Wooden furniture quality issues represent the primary cause of profit margin erosion and brand devaluation for global retailers and importers. When a batch of residential furniture arrives at a warehouse with warped panels or failing joints, the financial impact extends far beyond the cost of the individual unit. These defects trigger a cascading effect of customer returns, logistics nightmares, and damaged reputations that can take years to rebuild. Implementing a rigorous quality control framework is the only sustainable solution to mitigate these manufacturing risks and ensure long-term product viability.

I. Identifying Wooden Furniture Quality Issues

Wooden furniture quality issues are typically categorized into critical, major, and minor defects based on their impact on safety and functionality. Critical defects involve safety hazards such as sharp edges or structural instability that could lead to collapse. Major defects, while not necessarily dangerous, render the product unfit for its intended use, such as drawers that won’t open. Minor defects are usually cosmetic, affecting the aesthetic appeal without compromising the utility of the piece.

How do we categorize different defect levels?

The industry standard relies on the Acceptable Quality Limit (AQL) to determine if a batch passes inspection. Most professional manufacturers focus on eliminating critical safety risks first before refining aesthetic consistency.

Think about it:

- Critical: Collapse risk, toxic lead paint, or protruding nails.

- Major: Significant warping, missing hardware, or incorrect dimensions.

- Minor: Small scratches, slight color variation, or dust under the lacquer.

Why is the AQL standard necessary for B2B?

Standardized metrics allow for objective communication between the factory and the buyer during the inspection phase. This prevents subjective disputes regarding what constitutes a “fail” for high-volume kids furniture orders.

Key Takeaway

| Defect Category | Manufacturer Action |

|---|---|

| Critical | Immediate rejection of the entire batch |

| Major | Rework or sorting required before shipment |

Analysis: Establishing clear AQL thresholds early in the procurement process ensures that both the factory and the importer have a unified definition of success.

II. Moisture Content and Wooden Furniture Quality Issues

Wooden furniture quality issues are most frequently rooted in improper moisture management during the kiln-drying and storage phases. Wood is a hygroscopic material, meaning it constantly gains or loses moisture to remain in equilibrium with its environment. If the moisture content (MC) is too high at the time of manufacture, the wood will eventually shrink, leading to cracks and split seams. Conversely, wood that is too dry may swell and buckle when moved to a more humid climate.

What is the ideal moisture content for export?

For most global markets, a moisture content between 8% and 12% is considered the industry gold standard. Maintaining this range prevents the internal stresses that lead to structural failure after the product is packaged and shipped.

Here is the kicker:

- Testing: Digital moisture meters must be used on multiple points of the component.

- Acclimatization: Raw timber needs sufficient time to stabilize after kiln drying.

- Environment: Workshop humidity must be controlled to prevent re-absorption.

Can moisture issues lead to mold growth?

High moisture levels trapped inside airtight shipping containers create the perfect breeding ground for mold and mildew. This can ruin an entire container of outdoor furniture before it even reaches the port.

Key Takeaway

| Moisture Metric | Significance |

|---|---|

| 8% – 12% MC | Target range for structural stability |

| Over 15% MC | High risk of mold and shrinkage |

Analysis: Rigorous moisture testing at the pre-assembly stage is the single most effective way to prevent latent structural defects.

III. Structural Integrity and Frame Distortion

Wooden furniture quality issues often manifest as frame distortion, where the piece fails to sit level on the floor or wobbles during use. This instability usually stems from poor assembly techniques, inaccurate drilling, or the use of sub-standard internal bracing. In high-volume production, even a one-millimeter deviation in a leg’s length can result in a product that feels “cheap” to the end consumer.

How is stability tested during QC?

A standard stability test involves placing the unit on a level surface and applying specific pressure to simulate daily use. If the unit tips or exhibits excessive lateral movement, it fails the safety protocol.

Think about it:

- Leveling: All four legs must make contact with the floor simultaneously.

- Squareness: Inspectors use large squares to ensure 90-degree angles are maintained.

- Load Bearing: Static loading tests verify the frame can handle the rated weight.

Does frame distortion affect durability?

When a frame is distorted, the stress of the weight is unevenly distributed across the joints, leading to premature failure. Over time, these minor misalignments cause the joinery to loosen and eventually break.

Key Takeaway

| Test Type | Objective |

|---|---|

| Stability Test | To ensure the unit does not tip or wobble |

| Static Loading | To verify weight capacity without deformation |

Analysis: Frame distortion is rarely a singular error but rather a symptom of systemic inaccuracies in the machining and assembly line.

IV. Joinery Failures and Wooden Furniture Quality Issues

Wooden furniture quality issues relating to joinery are among the most difficult to repair once the product is finished. Whether using mortise-and-tenon, dovetails, or cam-lock systems, the precision of the fit determines the lifespan of the furniture. Gaps in the joints or excessive glue usage indicate a lack of craftsmanship and suggest that the piece may fall apart under environmental stress.

Why do joints fail after shipment?

Poorly fitted joints rely too heavily on adhesives rather than mechanical friction to stay together. When the wood expands or contracts due to temperature changes, the brittle glue line snaps, causing the joint to fail.

The reality is:

- Fitment: Joints should require a light mallet tap to seat correctly.

- Adhesion: High-quality PVA glues must be applied to all mating surfaces.

- Clamping: Proper pressure must be applied for the duration of the glue’s set time.

Are mechanical fasteners better than wood joints?

While modern cam-locks and screws are efficient for flat-pack items, they often lack the long-term shear strength of traditional wood-to-wood joinery. For premium residential pieces, traditional joinery remains the benchmark for quality.

Key Takeaway

| Joinery Type | Primary Failure Point |

|---|---|

| Mortise & Tenon | Loose fitment leading to structural “racking” |

| Cam-Lock | Metal fatigue or wood stripping at the hole |

Analysis: The strength of a piece of furniture is entirely dependent on the integrity of its hidden connections.

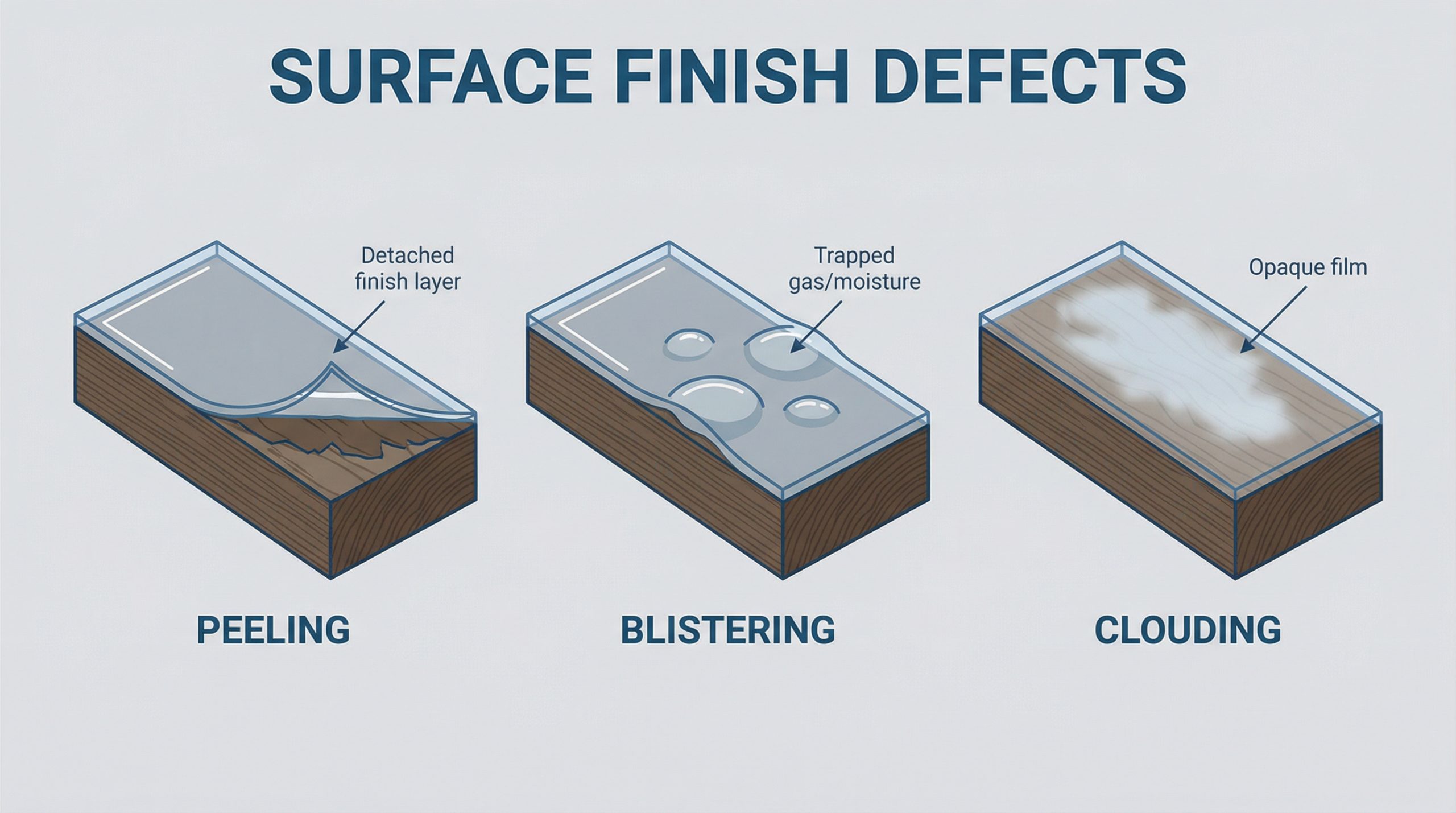

V. Surface Finish and Aesthetics

Wooden furniture quality issues involving the surface finish are the most visible defects and the leading cause of retail-level complaints. Common issues include “orange peel” textures, runs in the lacquer, dust contamination, or uneven staining. A high-quality finish serves a dual purpose: it enhances the natural beauty of the wood and provides a protective barrier against moisture and household chemicals.

What causes peeling paint or lacquer?

Peeling is often the result of poor surface preparation or “contamination” by oils and dust before the finish is applied. If the wood is not sanded to the correct grit or if the moisture content is too high, the finish cannot bond effectively.

Here is the kicker:

- Consistency: Batch-to-batch color must be checked against a Pantone master.

- Hardness: Finished surfaces should pass a “pencil hardness” or cross-cut adhesion test.

- Clarity: The finish should be free of clouding or trapped air bubbles.

How do we prevent color inaccuracy?

Factories must use standardized light boxes to verify color matching under various lighting conditions, such as D65 (daylight) and TL84 (store lighting). This ensures that the furniture looks the same in the showroom as it did on the factory floor.

Key Takeaway

| Finish Defect | Root Cause |

|---|---|

| Orange Peel | Improper spray gun pressure or drying time |

| Color Variation | Inconsistent stain application or wood species mix |

Analysis: Surface finishing is as much a chemical science as it is a craft, requiring strict environmental controls to achieve perfection.

VI. Wooden Furniture Quality Issues in Hardware

Wooden furniture quality issues frequently arise from the selection and installation of functional hardware like hinges, drawer slides, and handles. Even the most beautiful solid wood wardrobe becomes a liability if the hinges sag or the drawer tracks jam after a month of use. Rusting or corroding metal components are also major concerns, particularly for items destined for humid or coastal regions.

Can cheap hardware ruin a premium product?

Inferior hardware significantly reduces the perceived value of the furniture and increases the likelihood of mechanical failure. High-quality manufacturers typically spec name-brand hardware with salt-spray test certifications to ensure durability.

Think about it:

- Alignment: Handles and knobs must be perfectly level and centered.

- Smoothness: Drawers must open and close without catching or excessive noise.

- Security: All screws must be tightened and countersunk correctly.

What is the cycle test for hardware?

A fatigue test involves opening and closing a drawer or door for 20,000 to 50,000 cycles to simulate years of use. This identifies potential failures in the metal or the wood-mounting points before mass production begins.

Key Takeaway

| Hardware Metric | Quality Standard |

|---|---|

| Salt Spray Test | Minimum 48 hours for corrosion resistance |

| Cycle Testing | 20,000+ repetitions without failure |

Analysis: Hardware is the primary point of physical interaction for the user; its failure is interpreted as a total product failure.

VII. Sanding and Smoothness Standards

Wooden furniture quality issues often relate to the “tactile” quality of the wood, which is determined by the sanding process. Rough spots, cross-grain sanding marks, and “fuzzy” wood fibers are signs of a rushed production schedule. In professional manufacturing, sanding is a multi-stage process that moves from coarse grits to fine finishing papers to ensure a glass-smooth surface.

Is rough sanding a safety hazard?

Rough surfaces can lead to splinters, which are classified as a critical safety defect, especially in nursery or children’s furniture. Beyond safety, poor sanding causes stains to absorb unevenly, resulting in a blotchy appearance.

The reality is:

- Grit Progression: Skipping grits (e.g., going from 80 to 180) leaves visible scratches.

- Hidden Areas: The undersides of tables and the backs of cabinets must still be smooth.

- Edge Detail: Sharp corners must be “broken” or slightly rounded for safety.

How do inspectors check for sanding marks?

Inspectors use strong, low-angle lighting to cast shadows in any micro-scratches left by the sanding belts. This “raking light” technique reveals imperfections that are invisible under standard overhead factory lighting.

Key Takeaway

| Sanding Grade | Application |

|---|---|

| P120 – P150 | Preparatory sanding for solid wood |

| P180 – P220 | Final sanding before the first coat of sealer |

Analysis: Superior sanding is the foundation of a high-end finish; you cannot hide poor wood preparation under thick layers of paint.

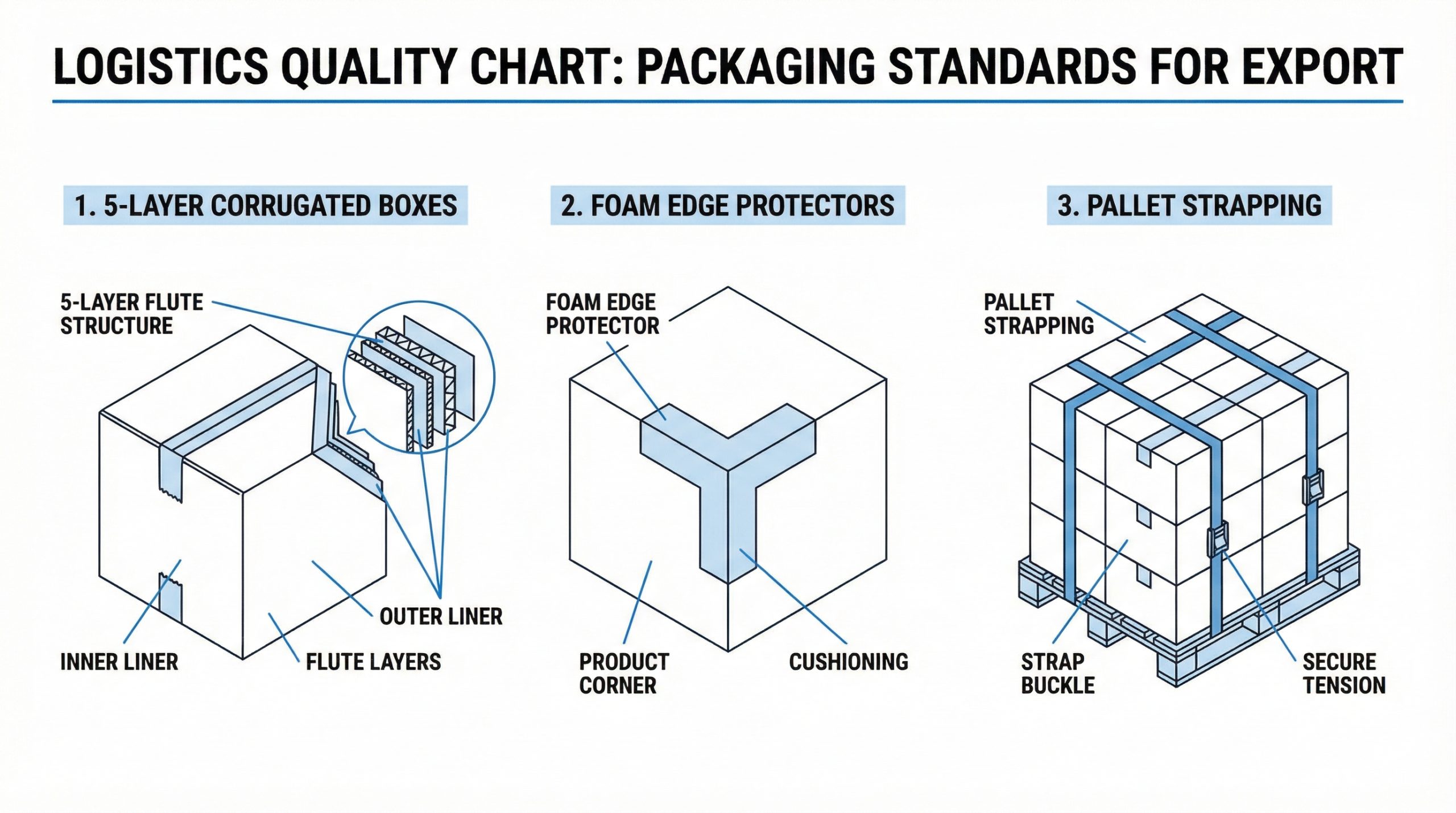

VIII. Wooden Furniture Quality Issues in Packaging

Wooden furniture quality issues don’t always happen on the production line; many occur during transit due to inadequate packaging. Export-grade furniture requires 5-layer corrugated boxes, foam edge protectors, and moisture-absorbing desiccant packs. Without these protections, items are susceptible to crushed corners, surface abrasions, and impact damage from rough handling at the docks.

What is the ISTA drop test?

The International Safe Transit Association (ISTA) 2C test involves dropping a packaged product from specific heights and angles. This simulates the drops and vibrations a carton will experience during its journey from the factory to the consumer’s home.

Here is the kicker:

- Cushioning: There must be a minimum 2cm gap between the product and the carton wall.

- Bracing: Heavy items need internal wooden or honeycomb cardboard frames.

- Labeling: Fragile and “this side up” icons must be clearly visible on all sides.

Do moisture packs really work?

Silica gel or calcium chloride pouches are essential for absorbing the “container rain” that occurs during temperature shifts at sea. This prevents the warping and mold issues mentioned earlier in this guide.

Key Takeaway

| Packaging Component | Function |

|---|---|

| 5-Layer Corrugated | Structural protection against stacking pressure |

| PE Foam / EPE | Surface protection against scratches and dents |

Analysis: The best-manufactured piece of furniture is worthless if it arrives at its destination in pieces due to cost-cutting in packaging.

IX. Compliance and Safety Standards

Wooden furniture quality issues can lead to legal liabilities if the products do not comply with regional safety regulations like ANSI/BIFMA or EU EN standards. These regulations cover everything from the chemical content of the finishes (lead-free) to the physical tip-over resistance of tall dressers. Failing to meet these standards can result in massive product recalls and heavy fines from consumer protection agencies.

What are the main regulatory concerns?

For the US market, compliance with the CARB Phase 2 or EPA TSCA Title VI regarding formaldehyde emissions from composite wood is mandatory. In the EU, the REACH regulation governs chemical substances in all consumer goods.

Think about it:

- Labelling: Country of origin and tracking labels must be permanently attached.

- Tip-Over: Tall units must include anti-tip kits that meet ASTM standards.

- Toxicity: Finishes must be tested for heavy metals and phthalates.

How do factories prove compliance?

Reputable manufacturers provide third-party lab test reports for every material used, from the wood and glue to the hardware and coating. These certificates should be renewed annually to ensure ongoing compliance.

Key Takeaway

| Regulation | Scope |

|---|---|

| TSCA Title VI | Formaldehyde emissions in wood products |

| ANSI/BIFMA | Safety and performance standards for office furniture |

Analysis: Compliance is not an “extra” feature; it is a baseline requirement for any professional B2B furniture transaction.

X. Final Inspection and Wooden Furniture Quality Issues

Wooden furniture quality issues are caught and corrected during the Final Random Inspection (FRI) before the goods leave the factory. This last line of defense involves a comprehensive check of the quantity, workmanship, labeling, and packaging. By conducting a thorough FRI, importers can ensure that the batch matches the approved “Golden Sample” and meets all agreed-upon specifications.

What happens during a final assembly check?

Inspectors will select several units at random and perform a full assembly. This identifies if any holes were drilled incorrectly, if hardware is missing, or if the instructions are unclear for the end user.

The reality is:

- Sampling: Units are selected using the ISO 2859-1 sampling plan.

- Weight/Dims: Every piece is weighed and measured against the spec sheet.

- Odor: A “smell test” is conducted to ensure no offensive chemical odors remain.

Should you use a third-party inspector?

While many factories have internal QC, hiring a third-party inspection firm provides an unbiased assessment of the goods. This investment is small compared to the cost of shipping a container of defective products across the ocean.

Key Takeaway

| Inspection Step | Purpose |

|---|---|

| Random Sampling | To get a statistically significant view of the batch |

| Odor Check | To prevent chemical VOC complaints from consumers |

Analysis: The final inspection is the “moment of truth” where all previous QC efforts are verified before the transfer of ownership.

Conclusion: Elevating Manufacturing Excellence

Navigating the landscape of wooden furniture manufacturing requires a relentless focus on detail and a refusal to compromise on fundamental standards. By understanding and addressing these common pitfalls—from moisture control to final packaging—brands can secure their supply chains and build lasting consumer trust. To maintain this level of excellence, we invite you to explore our approach and see how standardized quality control transforms furniture manufacturing from a risk into a competitive advantage.

FAQ

Q1: Can I repair furniture with moisture damage once it has arrived?

Generally, major moisture damage like severe warping or split panels cannot be repaired economically at the retail level. Prevention through kiln-drying and factory-level moisture control is the only viable strategy.

Q2: What’s the best way to handle minor cosmetic defects in a large shipment?

The most efficient method is to negotiate a “spare parts” or “repair allowance” percentage in your contract. This allows for local touch-ups or part replacements without returning entire units to the origin factory.

Q3: Can I skip third-party inspections if the factory has ISO 9001 certification?

No, ISO 9001 certifies the management system, not the specific product quality of a single batch. Physical inspections of the actual goods remain necessary for every shipment.

Q4: What is the most common cause of “wobbly” chairs?

The most common cause is inconsistent leg length or uneven joinery tension. This is usually identified during the factory’s final assembly and stability testing on a level surface.

Q5: How do I know if the wood finish is safe for children’s furniture?

You must request a “Lead and Phthalate” test report from a certified lab (like SGS or Intertek). Reputable manufacturers will have these certificates readily available for all coatings used in their facility.