Wooden furniture manufacturing often looks simple from the outside.

Cut wood, assemble, finish, ship.

But here’s the reality—most quality issues and cost overruns hide inside factory processes. This article explains how wooden furniture manufacturing really works, using real export workflows, so buyers know where risks start and how to control them.

I. The Linear Progression of Modern Industrial Production

Modern wooden furniture manufacturing is a high-stakes race where precision meets raw lumber. Success on the factory floor depends entirely on a synchronized workflow that eliminates bottlenecks before they occur.

Optimized Factory Workflows

- Sequential Processing: Raw timber moves through a strict linear path to prevent cross-contamination and logistics tangles.

- Station Specialization: Each operator focuses on a singular technical task to maintain a 0.1mm tolerance standard across the board.

- Throughput Monitoring: Digital tracking systems measure the speed of every component as it transitions from the saw to the assembly line.

| Production Phase | Key Objective | Primary Equipment Used |

|---|---|---|

| Primary Processing | Log breakdown and grading | Band saws and hydraulic splitters |

| Secondary Processing | Dimensional accuracy | Planers and thicknessers |

| Tertiary Processing | Detailed shaping | CNC routers and boring machines |

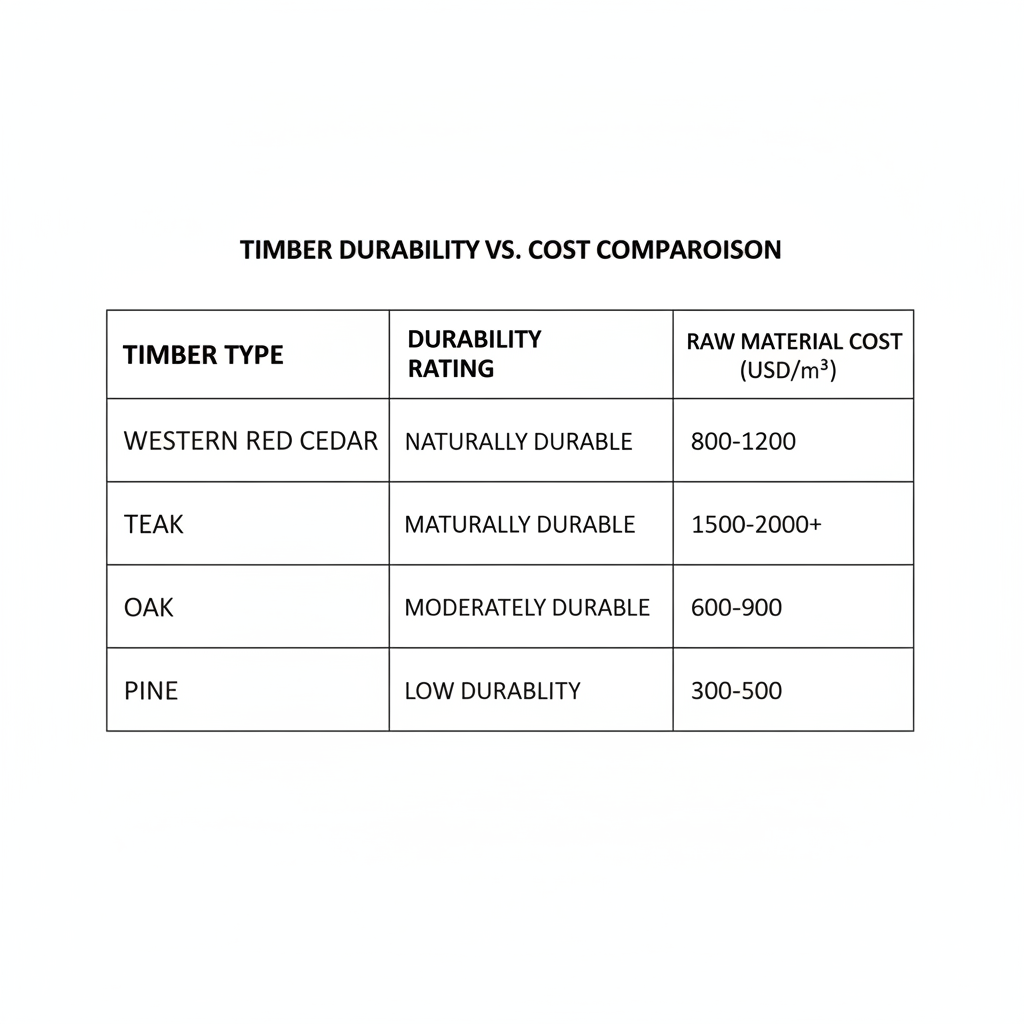

II. Material Selection and Timber Grading Standards

The foundation of every high-end piece starts with the rigorous selection of species based on end-use requirements. This is particularly critical for residential furniture , where the balance between grain aesthetics and structural density must be perfect. Here is the kicker: not all “A-grade” wood is created equal in an industrial setting.

Raw Material Categorization

- Species Density: Hardwoods like oak are reserved for weight-bearing frames, while softwoods provide cost-effective internal support.

- Grain Alignment: Technicians inspect every plank to ensure the grain direction won’t lead to structural warping after assembly.

- Visual Defect Removal: Knots and sapwood are identified early and either removed or strategically placed where they won’t impact integrity.

But wait, there’s more to it than just picking the right tree. The grading process involves a technical assessment of “clear-face” percentages to maximize yield and minimize waste.

Timber Grading Protocols

- FAS (First and Seconds): This provides the manufacturer with long, clear cuttings best suited for tabletops and wardrobes.

- Select Grade: This grade is used for components where one side remains hidden from the consumer’s view.

- Common Grades: These are utilized for smaller parts or painted furniture where natural defects can be filled and covered.

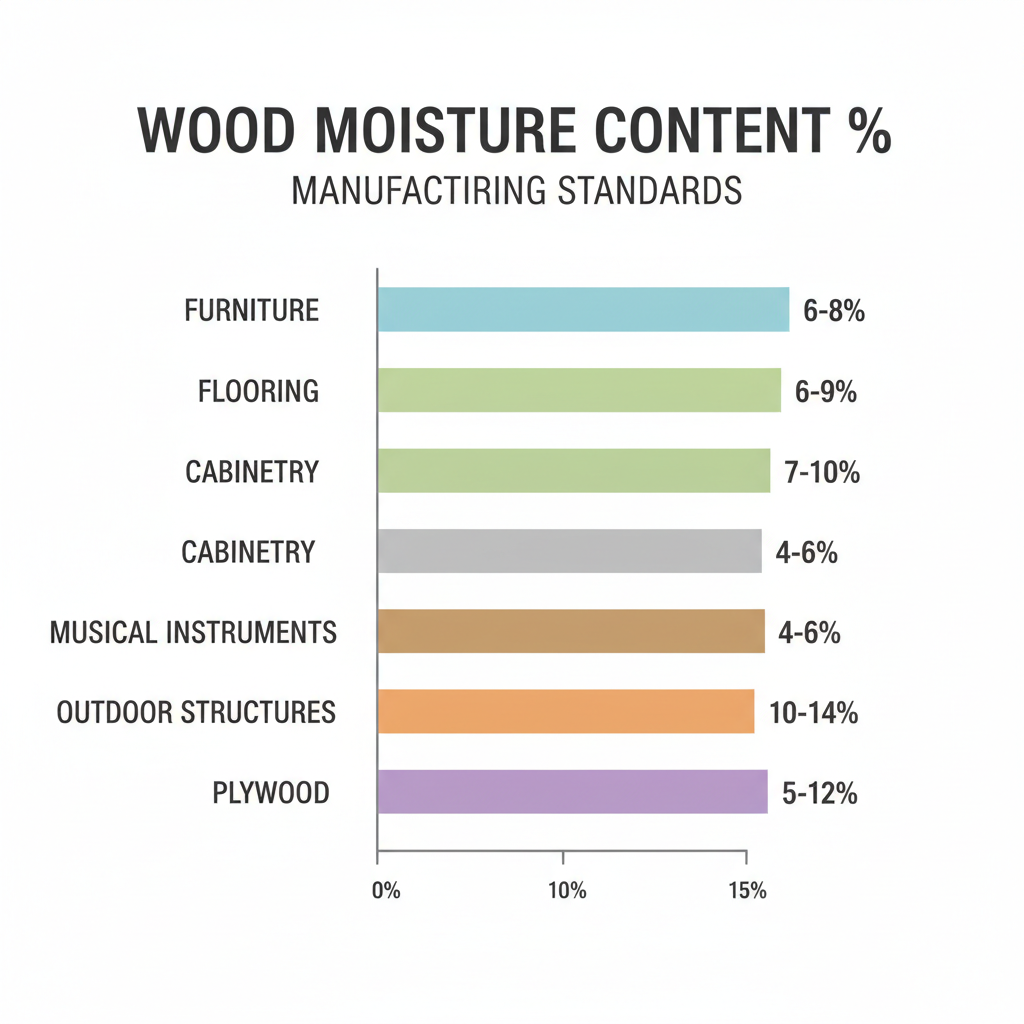

III. The Science of Moisture Content and Kiln Drying

If you ignore the cellular structure of wood, the furniture will eventually fail. Factories in the Shandong region prioritize moisture stabilization to ensure products can survive global shipping climates. You might be wondering why this step takes the longest in the entire production cycle.

Moisture Stabilization Techniques

- Air Seasoning: Initial outdoor stacking allows timber to reach an equilibrium moisture content before entering the heat.

- Dehumidification Kilns: These systems pull water out of the wood at a controlled rate to prevent internal checking.

- Moisture Metering: Handheld and inline sensors verify that every board falls within the 6-10% range required for stability.

The reality is that wood is a “living” material that reacts to its environment. Without professional kiln drying, joints will shrink and expand, eventually leading to catastrophic structural failure.

| Material State | Moisture Range | Recommended Use Case |

|---|---|---|

| Green Lumber | 25% – 50% | Structural framing only (non-furniture) |

| Air Dried | 12% – 20% | Outdoor garden structures and fencing |

| Kiln Dried | 6% – 10% | Premium indoor residential furniture |

IV. Technical Design and Prototyping Blueprints

Before a single saw blade spins, the piece exists as a complex digital map. Modern CAD (Computer-Aided Design) software allows engineers to simulate stress loads and material optimization. Make no mistake, the transition from sketch to shop floor is where most designs succeed or fail.

Engineering and CAD Workflows

- 3D Modeling: Designers create digital twins of every component to check for interference and fitment issues.

- Exploded View Analysis: This allows the assembly team to understand the sequence of fasteners and glue points required.

- BOM (Bill of Materials) Generation: The software automatically calculates the exact volume of wood and hardware needed for the run.

Efficiency is the name of the game in large-scale production. By optimizing the “cut list” digitally, factories can reduce material waste by up to 25%, significantly lowering the carbon footprint.

Prototyping Milestones

- White Wood Prototype: A raw, unpainted version is built to test the ergonomics and physical balance of the design.

- Stress Testing: The prototype is subjected to mechanical weights to ensure it meets international safety certifications.

- Final Master Sample: Once approved, this sample becomes the “gold standard” that all production units must match exactly.

V. CNC Precision and Automated Machine Shaping

The era of the hand-chisel is largely over in the industrial volume world. Precision CNC (Computer Numerical Control) routers are the workhorses that ensure every chair leg and table apron is identical. Here is the bottom line: automation doesn’t replace quality; it enforces it.

CNC Routing Capabilities

- Multi-Axis Milling: Machines can carve complex 3D shapes that would be impossible or too slow for human hands.

- Nested Base Manufacturing: Large sheets of plywood or solid wood are cut with minimal gaps to maximize material yield.

- Tool Path Optimization: Software calculates the most efficient movement for the router bits to reduce heat and wood burning.

Think about the sheer scale of a factory producing thousands of units per month. Without the 0.1mm accuracy of CNC technology, the assembly line would grind to a halt due to misaligned parts.

Shaping and Boring Operations

- Edge Banding: For engineered woods, automated machines apply high-pressure veneers to protect edges from moisture.

- Multi-Spindle Boring: These machines drill all necessary hardware holes in a single pass, ensuring 100% alignment.

- Profile Sanding: Automated belts smooth out curved edges immediately after cutting to prepare for the finishing booth.

VI. Advanced Joinery and Structural Standards

A piece of furniture is only as strong as its weakest connection. Factories choose joinery methods based on the intended lifespan and the shipping method of the product. It’s a delicate balance between traditional craftsmanship and modern mechanical fasteners.

Industrial Joining Methods

- Mortise and Tenon: The gold standard for solid wood frames, providing massive surface area for glue bonding.

- Dovetail Joints: Primarily used in drawer construction to resist the pulling forces of daily use.

- Dowel and Cam-Lock: The preferred method for “Ready-to-Assemble” (RTA) furniture, allowing for flat-pack shipping.

But here is the real secret: the type of glue used is just as important as the joint itself. Industrial PVAc (Polyvinyl Acetate) glues are designed to be stronger than the wood fibers they connect.

Assembly Line Protocols

- Clamping Pressure: Pneumatic jigs apply consistent pressure across the entire joint to ensure a perfect bond.

- Squareness Verification: Technicians use laser levels to ensure the frame hasn’t twisted during the clamping process.

- Glue Clean-up: Excess adhesive must be removed while wet to prevent “ghosting” or spotting during the staining phase.

VII. Surface Treatment and Professional Finishing Stations

The finishing department is often the most restricted area of the factory. Dust control and temperature regulation are mandatory to achieve a “mirror-smooth” surface. This is where the raw timber finally transforms into a marketable product.

Multi-Stage Finishing Process

- Mechanical Sanding: Wide-belt sanders remove mill marks, followed by orbital hand-sanding for final smoothing.

- Vacuum Staining: This process forces pigment into the wood pores for a deep, consistent color that won’t fade.

- UV-Cured Topcoats: High-intensity lights instantly harden the protective layer, creating a scratch-resistant barrier.

In a professional setting, we don’t just “paint” wood; we build a finish in layers. This includes sealers, glaze coats for depth, and final topcoats that determine the gloss level.

| Finish Type | Durability | Best Application |

|---|---|---|

| Nitrocellulose Lacquer | Moderate | Classic residential furniture and antiques |

| Polyurethane (PU) | High | Dining tables and heavy-use surfaces |

| Water-Based Acrylic | High | Eco-friendly nursery and kids furniture |

VIII. Quality Control and Safety Testing Protocols

Quality control is the final gatekeeper before a product leaves the Shandong facility. This stage is non-negotiable, especially for kids furniture , where chemical safety and physical stability are life-or-death requirements. If it doesn’t pass the “stress-load” test, it goes back to the scrap pile.

Rigorous Inspection Checklists

- Moisture Re-Verification: Ensuring the wood hasn’t absorbed humidity during the manufacturing process.

- Hardware Functionality: Every drawer slide and door hinge is tested for hundreds of cycles to ensure smooth operation.

- Non-Toxic Certification: Finishing samples are lab-tested to ensure they are free from lead, phthalates, and VOCs.

Beyond aesthetics, the “tip-over” test is perhaps the most critical for safety. Heavy-duty sensors measure exactly how much force is required to destabilize a wardrobe or dresser.

Structural Performance Testing

- Static Load Test: Placing 2x the rated weight on a surface for 24 hours to check for permanent deflection.

- Drop Testing: Dropping packaged units from specific heights to simulate the rigors of international courier handling.

- Salt Spray Testing: Used primarily for hardware to ensure it won’t corrode in coastal or high-humidity environments.

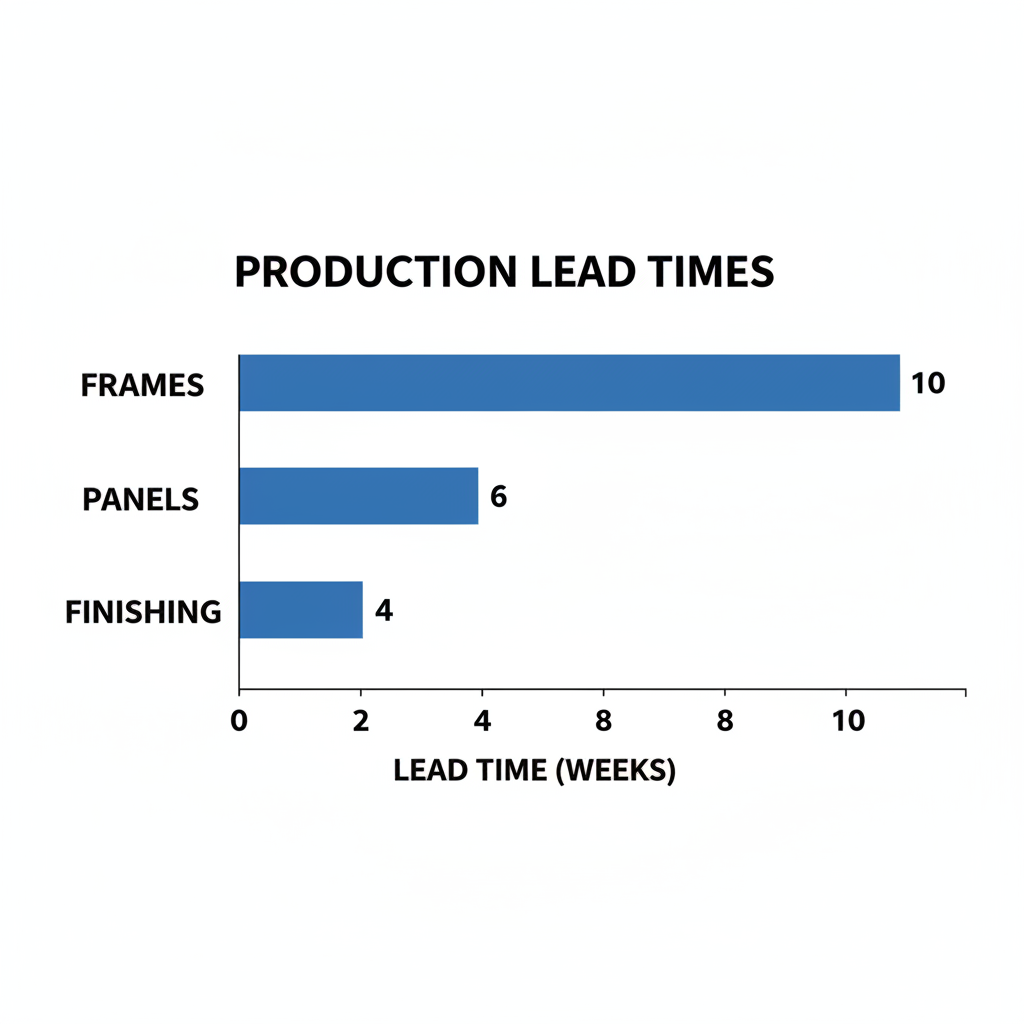

IX. Industrial Logistics and Specialized Packaging

The journey from the factory to the consumer’s home is a brutal environment for wooden products. Specialized packaging is required for outdoor furniture , which must endure the extreme humidity fluctuations of sea freight. This is more than just a box; it’s a protective ecosystem.

Engineering the Perfect Package

- ISTA-6 Standard: Many factories utilize these specific test standards to ensure the “flat-pack” design survives the shipping cycle.

- Corner Protection: High-density foam or honeycomb cardboard is used to prevent the most common type of shipping damage.

- Vapor Barriers: Plastic liners prevent the wood from absorbing moisture during its 30-day journey across the ocean.

The logistics team also manages the “Container Load Optimization” to ensure every cubic inch of the shipping container is utilized. This reduces shipping costs and the overall environmental impact per unit.

Export and Fulfillment Steps

- Palletization: Units are stacked and shrink-wrapped to prevent shifting during truck and ship transit.

- Customs Documentation: Detailed “Lacey Act” filings and certificates of origin are prepared for international clearance.

- Inventory Tracking: RFID tags allow the factory and the client to track the shipment in real-time across the globe.

X. Sustainable Wood Production and FSC Certifications

The future of wooden furniture manufacturing is green or it’s non-existent. Factories are now transitioning to 100% FSC-certified timber to meet the demands of environmentally conscious global markets. It’s no longer just about the product; it’s about the legacy of the forest.

Eco-Friendly Manufacturing Shifts

- FSC Chain of Custody: This ensures that every piece of wood can be traced back to a responsibly managed forest.

- Waste Upcycling: Sawdust and wood scraps are compressed into briquettes or used to fuel the factory’s kiln heaters.

- Low-VOC Adhesives: Switching to water-based glues reduces the “off-gassing” that can affect indoor air quality for the user.

Ultimately, manufacturing is a commitment to both quality and sustainability. By choosing factories that prioritize these standards, brands can ensure they are providing value without compromising the planet. For more information on how we implement these standards, please contact us.

Frequently Asked Questions

1. Why is kiln-dried wood better than air-dried wood?

Kiln-dried wood is superior because the controlled environment kills wood-boring insects and reduces moisture to a level that prevents warping. Air-dried wood often retains too much moisture for indoor use, leading to joint cracks.

2. What is the benefit of CNC routing over hand-cutting?

CNC routing provides 100% repeatability and sub-millimeter precision, which is essential for furniture that requires assembly. It also significantly reduces material waste by optimizing the layout of parts on the raw board.

3. How do factories ensure children’s furniture is safe?

Factories use specialized “lead-free” and “low-VOC” finishes that are safe for oral contact. Additionally, they perform rigorous “tip-over” and “entrapment” tests to meet international safety regulations like ASTM.

4. Can solid wood furniture be shipped as a flat pack?

Yes, by using high-quality hardware like cam-locks and threaded inserts, solid wood can be shipped flat. This reduces shipping costs and environmental impact while maintaining structural integrity.

5. What does FSC certification actually mean?

FSC (Forest Stewardship Council) certification means the wood was harvested from a forest that is managed to preserve biological diversity. It also ensures that the workers and local communities involved are treated fairly.