Damaged inventory due to moisture and UV exposure causes massive financial claims. Agitated by poor storage, wood warps and finishes fail. High-spec outdoor furniture covers provide the ultimate B2B risk mitigation solution.

The best outdoor furniture covers for B2B storage utilize heavy-duty 600D polyester with waterproof PU coatings and integrated ventilation. These features prevent moisture buildup, mold, and UV degradation. Secure fixation systems are essential for protecting bulk inventory during long-term warehousing or retail display.

I. Importance of Quality Furniture Storage

Outdoor furniture covers are indispensable assets for any commercial enterprise seeking to preserve the structural integrity and aesthetic appeal of high-value timber or metal inventory. Using premium Outdoor Furniture Solutions ensures that products remain in showroom condition despite the environmental fluctuations commonly encountered in industrial warehouse settings. Procurement managers must prioritize protective layering to avoid the steep costs associated with refurbishing or discounting damaged stock before it reaches the end consumer.

Economic Impact of Storage-Related Claims

The best outdoor furniture covers directly reduce the frequency of logistics-based insurance claims and customer returns by providing a physical barrier against dust and humidity.

- Inventory Loss Prevention: High-quality covers mitigate the risk of surface scratches during forklift operations or manual stacking.

- Brand Reputation Management: Delivering pristine, mold-free products to retailers strengthens long-term partnership trust and reduces replacement cycles.

- Reduced Refurbishment Costs: Eliminating the need for sanding or re-staining wood after seasonal storage significantly improves profit margins per unit.

Identifying High-Risk Environmental Factors

Outdoor furniture covers act as a critical defense mechanism against the invisible threats of fluctuating relative humidity and stagnant air pockets. Think about this: Industrial storage environments are rarely climate-controlled, making bulk inventory highly susceptible to the rapid expansion and contraction of organic fibers. Without a consistent protective barrier, even the most durable teak or acacia can develop structural micro-cracks before leaving the distribution center.

Standardizing Protective Protocols

Strategic implementation of outdoor furniture covers requires a standardized approach to material handling and quality assurance across the entire supply chain. Integrating these protective measures into the standard operating procedure ensures that every piece of furniture receives a uniform level of defense against ambient environmental stressors. By analyzing the cost-to-benefit ratio of protective investments, firms can optimize their storage overhead while ensuring product longevity.

Key Takeaway: Implementing high-spec covers is a proactive financial strategy that secures the underlying value of bulk furniture investments against environmental degradation.

| Metric | Unprotected Storage | Standard Protective Cover | Premium High-Spec Cover |

|---|---|---|---|

| Annual Loss Rate | 8.5% – 12% | 3% – 5% | < 1% |

| Surface Finish Decay | High Risk | Moderate Risk | Negligible |

| Refurbishment Need | Frequent | Occasional | Rare |

Look: Maintaining a zero-defect policy requires a deep understanding of textile durability and its direct correlation with long-term inventory stability.

II. Choosing Durable Outdoor Furniture Covers

The selection of outdoor furniture covers should be based on a rigorous evaluation of fabric density and tensile strength to withstand industrial handling. Higher denier counts, specifically 600D polyester, offer the necessary resistance to tearing and abrasion required for frequent application and removal in a high-volume warehouse. Choosing the right material grade ensures that the protective barrier does not become a source of debris or failure itself during the storage cycle.

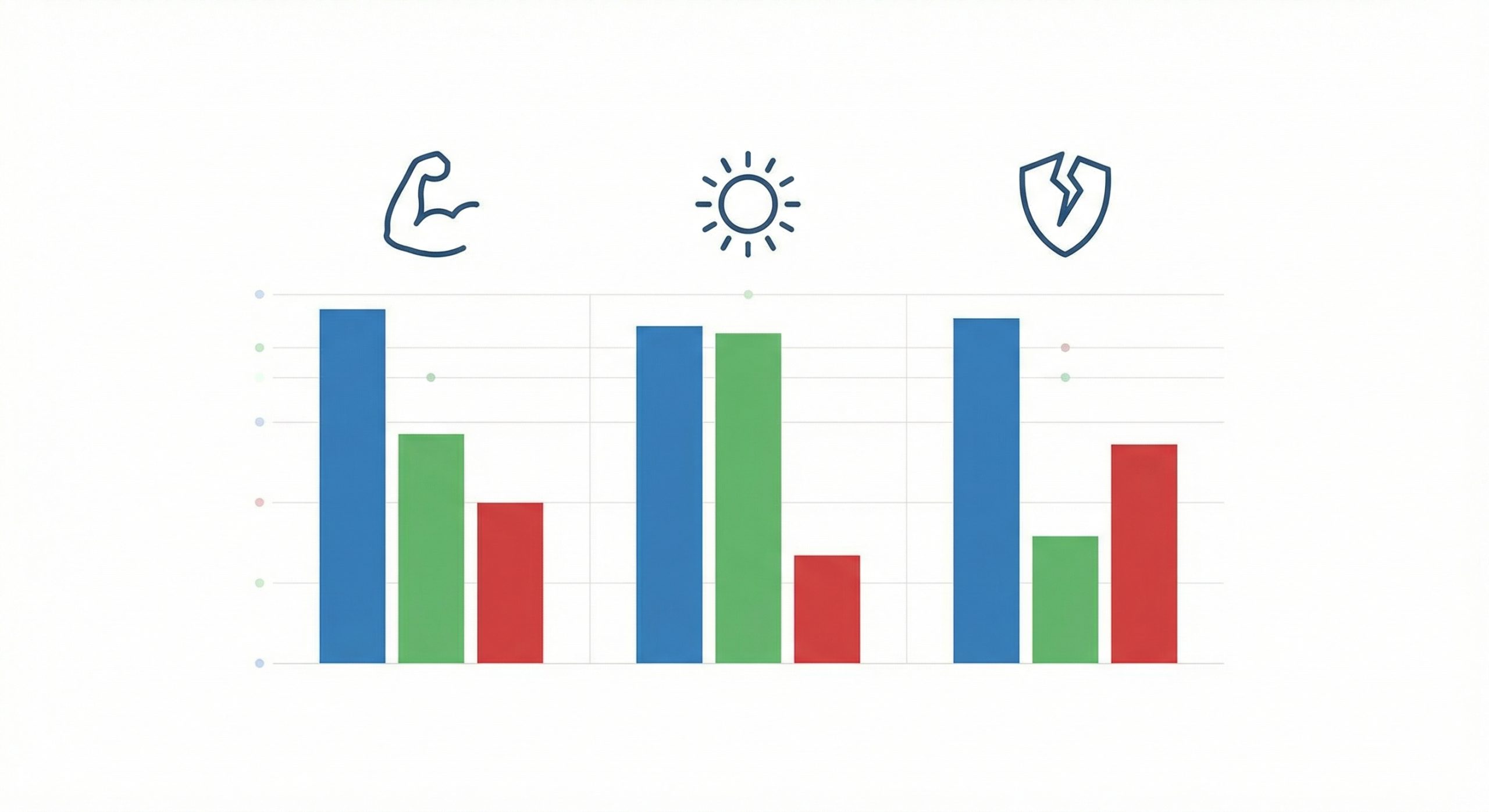

Comparing 600D vs. 420D Polyester Denier

Outdoor furniture covers manufactured from 600D polyester provide a superior weight-to-strength ratio that is essential for protecting heavy, large-scale dining sets.

- Puncture Resistance: The dense weave of 600D fabric prevents sharp corners of furniture from piercing the cover during transit.

- Longevity and Reuse: Commercial-grade 600D textiles maintain their structural integrity over multiple seasons, offering a better return on investment than thinner alternatives.

- Shape Retention: Heavy-duty materials are less likely to sag, which prevents water from pooling and creating localized pressure points on the furniture surface.

Evaluating PU vs. PVC Coating Longevity

Outdoor furniture covers utilizing Polyurethane (PU) coatings offer better breathability and environmental stability compared to traditional Polyvinyl Chloride (PVC) backings. Here is the truth: While PVC is often cheaper, it is prone to cracking in cold temperatures and releasing harmful chemicals that can react with certain wood finishes or oils. PU coatings remain flexible across a wider temperature range and provide a much more reliable waterproof barrier for long-term industrial application.

Optimizing Fabric Selection

Outdoor furniture covers must be vetted for their ability to balance weight, flexibility, and impenetrable protection against external contaminants and spills. This selection process involves comparing specific technical data points to ensure the chosen textile meets the unique demands of the specific furniture line. Choosing a material that matches the expected storage duration and environmental exposure is the hallmark of professional procurement management.

Key Takeaway: Selecting 600D polyester with a high-quality PU coating is the industry standard for ensuring durable, long-term protection of commercial furniture.

| Fabric Attribute | 600D Polyester (PU) | 420D Polyester (PVC) | Lightweight Nylon |

|---|---|---|---|

| Tensile Strength | 2100N | 1450N | 800N |

| Crack Resistance | Excellent (to -20°C) | Poor (Brittle in cold) | Moderate |

| B2B Utility | High (Multi-season) | Medium (Single use) | Low (Dust only) |

Let’s dig deeper: The underlying chemistry of the waterproof coating is just as important as the denier of the base fabric when calculating total cost of ownership.

III. Waterproof Ratings for Outdoor Furniture Covers

Outdoor furniture covers must possess high hydrostatic pressure ratings to effectively block moisture penetration during heavy rain or warehouse leaks. A cover’s ability to remain truly waterproof is determined by the quality of the internal coating and the integrity of the manufacturing seams. Without a high waterproof rating, moisture can seep through the fabric, leading to wood swelling and the eventual failure of the furniture’s structural joints.

Understanding Hydrostatic Pressure Tests

Outdoor furniture covers are technically validated through hydrostatic pressure testing, which measures the amount of water pressure the fabric can withstand before leaking.

- Rating Benchmarks: Commercial covers should ideally offer a rating of at least 3000mm to ensure they remain waterproof under substantial environmental stress.

- Surface Beading: High-quality DWR (Durable Water Repellent) treatments cause water to bead and roll off, preventing the fabric from becoming saturated.

- Saturation Prevention: Preventing the base textile from soaking through is crucial for maintaining a lightweight profile and avoiding the growth of mildew on the cover itself.

Seam Sealing Techniques for Bulk Stock

Outdoor furniture covers require heat-taped or sonic-welded seams to prevent water from entering through the small needle holes created during the sewing process. Why does this matter? The most expensive waterproof fabric is essentially useless if the seams are not properly reinforced, as water will naturally migrate to the stitching and drip onto the furniture. Professional-grade manufacturing ensures that every junction point is sealed with a waterproof membrane, providing a 360-degree shield against moisture ingress.

Grading Waterproof Performance

Outdoor furniture covers can be categorized by their technical ability to repel water and withstand prolonged exposure to wet conditions without failing. Understanding these grades allows buyers to match the level of protection to the specific storage risks of their geographical location or warehouse condition. A rigorous grading system ensures that procurement decisions are based on empirical performance data rather than marketing claims.

Key Takeaway: Always verify hydrostatic ratings and seam sealing specifications to ensure a cover can survive more than just a light misting.

| Pressure Rating | Classification | Protection Level | Industrial Application |

|---|---|---|---|

| < 1500mm | Water Resistant | Light drizzle only | Temporary indoor dust cover |

| 1500mm – 3000mm | Waterproof | Moderate rain/leaks | Standard commercial storage |

| > 3000mm | Heavy Duty WP | Storm-proof | Long-term outdoor exposure |

Here’s the deal: Investing in a higher hydrostatic rating today prevents the catastrophic loss of a full furniture set tomorrow due to simple water ingress.

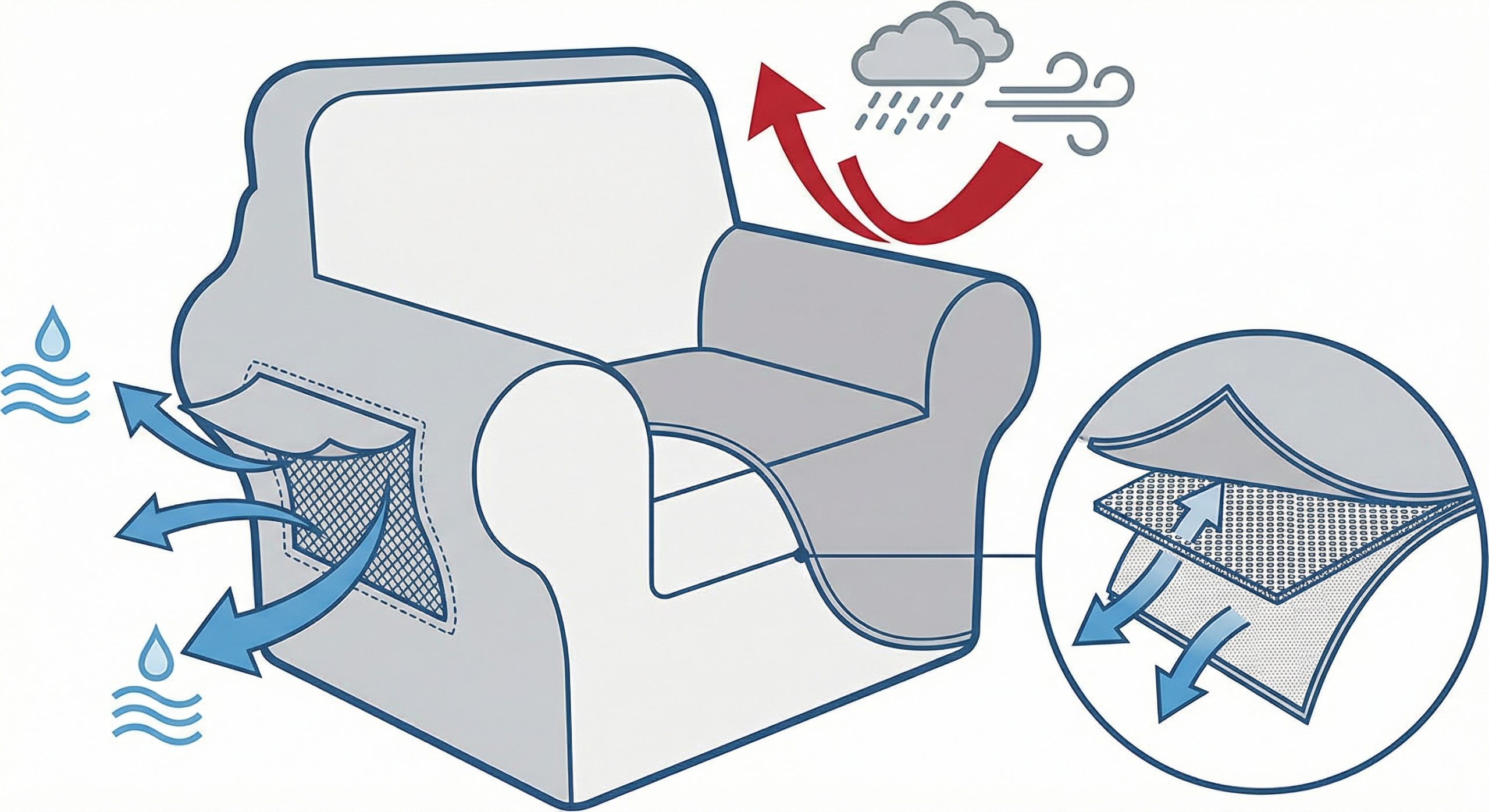

IV. Breathability in Outdoor Furniture Covers

Outdoor furniture covers must incorporate sophisticated ventilation systems to prevent the buildup of condensation and the subsequent growth of mold and mildew. While preventing external water from entering is vital, allowing internal moisture to escape is equally important for preserving the health of natural wood products. Without proper breathability, the cover creates a greenhouse effect that accelerates decay and compromises the finish of the furniture it is meant to protect.

The Role of Covered Vents in Preventing Mold

Outdoor furniture covers use mesh-lined, hooded vents to facilitate a continuous exchange of air while simultaneously blocking the entry of wind-driven rain.

- Strategic Placement: Vents are typically placed on the sides or near the top of the cover to leverage natural convection and airflow patterns.

- Mesh Barriers: Fine-mesh linings prevent insects and debris from entering the vent while still allowing water vapor to dissipate freely.

- Mold Inhibition: Constant air movement prevents the stagnant, humid conditions that allow fungal spores to colonize the surface of wood or fabric cushions.

Avoiding Condensation and “Sweating” Risks

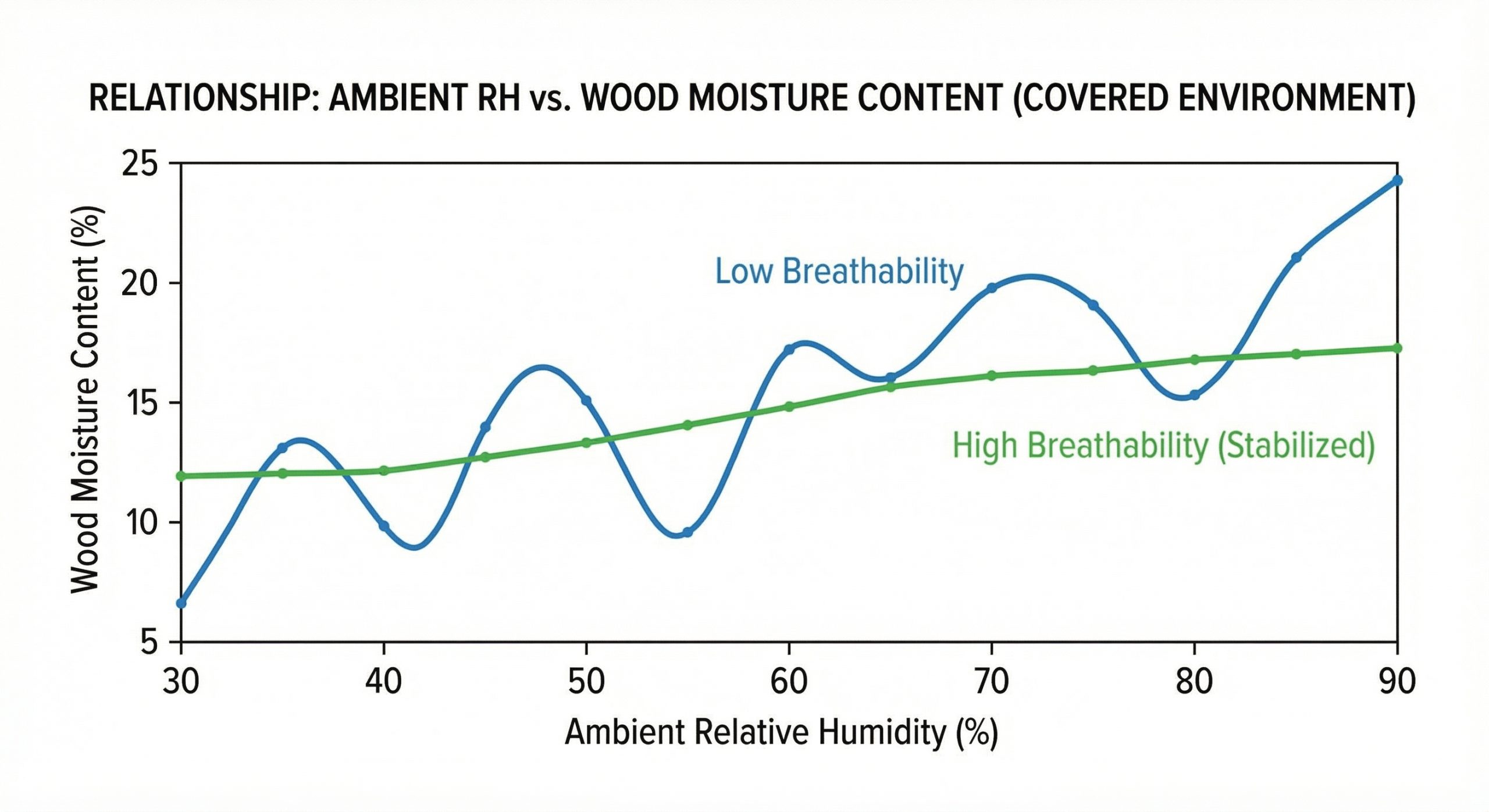

Outdoor furniture covers that lack breathability can cause “sweating,” where moisture trapped under the cover condenses on the furniture surface as temperatures drop. It gets better: By specifying covers with high moisture vapor transmission rates, you can ensure that the relative humidity inside the cover remains in equilibrium with the outside environment. This stability is crucial for preventing the wood from “working,” which is the process of expanding and contracting that leads to warping and structural failure.

Evaluating Airflow Efficiency

Outdoor furniture covers should be assessed based on the ratio of ventilated surface area to the total volume of air trapped within the protective envelope. This technical evaluation ensures that even during high-humidity cycles, the airflow is sufficient to move moisture away from the furniture before it can condense. Efficient ventilation is the most effective way to protect organic materials like teak or eucalyptus over long storage durations.

Key Takeaway: Breathability is not optional; integrated vents are the primary defense against internal moisture damage and mold proliferation.

| Feature | Low Breathability | High Breathability | Impact on Inventory |

|---|---|---|---|

| Ventilation Style | No vents / Closed seams | Dual mesh-lined vents | Reduces moisture spikes |

| Condensation Risk | High (Water pooling) | Very Low | Prevents surface mold |

| Finish Protection | Moderate (Risk of haze) | Excellent | Maintains clear-coat integrity |

But wait, there’s more: The interaction between ventilation and ambient temperature is what determines the dew point inside the cover, making airflow a critical engineering concern.

V. UV Resistance for Outdoor Furniture Covers

Outdoor furniture covers must be engineered with UV-stabilized textiles to prevent the fabric from becoming brittle and to protect the underlying furniture from sun damage. UV radiation is a primary cause of color fading in wood and the degradation of protective clear coats, leading to a “greyed out” appearance that devalues the product. High-spec covers act as a sunblock for bulk inventory, ensuring that pieces look brand new even after being stored near warehouse windows or in open lots.

Testing for UV Stabilization Levels (UPF)

Outdoor furniture covers are rated using Ultraviolet Protection Factor (UPF) benchmarks to determine how effectively they block both UVA and UVB rays.

- UPF 50+ Protection: This industry-leading rating ensures that more than 98% of harmful UV rays are blocked from reaching the furniture surface.

- Colorfastness Tests: High-quality fabrics are solution-dyed, meaning the color is part of the fiber itself, preventing the cover from fading over time.

- Material Degradation: UV stabilization prevents the chemical breakdown of the polyester fibers, ensuring the cover doesn’t tear like paper after a few months of exposure.

Preserving Color Integrity in Premium Wood

Outdoor furniture covers are essential for maintaining the rich, natural hues of high-end timber species such as Grade A teak and acacia. Look: Unprotected exposure to UV rays rapidly bleaches the natural oils and pigments in wood, forcing retailers to spend significant labor hours on sanding and oiling before sale. By using a UV-resistant cover, the natural patina of the wood is preserved, allowing the furniture to be sold at its peak aesthetic value without additional processing.

Analyzing UV Blockage Performance

Outdoor furniture covers provide varying levels of protection based on the density of the weave and the specific UV-inhibiting additives used during the textile manufacturing process. Comparing these levels is vital for procurement teams managing inventory in high-altitude or tropical regions where solar intensity is maximized. Selecting the appropriate UV tier ensures that the protective investment lasts as long as the furniture it guards.

Key Takeaway: High UV resistance is critical for maintaining the showroom-ready appearance of wooden furniture and the structural integrity of the cover itself.

| Exposure Tier | UV Factor | Cover Lifecycle | Wood Finish Impact |

|---|---|---|---|

| Low Exposure | UPF 15-20 | 12-18 Months | Moderate fading |

| Moderate Exposure | UPF 30-40 | 24-36 Months | Minimal color shift |

| High Exposure | UPF 50+ | 48+ Months | Full color preservation |

You might be wondering: Does UV protection actually matter inside a warehouse? The answer is a resounding yes, as solar gain through windows and skylights is often concentrated and destructive.

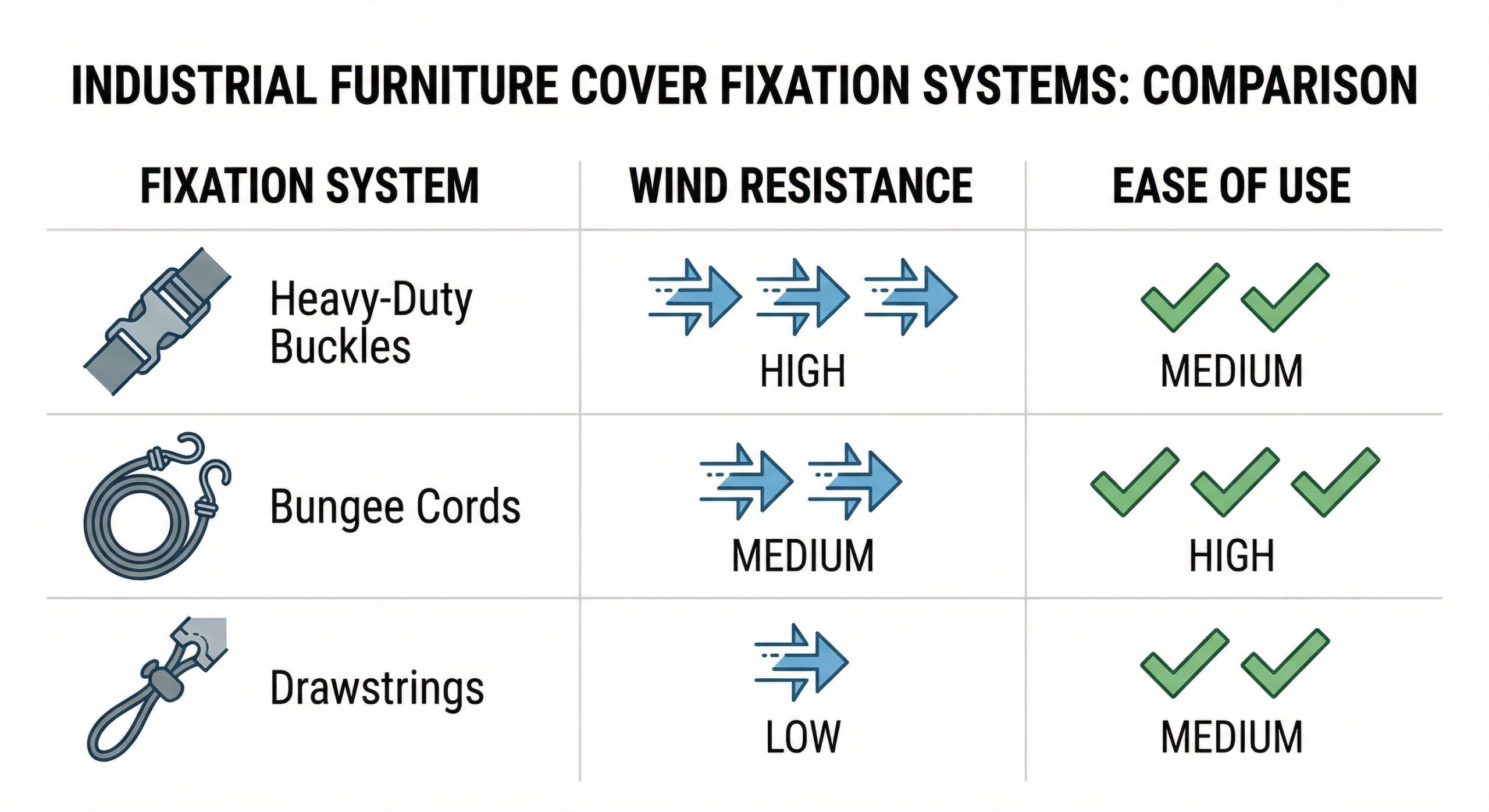

VI. Fixing Systems for Outdoor Furniture Covers

Outdoor furniture covers must include robust fixation systems to ensure they remain securely in place during high winds or movement within the distribution center. A cover that blows off or shifts during storage leaves the furniture vulnerable to the very elements it was intended to block. Modern B2B covers utilize a combination of heavy-duty buckles, elastic hems, and drawstrings to provide a customized, snug fit for various furniture configurations.

Heavy-Duty Buckles and Click-Close Straps

Outdoor furniture covers equipped with click-close straps provide the most secure attachment method by anchoring the cover directly to the furniture legs.

- Wind Resistance: Buckles prevent the “parachute effect,” where wind enters the bottom of the cover and lifts it off the furniture entirely.

- Ease of Use: Quick-release buckles allow warehouse teams to rapidly secure or remove covers, minimizing labor time during inventory audits.

- Adjustability: Reinforced straps can be tightened to take up slack, ensuring the cover stays taut and prevents water from pooling on the top surface.

Wind Resistance for Exposed Warehouse Lots

Outdoor furniture covers often face extreme wind speeds in open loading docks or outdoor staging areas, necessitating advanced structural reinforcement. The best part? A well-secured cover doesn’t just protect against moisture; it also prevents the fabric from flapping, which can cause abrasive damage to the furniture’s finish over time. By using a multi-point fixation system, you create a stable micro-environment that remains undisturbed even during seasonal storms or high-velocity industrial fans.

Comparing Attachment Methods

Outdoor furniture covers utilize different mechanisms for securing the hem, and the choice between them should depend on the expected wind exposure and frequency of access. Comparing the pros and cons of bungee cords, buckles, and drawstrings allows logistics managers to select the most efficient system for their specific workflow. A secure fit is the final step in ensuring that the protective barrier functions as intended throughout the storage lifecycle.

Key Takeaway: Secure fixation systems like heavy-duty buckles are non-negotiable for furniture stored in high-traffic or wind-prone environments.

| Fixation System | Wind Rating | Application Speed | Durability |

|---|---|---|---|

| Click-Close Buckles | High | Medium | Very High |

| Bungee/Shock Cords | Medium | High | High |

| Drawstrings Only | Low | High | Medium |

Why does this matter? Even the heaviest 600D cover will fail to protect the inventory if it is not securely anchored to the base of the furniture unit.

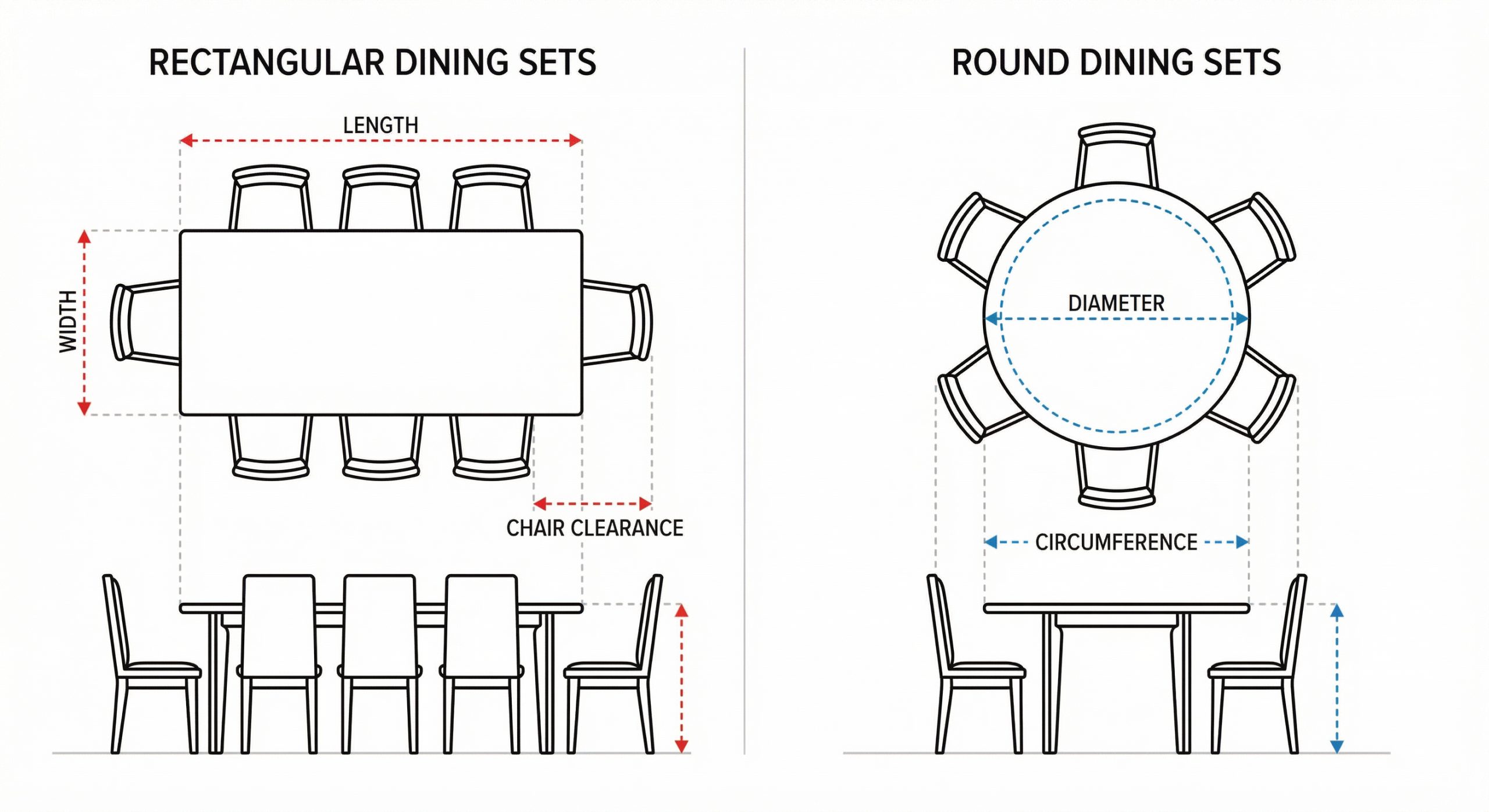

VII. Measuring for Bulk Outdoor Furniture Covers

Outdoor furniture covers must be accurately sized to provide full coverage without excessive slack that could trap water or allow wind to enter. Proper measurement protocols are essential for procurement managers who need to order hundreds of units for varied sets, from rectangular dining tables to circular lounge arrangements. Utilizing a standardized measurement guide ensures that the covers provide a professional appearance and functional protection across the entire inventory.

Sizing Large Rectangular vs. Round Sets

Outdoor furniture covers are designed for specific silhouettes, and choosing the correct shape is the first step in achieving a secure and protective fit.

- Rectangular Sets: Measuring the length and width of the table with the chairs pushed in is the industry standard for determining the total footprint.

- Round Sets: Diameter measurements should include the outermost point of the chair backs to ensure the cover doesn’t snag or leave legs exposed.

- Height Considerations: Covers should generally be 1-2 inches shorter than the furniture height to allow for proper air circulation at the base.

Calculating Clearance for Airflow Efficiency

Outdoor furniture covers require a precise amount of “breathable clearance” at the bottom to facilitate the intake of fresh air and the exhaust of humidity. Think about this: If a cover is too long and touches the ground, it can actually wick moisture up from the wet floor, creating a damp environment directly against the furniture. A slightly shorter hem ensures that air can flow freely underneath the furniture, keeping the undersides of tables and chairs dry and mold-free.

Standardizing Bulk Dimensions

Outdoor furniture covers for large-scale orders benefit from a simplified sizing matrix that groups similar furniture sets into standardized cover dimensions. This approach reduces the complexity of inventory management and ensures that the warehouse team can easily identify the correct cover for each product line. Standardized sizing also simplifies the replenishment process when protective gear needs to be replaced after several years of use.

Key Takeaway: Accurate measurements and a 1-2 inch ground clearance are the dual requirements for a professional and effective fit.

| Furniture Type | Measurement Focus | Recommended Clearance | Optimal Fit Goal |

|---|---|---|---|

| Rectangular Dining | L x W (Chairs in) | 2 Inches | Taut top, vented base |

| Round Bistro | Diameter (Full set) | 1 Inch | Centered coverage |

| Modular Sofa | Sectional length | 2 Inches | No sagging in joints |

Look: Getting the measurements right the first time avoids the logistical nightmare of returning bulk textile orders that don’t fit the furniture properly.

VIII. Wood Decay and Protective Solutions

Outdoor furniture covers are the primary tool for preventing the structural decay of wooden inventory caused by fluctuating moisture levels and fungal attacks. Natural timber is a hygroscopic material, meaning it constantly exchanges moisture with the surrounding air, which can lead to swelling, cracking, and common quality issues if not managed. A high-quality cover stabilizes the micro-environment around the wood, maintaining its moisture content within a safe operational range.

Moisture Control and Structural Integrity

Outdoor furniture covers help maintain the Wood Moisture Content (WMC) at a stable level, preventing the internal stresses that cause joints to fail.

- Equilibrium Moisture Content: Covers buffer the wood against rapid spikes in humidity, slowing the rate at which the timber absorbs water from the air.

- Joint Preservation: Stabilized WMC ensures that mortise and tenon joints remain tight and functional, preventing wobbling in chairs and tables.

- Surface Check Prevention: By limiting rapid drying, covers prevent the surface of the wood from checking or developing small, unsightly cracks.

Common Quality Risks in Wooden Manufacturing

Outdoor furniture covers address the specific vulnerabilities of wood species like acacia and teak, which are prized for their durability but still require protection during long-term storage. Here is the truth: Even the most expensive, oil-rich woods are susceptible to surface mold if stored in a damp, unventilated environment for several months. Proactive covering with a breathable, waterproof material is the most cost-effective way to ensure that “factory fresh” quality is maintained until the moment of delivery.

Analyzing Humidity Impacts

Outdoor furniture covers act as a vital barrier in the relationship between ambient relative humidity and the physical dimensions of wooden furniture components. Understanding how a cover stabilizes the Wood Moisture Content relative to warehouse humidity allows managers to predict and prevent potential structural failures. Data-driven protection strategies ensure that every piece of inventory remains within its engineered tolerances.

Key Takeaway: Moisture stabilization through high-quality covering is essential for preventing structural wood damage and preserving joint integrity.

| Ambient Humidity | Uncovered Wood WMC | Covered Wood WMC | Structural Risk |

|---|---|---|---|

| 30% (Dry) | 6% (Risk of crack) | 10% (Stable) | High without cover |

| 60% (Moderate) | 11% (Standard) | 11% (Stable) | Low |

| 90% (Damp) | 21% (Risk of mold) | 15% (Safe) | Very High without cover |

Let’s dig deeper: The goal of covering is not just to keep the wood dry, but to keep its moisture content consistent over the entire storage period.

IX. Maintenance for Outdoor Furniture Covers

Outdoor furniture covers require their own maintenance schedule to ensure they continue to provide a high level of protection over multiple years of industrial use. Dust, industrial pollutants, and bird droppings can accumulate on the cover, potentially degrading the UV coating or clogging the ventilation mesh if left unaddressed. Implementing a simple cleaning and inspection protocol ensures that the protective investment remains effective and the furniture beneath stays pristine.

Safe Cleaning Protocols for Long-Term Use

Outdoor furniture covers should be cleaned using mild soap and soft brushes to avoid damaging the waterproof PU coating or the DWR treatment.

- Avoid Harsh Chemicals: Bleach or strong detergents can strip the UV inhibitors and waterproof membranes, significantly shortening the cover’s lifespan.

- Air Drying Only: Never put commercial-grade covers in an industrial dryer; high heat will melt the waterproof backing and destroy the fabric’s integrity.

- Debris Removal: Regularly brushing off leaves and standing water prevents organic matter from breaking down and staining the textile surface.

Inspection Schedules for Warehousing Teams

Outdoor furniture covers should be inspected quarterly for signs of wear, such as thinning fabric, failing seams, or broken buckles. Why does this matter? A small tear that is caught early can be easily patched, preventing a much larger failure that would expose the underlying furniture to damage. Regular audits of the protective gear ensure that the entire warehouse remains under a consistent shield of protection, minimizing the risk of unexpected inventory loss.

Optimizing Maintenance Cycles

Outdoor furniture covers are best maintained through a structured schedule that aligns with seasonal inventory rotations or major warehouse cleaning events. This systematic approach ensures that every cover is vetted for performance before it is redeployed for the next storage cycle. Efficient maintenance extends the life of the covers and provides a reliable baseline for budgeting replacement costs.

Key Takeaway: Regular cleaning and quarterly inspections are essential for maximizing the lifespan and effectiveness of your protective covers.

| Task | Frequency | Purpose | Required Tools |

|---|---|---|---|

| Dust Removal | Monthly | Prevents vent clogging | Soft brush / Compressed air |

| Deep Clean | Annually | Preserves PU coating | Mild soap / Lukewarm water |

| Seam Inspection | Quarterly | Ensures waterproofing | Visual audit / Flashlight |

Here’s the deal: The durability of your furniture protection is directly proportional to the consistency of your maintenance efforts.

X. Strategic Sourcing and Reliability

Outdoor furniture covers should be sourced from reliable manufacturers who can provide consistent quality and adhere to international standards for industrial textiles. Choosing a supplier that offers comprehensive factory audit checklists ensures that the covers are produced ethically and meet the technical specifications required for bulk protection. Strategic sourcing is the final step in building a resilient supply chain that prioritizes product quality from the factory floor to the customer’s patio.

Factory Audit Standards for Industrial Textiles

Outdoor furniture covers must be manufactured in facilities that maintain rigorous quality control over the weaving, coating, and sewing processes.

- Material Certification: Ensure the factory uses genuine 600D polyester and certified PU coatings rather than lower-grade substitutes.

- Technical Testing: Reliable suppliers provide lab reports for hydrostatic pressure, UV resistance, and tensile strength for every batch.

- Ethical Manufacturing: Verifying labor standards and environmental compliance is a core component of modern B2B sourcing strategies.

Global Distribution and Logistics Support

Outdoor furniture covers are often required in large quantities across multiple international locations, making supplier logistics a key decision factor. It gets better: A supplier with a robust distribution network can offer lower shipping costs and more reliable lead times, ensuring your inventory is never left unprotected. Partnering with a manufacturer that understands the nuances of global furniture shipping allows you to scale your operations without compromising on product safety.

Comparing Supplier Capabilities

Outdoor furniture covers are a technical product, and evaluating suppliers based on their R&D capabilities and quality assurance protocols is essential for long-term success. Comparing these capabilities allows procurement teams to identify partners who can provide customized solutions for unique furniture designs. A reliable supplier is a strategic asset that adds value to your entire furniture portfolio.

Key Takeaway: Partnering with a technically proficient and ethically audited manufacturer is the only way to ensure the consistent quality of bulk protective orders.

| Selection Criteria | Tier 1 Supplier | Tier 2 Supplier | Generic Wholesaler |

|---|---|---|---|

| Quality Control | 100% Batch Testing | Random Sampling | None / Visual Only |

| Customization | Full OEM Support | Limited Sizes | Stock Only |

| Reliability | Guaranteed Timelines | Variable | High Risk |

The best part? When you source from a proven expert, you gain more than just a product; you gain the peace of mind that your inventory is secured by the best protection available.

FAQ

Can I leave wooden furniture covered outdoors all winter?

Yes, provided the cover is highly breathable. While the waterproof layer blocks snow and rain, the integrated vents are what prevent the wood from rotting by allowing internal moisture to escape throughout the winter season.

What’s the best denier for retail-ready covers?

600D polyester is the industry standard for commercial durability. This density provides the optimal balance of puncture resistance, weight, and longevity required for both warehouse storage and high-end retail presentation.

How do I know the difference between ‘Water-Resistant’ and ‘Waterproof’ covers?

Check the hydrostatic pressure rating and seam construction. Water-resistant covers only handle light rain and lack sealed seams, whereas waterproof covers feature PU coatings rated over 3000mm and heat-taped seams for total protection.

Protecting your inventory is a critical step in maintaining profitability and customer satisfaction. As a leading manufacturer, we specialize in high-durability solutions that safeguard your products from factory to front door. For premium protection and expert guidance, visit EverWoody to explore our full range of B2B outdoor solutions.