golden Sample” using Acceptance Quality Limit (AQL) standards. You must ensure that the inspector has the approved sample—or at least high-resolution photos and a detailed spec sheet—on-site to make accurate comparisons. If the FRI reveals a failure rate higher than the agreed AQL, responsibility for rework falls on the factory — provided your initial approval criteria were clearly documented.

Key Takeaway: Quality control is not an audit of the factory; it is a verification of the factory’s commitment to your approved sample.

| Inspection Type | Timing | Decision Power |

|---|---|---|

| Pre-Production | Before mass-cutting begins. | High – Can stop production before costs mount. |

| DUPRO | 20-50% completion. | Medium – Can correct process errors mid-stream. |

| Final Random | 100% finished, 80% packed. | Critical – Final “Go/No-Go” for shipment. |

This judgment table compares the relative impact of different inspection stages on the final outcome of the order.

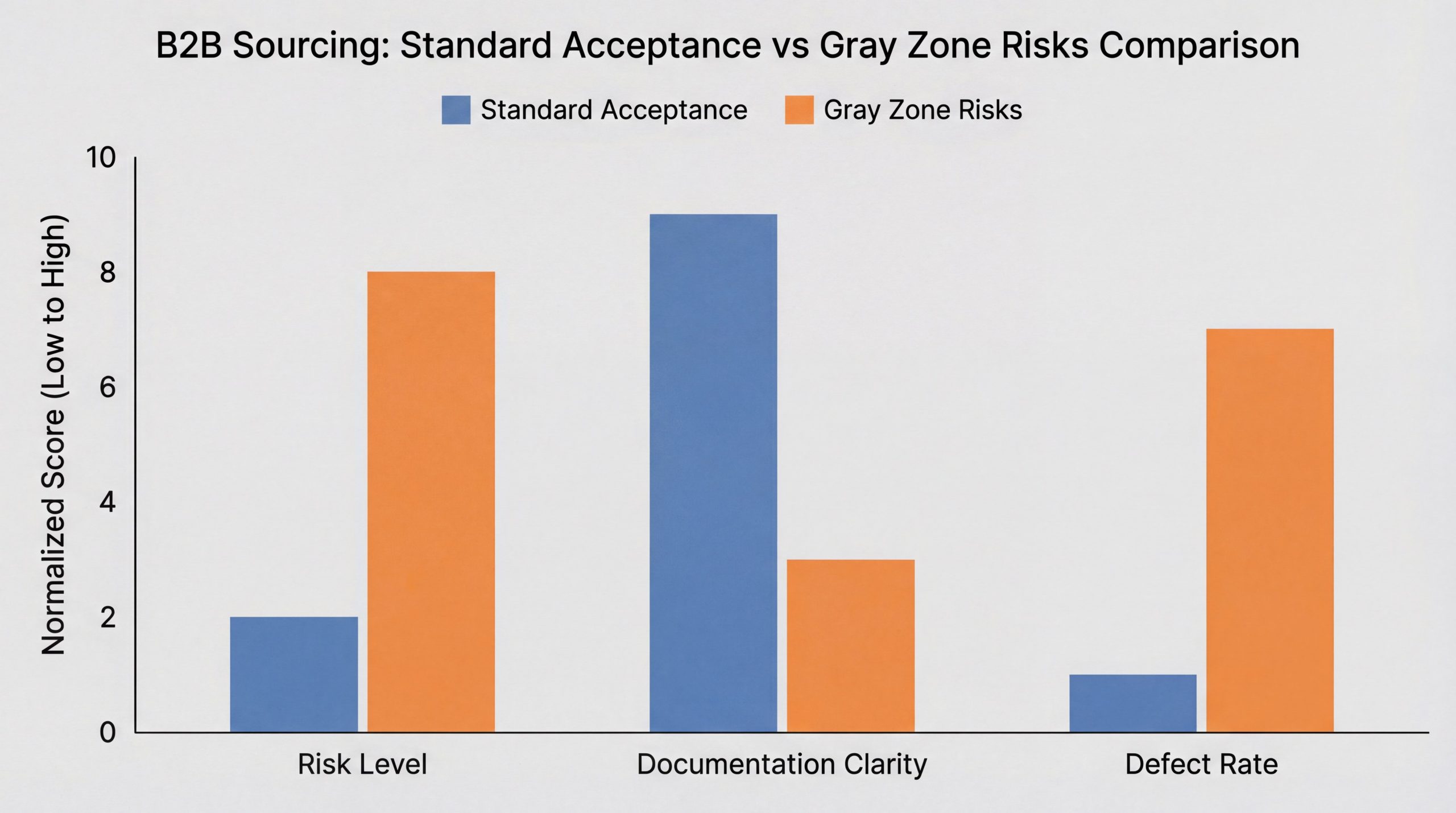

<center>Data showing the correlation between detailed specs and the reduction of production disputes.</center>

Documentation for sample approval responsibility

Robust documentation is the only way to solidify sample approval responsibility into a legally and operationally binding framework. You should treat your approval documents as a “contract within a contract,” detailing exactly what was agreed upon and providing a clear path for resolving any future quality discrepancies.

The Requirements Traceability Matrix

An RTM is a document that maps every one of your requirements—from the “soft touch” of a fabric to the “weight capacity” of a stool—to the specific test or inspection that will verify it. This ensures that no part of your quality control process is left to chance and that every stakeholder knows exactly who is responsible for each metric. But here is the catch: an RTM only works if it is updated throughout the sampling process to reflect changes made during prototyping.

Physical Component Tagging

For complex furniture pieces, it is often wise to sign and date individual components of the approved sample, such as a drawer slide or a specific upholstery swatch. You should use tamper-evident tags or high-resolution “macro” photography to document unique features, creating a visual record that can be sent to the factory’s floor managers as a daily reference.

- Sign the back of the tabletop to verify the wood grade.

- Tag the internal frame to confirm the use of solid wood vs. plywood.

- Photograph the underside of the chair to document the corner block reinforcement.

The Archival and Retrieval Process

A sample is only useful if it can be retrieved and compared to the bulk production months or years later. You should maintain a “Master Sample Library” where approved items are stored in a climate-controlled environment, along with a digital folder containing all correspondence, spec changes, and testing reports. Look at it this way: your documentation is your insurance policy against “factory amnesia” or personnel turnover at the manufacturing site.

Key Takeaway: Documentation transforms a fleeting moment of approval into a permanent standard of accountability.

| Document Name | Function | Storage Method |

|---|---|---|

| Signed Sample Tag | Physical proof of client acceptance. | Attached to the physical sample. |

| Approved Spec PDF | The “Bible” for the production floor. | Digital Cloud + Factory Printout. |

| Testing Report | Proof of functional safety compliance. | QA Archive / Compliance Folder. |

This summary table identifies the key documents that form the backbone of a professional approval process.

Structural integrity and responsibility gaps

Structural integrity is the most dangerous gray zone because failures often don’t appear until the furniture is in the customer’s home, long after the sample approval responsibility has theoretically ended. You must ensure that your approval process goes “under the skin” of the furniture to verify that the joinery and reinforcements are built for longevity, not just for a quick photoshoot.

Shandong Joinery Standards

In the Shandong furniture cluster, traditional woodworking skills like mortise and tenon joinery are highly valued, but they must be correctly applied to withstand the rigors of global shipping and daily use. You should specify that all load-bearing joints in your sample use a “tight-fit” tenon with high-quality PVA glue, rather than relying on metal brackets or screws that can loosen over time. Think about it this way: a beautiful chair that collapses after six months is a failure of both the factory’s craft and your approval oversight.

Load-Bearing and Stress Testing

Your sample approval should include a functional test where the piece is subjected to weights and stresses that exceed typical daily use, such as the BIFMA or EN 1022 standards. If your sample passes a 200kg static load test, you have a clear baseline for production; if the bulk order then fails at 100kg, the responsibility for the structural defect is indisputable.

- Static Load: Checks for immediate breakage under heavy weight.

- Dynamic Load: Simulates years of use (e.g., a chair being sat in 10,000 times).

- Tip-Over Testing: Ensures the piece remains stable and safe for children.

Fastener and Hardware Longevity

The screws, hinges, and drawer slides you approve in the sample must be of the same “industrial grade” as those used in production to prevent premature failure. You should require the factory to provide the brand name and technical data sheet for all hardware, as generic “no-name” components often have inconsistent metal plating that leads to rusting or stripping. The reality is simpler: hardware is often where factories look to save costs, making it a primary site for responsibility gaps.

Key Takeaway: Structural responsibility is established by testing the limits of the sample, not just its appearance.

| Structural Component | Standard to Meet | Verification Method |

|---|---|---|

| Main Frame | Solid Hardwood (e.g., Oak/Ash). | Cross-section check or weight check. |

| Joinery | Mortise and Tenon + Glue. | Stress testing and moisture check. |

| Hardware | ISO-certified soft-close/stainless. | Cycle testing (e.g., 50,000 opens). |

This summary table outlines the structural benchmarks that must be verified during the sample stage.

Shipping risks and responsibility boundaries

The moment your order leaves the factory gate, a new set of risks emerges that can blur the lines of sample approval responsibility if you haven’t prepared for the stresses of international transit. You must define the “packaging and logistics” standards during the sample stage to ensure that the perfectly approved furniture arrives in the same condition at its final destination.

ISTA Packaging Standards

A common gray zone occurs when a sample is approved but the “bulk packaging” is inadequate, leading to corner damage or crushed boxes during ocean freight. You should require the factory to perform a “Drop Test” (following ISTA-1A or 3A standards) on a fully packed sample to prove that the foam density and cardboard strength are sufficient for the journey. Here is the kicker: if the sample packaging passes the test but the bulk order arrives damaged due to thinner cardboard, the factory is clearly responsible for the deviation.

Container Loading Supervision

The way furniture is stacked inside a shipping container can lead to “pressure damage” or “heat buildup” that distorts the wood or ruins the finish. You should specify loading protocols—such as “heavy items on bottom” and “no double-stacking without pallets”—to protect your investment from the logistical chaos of global shipping.

- Use desiccant bags to control humidity inside the container.

- Record the container seal number and take photos of the final stack.

- Verify that the “carton markings” match your shipping requirements exactly.

Transit Moisture and Acclimatization

Furniture shipped from the relatively dry climate of Shandong to a humid tropical port (or vice versa) will undergo significant internal stress as the wood expands or contracts. You must ensure that your sample approval responsibility includes a “shipping simulation” or at least a theoretical review of how the finish and joinery will react to these environmental shifts. Look at it this way: your responsibility doesn’t end at the factory door; it ends when the customer unboxes a perfect product.

Key Takeaway: Packaging is not just an accessory; it is a functional component of the product that requires its own approval and responsibility framework.

| Risk Factor | Factory Responsibility | Buyer Responsibility |

|---|---|---|

| Transit Damage | Must provide ISTA-certified packing. | Must specify shipping method/carrier. |

| Moisture/Mold | Must use desiccants and dry wood. | Must ensure timely pickup from port. |

| Missing Parts | Must follow the approved BOM. | Must verify assembly manual is clear. |

This judgment table clarifies how the responsibility for shipping outcomes is shared between the manufacturer and the importer.

Strategies to minimize order risk

Minimizing the risks associated with sample approval responsibility requires a proactive approach that emphasizes transparency, continuous feedback, and small-batch validation. You can significantly reduce your exposure to “gray zone” disputes by implementing a sourcing strategy that favors long-term partnerships over one-off transactions.

Small Batch Trial Runs

Instead of jumping from a single sample to a 1,000-unit order, you should consider a “pilot run” of 50 to 100 units to test the factory’s ability to scale the approved quality. This allows you to identify any production bottlenecks or material inconsistencies in a lower-risk environment and refine the sample approval responsibility before the large investment is made. Actually, there is more: a pilot run often reveals “unspoken details”—like the time it takes for a finish to dry in mass production—that a single sample never could.

Third-Party Audits and Escrow

Using a third-party inspection company provides an unbiased “set of eyes” that holds the factory to your technical specs without the emotional or financial pressure of the direct relationship. You can also use “Quality Escrow” payments, where a portion of the final payment is held until the goods are inspected and found to match the approved sample, creating a powerful incentive for the factory to maintain standards.

- Audit the factory’s about us page and history for reliability.

- Check for ISO 9001 certifications and environmental compliance.

- Interview the QC manager to ensure they understand your specific tolerances.

Establishing a Feedback Loop

Quality is not a static target; it is a process of continuous improvement that requires a healthy feedback loop between you and your factory. You should share customer reviews, return data, and assembly photos with the factory team so they can adjust their production methods to solve real-world problems. Consider this for a moment: the best factories in Shandong aren’t the ones that never make mistakes, but the ones that take responsibility and fix them for the next order.

Key Takeaway: Risk mitigation is an ongoing investment in communication and verification, not a one-time event at the sample stage.

| Strategy | Benefit | Implementation Cost |

|---|---|---|

| Pilot Run | Identifies scaling issues early. | Moderate – Higher unit cost but lower risk. |

| 3rd Party QC | Provides objective verification. | Low – Usually 1-2% of order value. |

| Joint Design Review | Prevents structural failures. | Low – Only requires time and communication. |

This summary table highlights the most effective strategies for reducing risk after the sample approval stage.

Future of sample approval responsibility

The future of sample approval responsibility is being shaped by digital technologies and sustainability mandates that demand higher levels of transparency and precision than ever before. You must stay ahead of these trends to remain competitive in a B2B market that is increasingly moving toward “smart manufacturing” and data-driven quality assurance.

Digital Twins and AI Inspection

Artificial Intelligence (AI) is now being used to inspect furniture finishes and wood grain patterns in real-time, comparing the production output to a “digital twin” of the approved sample with superhuman accuracy. You should look for factory partners who are investing in these technologies, as they can provide automated reports that show exactly how much your order deviates from the benchmark. In practice, material behavior can be assessed using historical data such as grain density and moisture records.

Sustainability and the Digital Product Passport

The European Union’s upcoming “Digital Product Passport” will require every piece of furniture to have a traceable history of its materials, labor, and environmental impact. Your sample approval responsibility will soon include verifying the “Scope 3” carbon emissions of your timber and the recyclability of your lacquers, making documentation a mandatory legal requirement rather than just a best practice.

- Implement QR codes on every piece of furniture for traceability.

- Use blockchain to secure the “Chain of Custody” for FSC timber.

- Conduct life-cycle assessments (LCA) during the design phase.

Collaborative Cloud-Based Platforms

Cloud platforms are replacing email chains as the primary way to manage sample approval responsibility, providing a single “source of truth” where drawings, photos, and approvals are stored for all parties to see. You can now use real-time dashboards to track the progress of your order, view inspection photos as they are taken, and chat directly with the factory’s QC team to resolve issues instantly. Actually, there is more: these platforms create an audit trail that is invaluable during contract renewals or legal disputes.

Key Takeaway: The future belongs to those who treat quality and responsibility as data points in a transparent, digital ecosystem.

| Trend | Impact on B2B | Timeline |

|---|---|---|

| AI Quality Control | Eliminates human error in inspection. | 1-3 Years (Early adoption phase). |

| Digital Passports | Mandatory transparency for EU imports. | 2-5 Years (Legislative rollout). |

| Cloud PLM | Streamlined global communication. | Immediate (Standard for top-tier factories). |

This summary table forecasts the technological and regulatory shifts that will redefine how we manage furniture quality in the coming decade.

An analytical sentence following this table: The integration of digital tracking and AI-driven metrics is fundamentally shifting the burden of proof from subjective visual checks to irrefutable data streams.

FAQ

Can I hold a factory responsible for color variations in a bulk order if the sample was approved?Yes, but only if you defined a measurable color tolerance (such as a Delta E value) or provided a range of acceptable swatches during the approval stage. Without these benchmarks, most factories will argue that “natural variation” is a standard part of the material, leaving you with little recourse.

What’s the best way to handle a sample that looks perfect but fails a structural test?You must reject the sample and work with the factory’s engineers to redesign the failed component, even if it requires changing the aesthetic slightly. A “perfect-looking” failure is a liability waiting to happen; use the failure as evidence to redefine the structural requirements in your final approval document.

How do I know if my factory is actually using the same wood for production as they used for the sample?The only way to be certain is to conduct a Pre-Production Inspection where your inspector verifies the raw timber lot against the approved sample’s grain characteristics and moisture content. You should also require the factory to provide the timber purchase invoices and certificates of origin to ensure the species and grade are consistent.

Final check: Navigating the complexities of B2B furniture sourcing requires more than just a good eye; it requires a disciplined approach to technical clarity. At Everwoody, our mission is to provide global importers with high-quality, sustainable wooden furniture that bridges the gap between artisanal design and industrial scale. To see how our rigorous QC standards can protect your next order, please contact us for a professional consultation and custom quote.