Facing consistent customer returns due to warped panels or stuck drawers? Uneven moisture management throughout the manufacturing chain causes these structural failures. We provide the technical insights necessary to ensure your stock remains stable.

Wooden bedroom furniture warps primarily due to uneven moisture loss or absorption, causing wood fibers to shrink or expand at different rates. This instability is often the result of improper kiln drying, one-sided finishing, or poor climate control during the international shipping and warehousing process.

I. The Science of Wooden Bedroom Furniture Warps

Wood warps because it is a natural, hygroscopic material that constantly seeks to reach a physical balance with the humidity levels of its surrounding environment. When you source wooden bedroom furniture, you are essentially managing a biological material that retains its cellular memory of water absorption long after it has been harvested.

- Hygroscopic nature means wood acts like a sponge, expanding when wet and contracting when dry.

- Cellular tension occurs when one side of a board dries faster than the opposite side, leading to structural stress.

- Environmental equilibrium is the target state where the wood neither gains nor loses moisture to the air.

Defining Equilibrium Moisture Content (EMC)

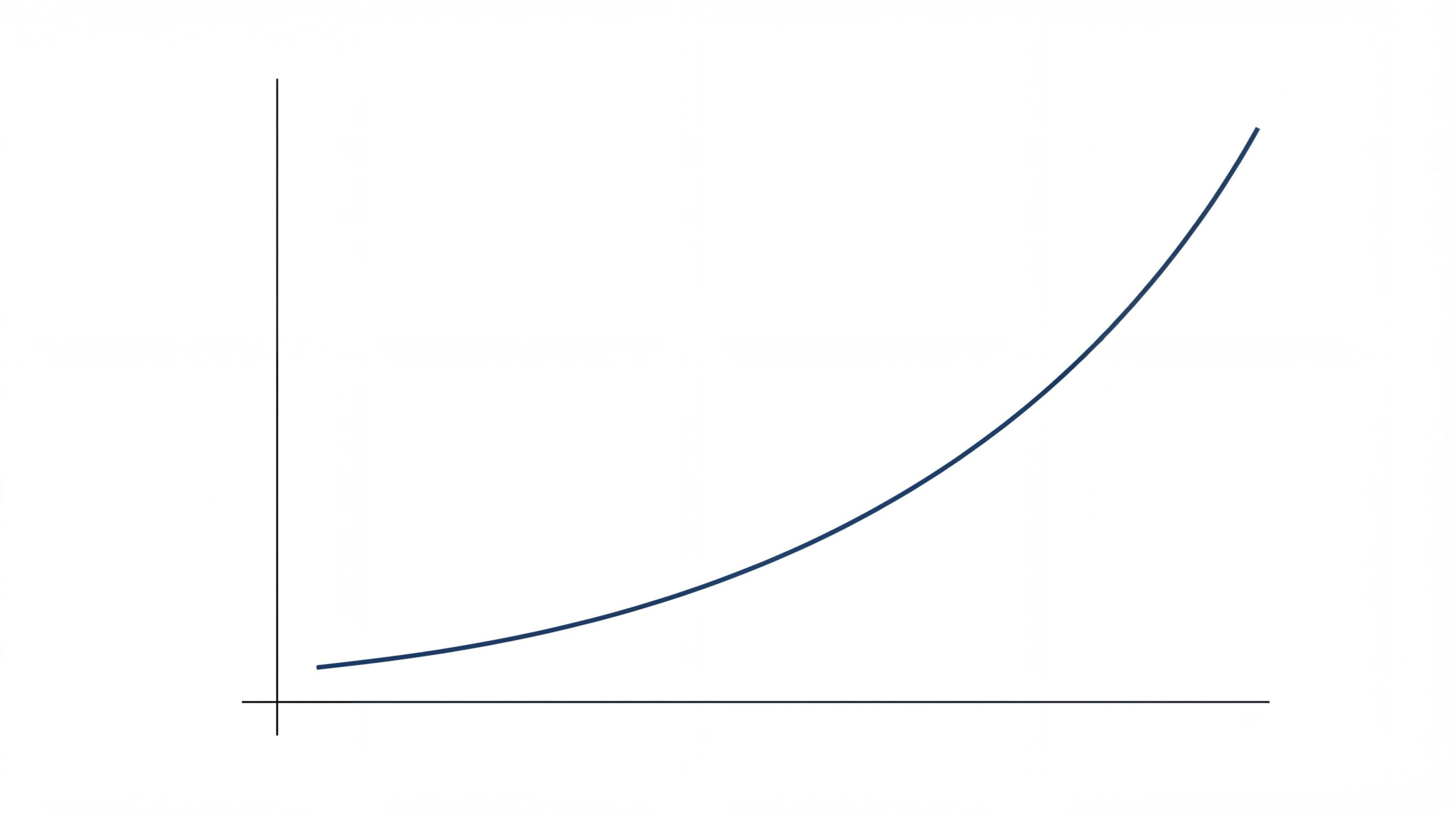

Equilibrium Moisture Content represents the specific point where wood has reached a stable relationship with the ambient temperature and humidity. For manufacturers, targeting an EMC of 6% to 8% is standard for most indoor environments to prevent the wood from moving after assembly. Failure to hit this target during the initial stages of production leads to immediate deformation once the product hits the retail floor.

How Wood Fibers Retain Trapped Water

Wood contains two types of water: “free water” held within the cell cavities and “bound water” trapped within the cell walls themselves. While free water evaporates quickly without much structural impact, the removal of bound water causes the actual shrinkage that results in warping. Procurement teams must verify that the manufacturing process has successfully addressed the removal of this bound water before the wood is milled into final components.

The following table summarizes how different moisture states impact the structural integrity of the timber used in your furniture orders.

| Moisture State | Location in Wood | Impact on Dimensions | Manufacturing Risk |

|---|---|---|---|

| Free Water | Cell Cavities | Negligible change | Minimal risk if dried quickly |

| Fiber Saturation | Cell Walls (Full) | Maximum expansion | High risk of mold if not moved |

| Bound Water | Cell Walls (Partial) | Active shrinkage/warping | Critical phase for kiln control |

It’s simpler than you think.

Key Takeaway: Understanding that wood is a “living” material even after manufacturing allows you to set more rigorous moisture standards for your suppliers, ensuring that the EMC matches the destination climate.

II. Why Wooden Bedroom Furniture Reacts to Moisture

Moisture reaction occurs because the wood’s internal cellular structure expands or contracts as it attempts to achieve a state of balance with the atmospheric humidity. In high-volume wooden bedroom furniture production, even a minor shift in the relative humidity of the factory floor can trigger a chain reaction of fiber movement that ruins an entire production run.

- Relative humidity directly dictates the amount of moisture the wood will eventually hold.

- Cellular walls thicken during absorption, leading to measurable increases in panel width.

- Contraction occurs as water molecules exit the cells, pulling the fibers closer together and creating internal tension.

The Role of Hygroscopic Fiber Expansion

When wood fibers absorb moisture from the air, the physical volume of the wood increases, primarily across the grain rather than along its length. This anisotropic movement means that a wide dresser top will expand significantly in width, potentially cracking the frame if the design does not allow for movement. Manufacturers must account for this expansion by using “floating” panels or specialized joinery that accommodates these natural shifts.

Environmental Factors: UV and Heat

While humidity is the primary culprit, exposure to direct ultraviolet rays and high heat can accelerate the drying process on one side of the furniture. This rapid, localized drying causes the surface fibers to shrink while the core remains moist, resulting in a permanent “cup” or “bow” in the wood. In a B2B context, this often happens during unloading in hot ports or when products are stored near large warehouse windows.

We have analyzed how temperature and humidity interact to create the “danger zones” for furniture stability.

| Environmental Factor | Physical Effect on Wood | Procurement Solution |

|---|---|---|

| Low Humidity | Rapid fiber contraction | Mandate humidified storage |

| High Heat | Surface moisture depletion | Use UV-reflective packaging |

| Direct Sunlight | Uneven thermal expansion | Improve warehouse layout |

Let’s dive deeper.

Key Takeaway: Dimensional stability is a direct result of how well a manufacturer manages the interaction between hygroscopic expansion and external environmental stressors like heat and UV.

III. Identifying Warp Types in Wooden Bedroom Furniture

Warp types are categorized by the specific direction and shape of the deformation, which tells a story about where the manufacturing process failed. By learning to identify these specific defects in wooden bedroom furniture, your quality control team can pinpoint whether the issue stems from poor drying, incorrect cutting, or improper storage.

- Directional stress determines whether a board will bend along its face or its edge.

- Uniformity of grain is the biggest predictor of which way a piece of wood will eventually move.

- Manufacturing defects are often systemic, appearing across entire batches of the same product.

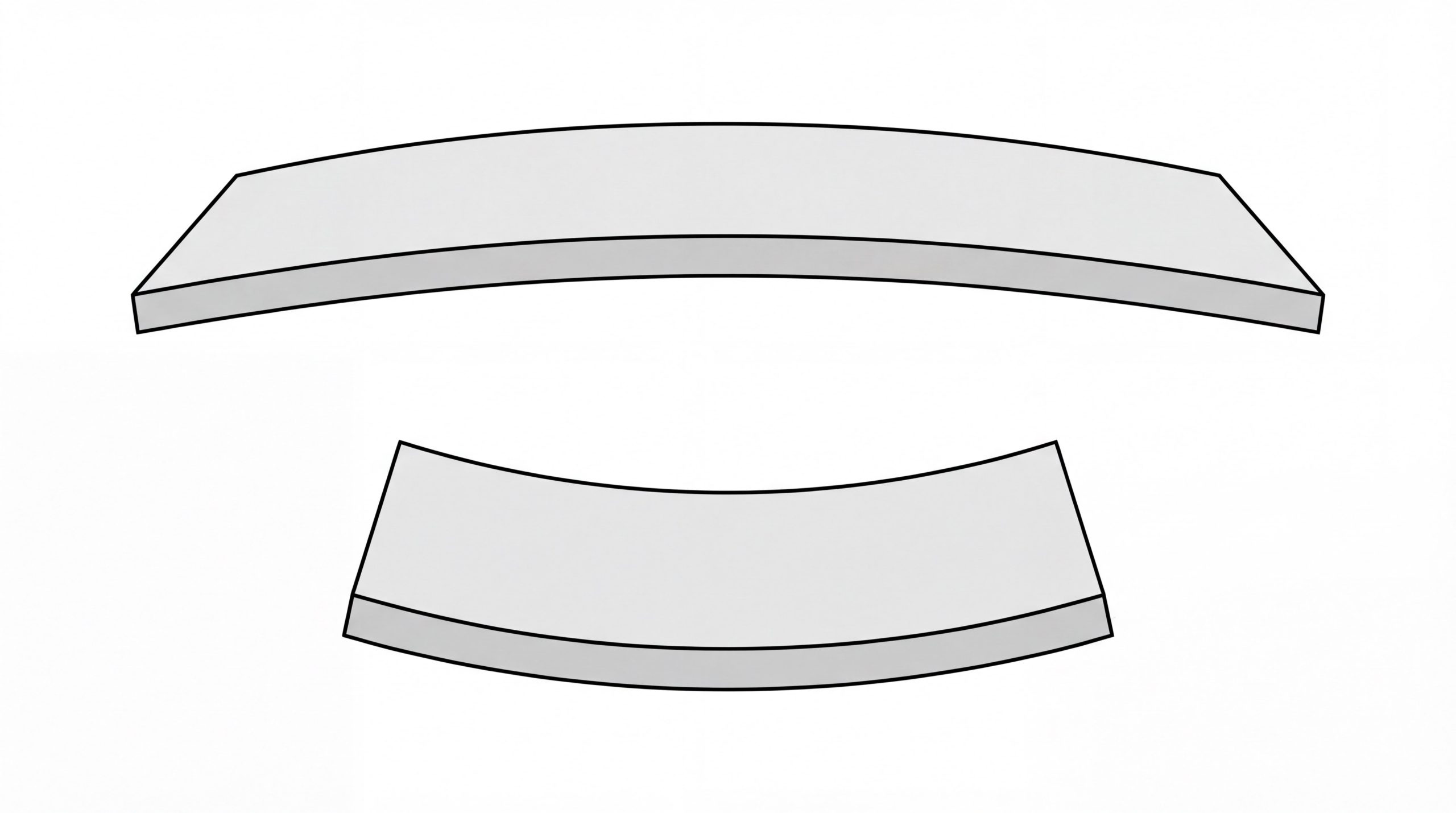

Differences Between Bowing and Cupping

Bowing occurs when a board bends along its length, resembling the shape of an archer’s bow, usually due to being stored without proper support. Cupping, conversely, happens across the width of the board where the edges turn upward or downward relative to the center. Cupping is a classic sign of a moisture imbalance between the face and the back of a panel, often caused by finishing only one side.

Analyzing Kinks and Twisted Frames

Kinking is a localized warp often found near knots, where the grain direction changes abruptly and causes a sharp bend. Twisting is perhaps the most difficult defect to manage, as the board turns in multiple directions simultaneously, often making drawers or doors impossible to close. These complex warps typically indicate that the wood was under significant internal stress before it was ever cut into furniture components.

Identifying these defects early in the QC process is essential for maintaining your brand’s reputation for quality.

| Warp Type | Visual Identifier | Likely Root Cause |

|---|---|---|

| Bow | Bend along the length | Improper stacking/weight |

| Cup | Curve across the width | One-sided moisture entry |

| Twist | Spiraling deformation | Spiral grain/Internal stress |

| Kink | Sharp bend at a knot | Natural wood defect/Drying |

The truth might surprise you.

Key Takeaway: Recognizing the visual differences between bowing, cupping, and twisting allows procurement managers to hold manufacturers accountable for specific failures in drying or storage.

IV. The Impact of Species on Wooden Bedroom Furniture

Species selection is the foundation of structural stability, as different woods have vastly different rates of shrinkage and expansion. When selecting wooden bedroom furniture for a high-volume contract, you must evaluate whether the chosen species can withstand the environmental fluctuations of the destination market.

- Density impacts how slowly or quickly a wood reacts to moisture changes.

- Hardwoods generally offer better stability than softwoods, though there are notable exceptions.

- Species with straight, predictable grain patterns are significantly less likely to warp than those with figured or wild grain.

Comparing Pine, Cedar, and Hardwoods

Softwoods like pine are popular for their cost-effectiveness but are highly susceptible to moisture-induced movement if not treated correctly. For premium projects, you might consider solid wood bedroom sets that utilize denser hardwoods like Oak or Walnut, which provide much higher dimensional stability. Cedar is an excellent middle ground, offering natural resistance to rot and moisture while remaining relatively lightweight.

Grain Patterns and Dimensional Stability

The way the grain is oriented within the board dictates how much it will move; straight grain is the gold standard for stability. Boards with interlocking or wavy grain patterns may be aesthetically pleasing, but they are far more prone to twisting as they dry. Manufacturers who prioritize “clear” lumber for structural components like bed rails or dresser frames will always produce a more durable product.

Consider this comparison of common furniture woods and their relative stability in B2B applications.

| Wood Species | Hardness/Density | Stability Rating | Best Use Case |

|---|---|---|---|

| Pine | Low | Moderate | Budget-friendly frames |

| Oak | High | High | Durable |

| Cedar | Medium | Very High | Wardrobes/Closet liners |

| Walnut | High | Very High | High-end |

Here is why it matters.

Key Takeaway: Species choice is not just an aesthetic decision; it is a technical one that determines the long-term failure rate of your furniture inventory.

V. Precision Kiln Drying: A Manufacturing Necessity

Kiln drying is the only reliable way to ensure that lumber has reached the precise moisture content required for stable furniture production. For modern wooden bedroom furniture, relying on natural air drying is insufficient, as it cannot achieve the low moisture levels necessary for heated indoor environments.

- Industrial kilns use controlled heat, humidity, and airflow to pull moisture from the core of the wood.

- Controlled drying prevents the “case hardening” that occurs when the outside of the wood dries faster than the inside.

- Uniformity across a single batch of lumber is only possible with computerized kiln monitoring.

Beyond Natural Air Drying Methods

While air drying is a traditional method, it often leaves the wood with a moisture content of 15% or higher, which is too wet for most modern homes. This “residual” moisture will inevitably evaporate once the furniture is placed in a climate-controlled room, leading to shrinking and cracking. Precision kiln drying allows manufacturers to “cook” the wood down to 6-8%, effectively “locking” the fibers into a stable state.

Controlling Humidity in Industrial Ovens

Modern kilns are not just ovens; they are sophisticated climate chambers that manage the “drying schedule” based on the specific wood species. If the kiln dries the wood too fast, it creates internal checks and cracks; if too slow, it can lead to staining and fungal growth. A reputable manufacturer will be able to provide “kiln logs” as proof that their lumber was dried according to the correct technical schedule.

Compare the industrial standards for drying to see why kilns are mandatory for export-quality goods.

| Method | Time to Dry | Final Moisture % | Structural Stability |

|---|---|---|---|

| Air Drying | 6-12 Months | 12-18% | Low (Highly Variable) |

| Kiln Drying | 2-4 Weeks | 6-10% | High (Predictable) |

| Vacuum Drying | 3-7 Days | 5-8% | Very High (Premium) |

It gets even better.

Key Takeaway: Never source solid wood furniture from a factory that cannot verify its kiln-drying protocols, as air-dried wood will almost certainly warp in a modern retail environment.

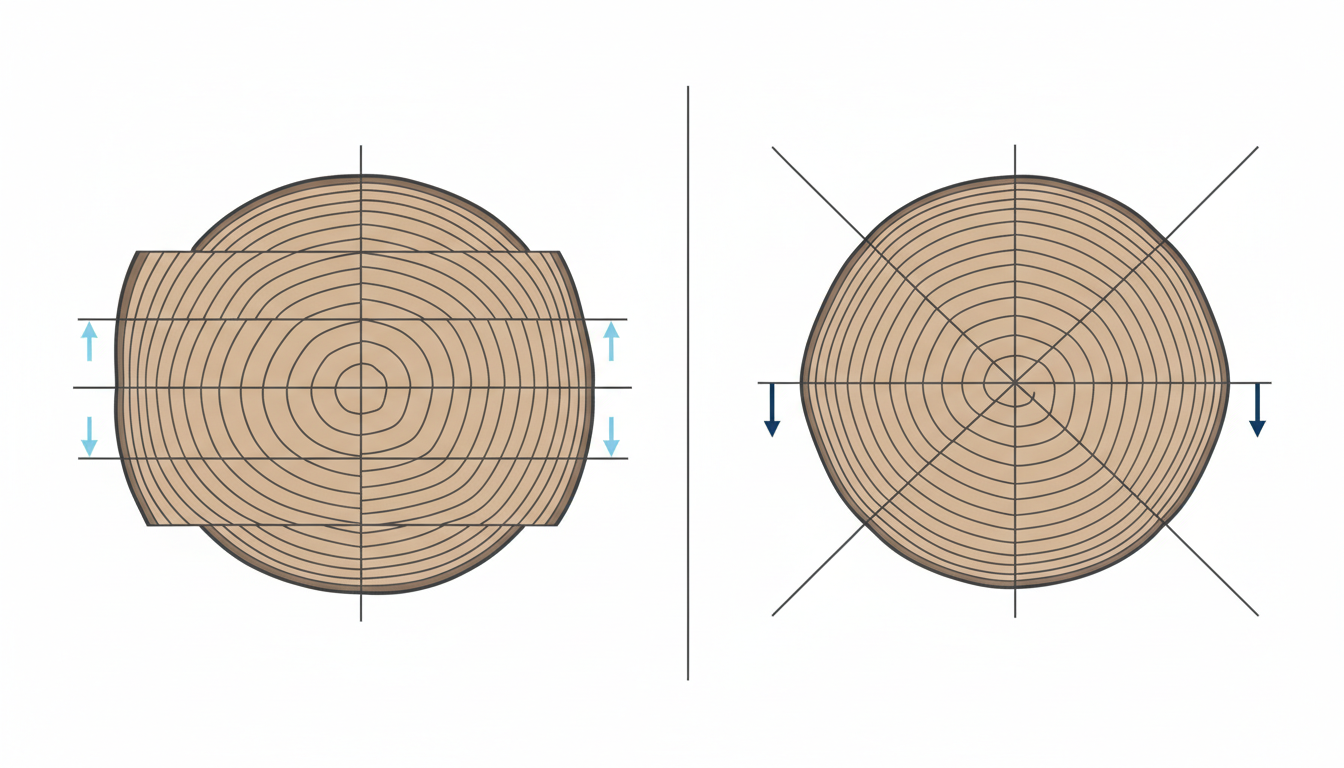

VI. Why Cut Direction Matters for Bedroom Sets

The way a log is sawn into boards—known as the cut direction—has a profound impact on how that wood will shrink or expand. In high-quality wooden bedroom furniture, the use of specialized cuts like quarter-sawn or rift-sawn timber can virtually eliminate the risk of cupping, albeit at a higher material cost.

- Shrinkage is always greater along the growth rings (tangential) than across them (radial).

- Plain sawn lumber is the most common but also the most prone to cupping.

- Quarter sawn lumber features vertical grain that expands and contracts in thickness rather than width.

Plain Sawn vs. Quarter Sawn Stability

Plain sawn boards are cut tangentially to the growth rings, which results in the classic “cathedral” grain pattern often seen on products like the Montauk solid wood bed . However, because the rings are curved across the width of the board, the wood will naturally try to “straighten” those rings as it dries, causing a cup. Quarter sawn boards have rings that run perpendicular to the face, ensuring that any movement is uniform and stays within the plane of the board.

Managing Radial and Tangential Shrinkage

Technical woodworkers know that tangential shrinkage can be twice as great as radial shrinkage. This means that a wide, plain-sawn panel used for a tabletop or a solid wood wardrobe is a high-risk component if moisture levels are not perfectly controlled. By selecting rift-sawn or quarter-sawn lumber for these critical wide surfaces, manufacturers significantly reduce the likelihood of structural failure.

The following table highlights the trade-offs between different sawing methods in furniture production.

| Cut Type | Grain Appearance | Stability | Material Waste |

|---|---|---|---|

| Plain Sawn | Cathedral Pattern | Low (Cups Easily) | Minimal |

| Quarter Sawn | Vertical/Straight | High | Significant |

| Rift Sawn | Linear/Uniform | Very High | Maximum |

But there’s a catch.

Key Takeaway: While quarter-sawn lumber is more expensive due to higher waste, it is the superior choice for large panels and critical structural components in furniture manufacturing.

VII. Critical Sealant Gaps in Wooden Bedroom Furniture

One of the most common—and avoidable—manufacturing errors is the failure to seal all six sides of a wooden component. When wooden bedroom furniture is finished only on the visible surfaces, the unfinished sides remain porous and highly reactive to humidity changes, leading to immediate warping.

- Unfinished wood acts as a “gateway” for moisture to enter and exit the fibers.

- Balanced finishing ensures that both sides of a panel react to the environment at the same rate.

- Edge sealing is critical for preventing moisture from traveling up the end-grain.

The Importance of Six-Sided Finishing

If a manufacturer finishes the top of a dresser but leaves the underside raw, the top surface is protected by a moisture barrier while the bottom is not. On a humid day, the bottom fibers will absorb water and expand, while the top fibers remain static, forcing the entire panel to cup upward. Proper B2B specifications should always mandate “six-sided finishing” to ensure that every square inch of the wood is protected.

How Uneven Sealants Cause Tensions

Even when both sides are finished, using different types of sealants or applying a different number of coats can create an imbalance. A heavy lacquer on the front of a door and a thin wash coat on the back will still allow moisture to penetrate unevenly over time. This creates a “tug-of-war” within the wood fibers that eventually leads to a permanent twist or bow in the frame.

We recommend auditing your supplier’s finishing line to ensure they are following these balanced coating standards.

| Component | Minimum Finish Requirement | Common Manufacturing Error |

|---|---|---|

| Table Tops | Identical coats top and bottom | Only finishing the top surface |

| Drawer Bottoms | Seal both faces and edges | Leaving the underside raw |

| Door Panels | 360-degree sealant wrap | Skipping the top and bottom edges |

Why does this happen?

Key Takeaway: A beautiful finish is useless if it is not balanced; ensure your manufacturer seals the hidden sides of every panel to maintain dimensional stability.

VIII. Safeguarding Wooden Bedroom Furniture in Transit

The journey from a factory in Asia or South America to a warehouse in Europe or North America is the most dangerous time for wood stability. Wooden bedroom furniture is often subjected to “container rain”—a phenomenon where moisture evaporates from the cargo and condenses on the ceiling, dripping back onto the products.

- Container rain is caused by rapid temperature shifts during sea transit.

- Unprotected wood can absorb several percentage points of moisture in a single 30-day voyage.

- Packaging must act as a hermetic seal against external environmental changes.

Vapor Barriers and Moisture Desiccants

To prevent moisture absorption during transit, manufacturers should use industrial-grade polyethylene vapor barriers to wrap individual units. Additionally, the inclusion of high-capacity silica gel desiccants or moisture-absorbing “poles” within the shipping container is a necessary investment for any large-scale furniture procurement. These tools work together to keep the internal humidity of the box at the same level as the factory environment.

Climate-Controlled Logistics Standards

For premium orders, utilizing climate-controlled containers (reefers) can mitigate the risks of extreme heat and humidity. While more expensive, this ensures that the wood never experiences the “thermal shock” that leads to joint separation and glue failure. At a minimum, your logistics partner should ensure that containers are stored below deck or in shaded areas of the port whenever possible.

Use this checklist to evaluate the transit protection of your next international furniture shipment.

| Protection Layer | Purpose | Recommendation |

|---|---|---|

| PE Wrapping | Direct moisture barrier | 0.05mm thickness minimum |

| Silica Gel | Humidity regulation | 50g per cubic meter of cargo |

| Corner Protectors | Structural integrity | Double-walled corrugated |

Think about it.

Key Takeaway: The cost of high-quality vapor barriers and desiccants is a fraction of the cost of a rejected container due to moisture damage and mold.

IX. Warehouse Storage: Preventing Latent Warpage

Even the most perfectly manufactured wooden bedroom furniture can warp if stored incorrectly in a distribution center. Warehouse managers often prioritize space efficiency over wood health, leading to stacking practices that trap moisture and create permanent bends in flat panels.

- Direct contact with concrete floors allows moisture to “wick” into the wood from the ground.

- Tight stacking prevents airflow, creating localized humidity pockets.

- Excessive weight on top of unlevel stacks will force boards to take a permanent set.

Flat Stacking and Sticker Ventilation

When storing unboxed panels or frames, they should always be “stickered”—a process of placing 1×1 inch wooden spacers between each layer. This allows air to circulate around all six sides of the piece, preventing the moisture imbalances that cause cupping. For boxed inventory, ensuring that pallets are level and not over-stacked is critical to maintaining the structural geometry of the furniture inside.

Avoiding Direct Ground Contact Damage

Concrete is naturally porous and often holds significant amounts of moisture, even in seemingly dry warehouses. Storing furniture boxes directly on the floor is a recipe for disaster, as the bottom unit will absorb moisture through the cardboard and into the wood. All wooden bedroom furniture inventory should be kept on pallets or racking systems that provide at least 4 inches of clearance from the floor.

Proper warehouse management is the final step in protecting your investment before it reaches the customer.

| Storage Rule | Technical Reason | Implementation |

|---|---|---|

| Elevate Units | Prevent concrete wicking | Use standard 4″ pallets |

| Limit Stacking | Prevent pressure bowing | Max 3-4 units high |

| Airflow Gaps | Prevent humidity pockets | 2-foot gaps between rows |

You can’t afford to ignore this.

Key Takeaway: Warehouse conditions are just as important as factory conditions; maintain a stable environment and proper stacking to prevent latent warping in your stock.

X. B2B Quality Control for Lasting Wood Products

Final quality control must go beyond visual inspections and include objective, data-driven testing of the wood’s physical state. For procurement professionals, this means mandating the use of moisture meters and acclimation protocols as part of the “Pass/Fail” criteria for every batch of wooden bedroom furniture.

- Digital moisture meters provide an instant reading of the internal water content.

- Batch testing ensures that the entire production run is uniform and stable.

- Acclimation periods allow the wood to “settle” before the final hardware is installed.

Pre-Shipment Moisture Meter Testing

A high-quality manufacturer will use pin-less or pin-type moisture meters to check multiple points on every large component before packing. If a headboard reads 8% at the top but 12% at the bottom, that unit is a failure and will warp as it dries out. These readings should be documented in a QC report that is submitted to you before the container is ever loaded.

Factory Acclimation Protocols for Exports

Before the final assembly and finishing, the milled components should be allowed to acclimate to the factory’s assembly room for at least 48 to 72 hours. This period allows any “stress” introduced during the milling process to manifest and be corrected before the final finish is applied. This is a critical step that many “fast-fashion” furniture manufacturers skip to save time, leading to high failure rates in the field.

Implementing these three QC checks will significantly reduce your return rates and improve customer satisfaction.

| QC Check | Tool/Method | B2B Standard |

|---|---|---|

| MC Verification | Digital Moisture Meter | 6-9% (Target Destination) |

| Flatness Test | Precision Straight Edge | Max 2mm deviation per meter |

| Acclimation | 72-hour rest period | Mandated before final QC |

Now, here is the solution.

Key Takeaway: Objective data from moisture meters is your best defense against future warranty claims; never accept a shipment without a verified moisture report.

FAQ Section

Can I fix a warped table or headboard after it arrives?

No, there is no reliable, foolproof method to restore a warped piece of wood to its original sturdiness once the fibers have taken a permanent set. While steam and pressure can sometimes temporarily straighten a board, the structural integrity is compromised, and it will often return to its warped state over time.

How long should I acclimate furniture before selling it?

It depends on the difference between the factory climate and your local environment, but a minimum of 72 hours of unboxed acclimation is recommended. This allows the wood to adjust to local humidity levels and identifies any immediate “latent” warping issues before the product reaches the end-user.

Does solid wood furniture always warp eventually?

No, well-manufactured furniture made from properly kiln-dried wood and finished on all six sides can remain stable for decades. Warping is not an inevitability of wood; it is a symptom of a failure in the manufacturing, shipping, or storage environment.

Final Check

In this guide, we have dissected the technical causes of wood warping, from the cellular science of hygroscopic expansion to the critical importance of six-sided finishing and kiln-drying logs. By understanding these manufacturing “gray areas,” you can shift your procurement strategy from reactive troubleshooting to proactive quality assurance. Ensuring that your wooden bedroom furniture is built on a foundation of stable moisture content and precision engineering is the only way to protect your margins and your brand reputation in the B2B marketplace.

If you are ready to upgrade your supply chain with products that prioritize technical stability and long-term durability, we invite you to contact us to discuss your specific manufacturing requirements. At Everwoody, we specialize in high-volume, B2B solid wood production where precision moisture control and expert craftsmanship are at the core of every unit we build. Let us help you eliminate the headache of returns and build a furniture line that stands the test of time.