A furniture factory audit prioritizes manufacturing ownership, material moisture control, and structural testing over superficial showroom aesthetics. Selecting the wrong supplier leads to devastating product failures that can drain your budget and destroy customer trust. This comprehensive guide provides the industry standards required to separate high-performing manufacturers from risky intermediaries.

Ⅰ. Strategic Value: Furniture Factory Audit

A professional furniture factory audit determines if a facility possesses the actual technical capacity to execute your designs without outsourcing to unverified workshops. By verifying the physical ownership of heavy machinery, the industry ensures you are dealing directly with the source. This prevents the hidden markups and quality drift common when working with trading companies posing as factories.

Is the factory a real manufacturer?

Verifying business licenses and physical asset logs is the only way to confirm you are not being misled by a middleman. You need to see the machinery in operation to ensure the facility you visit is actually the one producing your goods.

- Inspect original business licenses and tax registrations onsite.

- Cross-reference machinery serial numbers with company asset registries.

- Observe the staff to ensure they are full-time employees rather than temporary day laborers.

Here is the truth.

| Category | High Priority | Low Priority |

|---|---|---|

| Ownership | Direct ownership of CNC and kiln drying assets | Rented or shared assembly spaces |

| Transparency | Full access to all production halls | Restricted areas and “secret” workshops |

| Staffing | Consistent payroll and safety training records | High turnover of seasonal migrant labor |

The core of a successful partnership lies in identifying factories that invest in their own long-term production infrastructure.

Ⅱ. Floor Management: Furniture Factory Audit

An organized floor layout during a furniture factory audit reveals the management’s commitment to efficiency and safety. When you see a clear separation between raw wood processing and final finishing areas, you know the risk of cross-contamination is minimized. This structural organization is a leading indicator of a factory’s ability to maintain high quality across large volume orders.

Does the factory layout prevent defects?

A chaotic workspace often hides deeper issues like wood dust settling on fresh lacquer or components getting damaged during internal transport. You should look for designated zones for material storage, fabrication, and quality control.

- Check for clearly marked walkways and hazard-free zones.

- Evaluate the proximity of the sanding department to the spray booth.

- Observe how “work in progress” items are protected from moisture and dust.

But that’s not all.

| Factor | Optimal Audit Finding | Critical Red Flag |

|---|---|---|

| Work Flow | Linear movement from raw timber to packing | Backtracking and disorganized component piles |

| Cleanliness | High-power dust extraction in all cutting areas | Thick dust accumulation on windows and lights |

| Lighting | Bright, uniform light over inspection stations | Dimly lit finishing or final assembly areas |

A clean and logically arranged factory floor significantly reduces the incidence of random surface damage during production.

Ⅲ. Material Testing: Furniture Factory Audit

Validating raw materials during a furniture factory audit is essential for long-term product durability, especially for kids-furniture which requires the highest safety standards. The most common cause of structural failure is improper wood moisture content, which leads to warping or cracking after the product is shipped. Verifying these metrics onsite protects you from receiving goods that look perfect but fail within months.

How do they track wood moisture?

Using digital moisture meters is the industry standard for ensuring timber is properly seasoned for the destination climate. You must confirm that the factory tests every batch of timber before it enters the cutting phase.

- Demand to see the digital moisture meter readings on random planks.

- Review the kiln-drying logs to verify consistency in temperature and time.

- Inspect the raw material storage area for adequate humidity control.

Let’s dig deeper.

| Material Metric | Industry Standard | Audit Check Method |

|---|---|---|

| Moisture Content | 8% to 12% (climate dependent) | Handheld digital meter testing |

| Timber Grade | FAS (First and Seconds) or better | Visual inspection for knots and sapwood |

| Storage | Elevated pallets in climate-controlled zones | Visual check for ground-level dampness |

Moisture management is the single most important technical check for ensuring wood products remain stable across different global regions.

Ⅳ. Efficiency Data: Furniture Factory Audit

Analyzing production timelines during a furniture factory audit provides the hard data needed to judge lead time reliability. Factories that keep detailed logs of production throughput are much more likely to hit their shipping windows than those that rely on verbal estimates. This data-driven approach allows you to identify potential bottlenecks before they cause significant commercial delays.

Can the factory meet tight deadlines?

Reliable lead times depend on the synchronization between machine capacity and the total volume of active orders. You can often predict a delay by simply reviewing the factory’s current order book against their machine hours.

- Verify the current machine utilization rates in the cutting shop.

- Check historical shipping data for the past twelve months.

- Review the headcount of the final assembly team during peak hours.

Think about it.

| Performance Indicator | Audited Supplier | Non-Audited Supplier |

|---|---|---|

| Lead Time Stability | High (Consistent 15-day variance) | Low (Fluctuates by 30+ days) |

| Output Consistency | Stable daily production quotas | Sporadic output based on labor availability |

| Communication | Data-backed progress reports | Vague status updates and excuses |

Utilizing factories with stable production data ensures that your supply chain remains resilient during high-demand seasons.

Ⅴ. Tech Precision in a Furniture Factory Audit

Modern automation is a critical point of inquiry in any furniture factory audit as it removes the human error associated with complex joinery. High-precision CNC machines ensure that every part is identical, which is vital for the assembly of high-volume furniture lines. Verifying the calibration of this equipment ensures that your parts will fit together perfectly without requiring onsite rework.

Do they use CNC for precision?

Manual carving and cutting often result in dimensional variances that make final assembly difficult or impossible for the end consumer. You should look for high-end CNC wood-carving equipment that can maintain tolerances within millimeters.

- Observe the CNC machine while it is actively cutting a panel.

- Check the maintenance logbooks for recent calibration signatures.

- Measure a finished part against the original technical drawing.

Now, consider this.

| Technology Level | Impact on Quality | Audit Verification |

|---|---|---|

| Automated CNC | Zero dimensional variance in parts | Live operation and logbook review |

| Manual Cutting | High risk of assembly misalignment | Visual check of saw guide stability |

| Edge Banding | Smooth, long-lasting panel edges | Scratch and heat resistance testing |

Investment in automation is the clearest sign that a factory is capable of producing world-class furniture at scale.

Ⅵ. Ethical Standards and Social Compliance

Social compliance audits protect your brand from the reputational damage associated with poor labor practices or unsafe working environments. For brands focusing on residential-furniture , knowing that workers are treated fairly is as important as the quality of the finish. A safe workplace is also a more productive one, leading to higher quality products and fewer production interruptions.

Is the workplace safe for staff?

Protecting workers from wood dust and chemical fumes is a legal and ethical requirement that impacts your brand’s integrity. You must ensure that the factory provides high-quality respirators and has functioning dust extraction systems.

- Inspect the usage of personal protective equipment in the spray room.

- Check that fire exits are clearly marked and never obstructed.

- Verify that first aid kits are fully stocked and accessible to all.

It gets better.

| Compliance Point | Required Standard | Visual Evidence |

|---|---|---|

| Respiratory Safety | Professional grade masks for painters | Masks worn properly by all booth staff |

| Air Quality | Active industrial dust extraction | Absence of airborne dust in the main hall |

| Labor Records | Proof of legal age and fair wages | Payroll logs and ID card verification |

Ethical manufacturing is no longer optional; it is a fundamental requirement for any brand selling in international markets.

Ⅶ. The Full Scope of a Furniture Factory Audit

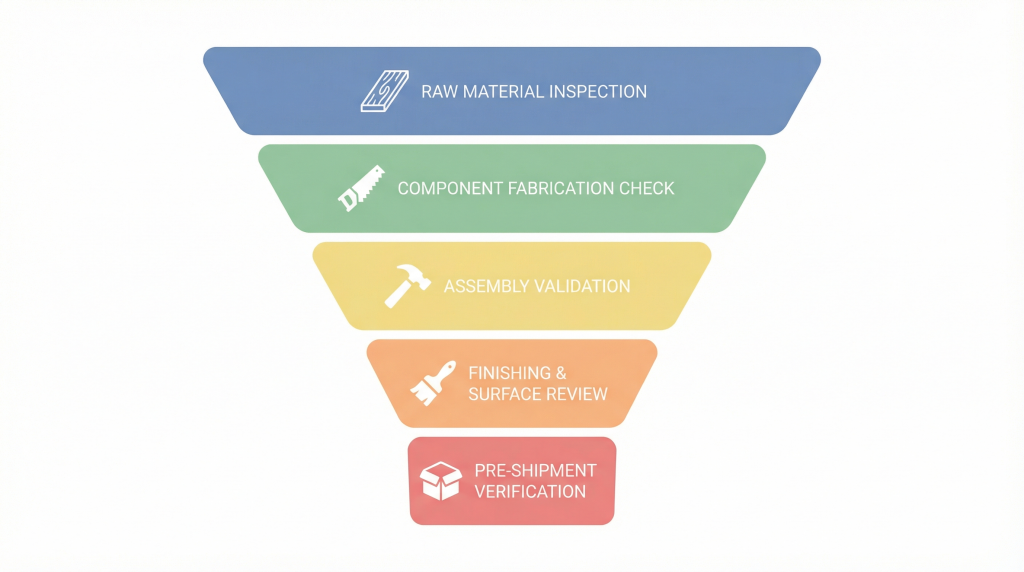

A thorough furniture factory audit must follow a structured 5-step process to ensure no quality detail is overlooked, especially for durable goods like outdoor-furniture . From raw material inspection to final container loading, each step serves as a filter to catch defects before they leave the factory gates. This systematic approach is what differentiates a professional audit from a simple casual walkthrough.

Is the quality funnel effective?

An effective audit system identifies errors early in the production cycle when they are still cheap and easy to fix. You need to confirm that the factory has dedicated quality control stations at every major stage of fabrication.

- Review the internal quality control checklist used by the factory.

- Witness a random inspection of a semi-finished furniture component.

- Check the “quarantine area” for rejected parts that failed inspection.

Believe it or not.

| Audit Step | Objective | Expected Outcome |

|---|---|---|

| Raw Material | Catch wood and hardware defects early | Rejection of substandard timber batches |

| Fabrication | Verify dimensional and joinery accuracy | Precise components for final assembly |

| Finishing | Ensure color and coating consistency | Flawless surface tactile quality |

A multi-stage quality funnel ensures that only products meeting your exact specifications make it into the shipping container.

Ⅷ. Testing Safety in a Furniture Factory Audit

Ensuring that products survive international shipping is a vital part of a furniture factory audit, as transit damage is a major source of loss for B2B buyers. The industry uses standardized drop tests to simulate the physical stress that packages undergo in ports and trucks. If the packaging is not audited, even the highest quality furniture can arrive at your warehouse as a pile of broken wood.

Is the packaging ISTA-certified?

Standardized testing ensures that the grade of cardboard and the internal padding are sufficient to protect the furniture corners and surfaces. You should insist on seeing a live drop test of a fully packed carton during the audit.

- Conduct an onsite ISTA-1A drop test on a random unit.

- Inspect the thickness and bursting strength of the export cartons.

- Check for the use of moisture-absorbing silica gel packs in every box.

Best of all.

| Test Type | Procedure | Success Criteria |

|---|---|---|

| Corner Drop | Hardware remains secure, and the finish is intact | No structural damage to the wood inside |

| Compression | Stack weights on top of the shipping carton | Carton maintains shape without collapsing |

| Vibration | Simulate ocean or truck movement stress | Hardware remains secure, and the finish is intact |

Packaging is the final safeguard that preserves the value of your manufacturing investment during the long journey to the customer.

Ⅸ. Environmental Impact and Waste Laws

Environmental compliance is now a critical survival factor for Chinese factories, as government shutdowns for non-compliance can stop your production overnight. An audit must verify that the factory uses high-capacity dust extraction and legal chemical waste disposal methods. Sourcing from a factory that ignores these laws puts your entire supply chain at risk of sudden regulatory interruption.

Do they manage waste legally?

Factories must provide documentation showing that sawdust and finishing chemicals are handled by certified waste contractors. You can often judge a factory’s compliance by looking at the sophistication of their outdoor filtration systems.

- Inspect the hazardous waste storage room for secondary containment.

- Review the official air discharge permits issued by local authorities.

- Check the maintenance records for the central dust collection unit.

In other words.

| Feature | Green Factory | Non-Compliant Factory |

|---|---|---|

| Dust Extraction | Centralized high-suction industrial systems | Small, localized units with poor filtration |

| Waste Disposal | Documented manifests from legal contractors | Unverified or illegal dumping practices |

| Regulatory Risk | Low (Full permits and recent inspections) | High (At risk of immediate closure) |

A factory’s environmental management is a direct reflection of its long-term stability and respect for global industry standards.

<p align=’center’></p>

Ⅹ. Legal Safeguards and Certification

The final verification in any professional audit is the review of the factory’s certifications and legal documentation. Without valid FSC or ISO certificates, you may face severe customs delays or even total import bans in certain markets. These documents provide the legal foundation for your brand’s quality claims and environmental promises.

Are certifications up to date?

Always demand to see the original physical certificates rather than relying on digital copies that can be easily edited. You should verify the unique certificate numbers directly on the official database of the accreditation body.

- Verify the FSC chain of custody for the specific wood species used.

- Check that ISO 9001 quality systems are audited annually.

- Confirm the authenticity of chemical test reports for paints and glues.

The bottom line.

| Certificate | Value to Buyer | Verification Method |

|---|---|---|

| FSC | Proof of sustainable timber sourcing | Online database search by certificate ID |

| ISO 9001 | Evidence of a consistent quality process | Check the expiry date on the original hard copy |

| Lab Reports | Confirmation of non-toxic chemical levels | Direct contact with the testing laboratory |

Proper documentation is your insurance policy against legal liability and regulatory challenges in your home market.

Conclusion

Auditing a furniture manufacturer is not about finding a perfect facility, but about identifying a partner committed to technical transparency and structural safety. By focusing on moisture control, machinery precision, and legal compliance, you eliminate the “guessing game” from your supply chain. Our team specializes in conducting these rigorous on-site evaluations to ensure every piece of furniture meets your exacting standards before it ever hits the water. We invite you to explore our approach to furniture manufacturing and see how we protect your brand at the source.

FAQ

Can I skip an audit if the factory provides high-resolution photos?

No. Photos can be easily staged or taken from a different facility, so a physical audit is the only way to verify real ownership and daily production quality.

What’s the best way to handle a factory that refuses an audit?

Move to another supplier. A refusal to allow a professional audit is the clearest indicator that the factory is either a middleman or hiding significant quality issues.

Can I rely on the factory’s internal quality control reports?

Partially, but only as a supplement to independent third-party inspections. Internal reports often overlook defects to meet shipping quotas, whereas an independent audit provides unbiased truth.

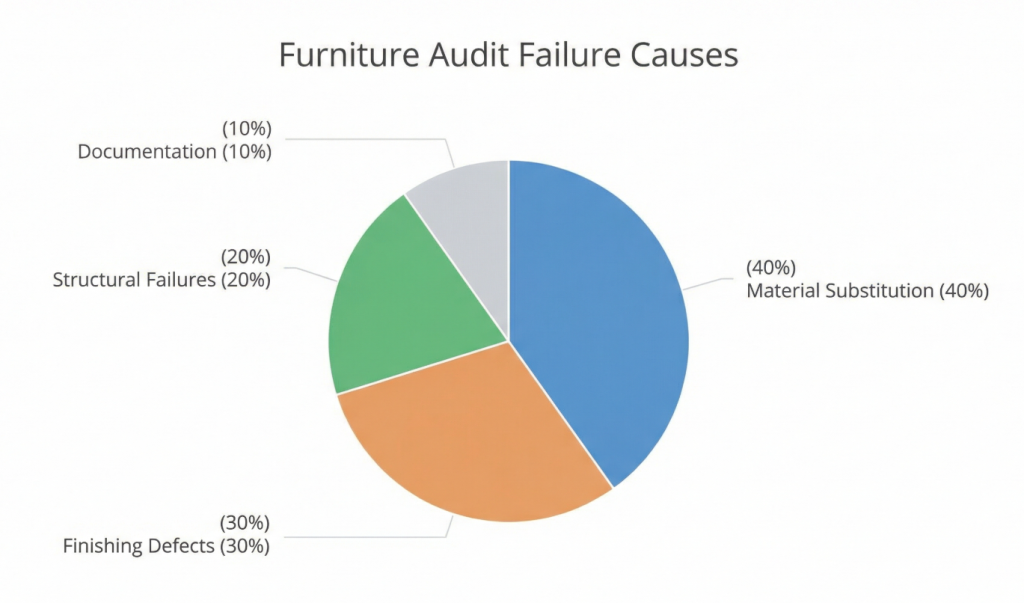

What is the most common reason furniture fails a factory audit?

Moisture content violations. Timber that is not properly dried will always warp or crack, making it the highest priority check for any wood-based furniture product.

How often should I conduct an audit on a long-term supplier?

Annually. Even the best factories can experience staff turnover or machinery degradation, so yearly re-audits ensure that standards are maintained over the long term.