Outdoor wood furniture often peels and rots within months of arriving at your warehouse, leading to expensive returns and damaged retail reputations. These failures are rarely about the wood alone; they stem from choosing the wrong industrial coating for high-volume production. This guide details the technical standards required to secure the best paint for outdoor wood furniture and ensure your inventory survives diverse global climates.

The best paint for outdoor wood furniture is industrial-grade water-based acrylic, as it provides the essential flexibility to move with the timber while offering superior UV resistance and breathability. For B2B importers, these specialized coatings are the industry standard for reducing warranty claims, preventing moisture-related rot, and maintaining structural integrity throughout the international shipping and retail cycles.

I. Why the Best Paint for Outdoor Wood Furniture Matters for B2B Durability

Modern automated factory line for industrial outdoor furniture coating.

Selecting the best paint for outdoor wood furniture in a factory setting is a critical financial decision that directly influences your bottom line and customer retention rates. If the coating fails to provide a hermetic yet breathable seal, the resulting rot can lead to the total loss of a container-wide shipment during transit or shortly after delivery. We recognize that high-performance finishes are not just an aesthetic choice but a fundamental barrier against the moisture fluctuations inherent in international logistics.

The Financial Risk of Systemic Coating Failure

When mass-produced furniture fails in the field, the financial repercussions extend far beyond the cost of a single replacement unit to include shipping, handling, and administrative overhead. For an importer moving 20 containers monthly, a failure rate of even 5% due to poor paint selection can result in tens of thousands of dollars in annual losses. Brand reputation is particularly vulnerable to systemic coating failures, as consistent peeling or discoloration signals poor manufacturing standards to your retail partners and end-consumers.

ROI of Premium Industrial Coatings

While the initial price per liter of the best paint for outdoor wood furniture may be higher than entry-level alternatives, the long-term ROI is undeniable. High-quality acrylic systems reduce warranty claims by providing superior adhesion and UV stability. This allows importers to offer extended warranties, which serves as a powerful marketing tool in the competitive B2B landscape. In the factory, these paints also improve throughput because they are formulated for rapid curing in industrial drying tunnels, reducing the production cycle time.

Strategic Sourcing and Finish Specifications

To secure a durable product, importers must move beyond specifying “painted wood” and instead demand detailed coating specifications. This includes identifying the resin type, the number of coats, and the specific UV blockers integrated into the pigment. A professional supplier should be able to provide a Technical Data Sheet (TDS) for the coating used, ensuring it meets international standards for durability and environmental safety.

II. Analyzing the Causes of Outdoor Furniture Coating Failure

Chart illustrating the primary mechanical and environmental causes of coating failure.

Finding the best paint for outdoor wood furniture requires a deep understanding of why most coatings fail within the first twelve months of exposure. Failure typically occurs at the interface between the wood and the paint, often driven by the wood’s natural hygroscopic nature—its tendency to absorb and release moisture from the atmosphere. When a paint film is too rigid, it cannot accommodate the swelling and shrinking of the timber, leading to micro-cracks that allow liquid water to penetrate the wood fibers.

UV Degradation and Photochemical Breakdown

Sunlight is the primary enemy of outdoor finishes. UV rays break down the polymer chains in the paint resin, a process known as photodegradation. This results in “chalking,” where the paint surface becomes powdery and the pigment fades. The best paint for outdoor wood furniture must contain high concentrations of hindered amine light stabilizers (HALS) and UV absorbers to shield the wood surface from these destructive rays, particularly in high-exposure markets like Australia or the southern United States.

Biological Attack: Mold and Fungal Growth

In humid environments, wood is highly susceptible to mold, mildew, and wood-rotting fungi. If the coating does not contain industrial-grade biocides, these organisms can colonize the wood beneath the paint film. This is a significant risk for B2B orders stored in warehouses with poor climate control. Once fungal growth begins, it breaks down the wood’s lignin, destroying the bond with the paint and causing the finish to flake off in large sheets.

Mechanical Stress and Dimensional Instability

Wood is a living material that moves significantly across its grain. If a coating lacks “extensibility”—the ability to stretch—it will rupture as the wood swells in high humidity. This mechanical failure is most common at joints and end-grains, where moisture ingress is most rapid. Selecting a coating with high elasticity is therefore non-negotiable for any product intended for varied global climates.

III. Moisture Control: The Foundation for the Best Paint for Outdoor Wood Furniture

Quality control technician conducting moisture content testing on timber before coating.

The performance of the best paint for outdoor wood furniture is entirely dependent on the moisture content (MC) of the timber at the moment of application. If the wood is too wet, the paint will trap moisture inside, leading to blistering and rot; if it is too dry, the wood will swell aggressively when it reaches the customer, cracking the finish. Controlling this variable is the hallmark of a high-quality factory.

Achieving Equilibrium Moisture Content (EMC)

For outdoor applications, timber should be seasoned to an EMC of 12% to 20%, depending on the destination market’s average humidity. This range ensures that the wood remains stable after it is painted and shipped. Manufacturers often use a combination of kiln-drying and air-drying to reach these targets. You can find detailed technical insights on why wooden furniture warps and how moisture management prevents structural failure.

Induction Moisture Metering in QC

A professional factory will implement 100% moisture inspection for all timber batches intended for outdoor use. Using induction moisture meters, QC teams can verify that every board is within the specified range without damaging the surface. Any timber that falls outside the target parameters must be sent back to the drying room, as applying even the best paint for outdoor wood furniture over improperly seasoned wood is a guaranteed recipe for field failure.

Sealing the End-Grain

One of the most critical, yet frequently overlooked, steps in moisture management is the sealing of the end-grain. The ends of furniture legs and slats are up to 250 times more absorbent than the flat surfaces. Without a specialized end-grain sealer, water will travel upward into the wood via capillary action, bypassing the surface coating entirely. Importers should ensure that their suppliers use a dedicated high-solids sealer on all end-grain surfaces before the final painting stage.

| Component | Absorption Rate | Critical Protection Needed |

|---|---|---|

| Face Grain | Low | Standard UV Coating |

| Edge Grain | Moderate | Multi-coat Sealing |

| End-Grain | Extreme | Specialized End-Grain Sealer |

IV. The Crucial Role of Priming the Best Paint for Outdoor Wood Furniture

Worker applying high-performance industrial primer in a spray booth.

A high-quality primer is the invisible foundation for the best paint for outdoor wood furniture. It is not merely a “base color” but a chemical bridge that creates a permanent bond between the wood fibers and the topcoat. In mass production, the primer serves three vital functions: improving adhesion, blocking tannins, and sealing the wood pores to ensure a uniform final finish.

Tannin Blocking and Stain Prevention

Species like Oak, Teak, and Cedar are rich in natural tannins—water-soluble chemicals that can bleed through the paint, causing unsightly yellow or brown staining. This is particularly problematic for white or light-gray furniture. A high-solids, tannin-blocking primer chemically traps these extracts so they cannot migrate to the surface. Without this step, your “best paint for outdoor wood furniture” will look aged and dirty within weeks of delivery.

Promoting Inter-Coat Adhesion

Industrial wood primers are formulated with specific resins that “bite” into the wood grain. This creates a rougher microscopic profile that the topcoat can grip. In the factory, the primer is often applied and then lightly sanded (scuff-sanding) to remove any raised grain (wood “fuzz”) caused by the moisture in the primer. This ensures that the final product feels smooth to the touch and that the paint film will not delaminate under stress.

Sealing Porosity for Color Consistency

Different parts of the same board can have varying levels of porosity, which can cause “splotchy” color if paint is applied directly. The primer saturates these thirsty fibers, ensuring that the expensive topcoat sits on the surface rather than soaking in unevenly. This allows the factory to achieve perfect color consistency across a thousand-piece order, a requirement for B2B retailers who sell matching sets.

V. Comparing Coating Chemistries: Identifying the Best Paint for Outdoor Wood Furniture

Comparison chart showing performance differences between oil-based and water-based acrylic coatings.

When identifying the best paint for outdoor wood furniture, importers must choose between traditional oil-based coatings and modern water-based acrylics. While oil paints were once the industry standard, technological shifts driven by environmental regulations and performance requirements have made water-based acrylics the superior choice for global furniture manufacturing.

The Problem with Oil-Based Coatings

Traditional oil-based paints (alkyds) create a very hard, brittle film. While this is excellent for scratch resistance, it is a liability for outdoor wood. As the oil paint ages, it continues to oxidize and harden, losing all flexibility. When the wood moves, the brittle oil film cracks. Furthermore, oil paints are high in Volatile Organic Compounds (VOCs), making them difficult to import into regions with strict environmental laws like the EU (REACH) and California (Prop 65).

Why Acrylic is the Best Paint for Outdoor Wood Furniture

Water-based acrylics are composed of flexible polymer chains that remain elastic for many years. This allows the coating to “breathe”—it is permeable to water vapor but resistant to liquid water. This means internal moisture can escape without blowing the paint off the surface. Acrylics also offer significantly better color retention; they do not yellow over time like oil paints do. For an importer, this means the furniture looks “new” for much longer in the retail environment.

VOC Compliance and Environmental Standards

Sustainability is no longer optional in the B2B sector. Using low-VOC water-based acrylics ensures that your products meet the most stringent global safety standards. This simplifies customs clearance and aligns your brand with the growing consumer demand for eco-friendly products. Most modern factories have transitioned to water-based systems to comply with air quality regulations and to provide a safer working environment for their employees.

| Metric | Oil-Based (Alkyd) | Water-Based (Acrylic) |

|---|---|---|

| Flexibility | Low (Brittle) | High (Elastic) |

| UV Stability | Poor (Yellows) | Excellent (Clear) |

| Dry Time | 8-24 Hours | 30-60 Minutes |

| Breathability | None | High |

| VOC Level | High | Low |

VI. Industrial Acrylic Solutions: Why They Are the Best Paint for Outdoor Wood Furniture

Professional application of industrial acrylic coating in a high-volume manufacturing facility.

To achieve a professional-grade finish, the best paint for outdoor wood furniture must be applied using industrial spray equipment. This allows for a perfectly uniform film thickness that is impossible to achieve with brushes or rollers. For importers, the consistency of the spray finish is a key quality indicator that separates high-end suppliers from “backyard” operations.

High-Volume Spray Application Techniques

Factories use High Volume Low Pressure (HVLP) or airless spray systems to apply coatings. This ensures that every crevice, joint, and underside of the furniture is covered—a technique known as “six-sided sealing.” You can see how this fits into the broader wooden furniture manufacturing process to ensure that no part of the timber is left vulnerable to moisture.

The Importance of Film Thickness (DFT)

The durability of the finish is directly proportional to its Dry Film Thickness (DFT). If the paint is applied too thinly, it will wear away prematurely; if too thick, it may sag or crack. The best paint for outdoor wood furniture is typically applied in a three-coat system: one coat of primer and two topcoats, resulting in a total DFT of approximately 80 to 120 microns. QC technicians use specialized gauges to verify these measurements during the production run.

Cross-Linking Polymers for Durability

Industrial acrylics often feature “cross-linking” technology, where the polymer chains chemically bond to one another as the paint dries. This creates a much tougher, more chemical-resistant surface than standard retail paints. This is essential for outdoor tables that will be exposed to spilled drinks, sunscreens, and cleaning agents. For B2B buyers, these high-performance acrylics provide the durability needed for commercial hospitality settings as well as residential gardens.

VII. Curing and Environmental Controls in the Factory

Automated drying tunnel for controlled curing of industrial furniture coatings.

Even the best paint for outdoor wood furniture can fail if it is not cured correctly. In a mass-production environment, drying must be carefully managed to ensure the paint film reaches its maximum hardness and adhesion. Professional factories use climate-controlled drying rooms or automated drying tunnels to eliminate variables like ambient humidity and temperature fluctuations.

Managing the “Flash-Off” Period

After the paint is sprayed, it must undergo a “flash-off” period where the majority of the water or solvent evaporates at room temperature. If the furniture is moved into a high-heat drying tunnel too quickly, the surface can skin over, trapping moisture underneath and causing “solvent pop” or blistering. A well-designed production line builds in specific timing to prevent these defects, ensuring the integrity of the finish for every unit.

Infrared and Forced-Air Drying Tunnels

To speed up production without compromising quality, factories use infrared (IR) or forced-air drying tunnels. IR drying heats the paint from the inside out, which is highly effective for thick industrial coatings. This ensures that the paint is fully cured and ready for packaging within hours, rather than days. For the B2B importer, this translates to faster lead times and lower inventory costs.

Dust and Debris Control

The drying area must be a “clean room” environment. Any dust or sawdust that settles on the wet paint will create a “gritty” finish that is unacceptable for high-end retail. Professional factories use positive-pressure ventilation systems to keep contaminants out of the painting and drying zones. During your factory audit, the cleanliness of the finishing department is a direct indicator of the manufacturer’s commitment to providing the best paint for outdoor wood furniture.

VIII. Advanced Testing for Verifying the Best Paint for Outdoor Wood Furniture

Technician performing a cross-hatch adhesion test to verify coating integrity.

Verification is the only way to ensure that your supplier is actually using the best paint for outdoor wood furniture. Importers should demand standardized laboratory test results as part of their Quality Assurance (QA) protocol. These tests simulate years of outdoor exposure in a matter of weeks, providing objective data on the coating’s performance.

Cross-Hatch Adhesion Testing (ASTM D3359)

The cross-hatch test is the industry standard for measuring how well the paint is bonded to the wood. A technician cuts a grid into the paint, applies a specialized tape, and then pulls it off. If any paint flakes away, the adhesion is insufficient. We recommend using a furniture factory audit checklist to ensure your supplier is conducting these tests regularly on every production batch.

Accelerated Weathering and UV Chambers

Advanced factories use QUV chambers to subject paint samples to intense UV light and moisture cycles. This test identifies if the paint will fade or crack prematurely. Importers should look for coatings that pass at least 500 to 1,000 hours of accelerated weathering without significant color change (measured as Delta E) or loss of gloss. This data provides the confidence needed to place large-volume orders for sunny climates.

Salt Spray and Humidity Testing

For furniture destined for coastal regions, salt spray testing is essential to ensure that both the paint and the underlying hardware can resist corrosion. Similarly, humidity chamber testing verifies that the “breathable” acrylic system can handle constant moisture without blistering. These tests are the only way to guarantee that your product won’t result in a wave of warranty claims after the first rainy season.

| Test Name | Standard | Passing Criteria |

|---|---|---|

| Adhesion | ASTM D3359 | 4B or 5B Rating |

| UV Resistance | ASTM G154 | Delta E < 2.0 after 500 hrs |

| Hardness | ASTM D3363 | H to 2H Pencil Hardness |

| Gloss Retention | ISO 2813 | >80% after weathering |

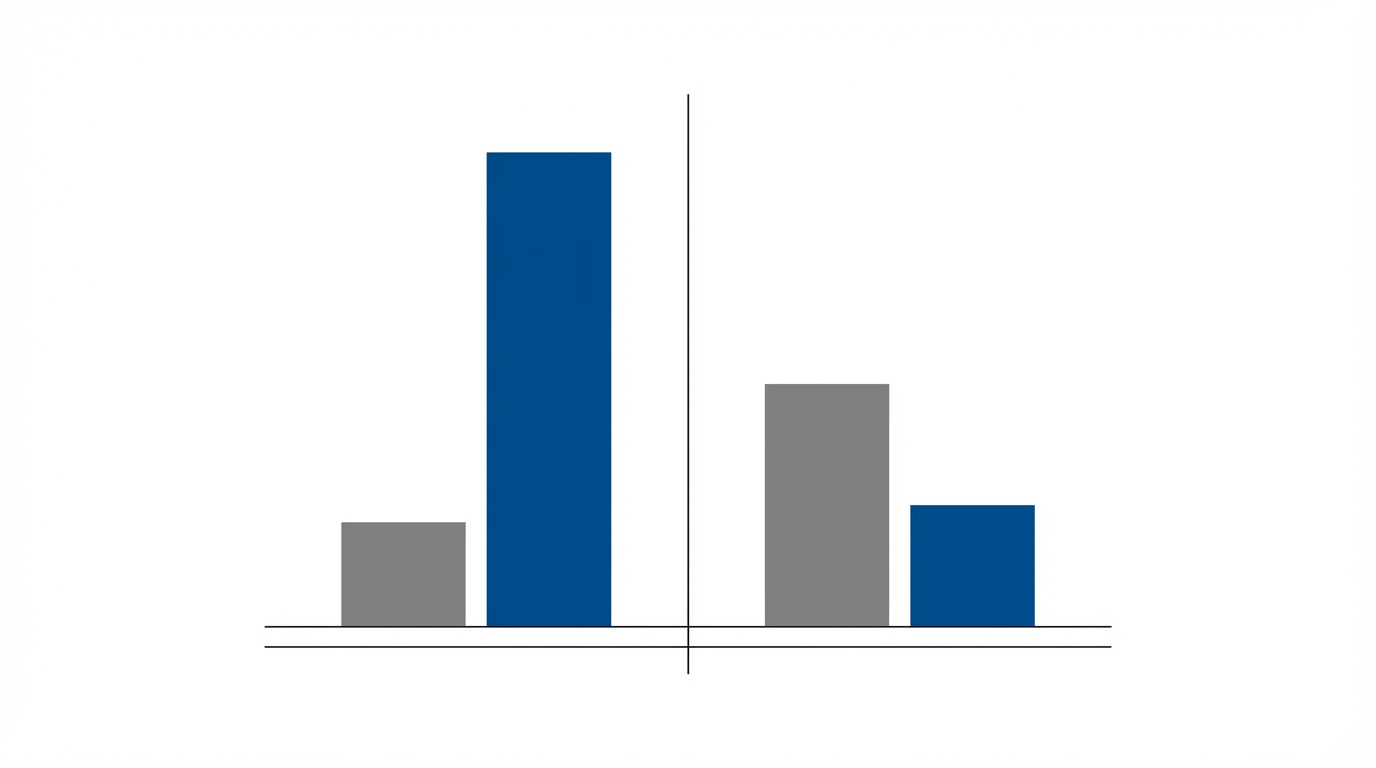

IX. Financial Impact: The Cost of Quality in B2B Furniture

Bar chart comparing the long-term costs of low-quality vs. high-quality industrial coatings.

Investing in the best paint for outdoor wood furniture is a strategic move to lower the “Total Cost of Ownership” for your inventory. While low-cost factories may offer lower per-unit prices, the hidden costs of poor finishing—including return logistics, warehouse inspections, and brand damage—often far outweigh the initial savings.

Reducing the Logistics of Failure

If a shipment arrives with peeling paint, the cost of return logistics can easily exceed the original value of the goods. For an importer, this is a logistical nightmare that disrupts supply chains and leaves retail shelves empty. By specifying high-performance industrial acrylics, you essentially purchase insurance against these failures. The goal for any high-volume B2B operation should be a “landed and perfect” rate of 99% or higher.

Warranty Savings and Customer Lifetime Value

High-quality coatings allow you to offer longer warranties, which builds trust with your retail partners. It also increases the “Customer Lifetime Value” by ensuring the end-consumer is satisfied with their purchase years later. A customer who sees their patio set looking great after three years is a customer who will return to your brand. In contrast, a failed finish within one year ensures that the customer—and the retailer—will seek a different supplier for their next order.

Efficiency Gains in Production

Professional-grade paints are designed for industrial efficiency. They have higher “build” (more solids), meaning the factory can achieve full opacity in fewer coats. They also cure faster and more predictably. For the manufacturer, this reduces labor and energy costs. For the importer, this means more stable pricing and more reliable delivery schedules. A factory that uses cheap, slow-drying paint is a factory prone to production bottlenecks and quality inconsistencies.

X. Logistics and Packaging Protection for Export

Workers loading export-grade cartons into a shipping container with protective barriers.

The journey across the ocean is the final test for the best paint for outdoor wood furniture. Shipping containers can experience 100% humidity and temperatures exceeding 60°C (140°F) as they cross the equator. If the packaging is not designed correctly, even a perfect paint job can be ruined by mold or “pressure marking” during transit.

Combating “Container Sweat” and Mold

“Container sweat” occurs when moisture evaporates from the wood and then condenses on the cold metal walls of the container, dripping back onto the boxes. To prevent this, factories should use high-capacity desiccants and ensure the furniture is packed with anti-mold paper or breathable liners. Traditional plastic polybags are dangerous because they trap moisture against the paint, creating a greenhouse effect that promotes rot.

Preventing Finish “Printing” and Stacking Damage

When painted furniture is stacked under heavy pressure in a container, the paint can “print”—the texture of the packaging material becomes embossed into the finish. To avoid this, the best paint for outdoor wood furniture must be fully cross-linked before packing, and non-woven fabric spacers must be used between finished surfaces. This ensures that when the customer unboxes the product, the finish is as smooth as it was when it left the factory.

ISTA-6 Packaging Standards for B2B

For high-volume importers, we recommend specifying ISTA-6 packaging standards. This includes drop tests and vibration tests to ensure that the furniture—and its protective coating—survives the mechanical stresses of global logistics. A robust carton with proper internal bracing prevents the furniture pieces from rubbing against each other, which can cause “rub-through” on the edges of the paint.

FAQ

What is the best paint for outdoor wood furniture in a commercial B2B setting?

The industry standard is an industrial-grade, water-based acrylic system. It offers the necessary flexibility to handle wood movement, superior UV resistance for long-term color retention, and low-VOC levels for global environmental compliance.

How can I verify the quality of the paint used by my factory?

You should request a Technical Data Sheet (TDS) for the coating, along with laboratory test reports for adhesion (ASTM D3359) and accelerated weathering (QUV). A professional supplier will have these documents readily available for their export clients.

Why is my outdoor furniture peeling even though the wood is high quality?

Peeling is almost always a failure of the coating’s adhesion or flexibility, not the wood itself. Common causes include applying paint over high-moisture timber, skipping the priming stage, or using a brittle oil-based paint that cannot accommodate the wood’s natural movement.

Closing note

Maintaining professional-grade finishes is essential for the longevity of your B2B inventory. By prioritizing moisture control, industrial acrylics, and rigorous testing, you ensure your products withstand global climates. For expert guidance on securing the best paint for outdoor wood furniture for your next project, please contact us .