Are your bulk furniture orders arriving with unsightly cracks or structural warping? These defects lead to expensive returns, frustrated retailers, and a damaged brand reputation in the competitive B2B market. Understanding the science of wood moisture and factory-level prevention is the only way to ensure long-term product stability.

This comprehensive guide analyzes why wooden bedroom furniture fails due to moisture fluctuations and outlines professional manufacturing standards. We cover everything from wood shrinkage ratios and kiln-drying techniques to design-led prevention strategies that protect your inventory and bottom line.

I. Identifying Checking vs. Splitting

From a professional supplier perspective, it is vital to distinguish between cosmetic surface checking and structural splits that compromise safety. Misidentifying these can lead to unnecessary waste or, conversely, the shipment of defective products that fail under load.

Surface Check Characteristics

A surface check is a shallow separation of wood fibers along the grain that typically does not penetrate through the entire thickness of the component. These are considered natural characteristics of solid timber and often add unique visual value to high-end collections.

Think about this:

- Checks are often less than 1/8 inch wide.

- They occur when the exterior dries faster than the core.

- Most checks remain stable once the wood reaches equilibrium.

- Finishing processes can often mask or fill these gaps safely.

Identifying Structural Splits

A split occurs when the wood fibers separate completely through the piece, often extending from one face to the other. These represent a major failure in the wood’s structural integrity and are usually grounds for immediate factory rejection.

But there is a catch.

- Splits often follow the entire length of a grain line.

- They are frequently found in “boxed heart” timber cuts.

- Structural splits can cause joints to wobble or detach.

- They are rarely fixable with simple wood fillers or sanding.

Factory QC Rejection Criteria

Quality control teams must follow strict metrics to decide whether a timber component is fit for assembly or must be recycled. Standard B2B tolerances allow for minor checking but strictly prohibit splits in weight-bearing posts or frames.

Here is the bottom line:

- Any gap through a mortise and tenon joint is rejected.

- Hairline surface checks under 2 inches long are often accepted.

- Cross-grain breaks are considered critical failures.

- All structural components must undergo a tactile stress test.

| Feature | Surface Checking | Structural Splitting | Cross-Grain Break |

|---|---|---|---|

| Visual Depth | Shallow / Surface only | Full thickness penetration | Lateral fracture |

| Structural Impact | Negligible in thick cuts | High risk of joint failure | Immediate collapse risk |

| B2B Standard | Accepted character | Conditional rejection | Automatic rejection |

| Repairability | High (sanding/filling) | Low (requires replacement) | Zero (unsafe) |

| Primary Cause | Rapid surface drying | Deep internal stress | Mechanical impact/Overload |

II. What is Checking in Wooden Bedroom Furniture?

Checking is a natural phenomenon that occurs as wooden bedroom furniture loses moisture and contracts during the seasoning process. It is often described as the “song of the wood” because of the audible pops and cracks heard during rapid humidity changes.

The Natural Drying Cycle

As a living tree is converted into furniture timber, it must release a significant amount of “free water” and “bound water” stored in its cells. This transition from a green state to a stable manufactured state inevitably causes the wood to shrink and pull apart.

It gets better:

- Living trees are often 50% water by total weight.

- Drying occurs from the outside toward the center.

- Internal stresses build up when the shell dries too fast.

- Checking is the wood’s way of relieving that internal pressure.

Aesthetic vs. Functional Damage

In the world of premium wooden bedroom furniture, minor checking is often embraced as a hallmark of authentic, solid material. Unlike veneered or engineered products, these marks prove the thickness and organic origin of the wood used in construction.

Why does this matter?

- Solid oak or walnut naturally develops hairline grain gaps.

- These marks distinguish real wood from synthetic imitations.

- Functional damage only occurs if the check affects the hardware.

- High-end buyers often prefer the “reclaimed” look of checked wood.

Internal Fiber Contraction

At the microscopic level, wood cells collapse and pull together as they lose moisture, creating tension across the grain. Because wood is non-homogeneous, this contraction happens at different rates, leading to the physical separation of the fibers.

Consider this:

- Wood is hygroscopic, meaning it constantly breathes.

- Cell walls shrink significantly as bound water evaporates.

- The pith (center) of the tree is the most unstable zone.

- Fiber strength determines how well a species resists checking.

| Attribute | Characterization | Professional Tolerance |

|---|---|---|

| Visual Appearance | Hairline fractures along the grain | Max 1/8″ width allowed |

| Tactile Feel | Slight ridges; smoothed by topcoat | Must be flush after finish |

| Industry Rating | Natural aesthetic variance | Grade A/B standard |

| Material Origin | Confirms solid timber usage | Preferred for high-end markets |

III. Why Wooden Bedroom Furniture Cracks or Splits

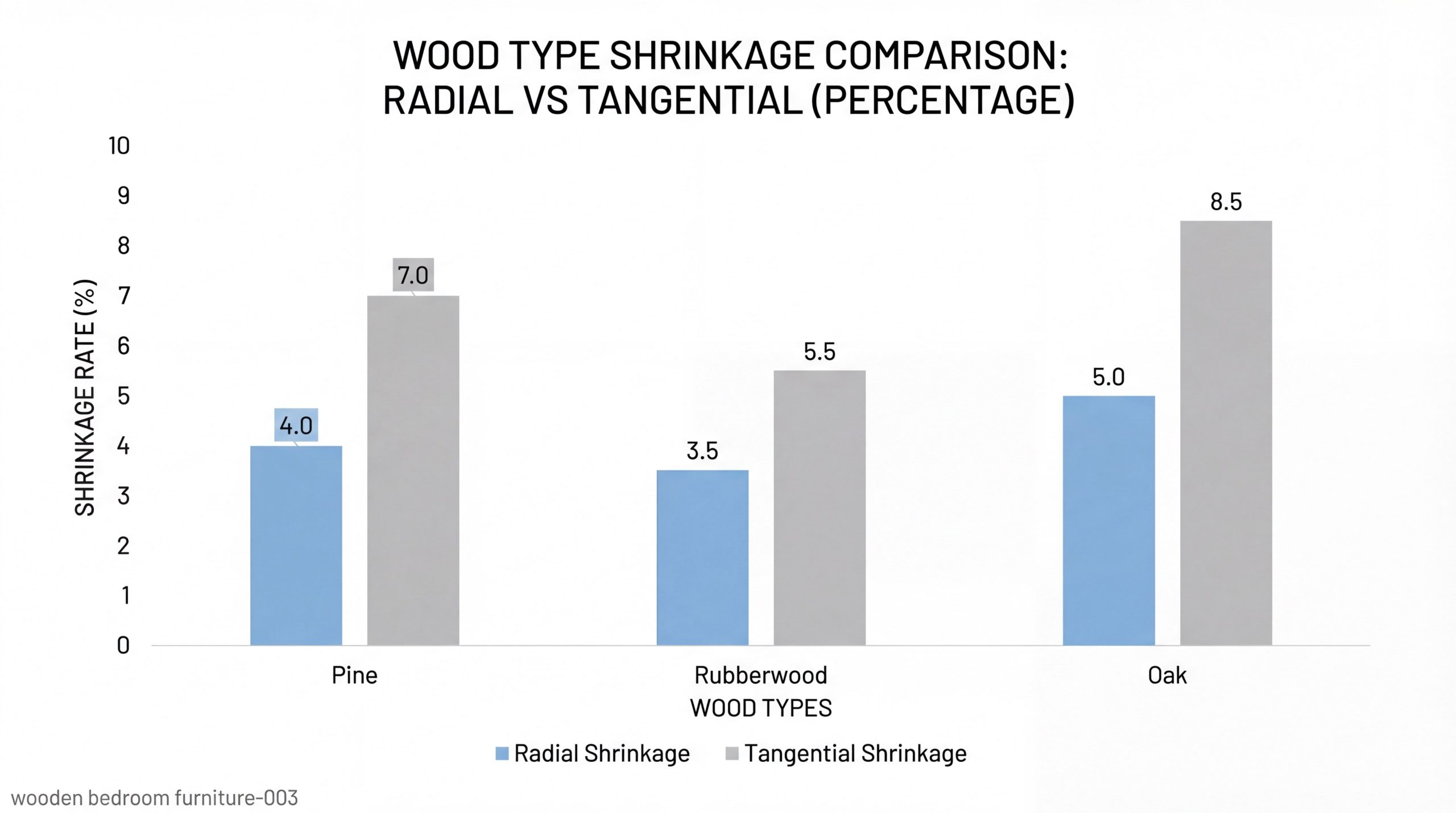

The geometric reality of wood growth is the primary driver behind why wooden bedroom furniture undergoes physical changes. Because wood is an anisotropic material, its physical properties and shrinkage rates vary depending on the direction of the grain.

Uneven Shrinkage and Growth Rings

Wood shrinks roughly twice as much along the growth rings (tangentially) as it does across them (radially) during the drying process. This differential creates massive internal tension that forces the wood to crack at its weakest points, usually the ends of the boards.

Here is the bottom line:

- Tangential shrinkage happens along the curvature of rings.

- Radial shrinkage happens from the center toward the bark.

- The difference between these two rates causes warping.

- Species with high T/R ratios are the most prone to failure.

Tangential vs. Radial Ratios

Selecting a species with a low Tangential-to-Radial (T/R) ratio is the secret to manufacturing stable residential furniture collections . Species like Teak or Western Red Cedar have low ratios, making them far more stable than denser hardwoods like White Oak.

But there is a catch.

- White Oak has a tangential shrinkage of over 10%.

- Western Red Cedar only shrinks about 5% tangentially.

- High-ratio woods require much slower kiln-drying schedules.

- Flat-sawn lumber highlights these ratios more than quarter-sawn.

High-Stress Timber Geometries

The shape of a furniture component significantly impacts its likelihood of cracking, with thick, square posts being the most vulnerable. Large cross-sections, such as those used in heavy bed legs, take much longer to reach a stable moisture equilibrium.

Why does this matter?

- A 12×12 post can take over six years to air dry naturally.

- Moisture trapped in the core creates a “pressure cooker” effect.

- Thin panels dry quickly but are prone to cupping and bowing.

- Geometric symmetry in cuts can help balance internal forces.

| Wood Species | Radial Shrinkage (%) | Tangential Shrinkage (%) | T/R Ratio |

|---|---|---|---|

| Western Red Cedar | 2.4% | 5.0% | 2.1 |

| Douglas Fir | 4.8% | 7.6% | 1.6 |

| White Oak | 5.6% | 10.5% | 1.9 |

| Teak | 2.5% | 5.8% | 2.3 |

| Rubberwood | 3.5% | 5.5% | 1.6 |

IV. Structural Risks in Wooden Bedroom Furniture

When evaluating the longevity of wooden bedroom furniture, suppliers must look beyond the surface to identify risks to the joinery. If a crack migrates into a mechanical connection, the entire piece of furniture could lose its weight-bearing capacity.

Assessing Mortise Joint Integrity

The mortise and tenon joint is the backbone of most high-quality bed frames, but it is also the area most susceptible to moisture stress. If the wood around the mortise checks, the glue bond can break, leading to a loose, squeaky, or unstable frame.

Think about this:

- Glue requires a tight surface-to-surface bond to work.

- Shrinkage in the tenon can cause it to pull away from the mortise.

- End-grain checking often starts exactly where joints are cut.

- Reinforcing joints with dowels or “drawboring” adds safety.

Load-Bearing Safety Standards

For heavy items like wardrobes or bunk beds, structural integrity is not just an aesthetic concern—it is a safety requirement. Factories must ensure that any checking in kids & nursery furniture does not compromise the vertical load limits of the unit.

It gets better:

- Structural members must be free of large knots and splits.

- Load tests should simulate 5-10 years of intensive use.

- Components with cross-grain fractures are always discarded.

- Safety-critical joints often use metal-to-metal connectors.

Cross-Grain Break Analysis

A cross-grain break is a lateral fracture that cuts across the wood fibers rather than following them, indicating a catastrophic material failure. This type of damage is usually caused by extreme impact or a severe defect in the original timber growth.

Why does this matter?

- Fiber continuity is what gives wood its bending strength.

- Cross-grain breaks cannot be repaired with glue or screws.

- They are often hidden beneath dark stains or thick paints.

- Ultrasonic testing can detect these internal breaks in bulk.

| Joint Fault | Structural Risk | Professional Solution |

|---|---|---|

| Split Tenon | High (Joint will detach) | Replace the component |

| Checked Mortise | Medium (Glue bond may fail) | Inject epoxy or reinforce |

| Loose Dowel | Low (Aesthetic/Slight wobble) | Re-glue or use larger dowel |

| Beam Bowing | High (Visual/Alignment issue) | Steam straightening or cull |

V. Can You Prevent Wooden Bedroom Furniture Cracks?

While it is impossible to stop wood from moving entirely, professional factories use advanced preparation techniques to mitigate risks. Preventing cracks in wooden bedroom furniture starts long before the wood reaches the assembly line.

Specifying Free-Of-Heart-Center Timber

The pith, or the very center of the tree, is the most unstable part of a log and is guaranteed to crack as it dries. By specifying Free-Of-Heart-Center (FOHC) timber, manufacturers can significantly reduce the internal stresses that lead to catastrophic splitting.

Here is the bottom line:

- FOHC wood is more expensive due to higher waste rates.

- Boxed-heart timber is cheaper but highly prone to twisting.

- FOHC cuts are more dimensionally stable over long periods.

- Most high-end B2B clients demand FOHC for structural posts.

Wax-Based End Sealing Techniques

Wood loses moisture ten times faster through its end grain than through its faces, which is the primary cause of “end checking.” Applying a thick, wax-based sealer to the ends of the timber slows down this moisture loss, allowing the board to dry more uniformly.

But there is a catch.

- Sealers must be applied immediately after the wood is cut.

- Clear sealers are preferred so grain can be inspected.

- Wax prevents “honeycombing” or internal cell collapse.

- This is a critical step for premium educational furniture durability.

Strategic Drying Kerf Implementation

A “kerf” is a deliberate saw cut made on an unseen face of a thick timber component, such as the back of a bed leg. This cut acts as a “relief valve,” giving the wood a pre-defined place to open up and relieve stress without ruining the visible faces.

Think about this:

- Kerfs are hidden against walls or inside frames.

- They drastically reduce the frequency of random surface cracks.

- Engineering drawings must specify kerf depth and location.

- This technique is common in heavy timber frame construction.

| Prevention Method | Efficiency | Cost Impact | Production Phase |

|---|---|---|---|

| FOHC Sourcing | Very High | Significant (+30%) | Raw Material Sourcing |

| End Sealing | Medium | Minimal | Initial Sawing |

| Drying Kerfs | High | Low | Machining/CNC |

| Kiln Drying | Critical | High | Post-Processing |

VI. Hidden Design Risks in Wooden Bedroom Furniture

Even the best-dried timber will crack if the furniture design does not allow for natural expansion and contraction. Engineering wooden bedroom furniture requires a deep understanding of “wood movement” to prevent internal forces from tearing the piece apart.

Hardware Tension and Movement

Metal fasteners like screws and bolts do not move with the wood, which can create a “conflict of interests” during seasonal humidity changes. If a screw is overtightened into a solid wood panel without room for movement, the wood will be forced to crack around the fastener.

Why does this matter?

- Wood moves primarily across the grain, not along it.

- Rigidly fixed desktops often split down the middle.

- Slotted screw holes allow the wood to slide slightly.

- Over-tightening during assembly is a leading cause of returns.

Floating Panel Joinery Benefits

A floating panel is not glued into its frame; instead, it sits in a groove that allows it to expand and contract freely. This is the gold standard for headboards and cabinet doors in high-quality wooden bedroom furniture designs.

It gets better:

- Floating panels can expand up to 1/2 inch without damage.

- They prevent the frame from warping or pulling apart.

- Space balls or foam inserts can keep panels centered.

- This technique is essential for shipping to diverse climates.

Rigid Frame Failure Points

Designing a rigid, unyielding frame for a solid wood product is a recipe for disaster in the furniture industry. When the wood is “trapped” between two fixed points, the internal pressure generated by humidity will eventually exceed the wood’s fiber strength.

Think about this:

- Avoid gluing cross-grain components together.

- Use “Z-fasteners” or “table buttons” for top attachments.

- Breadboard ends must be pinned, not fully glued.

- Design flexibility into every joint of the bed frame.

| Design Vulnerability | Potential Failure | Professional Solution |

|---|---|---|

| Trapped Panels | Split Headboards | Floating Panel Joinery |

| Rigid Fasteners | Corner Cracking | Slotted Screw Holes |

| Cross-Grain Gluing | Joint Separation | Breadboard Ends / Pins |

| Overtightened Bolts | Wood Crushing/Checking | Torque-limited Assembly |

VII. Factory Moisture Control Checkpoints

The difference between a reliable supplier and a high-risk factory lies in their moisture management protocols. High-quality wooden bedroom furniture must be dried to a specific target moisture content that matches its final destination.

Equilibrium Moisture Content Standards

Equilibrium Moisture Content (EMC) is the state where wood is neither gaining nor losing moisture to the surrounding air. For the North American and European markets, the industry standard target for indoor furniture is 6% to 9% moisture content.

Here is the bottom line:

- Arid climates (Arizona) require 6% EMC drying.

- Coastal climates (Florida) can tolerate 11% EMC.

- Shipping furniture at 15% to a dry zone will cause cracks.

- Factories must use climate-controlled storage for finished goods.

Radio Frequency Kiln Drying (RFKD)

Traditional kilns dry wood from the outside in, which often leaves the core wet and prone to future checking. Radio Frequency kilns work like a microwave, heating the wood from the center out to ensure uniform drying and reduced internal stress.

It gets better:

- RFKD reduces drying time from weeks to days.

- It is significantly more expensive but yields better results.

- Uniform drying prevents the “gunshot” cracks heard in winter.

- This is the preferred method for thick, heavy timber orders.

Professional Moisture Scanning Tools

Inexpensive pin-style moisture meters only measure the surface of the wood, which is often misleading for bulk furniture components. Professional factories use electromagnetic scanners that read moisture up to 3 inches deep without damaging the surface.

Why does this matter?

- Surface readings might show 8% while the core is 15%.

- Deep scanning prevents shipping “wet” centers.

- Every batch should have a logged moisture report.

- Scanners are calibrated for specific wood species.

| Drying Method | Uniformity | Time Required | Risk Level |

|---|---|---|---|

| Air Drying | Low (Outer layer only) | 1-5 Years | Very High |

| Conventional Kiln | Medium | 2-4 Weeks | Medium |

| Dehumidification | Medium-High | 3-6 Weeks | Low |

| RF Kiln Drying | Very High | 3-5 Days | Very Low |

VIII. Climate Shift Impacts on Bulk Orders

One of the greatest challenges for B2B importers is the “danger zone” during international transit. Wooden bedroom furniture that is perfectly stable in a humid Asian factory can undergo catastrophic failure when it reaches a dry warehouse in a different hemisphere.

Exporting to Diverse Humidity Zones

Importers must communicate the final destination’s climate to the factory to ensure the wood is “over-dried” or “under-dried” accordingly. A “one-size-fits-all” approach to moisture content is the leading cause of massive after-sales claims.

Think about this:

- Tropical zones have an EMC of 12% or higher.

- Desert zones can drop to an EMC of 4% in winter.

- Wood moves more during its first year in a new climate.

- Acclimatization periods are necessary before showroom display.

Container Rain and Desiccant Use

Shipping containers are subject to extreme temperature swings, which can cause “container rain” or condensation to drip onto the furniture. Using industrial desiccants and vapor barriers is essential to maintain a stable micro-climate for wooden bedroom furniture during sea transit.

But there is a catch.

- Desiccants must be sized correctly for the container volume.

- Pallet wrapping should be breathable to prevent mold.

- Cardboard packaging acts as a secondary moisture buffer.

- Sensors can track humidity levels throughout the voyage.

Regional Acclimatization Profiles

A professional supplier provides retailers with a regional map showing how the wood will likely behave in their specific area. This allows retailers to set correct expectations with customers and avoid unnecessary returns for natural wood movement.

Here is the bottom line:

- Coastal cities experience expansion (swelling joints).

- High-altitude cities experience contraction (checking).

- Humidifiers are often needed in retail showrooms.

- Properly seasoned wood adjusts faster with fewer cracks.

| Market Region | Target EMC (%) | Primary Risk | Packaging Requirement |

|---|---|---|---|

| North America (Standard) | 8% | Shrinkage in winter | Vapor Barrier |

| Southwest US / Desert | 6% | Severe Splitting | Double Desiccants |

| Gulf Coast / Tropical | 12% | Mold & Expansion | Anti-Microbial Finish |

| Northern Europe | 7-9% | Stable (if heated) | Standard Export |

IX. Minimizing After-Sales Wooden Bedroom Furniture Risks

The longevity of wooden bedroom furniture is a shared responsibility between the manufacturer, the retailer, and the end-user. Educating the consumer on how to care for solid wood can prevent 90% of moisture-related claims.

Optimal Home Humidity Maintenance

Retailers should advise customers to maintain a home humidity level between 35% and 55% for the best wood stability. Sudden drops in humidity—such as turning on central heating for the first time in winter—are the most common cause of sudden cracking.

Think about this:

- Wood “shocks” when humidity drops 20% overnight.

- Humidifiers help stabilize the environment in winter.

- Dehumidifiers prevent mold in basements or summer homes.

- Stable environments mean the wood never “sings” or pops.

Strategic Furniture Placement Guidelines

Where a customer places their bed or wardrobe can drastically affect its moisture stability. Placing solid wooden bedroom furniture directly over a heat vent or in the path of direct sunlight creates “hot spots” that cause uneven drying and warping.

Why does this matter?

- Localized heat evaporates moisture from only one side.

- This creates a massive tension imbalance in the timber.

- Direct UV rays can also break down the wood fibers.

- Curtains and vent deflectors are simple, effective fixes.

Retailer and End-User Education

Providing a detailed care guide with every bulk order ensures that the final buyer knows what is “normal” and what is a “defect.” When customers understand that minor hairline checks are a sign of real timber, they are less likely to demand a refund.

It gets better:

- Care guides should be included in the custom drawings and specs package.

- Explain the difference between character and failure.

- Offer simple maintenance tips like seasonal oiling.

- Empowering the customer reduces retailer headaches.

| Stakeholder | Responsibility | Key Action Item |

|---|---|---|

| Manufacturer | Material Preparation | Proper Kiln Drying to Target EMC |

| Retailer | Showroom Environment | Maintain 45% Humidity Levels |

| End-User | Home Environment | Avoid Heat Vents and Direct Sun |

| Service Team | Repair/Assessment | Distinguish Checks from Splits |

X. Quality Sourcing for Wooden Bedroom Furniture

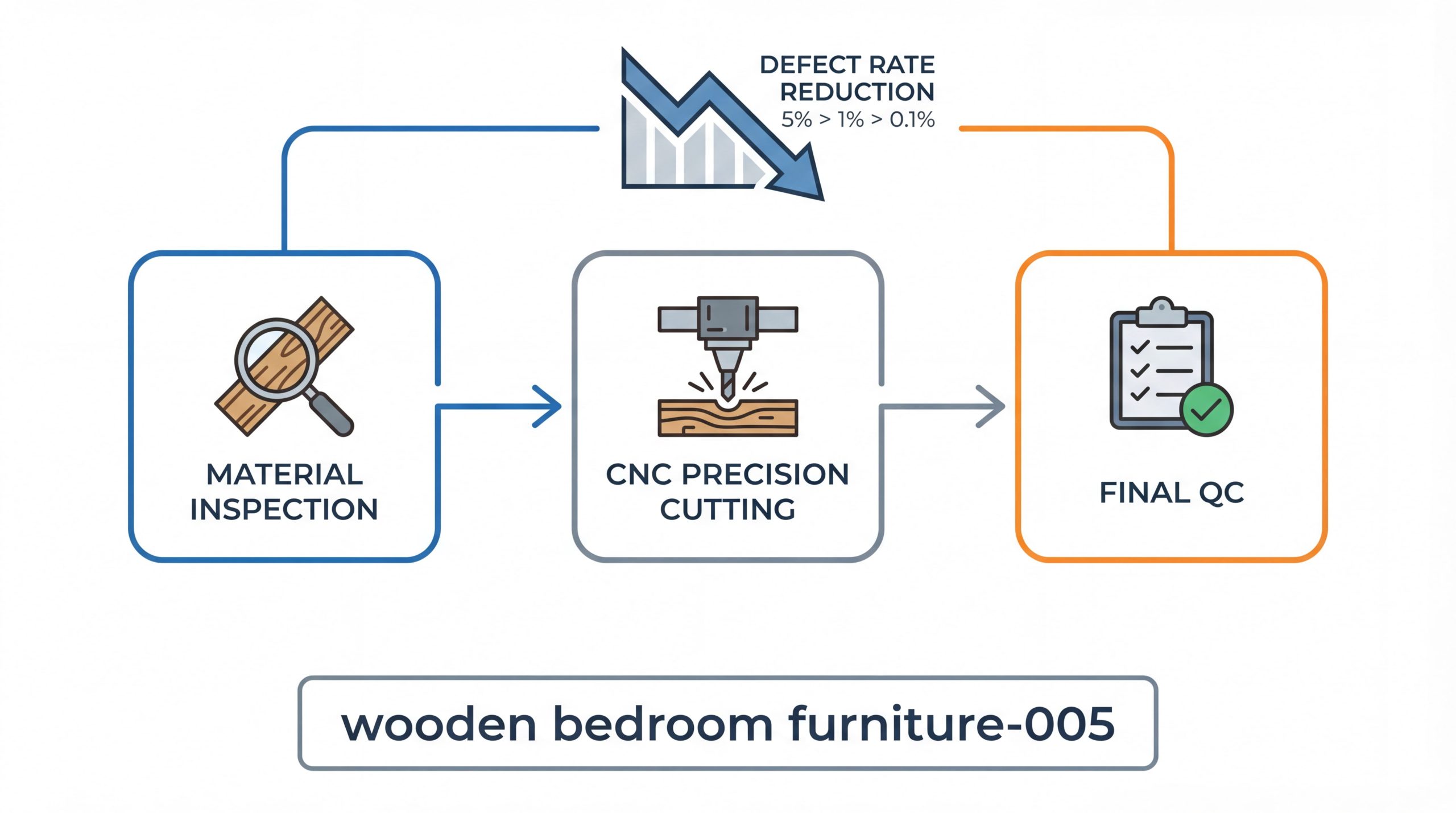

B2B buyers should look for specific factory capabilities when sourcing wooden bedroom furniture to ensure they receive a stable, long-lasting product. A cheap price often hides poor moisture control, leading to high return rates and lost profits.

Selecting Low-Shrinkage Wood Species

As discussed, not all wood is created equal. When sourcing high-stability wooden home accessories or large furniture, prioritize species like Rubberwood or Teak, which handle moisture fluctuations far better than Oak or Hickory.

Here is the bottom line:

- Rubberwood is highly stable and eco-friendly.

- Teak is the gold standard for moisture resistance.

- Pine is cheap but moves significantly with the seasons.

- Hardwoods are beautiful but require expert drying.

Verifying Factory Moisture Logs

A transparent supplier will provide moisture meter readings for every batch of furniture before it is packed. If a factory cannot provide these logs, it is a major red flag that they are not monitoring their kiln-drying process effectively.

Think about this:

- Demand a “Pre-Shipment Moisture Report.”

- Check the calibration date of the factory’s meters.

- Randomly sample items during a factory inspection.

- Consistency across the batch is as important as the average.

Evaluating Global Quality Certificates

Look for manufacturers who hold certifications for both material quality and safety. Compliance with international standards ensures that the wooden bedroom furniture is not only stable but also free from harmful chemicals often found in low-quality finishes.

Why does this matter?

- FSC certification ensures sustainable timber sourcing.

- EN71 and ASTM tests verify structural safety.

- ISO 9001 proves consistent factory management.

- Certificates provide a legal safety net for importers.

| Sourcing Criterion | Importance | Target Benchmark |

|---|---|---|

| Moisture Content | Critical | 8% (+/- 2%) |

| Wood Species | High | T/R Ratio below 2.0 |

| Grain Orientation | Medium | Vertical grain preferred for posts |

| Certification | Legal/Safety | FSC / EN71-3 / ASTM |

| QC Procedures | Operational | 100% Shipment Photo Records |

Frequently Asked Questions

Can I fix a crack in my wooden bedroom furniture if it appears after a few months?

Yes, minor surface checks can usually be filled with a matching wood wax or specialized timber putty and then sanded flush. However, if the crack is a structural split that goes through the wood, the component likely needs professional reinforcement or replacement.

How do I know if the moisture content is correct for my specific region?

You should ask your supplier to dry the wood to the Equilibrium Moisture Content (EMC) of your destination market, which is typically 6-8% for dry inland areas and 10-12% for humid coastal zones. Using a professional moisture meter to check the goods upon arrival will confirm if the factory met these specs.

Why does my furniture make loud popping or cracking sounds in the winter?

These sounds, often called “the song of the wood,” occur when your home’s humidity drops rapidly due to central heating, causing the wood to contract and release internal tension. Maintaining a stable home humidity between 35% and 55% with a humidifier will typically silence these noises and prevent cracks.

Closing Note

Understanding why wood cracks is essential for any professional buyer dealing with bulk inventory. By prioritizing moisture control at the factory level and choosing a partner with high QC standards, you can significantly reduce product failure. If you are looking for stable, export-ready designs, explore our latest wooden bedroom furniture collections built for global markets.