The MOQ for furniture orders is the industrial break-even point where a factory’s fixed setup costs, raw material procurement minimums, and labor efficiency curves align to ensure a production run does not result in a net financial loss for the manufacturer. You likely find yourself frustrated by rigid volume requirements that seem designed to gatekeep your growth, yet these figures are rarely arbitrary and instead reflect the uncompromising physics of mass production, where machine downtime and material waste are the primary enemies of profitability. The truth is: by understanding the factory-side logic governing these thresholds, you can transition from a combative negotiation stance to a strategic partnership that leverages industrial realities to your advantage.

I. Raw Material Math and MOQ for Furniture Orders

The MOQ for furniture orders is fundamentally dictated by the upstream supply chain because a furniture factory is essentially an aggregator of raw materials that are sold to it in massive, standardized industrial units. When you request a specific species of timber or a unique wood veneer, the factory must purchase that material in bulk volumes that often far exceed the requirements of a small-sized order, leaving the manufacturer with “dead stock” that occupies valuable warehouse space and ties up liquid capital.

Upstream Timber Procurement Minimums

Timber mills and lumber yards in major hubs like Shandong operate on a volume-first model where they sell by the container or the massive bundle, forcing furniture factories to commit to significant raw material intakes before a single saw blade even touches wood. The reality is:

- Factories must often buy 20 to 50 cubic meters of a specific grade of oak or walnut to secure a competitive price point.

- Small orders that use only a fraction of this bundle leave the factory with mismatched inventory that may not be used for months.

- These holding costs and the risk of wood warping during storage are factored directly into the minimums you are quoted.

The Waste Factor in Panel Optimization

Standardized MDF and plywood panels come in fixed dimensions, such as 1220mm by 2440mm, which means that any design that does not efficiently “nest” into these dimensions creates unusable scrap that you, as the buyer, must ultimately pay for. To maximize the yield of expensive materials like those found in high-end residential furniture , factories calculate MOQs based on how many units are required to leave near-zero waste on a standard industrial sheet.

- Advanced nesting software calculates the exact number of chair backs or cabinet doors that fit onto a master panel.

- An order for 15 units might leave 40% of a panel as scrap, whereas 40 units might achieve 98% utilization.

- Factories set MOQs to ensure they are not throwing your potential profit into the furnace.

The relationship between material intake and order volume is the primary anchor of industrial pricing.

| Variable | Small Order Impact | MOQ Order Impact |

|---|---|---|

| Material Yield | High Waste (15-30%) | Optimized Waste (<5%) |

| Inventory Risk | High (Dead Stock) | Low (Just-in-Time) |

| Unit Sourcing Cost | Retail Pricing | Wholesale Bulk Pricing |

Key Takeaway: Factories set MOQs to ensure that the raw materials purchased for your project are fully consumed, eliminating the financial drain of unallocated inventory and maximizing sheet-cut efficiency.

II. Machine Setup and MOQ for Furniture Orders

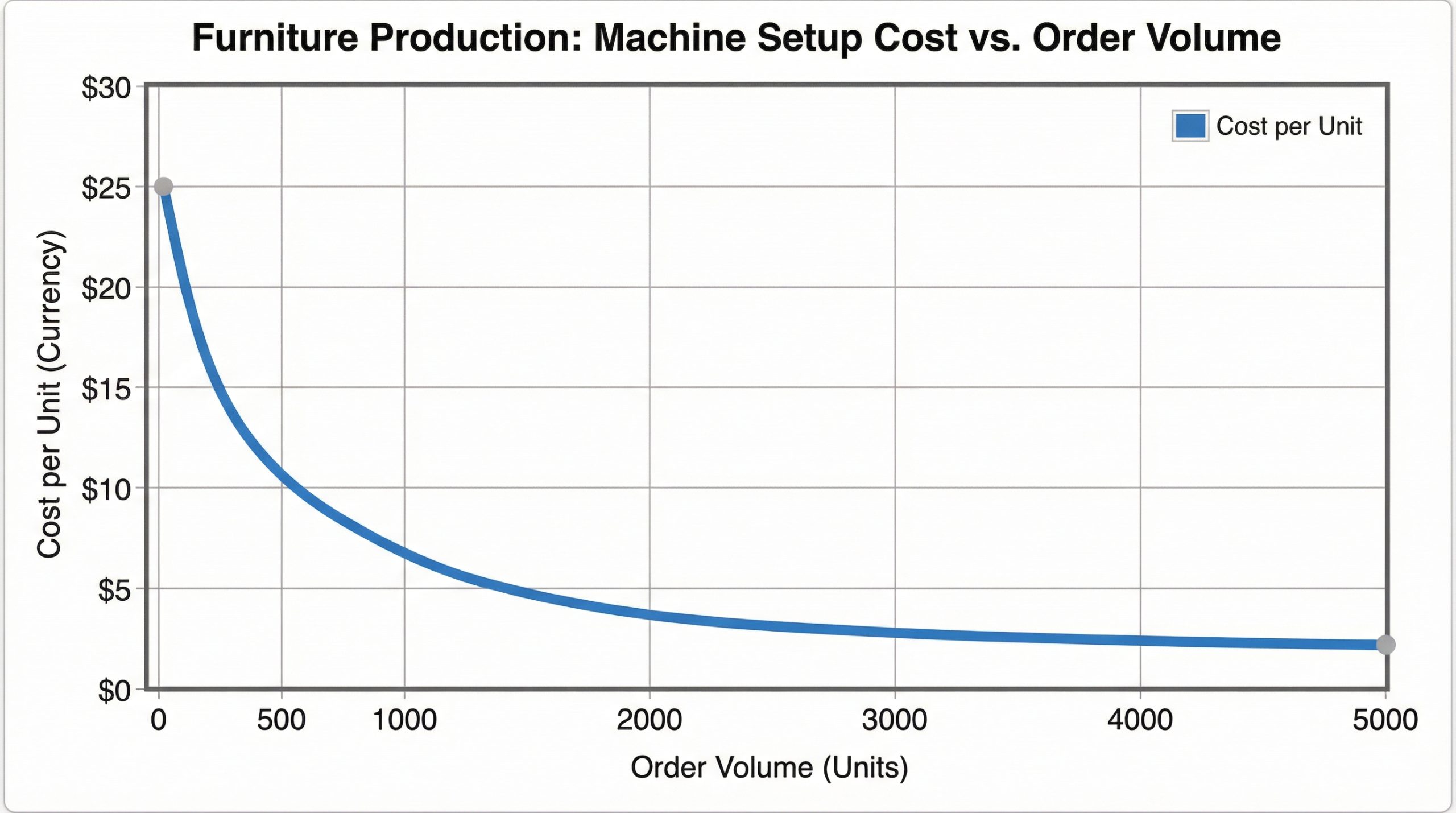

Machine calibration is the most expensive “invisible” cost in the factory because a multi-million dollar CNC router or an automated edge-banding line generates zero revenue while it is being adjusted for a new product design. The MOQ for furniture orders exists to amortize these non-productive setup hours across a sufficient number of units so that the “setup cost per unit” becomes negligible rather than a deal-breaking surcharge.

CNC Programming and Tooling Changeover

Every unique furniture component requires a specific digital path and a specific set of cutting bits that must be manually loaded and tested by a skilled technician before the high-speed production run can begin. You must realize that:

- A complex chair leg might require three different tool changes and a 90-minute calibration period.

- If the machine runs for only 20 minutes to complete your small order, the factory has effectively lost an hour of prime production time.

- MOQs are calculated to ensure the “Run Time” is at least four to five times longer than the “Setup Time.”

Edge Banding and Laminate Alignment

Automated edge-banding machines require precise temperature and pressure settings for specific PVC or wood tapes, and switching between different thicknesses or colors requires a full purge and recalibration of the glue pot system. The technical reality is:

- Each color change on the production line can result in 30 minutes of downtime for the entire assembly cell.

- Standardizing your finishes to match the factory’s existing “hot” colors can often lead to a lower MOQ.

- Factories group similar orders to avoid these resets, which is why your “custom” request always triggers a higher minimum.

Machine uptime is the heartbeat of factory profitability and any interruption must be financially justified.

| Setup Phase | Duration | Cost Implication |

|---|---|---|

| Software Loading | 15-30 mins | Technical labor overhead |

| Tooling Calibration | 45-60 mins | Machine idle time cost |

| Test Run / QC | 2-3 units | Material scrap cost |

Key Takeaway: MOQs protect the factory from the high cost of machine “downtime” by ensuring that once a line is calibrated for your design, it stays running long enough to generate profit.

III. Labor Flow and Furniture Order Minimums

The “Learning Curve” is a very real biological factor on the factory floor because workers on a manual assembly line only reach their peak speed after they have repeated the same task dozens of times in a single shift. When a factory accepts an order that is too small, the workers never leave the “slow” learning phase, which increases the labor cost per unit and significantly raises the probability of quality control errors during the initial units.

Muscle Memory in Assembly Lines

Assembly line workers depend on rhythmic repetition to maintain the high-output speeds required to keep office furniture prices competitive, and any new design breaks that rhythm and forces a mental reset. The fact is:

- The first 10 units of any order are produced up to 50% slower than the units produced after the 100th piece.

- Workers often make “rookie mistakes” on the first few carcasses of a new cabinet design as they learn the specific tension required for the fasteners.

- MOQs provide the volume necessary for the labor force to reach “autopilot” efficiency where quality and speed are maximized.

Station Switching and Team Momentum

A furniture factory is a synchronized ecosystem of cutting, sanding, assembly, and packing stations, and moving an entire 20-person team from one project to another causes a massive drop in collective momentum. Consider the following:

- Every time a line stops to switch projects, the “work-in-progress” (WIP) flow is severed, creating bottlenecks upstream.

- Small orders create “choppy” production schedules that frustrate management and lead to erratic delivery dates.

- High MOQs allow for “smooth” production runs that keep the workforce stable and the factory floor organized.

Efficiency is born from repetition, and small orders are the natural enemy of industrial rhythm.

| Production Stage | Units 1-10 Speed | Units 100+ Speed |

|---|---|---|

| Frame Assembly | 12 mins / unit | 5 mins / unit |

| Hardware Fitting | 8 mins / unit | 3 mins / unit |

| Final Inspection | 6 mins / unit | 2 mins / unit |

Key Takeaway: MOQs ensure that the assembly team has enough volume to move past the slow “learning phase” and into the high-speed, high-quality “repetition phase” of production.

IV. Component Sourcing and MOQ for Furniture Orders

Your furniture factory is rarely vertically integrated for every single part, meaning they must buy hinges, handles, and screws from specialized sub-suppliers who impose their own strict minimums on the factory. If your design requires a specific soft-close slide or a custom-colored knob, the factory’s MOQ for furniture orders is often just a reflection of the hardware supplier’s refusal to sell small quantities.

Sub-Supplier Hardware Constraints

The industrial hardware market in China is built on a massive scale, and vendors of drawer slides or cam-locks often refuse to break open a master carton of 1,000 units for a buyer who only needs 40. You must understand that:

- If your order requires 100 hinges but the supplier MOQ is 500, the factory must either eat the cost of 400 extra hinges or pass that cost to you.

- Standardizing your hardware to what the factory already keeps in stock is the fastest way to bypass these secondary MOQs.

- Inventory “orphans”—leftover custom hardware—are a major source of hidden loss for mid-sized manufacturers.

Custom Casting and Plastic Tooling

If your furniture design features a bespoke metal leg or a unique plastic molded handle, you are no longer just dealing with wood MOQs but with the high-volume requirements of foundries and injection molding shops. The technical constraints include:

- Casting molds for metal components require a high initial investment that is only viable over thousands of units.

- Plastic injection machines have massive “setup waste” where the first few pounds of plastic are used just to clear the previous color from the screw.

- Small buyers are often forced to use “off-the-shelf” hardware to avoid the 1,000+ unit minimums typical of custom component manufacturing.

Component MOQs act as a hard floor that the primary factory cannot lower without incurring a direct financial penalty from their own vendors.

| Component Type | Typical Sub-Supplier MOQ | Impact on Buyer |

|---|---|---|

| Standard Screws | 10,000 units | Negligible (Stocked) |

| Custom Handles | 1,000 – 2,000 units | Massive MOQ trigger |

| Branded Hinges | 500 – 1,000 units | Moderate MOQ trigger |

Key Takeaway: Many furniture MOQs are actually “Hardware MOQs” in disguise, triggered by the factory’s inability to source small quantities of specialized components.

V. Finishing Booth Dynamics and Batch Logic

The finishing department is the most significant bottleneck in any furniture factory because the process of mixing stains, cleaning spray guns, and managing drying rack space is nearly identical for 5 units as it is for 500 units. To maintain the consistent look required for professional outdoor furniture , factories must run finishes in large “dye lots” to ensure that the color on the first chair matches the color on the last chair perfectly.

Paint Mixing and Color Consistency

Chemical coatings and stains are mixed in large batches to ensure chemical stability and color accuracy, and trying to mix a “micro-batch” for a small order often leads to slight variations that result in buyer rejection. The truth is:

- Industrial sprayers require a minimum amount of liquid in the lines just to maintain consistent pressure.

- Cleaning a lacquer line takes 45 minutes of labor and several liters of solvent, regardless of how many pieces were sprayed.

- Small batches result in a higher “cleaning-to-spraying” ratio, making them a net loss for the finishing shop.

Drying Space and Curing Schedules

Furniture finishing is a spatial game where “drying time” is the ultimate constraint, and factories judge their daily capacity by how many square meters of drying rack or kiln space are occupied. Consider the logistical hurdles:

- Small, varied batches of furniture require multiple different curing times and temperatures, complicating the kiln schedule.

- High-volume runs of identical pieces allow the factory to pack the drying room to 100% density for maximum efficiency.

- A “mixed” finishing room increases the risk of dust contamination and cross-color overspray, which ruins the final product quality.

The finishing stage is where a factory’s margin is either protected through volume or destroyed through excessive downtime.

| Finishing Task | Fixed Labor Time | Variable Material Cost |

|---|---|---|

| Color Matching | 60 – 90 mins | High (Small batches) |

| Gun Cleaning | 30 mins / color | Low (Solvent waste) |

| Sanding / Prep | 15 mins / unit | Low (Manual labor) |

Key Takeaway: MOQs are set to maximize the utilization of the spray booth and drying kiln, ensuring that the heavy labor of cleaning and setup is distributed across a profitable number of units.

VI. Packaging Engineering and MOQ for Furniture Orders

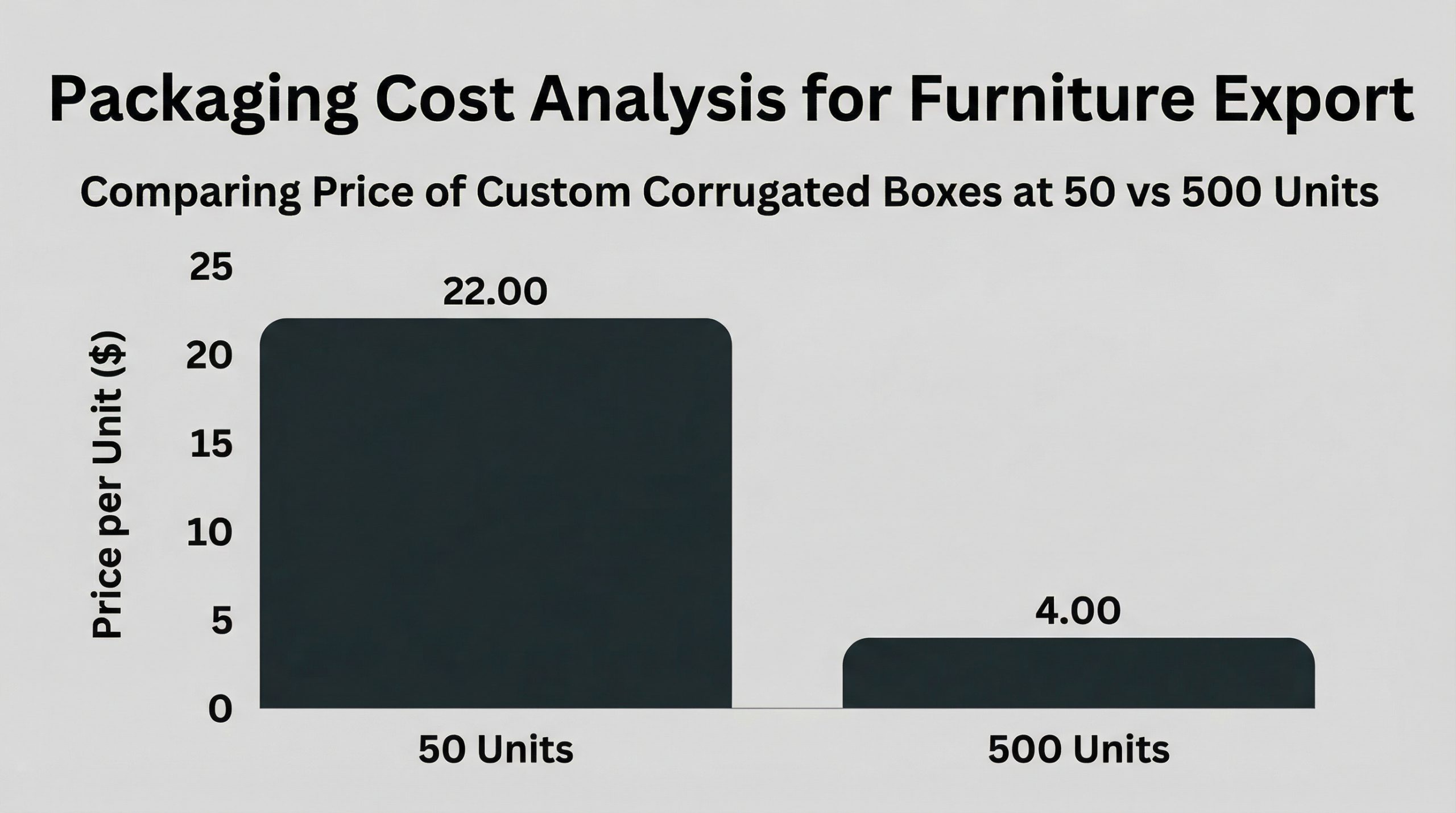

Packaging is frequently the “hidden” reason for high MOQs because corrugated box manufacturers are the most volume-sensitive players in the entire supply chain and will rarely accept an order for fewer than 500 or 1,000 custom-sized boxes. For a furniture factory to ship your goods safely, they need boxes that fit the product precisely, yet the cost of 50 custom boxes can sometimes exceed the cost of the furniture itself due to the astronomical setup fees charged by the box plant.

Corrugated Sheet and Plate Fees

The printing plates and “die-cut” molds used to create a custom export carton represent a significant upfront cost that must be amortized over a large production run to be viable. You must realize that:

- A custom-printed box with your logo might require a $300 plate fee before the first box is even folded.

- On a 50-unit order, that plate fee adds $6.00 to the cost of every single chair, making your retail price uncompetitive.

- Box factories prioritize 10,000-unit runs for phone chargers over your 100-unit run for coffee tables, leading to long lead times for small buyers.

ISTA Transit Testing Requirements

Protecting heavy furniture during international shipping requires engineered packaging solutions—such as honeycomb cardboard and custom foam inserts—that are only cost-effective when bought in bulk. The engineering reality is:

- Proper “Drop Testing” (ISTA standards) requires sacrificial units and multiple packaging prototypes.

- Factories are unwilling to invest the engineering hours to design a “safe” box for an order that only ships once.

- Small-batch packaging is often “over-engineered” or “under-engineered,” leading either to excessive costs or high damage rates during transit.

If you cannot meet the packaging MOQ, you are essentially asking the factory to lose money on the “wrap” of your product.

| Packaging Tier | Minimum Order | Unit Cost Impact |

|---|---|---|

| Custom Printed | 1,000+ Units | Low (4) |

| Plain Custom Size | 500+ Units | Moderate (8) |

| Stock Box + Inserts | 10+ Units | High ($15+) |

Key Takeaway: High furniture MOQs often protect the buyer from the predatory pricing of low-volume corrugated box manufacturing and ensure the product survives the journey across the ocean.

VII. Prototyping Risk and MOQ for Furniture Orders

Every new SKU introduced to a factory floor carries a high degree of technical risk, and the MOQ for furniture orders acts as a safety buffer that ensures the factory can identify and correct production flaws before they become catastrophic financial liabilities. A factory viewing a 20-unit order sees a project that is too small to “learn” from but large enough to cause a massive headache if a design flaw is discovered halfway through the run.

SKU Stability and Structural Testing

The first production run of a new table or bed frame is essentially a “live test” of the engineering drawings, and small batches don’t provide enough data points to confirm the design is truly stable for mass export. The fact is:

- Small batches make it difficult to identify if a wood-joint failure is a “one-off” worker error or a systemic design flaw.

- Factories use the first 50-100 units to “dial in” the tolerances of the joinery and the moisture content of the wood.

- MOQs provide the factory with enough “runway” to justify the time spent by their top engineers on your specific technical drawings.

Statistical Quality Control Limits

Quality control is based on statistical sampling, and when an order is too small, the sample size becomes too tiny to be mathematically significant, meaning the factory cannot guarantee the quality of the batch with any certainty. Consider the following:

- In a 500-unit order, a 10% QC check (50 units) gives a very accurate picture of the whole batch.

- In a 10-unit order, checking 1 unit tells the factory almost nothing about the remaining 9, yet the cost of checking all 10 is prohibitively high.

- Factories set MOQs to ensure their QC departments can operate within standardized industrial protocols that protect both the buyer and the brand.

Volume is the only effective way to mitigate the inherent risks of furniture engineering and material behavior.

| Risk Factor | Small Batch Hazard | MOQ Batch Mitigation |

|---|---|---|

| Design Flaws | Undetected until too late | Caught during “First Article” run |

| Material Variance | High (Small sample) | Low (Averaged across batch) |

| Labor Error | High (New process) | Low (Established rhythm) |

Key Takeaway: MOQs are a risk-management tool that gives the factory the volume necessary to perfect the production process and ensure the final goods meet international structural standards.

VIII. Logistics Efficiency and MOQ for Furniture Orders

The global furniture trade is built on the 40-foot High Cube (40HQ) container, and the administrative overhead of handling a small LCL (Less than Container Load) shipment is nearly the same as handling a full container, which makes small orders a massive bureaucratic drain on the factory’s export department. The MOQ for furniture orders is often calculated to ensure that at least a significant portion of a container is filled, as “empty air” in a container is the most expensive thing a furniture brand can ship.

Container Stuffing and CBM Optimization

Furniture is a “volumetric” product, and factories judge the success of an order by how many Cubic Meters (CBM) it occupies in a shipping container relative to the labor required to load it. You must understand that:

- Loading a “mixed” container with 15 different small orders takes four times longer than loading one 500-unit order.

- LCL shipments are handled multiple times at the port, which increases the risk of forklift damage—a liability the factory wants to avoid.

- By setting an MOQ that matches a “Full Container Load” (FCL) or a “Half Container,” the factory ensures the safest and most efficient transport for your goods.

Export Documentation and Admin Overhead

The paperwork required by Chinese customs, shipping lines, and your local port is identical whether you are shipping one chair or one thousand, creating a “paperwork tax” that disproportionately penalizes small buyers. The reality is:

- A dedicated export clerk must spend 4-6 hours on the documentation for every single shipment.

- Small orders “clog” the logistics department with low-value tasks that divert resources from high-volume clients.

- Factories set MOQs to ensure the “Administrative Cost per Unit” stays below 1% of the total order value.

Efficient logistics are the final step in protecting the slim margins of the international furniture trade.

| Logistics Mode | Administrative Burden | Risk of Transit Damage |

|---|---|---|

| FCL (Full Container) | Low (Per unit) | Low (Factory-sealed) |

| LCL (Mixed Load) | High (Per unit) | High (Multiple handlings) |

| Air Freight | Extreme | Low (Fast but expensive) |

Key Takeaway: Logistics-driven MOQs push buyers toward container-level efficiency, which reduces the total cost of ownership by lowering shipping rates and minimizing the risk of damage.

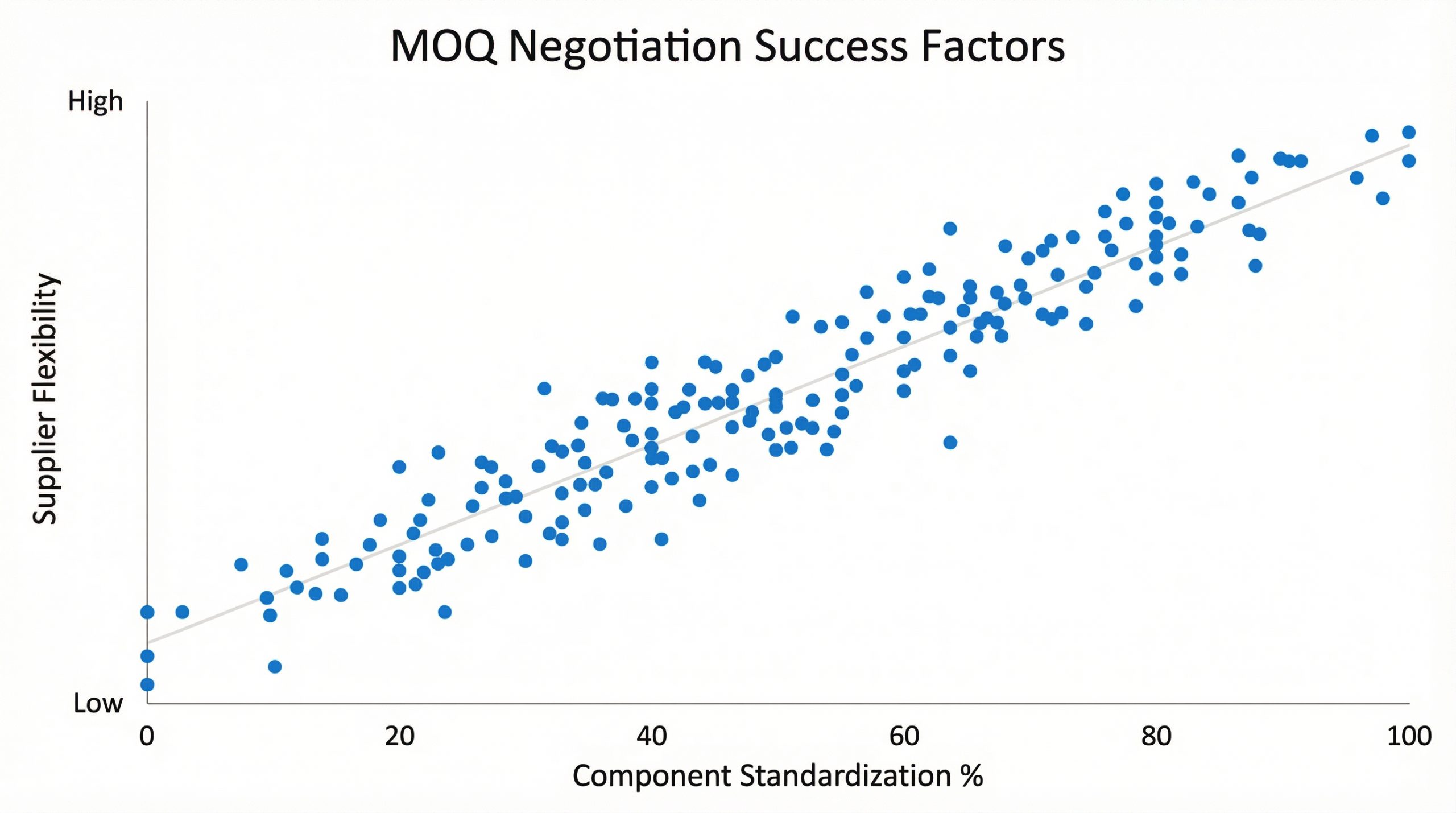

IX. Negotiating MOQ for Furniture Orders

If your business model simply cannot support a 200-unit initial order, you must change the conversation from “please lower your minimum” to “how can I make this order profitable for your factory floor?” Successful negotiation of the MOQ for furniture orders requires you to act as a problem-solver for the manufacturer, offering to alleviate the specific pain points—like machine downtime or material waste—that the MOQ was designed to prevent.

The Small-Batch Surcharge Strategy

The most effective way to lower an MOQ is to offer a “Small Batch Premium” that covers the factory’s fixed setup costs directly, transforming your order from a loss-leader into a high-margin specialty project. You should consider:

- Offering to pay 15% to 25% above the bulk price for the first two orders to “earn” your way into the factory’s schedule.

- Explicitly stating that you understand the setup costs and are willing to pay a flat “Calibration Fee” per SKU.

- This approach proves you are a professional buyer who understands the industrial process, which builds immediate trust with the factory owner.

Component and Finish Standardization

You can often bypass high MOQs by stripping away all custom requirements and using only the materials, hardware, and finishes that the factory is already running for their largest clients. The truth is:

- If the factory is already spraying 2,000 units of “Slate Grey” for a big European brand, they can easily add 20 units of your chair to the end of that run.

- Using “Stock” timber and “Stock” drawer slides removes the procurement hurdles that trigger 90% of sub-supplier MOQs.

- By “piggybacking” on the factory’s existing volume, you can often reach MOQs as low as 10-20 units without any surcharge.

Negotiation is about creating a “Path of Least Resistance” for the factory manager.

| Strategy | Difficulty | Resulting MOQ Reduction |

|---|---|---|

| Pay Surcharge | Easy | 50% – 70% Reduction |

| Standardize Parts | Moderate | 40% – 60% Reduction |

| Annual Contract | Hard | 80% – 100% Reduction |

Key Takeaway: To lower an MOQ, you must remove the factory’s “setup friction” by either paying for it directly or by choosing designs that align with their existing high-volume production lines.

X. Future-Proofing Your Furniture Supply Chain

The ultimate goal for a mid-size buyer should be to grow into a “Tier 1” client where the MOQ for furniture orders is no longer a barrier but a strategic tool used to maintain your own inventory health. As you scale, you should move away from transactional “per-order” thinking and toward an annual supply chain strategy that allows you to leverage your total yearly volume to secure flexible shipping terms and priority production slots.

Annual Volume Commitments

Instead of negotiating every order individually, offer the factory a “Letter of Intent” for your total projected volume over the next 12 months, which allows them to buy raw materials and hardware in bulk on your behalf. You must realize that:

- A factory is much more willing to ship 20 units a month if they know you are committed to 240 units for the year.

- This “Blanket Order” approach allows the factory to run your components in one large batch but assemble and ship them as you need them.

- It secures your production capacity during “Peak Season” (before Chinese New Year) when small buyers are typically pushed off the schedule.

Catalog Consolidation for Scale

Small and mid-size buyers often fail by having too many unique SKUs, which dilutes their buying power and forces them into high MOQs across every single product line. The strategic move is to:

- Narrow your catalog to a few “hero” products that you can order in high enough volume to truly command the factory’s attention.

- Use modular design where the same legs or drawers are used across five different products, effectively “pooling” your MOQ requirements.

- Focus on building a deep, multi-year relationship with one primary manufacturer rather than “window shopping” for the lowest price every season.

Scale is not just about having more money; it is about having more influence over the factory’s daily operations.

| Growth Phase | Strategy Focus | Supplier Relationship |

|---|---|---|

| Startup | Standardization | Transactional / Opportunistic |

| Mid-Size | Surcharge / Batching | Preferred Partner |

| Scaling | Annual Commitments | Strategic Core Supplier |

Key Takeaway: Future-proofing your supply chain requires a shift from “buying products” to “buying capacity,” using your total annual volume to dissolve the barriers of traditional MOQs.

FAQ: Navigating Furniture MOQs

Q1: Can I buy just 5 units for a showroom sample?

Usually Yes, but with a high surcharge. Factories treat this as a “Product Development” task rather than production, and you will likely pay 3x the wholesale price to cover the manual labor involved.

Q2: Why is the MOQ higher for solid wood than for veneer?

Timber waste and drying time. Solid wood is more prone to warping and requires more careful selection and seasoning, whereas veneer is a more standardized industrial material that is easier to “nest” and process.

Q3: What is the ‘real’ MOQ for a custom-branded sofa?

Typically 50~300 units per color. This is driven by the 50-meter rolls of high-quality fabric; if you want 5 colors, you must buy 5 rolls, which effectively quintuples your initial commitment.

Q4: Does ‘Mixed Container’ shipping help with MOQs?

It helps with logistics, not production. While you can ship many small orders in one container, each SKU still has to go through the cutting and finishing logic on the factory floor, so production MOQs remain.

Conclusion

The MOQ for furniture orders is the invisible boundary between a hobbyist and a professional importer. It is the industrial manifestation of raw material physics, machine economics, and human efficiency. To succeed as a small or mid-size buyer, you must stop viewing these numbers as obstacles to be avoided and start seeing them as the benchmarks of a healthy, profitable factory. When you understand why a factory asks for 50 chairs instead of 5, you gain the ability to negotiate with technical authority, choosing your battles between customization and cost.

If you are ready to stop relying on generic checklists and start building a robust, scaleable supply chain that leverages true factory logic, we invite you to explore our approach and see how we bridge the gap between industrial excellence and modern buyer needs. Our vision is to transform the traditional “Supplier-Buyer” dynamic into a transparent, data-driven partnership where your growth is limited only by your ambition, not by the mechanics of the factory floor.