Rotting furniture drains your budget and ruins your brand reputation. Poorly selected timber warps, cracks, and decays within months, frustrating customers. Invest in professional-grade materials to ensure long-term durability and profit.

Selecting the best wooden outdoor furniture requires balancing rot resistance, stability, and cost. High-performance species like Teak, Ipe, and White Oak offer the best longevity. Success starts with understanding moisture standards and sourcing high-quality timber for your specific climate.

I. Moisture Content Standards for Quality Lumber

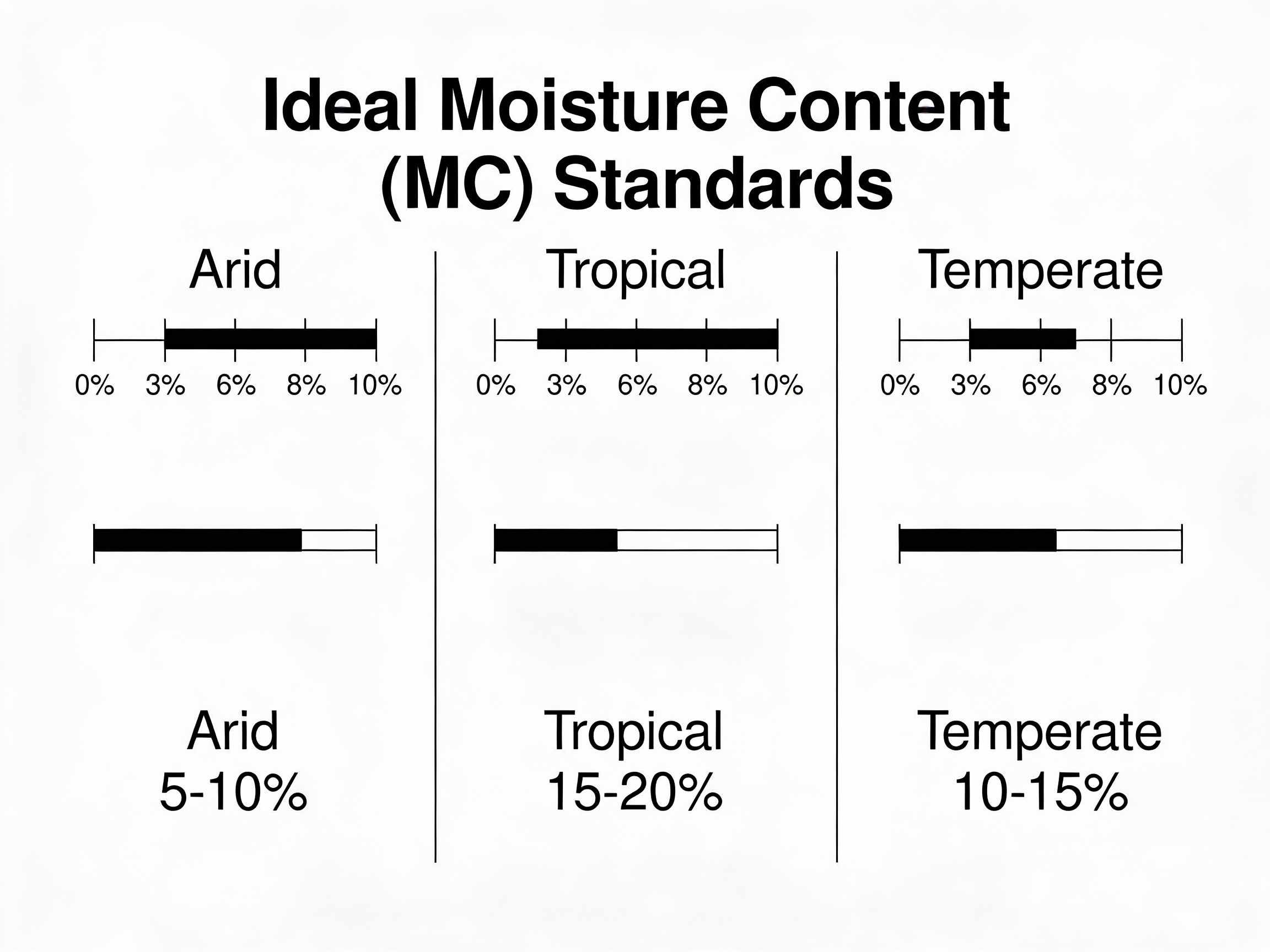

Achieving the correct moisture content is the most critical factor in preventing the warping of wooden outdoor furniture. Raw timber must be kiln-dried to specific percentages based on the final destination’s climate to ensure structural integrity. Failure to manage these levels leads to immediate checking and joint failure when the product hits the retail floor.

Regional Moisture Targets

Standardized moisture levels vary significantly across global markets. Procurement teams must specify these requirements during the ordering phase to avoid inventory loss.

- Arid Zones (5-10%): Essential for desert climates or high-altitude regions where low humidity causes rapid wood shrinkage.

- Temperate Zones (10-15%): The standard for most of Europe and North America, balancing seasonal humidity fluctuations.

- Tropical Zones (15-20%): Required for high-humidity coastal areas to prevent the wood from absorbing excess ambient moisture.

The Risk of Improper Drying

Why does this matter? When wood is not dried to its Equilibrium Moisture Content (EMC), it remains “active” and moves as it seeks balance with the air. This movement creates tension in mortise and tenon joints, eventually leading to catastrophic structural collapse.

Climate Impact Analysis

The relationship between ambient humidity and wood stability dictates the lifespan of your inventory. Proper wooden outdoor furniture sourcing requires matching the factory’s kiln capabilities with your regional environmental data.

| Climate Category | Target MC % | Primary Risk Factors | Stability Ranking |

|---|---|---|---|

| Arid | 5% – 8% | Radial cracking and splitting | Moderate |

| Moderate | 10% – 12% | Seasonal expansion and contraction | High |

| Humid | 15% – 18% | Mold growth and fungal decay | Low |

Here is the bottom line: neglect moisture standards, and you guarantee product returns.

Key Takeaway: Buyers must verify that their factory utilizes advanced kiln-drying processes tailored to the specific humidity profiles of their target market to ensure long-term furniture stability.

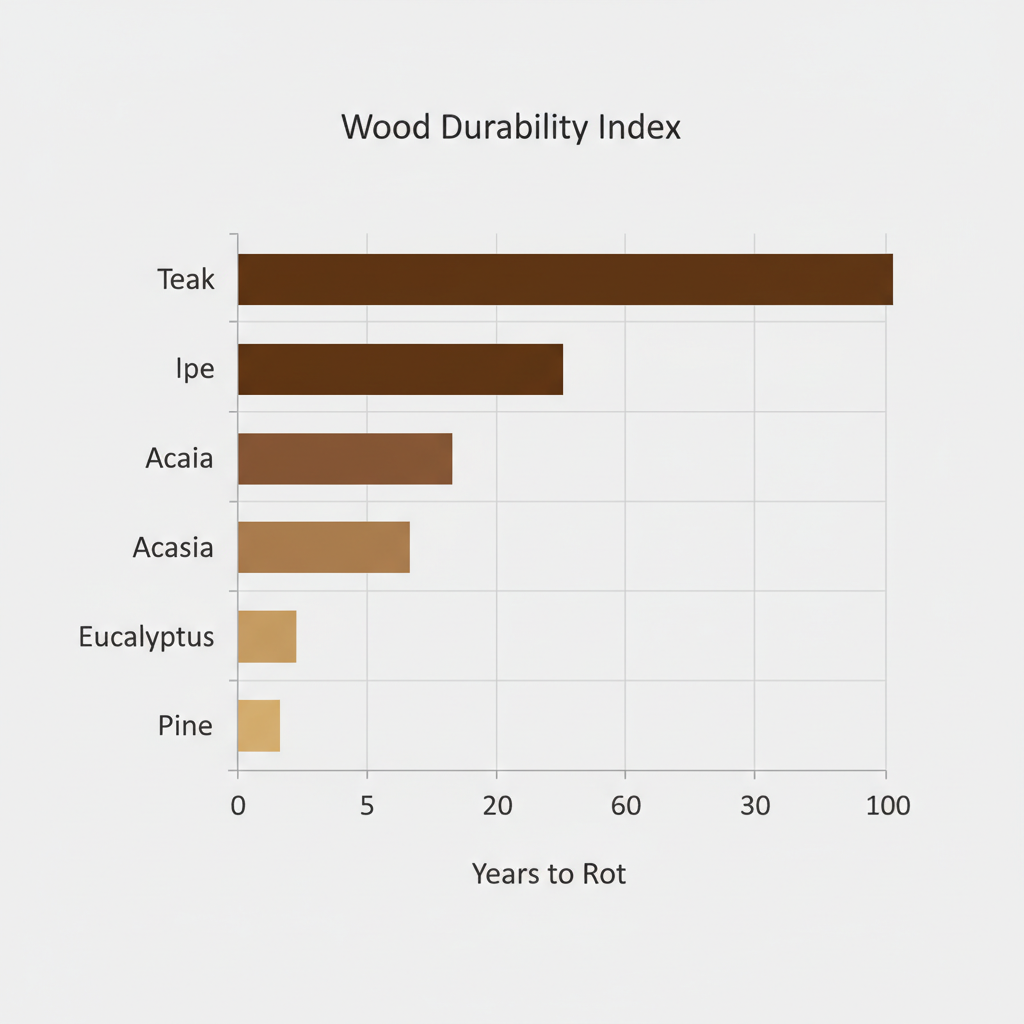

II. Comparative Durability of Wooden Outdoor Furniture

The durability of wooden outdoor furniture is measured by its natural resistance to decay, insects, and fungal attacks over several decades. Not all “hardwoods” are created equal, as many lack the natural oils required to withstand constant UV and rain exposure. Understanding the biological density of timber allows you to predict replacement cycles and warranty risks accurately.

The Durability Metric

Here’s the deal: natural rot resistance is a biological trait, not a chemical one. While finishes help, the core timber must possess inherent protection to survive ground contact or high-moisture environments.

Essential Durability Factors

Several factors contribute to the “Years to Rot” metric seen in premium species. Professional buyers should prioritize these three characteristics when evaluating a new product line.

- Silica Content: Found in species like Teak, this mineral blunts tools but acts as a natural barrier against wood-boring insects.

- Oil Density: High concentrations of natural oils repel liquid water, preventing the saturation that leads to rot.

- Tight Grain: Slow-growing hardwoods develop tight rings that restrict the entry of fungal spores into the wood’s vascular system.

Timber Performance Summary

Analyzing the lifespan of different species reveals why certain woods command a significant price premium in the B2B market. Investing in high-durability timber like teak collections often results in lower total cost of ownership over twenty years.

| Wood Species | Decay Resistance | Janka Hardness (lbf) | Estimated Lifespan |

|---|---|---|---|

| Teak | Exceptional | 1,070 | 50 – 100 Years |

| Ipe | Exceptional | 3,684 | 40 – 75 Years |

| Acacia | Moderate | 1,750 | 10 – 15 Years |

| Eucalyptus | Moderate | 1,125 | 10 – 20 Years |

| Pine | Low | 690 | 3 – 7 Years |

But wait, there’s more to consider regarding supply chain ethics.

Key Takeaway: Higher initial material costs for durable hardwoods are offset by significantly reduced warranty claims and higher customer satisfaction scores over the product’s life.

III. Teak Supply Chain and Premium Grading

Teak remains the gold standard for high-end wooden outdoor furniture due to its unparalleled weather resistance and aesthetic appeal. However, the global supply chain is complex, with vast differences between plantation-grown timber and old-growth wood. Managing the “Grade” of teak you purchase is essential for maintaining brand consistency in the luxury segment.

Understanding Teak Grades

Grade A teak represents the highest tier of quality, sourced from the heartwood of mature trees where the oil concentration is highest. Using lower grades can result in inconsistent coloring and reduced durability in harsh environments.

- Grade A: Heartwood only, rich in oils, uniform honey color, and no knots or white streaks.

- Grade B: Outer heartwood, contains less oil and may show slight color variations or smaller knots.

- Grade C: Sapwood from the outer layers of the tree, low oil content, and very prone to rot.

Managing Sourcing Risks

Why is this important? Many factories substitute Grade B/C teak to lower costs while still marketing the product as “solid teak.” This practice deceives the consumer and leads to premature silvering and cracking of the furniture.

Teak Specification Standards

Evaluating the physical properties of teak helps buyers justify the investment to their stakeholders. A factory’s ability to provide certified teak products is a hallmark of a reliable high-end partner.

| Feature | Grade A Teak | Grade B/C Teak | Value Impact |

|---|---|---|---|

| Oil Content | High (Natural) | Low (Needs Finish) | Critical for rot protection |

| Appearance | Honey Gold | Creamy/White streaks | High for luxury perception |

| Density | Very Dense | Moderate | High for joint strength |

| Lifecycle | 50+ Years | 5 – 10 Years | Extreme ROI difference |

Ready to explore a more cost-effective alternative?

Key Takeaway: Only Grade A teak offers the authentic “buy it for life” quality that defines the premium outdoor market; verify heartwood percentages before signing any contract.

IV. Acacia Stability in Wooden Outdoor Furniture

Acacia has become a dominant species for mid-range wooden outdoor furniture because it offers a balance of hardness and affordability. While it is naturally rot-resistant, acacia is prone to movement if the manufacturing process does not account for its interlocked grain. Successful acacia programs require stringent quality control at the factory level to ensure the wood remains stable after shipping.

Processing Acacia for Stability

Acacia is a fast-growing species, which can lead to high internal stresses within the timber. Managing these stresses through proper sawing and drying techniques is the only way to prevent bowing.

- Quarter-Sawing: Using this technique reduces the width of the boards but increases stability against cupping.

- Extended Conditioning: Allowing the wood to rest after kiln-drying helps equalize internal moisture levels.

- Protective Sealants: Applying a high-quality oil finish immediately after sanding prevents rapid moisture exchange.

The Cost-to-Performance Ratio

How do you win with Acacia? You leverage its high density and attractive grain to offer a product that looks expensive but remains accessible to the mass market.

Acacia Performance Metrics

Comparing Acacia to other common hardwoods shows why it is a favorite for high-volume retail. For many brands, acacia dining sets provide the best return on investment for seasonal promotions.

| Metric | Acacia | Comparison (Pine) | Advantage |

|---|---|---|---|

| Hardness | 1,750 lbf | 690 lbf | Highly scratch resistant |

| Rot Resistance | Moderate | Low | Better for humid gardens |

| Grain Pattern | Interlocked/Wild | Straight/Plain | Superior visual appeal |

| Supply | Abundant | Infinite | Sustainable and affordable |

It gets even better when you look at eucalyptus options.

Key Takeaway: Acacia is an excellent material for volume-driven programs, provided that you enforce strict kiln-drying protocols to manage its natural tendency to move.

V. Eucalyptus Sourcing for Commercial Use

Eucalyptus is an increasingly popular sustainable alternative for commercial wooden outdoor furniture applications. It shares many characteristics with teak, including a high oil content and density, but it grows much faster and is easier to source at scale. For large-scale hospitality projects, eucalyptus offers a consistent look and durable performance at a fraction of the cost of premium hardwoods.

Benefits of Eucalyptus Timber

Eucalyptus is prized for its rapid growth and adaptability to different soil types, making it a highly renewable resource. When harvested from FSC-certified plantations, it represents one of the most eco-friendly choices for outdoor furniture.

- Fast Growth: Reaches maturity in as little as 10-15 years, ensuring a steady supply chain.

- Natural Antimicrobials: The wood contains compounds that naturally repel pests and prevent fungal growth.

- Easy Maintenance: Like teak, it can be left to weather to a silver-grey or oiled to maintain its reddish-brown hue.

Sustainability and Scalability

What’s the catch? Eucalyptus is a “thirsty” wood that can crack if placed in extremely arid environments without proper finishing. You must ensure your manufacturer uses high-quality stains to lock in moisture.

Commercial Suitability Analysis

Eucalyptus stands out in commercial settings where durability and budget must coexist. Its strength-to-weight ratio makes it ideal for chairs and tables that are moved frequently in cafe environments.

| Factor | Commercial Eucalyptus | Residential Grade | Requirement |

|---|---|---|---|

| Joint Style | Double Mortise | Simple Screw | Higher weight capacity |

| Finish | UV-Rated Poly | Standard Oil | Resists frequent cleaning |

| Certification | FSC 100% | Non-Certified | Essential for ESG goals |

| Hardware | Stainless Steel | Zinc Plated | Prevents rust staining |

Let’s look at the heavy hitters of the tropical world.

Key Takeaway: Eucalyptus is the ideal choice for eco-conscious brands and commercial projects that require high-density timber without the premium price tag of teak.

VI. Ipe and Tropical Hardwoods Performance

Ipe is arguably the toughest wood used for high-end wooden outdoor furniture and luxury decking. Often called “ironwood,” its density is so high that it does not float in water and carries a fire rating similar to concrete and steel. While it is difficult to work with, the resulting products are virtually indestructible and can last for nearly a century in outdoor environments.

Unmatched Physical Properties

Ipe offers a level of durability that most other timbers cannot match. Its extreme hardness makes it resistant to scratches, dents, and even heavy foot traffic in public spaces.

- Class A Fire Rating: Provides safety in high-density urban environments or wildfire-prone areas.

- Insect Immunity: Termites and beetles find the wood too hard to penetrate and lack the nutrients they seek.

- Maximum Stability: Ipe has very low shrinkage rates once dried, meaning joints stay tight for decades.

High-End Manufacturing Challenges

Here is the deal: Ipe is notoriously hard on machinery. Only factories with specialized carbide-tipped tools and high-torque CNC machines can successfully produce furniture from this species.

Hardness and Weight Comparison

The physical weight of Ipe is a significant factor in logistics and shipping costs. However, its longevity makes it the ultimate luxury furniture material for permanent installations.

| Property | Ipe (Ironwood) | Teak | Teak Advantage |

|---|---|---|---|

| Janka Hardness | 3,684 lbf | 1,070 lbf | Ipe is 3x harder |

| Weight (Dry) | 69 lbs/ft³ | 41 lbs/ft³ | Teak is easier to move |

| Tool Wear | Extreme | Moderate | Teak is cheaper to make |

| Fire Rating | Class A | Class B | Ipe is safer in fire zones |

Does a traditional hardwood like White Oak still hold its own?

Key Takeaway: Ipe is the ultimate choice for “bulletproof” furniture in public or luxury coastal settings, though it requires specialized manufacturing expertise and a higher shipping budget.

VII. White Oak Performance for Wooden Outdoor Furniture

White Oak has a long history in maritime use, making it a naturally proven choice for wooden outdoor furniture. Unlike Red Oak, which has open pores, White Oak contains a cellular structure called “tyloses” that plugs its vascular tubes. This biological feature makes the wood nearly waterproof, explaining why it has been used for centuries in whiskey barrels and boat building.

The Science of Tyloses

The presence of tyloses in White Oak acts as a natural sealant against liquid penetration. This prevents water from traveling deep into the board, which is the primary cause of internal rot in other domestic hardwoods.

- Water Resistance: Ideal for areas with heavy rainfall or poolside furniture.

- Tannin Content: High tannins provide a natural defense against decay-causing fungi.

- Strength: Offers excellent structural integrity for benches and large dining tables.

Design and Aesthetic Appeal

Why does this matter? White Oak offers a timeless, sophisticated look that fits both modern and traditional design aesthetics. It takes stains beautifully but is often left natural to showcase its distinctive ray fleck grain pattern.

White Oak vs. Red Oak Analysis

The distinction between White Oak and Red Oak is critical for procurement. Red Oak will rot quickly if left outdoors, whereas White Oak thrives in the elements.

| Feature | White Oak | Red Oak | Critical Difference |

|---|---|---|---|

| Pore Structure | Closed (Tyloses) | Open (Like straws) | White Oak blocks water |

| Rot Resistance | High | Very Low | Red Oak fails in 2 years |

| Color | Tan / Brown | Pinkish / Red | White Oak is more modern |

| Cost | Higher | Moderate | Quality justifies price |

What about the more common softwoods used in DIY and retail?

Key Takeaway: Specify White Oak for a “domestic” hardwood look with “tropical” durability; it is the most reliable temperate timber for high-moisture outdoor environments.

VIII. Softwoods: Comparing Cedar and Pine

Softwoods like Western Red Cedar and Pressure-Treated Pine are the most common materials for mass-market wooden outdoor furniture. Cedar is prized for its natural oils and resistance to rot, while Pine relies on chemical treatments to survive the outdoors. For budget-conscious projects, understanding the maintenance requirements of these two softwoods is vital for managing consumer expectations.

Natural vs. Chemical Protection

Cedar provides protection through its natural chemistry, offering a pleasant aroma and beautiful reddish hue. Pine, conversely, is soft and porous, requiring heavy chemical infusion to prevent rapid decay.

- Cedar (Western Red): Contains thujaplicins, natural fungicides that preserve the wood.

- Pine (Pressure-Treated): Infused with copper-based chemicals to resist insects and rot.

- Weight Factor: Cedar is significantly lighter, making it ideal for folding chairs and children’s furniture.

Lifecycle Maintenance Costs

The real story? Cedar is more expensive upfront but requires less chemical maintenance over time. Pine tends to warp and “check” (split) more aggressively as it dries out under the sun.

Softwood Comparison Table

Selecting between these two depends largely on the price point of the product. While Pine dominates low-cost retail, Cedar provides a more “premium” feel for the eco-conscious consumer.

| Metric | Western Red Cedar | Pressure-Treated Pine | Market Position |

|---|---|---|---|

| Rot Resistance | High (Natural) | High (Chemical) | Cedar is safer |

| Stability | Excellent | Poor | Pine warps easily |

| Appearance | Rich Red/Pink | Greenish/Yellow | Cedar is more attractive |

| Hardness | 350 lbf | 690 lbf | Pine is slightly tougher |

Is the wood species the only thing that matters? Not at all.

Key TakeawayCedar is the superior choice for high-quality residential softwood furniture, while Pine should be reserved for price-sensitive utility items where longevity is secondary to cost.

IX. Surface Treatments for Wooden Outdoor Furniture

No matter how durable the wood, the right surface treatment is essential to protect wooden outdoor furniture from UV degradation and moisture intake. Modern finishing technology has evolved from simple oils to complex water-based resins that offer years of protection without the need for constant reapplication. Understanding the performance of these coatings helps you select the right finish for your brand’s maintenance profile.

Modern Coating Technologies

The transition from traditional oils to advanced water-based systems has revolutionized the outdoor furniture industry. These new coatings provide a breathable barrier that allows moisture to escape while blocking liquid water.

- Penetrating Oils: Deeply soak into the fibers to keep wood supple but require annual reapplication.

- Water-Based Stains: Offer superior UV protection and can last 3-5 years before needing a refresh.

- Marine-Grade Varnishes: Create a hard “film” over the wood; excellent for yachts but prone to peeling on furniture.

UV Protection and Aesthetics

Why is this important? UV rays break down the lignin in wood, causing it to turn grey and become brittle. A pigmented finish acts like “sunscreen” for the timber, preserving its structural strength and color.

Finish Performance Comparison

Analyzing different treatment types allows manufacturers to balance aesthetic beauty with functional protection. Choosing the right protective finish is a key differentiator in the B2B marketplace.

| Finish Type | UV Protection | Water Repellency | Maintenance |

|---|---|---|---|

| Natural Oil | Low | Moderate | Every 6-12 Months |

| Water-Based Stain | High | Excellent | Every 3-5 Years |

| Polyurethane | Very High | Exceptional | Hard to repair |

| No Treatment | None | Low | High (Silvering) |

How does the manufacturing process tie all of this together?

Key TakeawayInvest in high-quality water-based finishes to reduce the maintenance burden for your customers and ensure the furniture retains its showroom floor appearance for years.

X. Manufacturing Precision and Factory Standards

The best timber in the world will fail if the manufacturing precision is not up to industrial standards. High-end wooden outdoor furniture requires tight tolerances and advanced joinery to withstand the physical stresses of outdoor use. Modern factories in regions like Shandong utilize CNC technology to ensure that every mortise and tenon joint fits perfectly, preventing the wobbling and failure common in handmade alternatives.

The Role of CNC Technology

CNC (Computer Numerical Control) machines provide a level of consistency that manual labor simply cannot match. This precision is vital for large-scale B2B orders where every unit must meet identical quality specifications.

- Zero-Tolerance Joints: Ensures that joints are tight enough to resist water ingress but allow for natural wood movement.

- Efficient Material Use: Computer-guided cutting minimizes wood waste, lowering the overall cost of production.

- Complexity at Scale: Allows for intricate designs that would be too expensive or slow to produce by hand.

Joint Integrity and Longevity

Here’s the deal: most outdoor furniture fails at the joints first. If the joint is too loose, the glue will eventually crack; if it is too tight, the wood will split during seasonal expansion.

Factory Quality Standards

A world-class factory must integrate technology with skilled craftsmanship to produce export-quality goods. Understanding these manufacturing standards is the final step in selecting a reliable production partner.

| Standard | CNC Production | Manual Production | Impact |

|---|---|---|---|

| Accuracy | +/- 0.1mm | +/- 2.0mm | High Joint Strength |

| Scalability | High (24/7) | Low (Shift-based) | Faster Lead Times |

| Finish Quality | Uniform | Variable | Professional Look |

| Waste Reduction | Optimized | Manual | Sustainable Pricing |

Now, let’s address some common concerns buyers face in the market.

Key Takeaway: Prioritize manufacturers who invest in CNC technology and precision tooling; the structural integrity of your furniture depends more on joint fit than any other factor.

FAQ

Can I leave wooden outdoor furniture outside during the winter?

It depends on the wood species and the quality of the finish. High-oil hardwoods like Teak and Ipe can withstand freezing temperatures, but it is always recommended to use breathable covers or store furniture in a dry, unheated space to maximize its lifespan.

What is the best wood for a coastal environment with salt spray?

Teak and Ipe are the premier choices for coastal regions. Their high density and natural oil content provide a barrier against the corrosive effects of salt air, whereas softer woods or those with open pores will degrade rapidly in these conditions.

How often does wooden furniture need to be oiled?

Typically, a light application of oil once or twice a year is sufficient for most hardwoods to maintain their original color. If you prefer the weathered silver look, you can skip the oiling entirely for durable species like Teak, as the rot resistance remains even after the color fades.

Closing note

Choosing the right wood for your outdoor furniture collection is a strategic decision that impacts your brand’s longevity and bottom line. By focusing on moisture standards, biological durability, and manufacturing precision, you can provide products that stand the test of time and weather.

At our state-of-the-art factory, we specialize in combining premium Grade A materials with CNC-driven precision to meet the highest international standards. Whether you are looking for high-volume acacia programs or luxury teak designs, our team is equipped to scale your vision with uncompromising quality. Discover our full range of professional solutions and manufacturing capabilities by visiting Everwoody .