Outdoor wood failure ruins reputations and profit margins. Cracking, peeling, and UV graying turn premium inventory into liabilities. The right outdoor wood finish prevents these costly returns by sealing fibers against moisture and solar radiation.

The best outdoor wood finish is one that balances UV inhibitors with moisture resistance, typically found in high-quality oil-based stains or spar urethanes. These finishes fail when film-forming layers crack or oils evaporate, allowing water to penetrate wood fibers, causing rot, warping, and structural degradation over time.

I. Identifying Early Signs of Wood Finish Failure

Your first indication of a failing protective layer is often a subtle shift in the wood’s surface texture or a dulling of its original luster. If you ignore these early warnings, you risk deep-seated structural issues that can compromise the entire piece of furniture or architectural element. Understanding why wooden furniture cracks starts with recognizing when the surface protection is no longer providing an adequate barrier against the relentless outdoor elements.

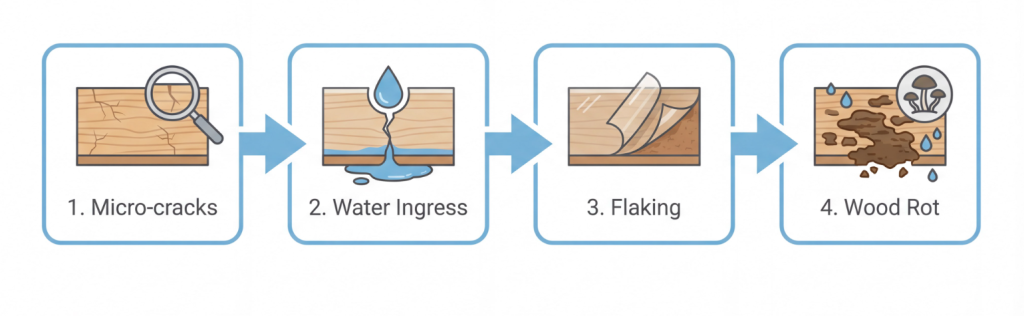

Surface Checking and Micro-Cracks

You will notice small, hair-thin lines appearing along the grain of the wood when the topcoat loses its flexibility. These micro-cracks act as channels for liquid water to enter the timber, leading to internal pressure and eventual fiber separation.

Think about it:

- Fine lines appearing parallel to the grain.

- A rough, sandpaper-like texture when you run your hand across the surface.

- Loss of water beading during rain events.

Discoloration and Silvering Patterns

When UV rays penetrate the coating, they destroy the lignin that holds wood cells together, causing the wood to turn a characteristic silvery-gray. You should watch for localized gray patches, as these indicate areas where the finish has completely eroded or evaporated.

Peeling and Delamination Risks

Film-forming coatings fail most spectacularly when they lose adhesion to the substrate, leading to large flakes or “sheets” of finish pulling away. You must distinguish between the natural weathering of an oil and the structural failure of a hard resin coating.

The following table compares the physical symptoms of failure to help you diagnose issues before they become terminal for your inventory.

| Symptom | Probable Cause | Impact Level |

|---|---|---|

| Silvering | UV Lignin Degradation | Moderate/Aesthetic |

| Peeling | Moisture Trapped Under Film | High/Structural |

| Cracking | Wood Movement vs. Brittle Finish | Critical |

Here is the kicker: If you wait until the wood is gray to re-apply a coating, you will spend three times as much on labor for sanding and preparation.

Key Takeaway: Early detection of micro-cracks and surface dulling is the only way to prevent the total failure of a protective system and ensure long-term durability for outdoor assets.

II. Comparing the Best Outdoor Wood Finish Categories

Choosing the right category of protection requires you to balance the aesthetic desires of your clients with the practical maintenance realities of the installation site. You will find that most professional-grade outdoor furniture utilizes either a penetrating oil for a natural feel or a high-build resin for maximum gloss and weather protection. The “best” choice is always context-dependent, relying on your specific climate and the wood species you have selected for production.

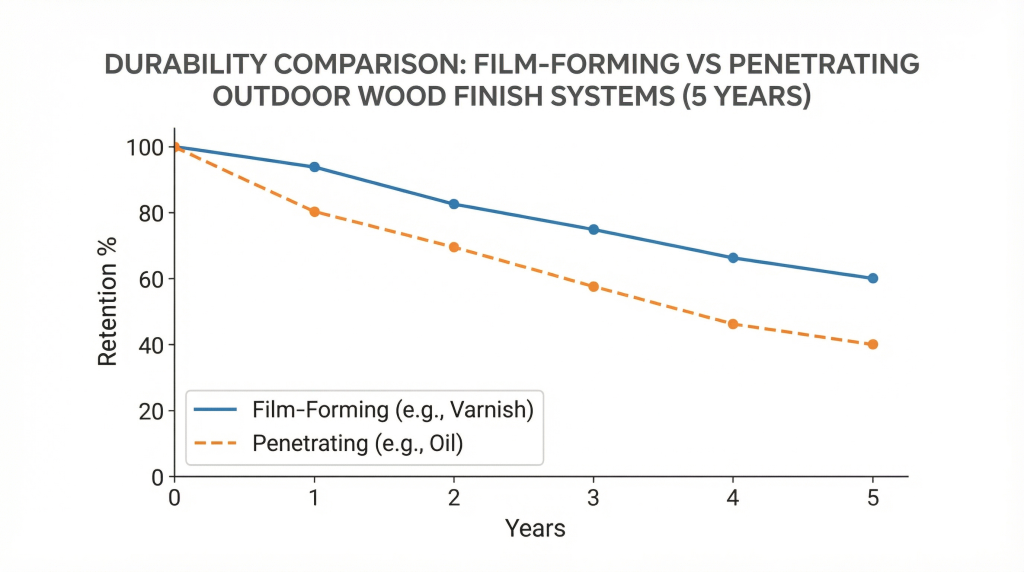

Penetrating Oils for Hardwoods

You should consider penetrating oils like teak or tung oil if your priority is maintaining the wood’s natural grain and providing an easy-to-maintain surface. These finishes work by soaking deep into the wood pores, displacing air and moisture with protective resins that cure within the fiber structure itself.

The reality is:

- No peeling or flaking since there is no surface film.

- Extremely simple maintenance involving just a clean and recoat.

- Deep color enhancement that highlights the wood’s natural figure.

Film-Forming Resins and Varnishes

If you need a high-gloss finish that provides a total physical barrier against liquid water, a film-forming resin like spar urethane is your best option. These coatings are engineered with extra oils to remain flexible, allowing the finish to expand and contract with the wood without cracking under thermal stress.

Water-Based Hybrid Coatings

Modern water-based finishes offer you a lower environmental impact and faster drying times while rivaling the durability of traditional solvent-based systems. These hybrids often combine the ease of water cleanup with the UV resistance of synthetic acrylics and polyurethanes.

This judgment table evaluates the primary coating types to determine which provides the superior value for large-scale B2B procurement.

| Feature | Penetrating Oil | Film-Forming Varnish |

|---|---|---|

| Primary Protection | Interior Pore Sealing | Exterior Physical Shield |

| Maintenance Difficulty | Very Low (Wipe on) | High (Sanding required) |

| Aesthetic Result | Matte/Natural | Glossy/Build-up |

But wait, there is more… Many manufacturers are now blending these technologies to create “one-coat” solutions that offer both depth of color and surface protection.

Key Takeaway: Penetrating oils are superior for maintenance-heavy environments, while film-forming resins offer the highest level of initial protection against extreme moisture and abrasion.

III. Why UV Rays Destroy an Outdoor Wood Finish

Sunlight is arguably the most persistent enemy you will face when managing wood products, as it attacks the finish and the wood substrate simultaneously. An outdoor wood finish without robust UV inhibitors will quickly turn brittle, allowing the sun’s energy to bleach the natural pigments and weaken the structural integrity of the surface. You must ensure that your specifications include high-quality pigments or chemical UV blockers to preserve the “freshly milled” look that buyers demand.

The Science of Lignin Degradation

When UV radiation hits unprotected wood, it breaks down the lignin, which effectively acts as the glue holding the cellulose fibers together. You will see the results of this process as the surface becomes “fuzzy” or “pulpy,” making it impossible for any new finish to adhere correctly without deep sanding.

Make no mistake:

- UV damage is cumulative and irreversible.

- Clear finishes offer the least protection against solar radiation.

- Pigmented stains act like sunscreen for wood by blocking rays.

Role of UV Absorbers and Hindered Amines

Higher-end coatings utilize chemical additives known as UV Absorbers (UVA) and Hindered Amine Light Stabilizers (HALS) to protect the resin itself from breaking down. You should verify that your supplier uses these additives, as they prevent the finish from becoming yellow, brittle, and eventually cracking.

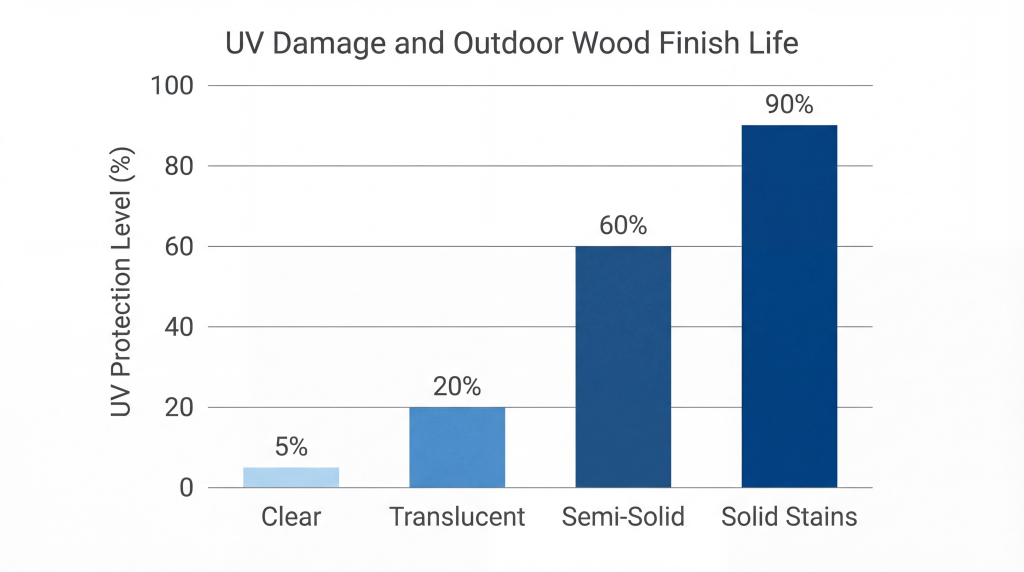

Pigment Density and Solar Protection

The more pigment a stain contains, the better it will protect the underlying wood from the sun’s destructive path. If you choose a solid-color stain, you are providing the maximum possible UV protection, though at the cost of obscuring the wood’s natural grain patterns.

The table below summarizes how different levels of transparency in a finish correlate with their expected UV protection capabilities.

| Transparency Level | UV Protection | Lifespan |

|---|---|---|

| Clear Coat | Low (Minimal) | 12-18 Months |

| Semi-Transparent | Medium | 2-3 Years |

| Solid Color | High (Maximum) | 5-7 Years |

Surprisingly: Even the most expensive clear “marine” grade finishes usually require a maintenance coat every year to stay ahead of UV degradation.

Key Takeaway: UV protection is directly tied to the level of pigmentation and the quality of chemical stabilizers present in the coating formula.

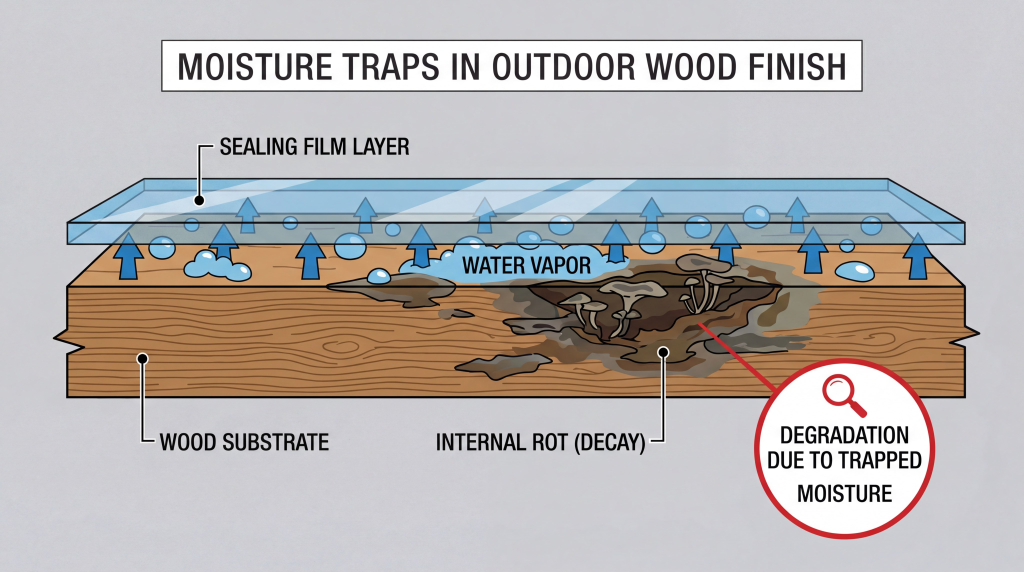

IV. How Moisture Seeps Through Outdoor Wood Finish

Liquid water and water vapor are the primary drivers of rot and fungal growth, making moisture management the most critical function of your chosen outdoor wood finish. Even a tiny breach in the coating can lead to “back-wetting,” where water gets trapped under the finish and cannot evaporate, leading to rapid decay. You must select a finish that is breathable enough to allow internal moisture to escape while being hydrophobic enough to repel external rain.

The Hydrophobic Beading Effect

A high-performance finish will cause water to bead on the surface rather than soaking in, which is your most visible indicator of a healthy protective layer. If you see water spreading out and darkening the wood, it means the surface tension has failed and moisture is entering the timber.

In other words:

- Beading indicates active wax or oil protection.

- Flat water indicates a porous surface.

- Dark spots indicate localized moisture penetration.

Breathability vs. Total Sealing

While you might think a total plastic-like seal is best, wood needs to breathe to accommodate changes in ambient humidity without building up internal pressure. You should look for “microporous” finishes that prevent liquid water from entering but allow individual water molecules (vapor) to pass through.

End-Grain Protection Strategies

The end-grain of a board is up to 250 times more absorbent than the face-grain, making it the most likely point of failure for any outdoor wood finish. You should always insist on a double-coating or a dedicated end-grain sealer for these areas to prevent moisture from “wicking” up into the wood.

This summary table outlines the moisture-handling characteristics of various sealing technologies used in modern woodworking.

| Sealing Method | Water Repellency | Vapor Permeability |

|---|---|---|

| Wax-Based | High (Temporary) | High |

| Polyurethane | Very High | Low |

| Acrylic Hybrid | Medium-High | Medium |

It gets better: Some modern sealers include “encapsulation” technology that chemically bonds to the wood fibers, making them permanently hydrophobic.

Key Takeaway: Effective moisture protection requires a balance of surface hydrophobicity and vapor permeability, with special attention paid to vulnerable end-grain sections.

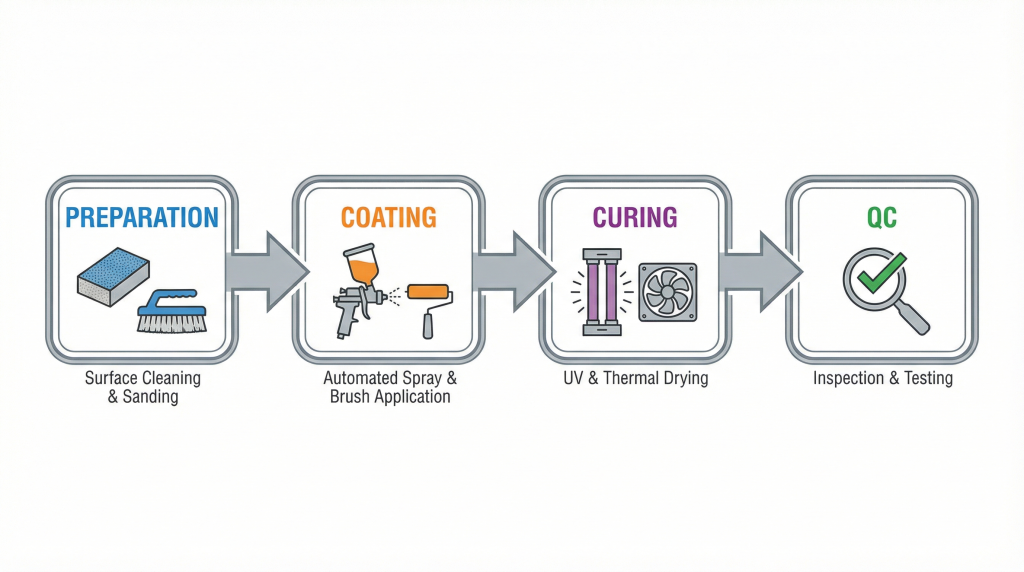

V. Manufacturing Protocols for Outdoor Wood Finish

The longevity of a finish is determined as much by the manufacturing process as it is by the chemistry of the coating itself. You will find that factory-applied finishes are generally superior to field-applied ones because of the controlled environment, consistent thickness, and specialized curing equipment. As a buyer, you must audit the factory’s finishing line to ensure they are following strict protocols regarding temperature, humidity, and sanding grits.

Controlled Drying Environments

If a finish dries too quickly in a hot factory, it may fail to level properly; if it dries too slowly, it can attract dust and contaminants. You should look for facilities that use flash-off zones and temperature-controlled curing ovens to ensure the coating reaches its full chemical resistance.

The bottom line:

- Dust-free environments prevent surface defects.

- Controlled humidity ensures proper adhesion.

- Consistent temperatures lead to uniform curing.

Multi-Step Sanding Sequences

You cannot achieve a professional-grade finish without a rigorous sanding schedule that opens the wood pores without “burnishing” the surface. You must verify that the factory uses progressive grits and removes all sanding dust before the first coat of outdoor wood finish is applied.

Automated Coating Thickness Control

In a professional setting, the use of automated spray lines or vacuum coaters ensures that every square inch of the wood receives the exact same “dry film thickness.” You should ask for the millage specifications to ensure your product isn’t being short-changed on the actual amount of protective resin applied.

This comparison table highlights the differences between manual application and automated factory finishing lines.

| Feature | Manual Application | Automated Factory Line |

|---|---|---|

| Consistency | Variable (Human Error) | High (Computer Controlled) |

| Waste | High Overspray | Efficient Recovery |

| Quality Control | Visual Only | Thickness Sensors |

Here is the kicker: A finish that looks identical on the showroom floor can last twice as long if it was applied under the tight tolerances of a modern factory.

Key Takeaway: Factory-controlled application provides a level of uniformity and chemical bonding that is virtually impossible to replicate through manual field application.

VI. Sourcing Materials with the Best Natural Durability

While the finish is vital, your choice of the best wood for outdoor furniture provides the foundation upon which that finish must perform. You will find that certain species contain natural oils and tannins that can actually interfere with some coatings while enhancing the performance of others. Sourcing the right species allows you to choose a finish that complements the wood’s inherent strengths rather than just covering up its weaknesses.

Natural Oil Content and Adhesion

Species like Teak and Ipe are prized for their high natural oil content, which provides built-in rot resistance but can prevent many film-forming finishes from sticking. You should specify a solvent-wipe protocol for these woods to ensure your outdoor wood finish can achieve a mechanical bond with the surface fibers.

The reality is:

- High-oil woods require specialized primers.

- Low-oil woods absorb more finish and may need extra coats.

- Tannin-rich woods like Oak may “bleed” through water-based finishes.

Dimensional Stability and Coating Stress

Wood that expands and contracts significantly will eventually “stretch” the finish until it snaps, leading to the cracking issues we discussed earlier. You should prioritize stable species like Eucalyptus or thermally modified timber (TMT) to reduce the mechanical stress placed on the protective coating.

Density and Penetration Depth

Denser hardwoods provide a very small “pore” for the finish to enter, which means you need low-viscosity oils that can actually penetrate the surface. If you use a thick varnish on a very dense wood, you are essentially creating a “shell” that is prone to chipping because it hasn’t anchored itself into the wood.

This table summarizes the compatibility between popular outdoor wood species and the most common finish types.

| Wood Species | Recommended Finish | Main Benefit |

|---|---|---|

| Teak | Teak Oil / Natural Oil | Enhances existing oils |

| Cedar | Semi-Transparent Stain | Allows moisture escape |

| White Oak | Spar Varnish | High durability barrier |

But wait, there is more… Thermally modified wood is becoming a favorite for B2B buyers because its extreme stability allows finishes to last significantly longer.

Key Takeaway: Matching the chemistry of your outdoor wood finish to the specific biological characteristics of the wood species is essential for preventing premature delamination.

VII. Testing Protocols for an Outdoor Wood Finish

You cannot rely on manufacturer claims alone; you must implement a rigorous testing phase to prove the durability of a finish in real-world conditions. For B2B importers, this means subjecting samples to accelerated weathering tests that simulate years of sun and rain exposure in just a few weeks. If you skip this step, you are effectively using your customers’ backyards as a laboratory, which is a high-risk strategy for any brand.

Accelerated Weathering (QUV) Testing

Professional labs use QUV chambers to blast wood samples with intense UV light and moisture cycles to see how an outdoor wood finish holds up over time. You should request “Hours to Failure” data from your factory to compare different coating options before placing a bulk order.

Think about it:

- 1,000 hours in a QUV chamber can simulate 3 years of sun.

- Cross-hatch adhesion tests prove how well the finish sticks.

- Salt spray tests are vital for coastal installations.

Cross-Hatch Adhesion Verification

You can perform a simple but effective “tape test” by scoring a grid into the finish and seeing if the squares pull away when adhesive tape is removed. This test tells you immediately if the factory’s surface preparation was adequate or if the outdoor wood finish is purely sitting on the surface.

Water Immersion and Recovery

Testing how a finished board reacts to being submerged in water for 24 hours will reveal its true “sealing” capability. You want to see minimal weight gain (water absorption) and a finish that does not turn milky or cloudy when wet, which indicates poor water resistance.

The table below outlines the standard battery of tests you should require for any new outdoor coating specification.

| Test Name | Methodology | Passing Criteria |

|---|---|---|

| QUV Exposure | UV Light + Condensation | No cracking after 500+ hours |

| Cross-Hatch | ASTM D3359 Grid Cut | 4B or 5B (Minimal flake) |

| Impact Test | Falling Weight | No brittle shattering |

The bottom line: Data from a lab is a far more reliable indicator of quality than a glossy marketing brochure from a coating supplier.

Key Takeaway: Implementing standardized testing protocols ensures that your outdoor wood finish meets the specific environmental demands of your target market.

VIII. Climate-Specific Outdoor Wood Finish Strategies

A finish that excels in the arid Arizona desert will likely fail miserably in the humid tropical environment of Florida. You must tailor your outdoor wood finish selection to the primary stressors of your geographic region to ensure the best possible performance for your end-users. As a global sourcer, you should maintain different “spec sheets” for products destined for different climatic zones to minimize warranty claims and maximize customer satisfaction.

High-UV Desert Environments

In regions with 300+ days of sun, the primary goal for your outdoor wood finish is solar rejection and preventing the wood from drying out too fast. You should specify high-solids, pigmented oils that can deeply nourish the wood while providing a heavy-duty UV shield.

Make no mistake:

- Clear coats will fail in months in desert climates.

- Re-oiling is required more frequently to prevent splitting.

- Lighter colors reflect more heat and stay cooler.

High-Humidity and Tropical Zones

In areas with high rainfall and humidity, your biggest threat is mold, mildew, and rot, requiring a finish with built-in fungicides. You need a coating that creates a very tight seal against liquid water but allows the wood to “breathe” out the constant humidity it will inevitably absorb.

Coastal and Salt-Air Considerations

Salt air is highly corrosive and can break down standard resins much faster than inland environments. You must ensure your outdoor wood finish is “marine grade,” meaning it has higher concentrations of UV blockers and flexible oils that can resist the abrasive nature of salt crystals.

This summary table helps you match the finish technology to the prevailing weather conditions of your installation site.

| Climate Type | Top Stressor | Recommended Strategy |

|---|---|---|

| Arid/Desert | Heat & UV | High-Pigment Penetrating Oil |

| Tropical | Humidity & Rot | Fungicidal Film-Formers |

| Coastal | Salt & Wind | High-Build Marine Varnish |

Even better: Some manufacturers now offer “regionalized” formulas that are specifically balanced for either high-UV or high-moisture zones.

Key Takeaway: Climate specificity is the secret to long-term coating success; a “one-size-fits-all” approach to finishing is a recipe for premature failure.

IX. Common Defects in Factory-Applied Coatings

Even with the best materials, poor execution on the factory floor can lead to “built-in” failures that may not appear until the product is in the customer’s home. You need to be able to identify these defects during your quality control inspections to prevent shipping a flawed batch. A deep understanding of these common issues allows you to provide constructive feedback to your production partners and maintain the integrity of your outdoor wood finish.

Bubbling and Solvent Trap

If the topcoat is applied too thickly or the “flash-off” time is too short, solvent vapors can become trapped under the surface, creating small bubbles or “craters.” This defect creates weak points in the outdoor wood finish where moisture can easily penetrate and begin the delamination process.

The reality is:

- Bubbles indicate a rushed application process.

- Craters (fish-eyes) usually mean the surface was contaminated with silicone.

- These defects cannot be “buffed out” and require a full sand-back.

Orange Peel and Poor Leveling

“Orange peel” is a textured surface that looks like the skin of an orange, usually caused by improper spray gun settings or finish viscosity. While mostly an aesthetic issue, it can trap dirt and pollutants, making the furniture harder to clean and accelerating the degradation of the coating.

Blushing and Moisture Haze

If the factory’s humidity is too high during application, moisture can get trapped within the drying finish, causing it to turn a milky-white color known as “blushing.” This haze is a sign of poor chemical bonding and usually indicates that the finish will eventually peel away from the wood.

This summary table categorizes common factory defects and their impact on the long-term viability of the coating.

| Defect Name | Visual Appearance | Long-term Risk |

|---|---|---|

| Solvent Trap | Tiny Pin-holes | Moisture Ingress |

| Orange Peel | Bumpy Texture | Difficult Cleaning |

| Blushing | White/Cloudy Haze | Total Peeling |

In other words: If your QC team finds more than 5% of samples with these defects, your entire batch is likely at risk of premature failure.

Key Takeaway: Vigilant quality control during the finishing stage is the only way to ensure that factory-applied coatings live up to their theoretical durability ratings.

X. Global Standards for an Outdoor Wood Finish

As a B2B professional, you should adhere to recognized global standards to ensure that your outdoor wood finish meets international safety and durability benchmarks. These standards provide a common language between you, the factory, and the end customer, ensuring that everyone’s expectations for quality are aligned. From VOC regulations to impact resistance, following these guidelines protects your business from legal liabilities and enhances your brand’s reputation for excellence.

VOC Compliance and Sustainability

Volatile Organic Compounds (VOCs) are increasingly regulated worldwide, and you must ensure your outdoor wood finish meets the requirements of your target market (such as REACH in Europe or CARB in California). Switching to low-VOC or water-based finishes is not just an environmental choice; it is a business necessity for future-proofing your supply chain.

Think about it:

- High-VOC finishes are being phased out globally.

- Sustainable coatings improve your brand’s ESG rating.

- Water-based finishes are often easier to ship internationally.

EN 927 and Performance Standards

The European standard EN 927 is a gold standard for evaluating exterior wood coatings, categorizing them based on their end-use and expected exposure levels. You should ask your suppliers if their outdoor wood finish has been tested against these criteria to guarantee a level of performance that meets global professional expectations.

Safety and Non-Toxicity (EN 71-3)

For products that may come into contact with children or food, ensuring the finish meets EN 71-3 (Safety of Toys) is a critical safety requirement. You must verify that the heavy metal content and chemical outgassing of your chosen finish are well within safe limits for residential use.

This comparison table looks at how different international standards impact the selection of professional wood coatings.

| Standard | Focus Area | Relevance to B2B |

|---|---|---|

| EN 927 | Weathering Durability | Essential for Warranty Claims |

| REACH/CARB | Chemical Emissions | Legal Requirement for Import |

| EN 71-3 | Consumer Safety | Critical for Home Furniture |

Here is the kicker: A finish that passes EN 927 standards is significantly more likely to withstand the 3-5 year warranty period most B2B buyers require.

Key Takeaway: Aligning your finishing specifications with international standards reduces risk, ensures legal compliance, and provides a measurable benchmark for quality.

FAQ

Can I apply a new finish over an old one?

Only if the old finish is compatible and in good condition, you must sand away any peeling or flaking areas and ensure the previous coating is clean and dull enough for the new outdoor wood finish to bond mechanically.

What’s the best way to maintain teak furniture?

A high-quality teak oil applied once or twice a year is the professional choice. This maintains the wood’s golden hue and replenishes natural oils that prevent the timber from becoming brittle and cracking under UV exposure.

How do I know if the finish has failed?

Perform the “water drop test” by placing several drops of water on the surface. If the water soaks into the wood within a few minutes rather than beading on top, your protective barrier has failed and requires immediate re-application.

Final check

Solving the dilemma of outdoor wood longevity requires a strategic marriage of species selection and coating chemistry. We provide the technical oversight to ensure your inventory withstands the most brutal environments through factory-level precision. Our commitment to excellence supports your growth by delivering durable, beautifully finished products that satisfy the most discerning global buyers. Please contact us for more.