Weather exposure ruins untreated wood, causing rot and structural failure. Professional manufacturing prevents this through engineered protection. Secure your investment with factory-grade waterproofing strategies.

Understanding the engineering behind wooden outdoor furniture is essential for long-term durability. This guide explores industrial moisture control, UV-resistant coatings, and precision joinery from a supplier’s perspective. Learn how factory-level processes ensure your furniture remains resilient against the most demanding environmental conditions year after year.

I. Wooden Outdoor Furniture Moisture Risks

High-quality wooden outdoor furniture must be engineered to resist the relentless cycle of moisture absorption and evaporation. Wood remains a biologically active material even after harvest, constantly seeking an equilibrium with the surrounding humidity levels. When water penetrates the cellular structure, it initiates physical changes that can lead to irreversible structural compromise.

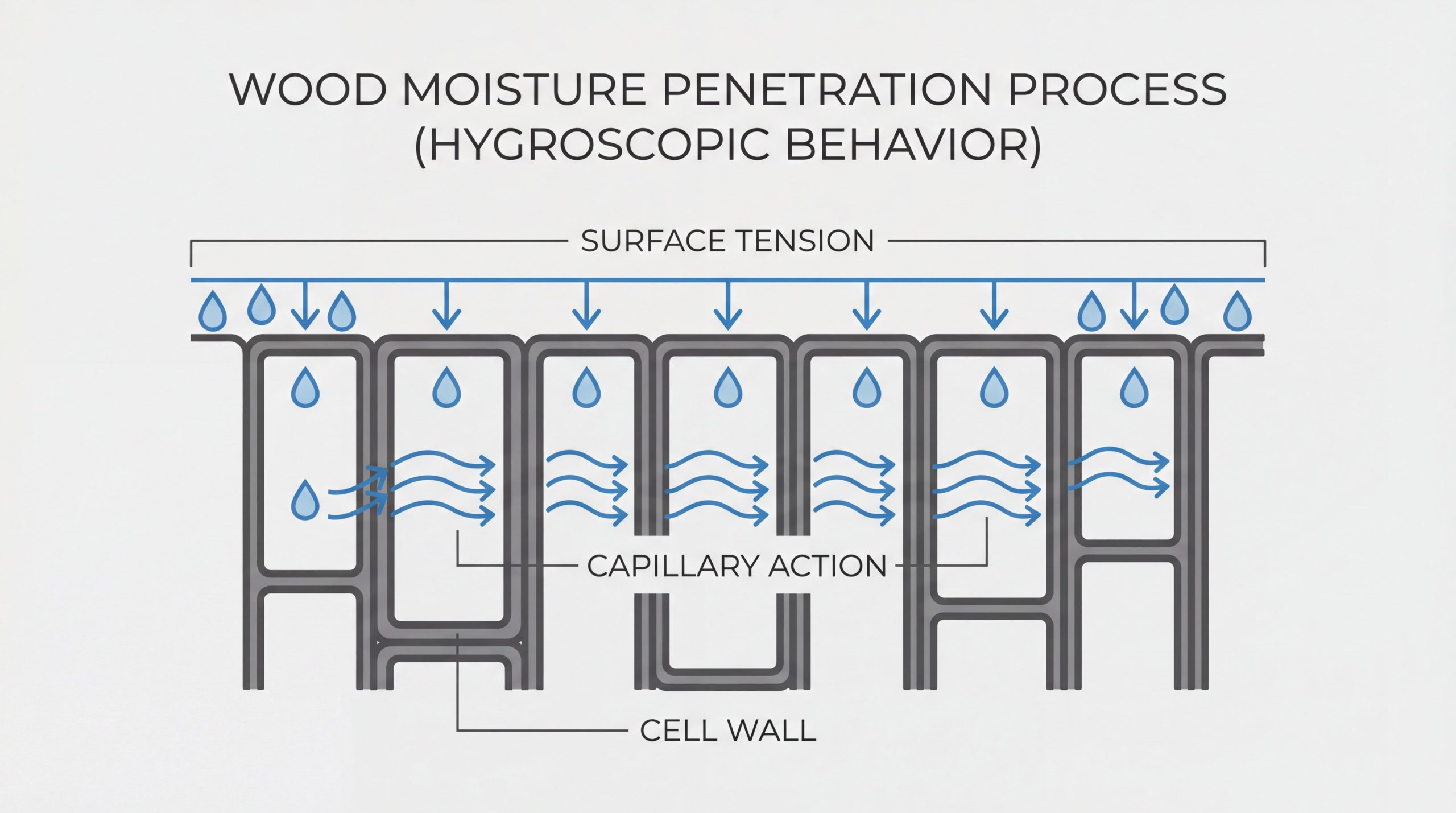

Microscopic Water Ingress Paths

At a molecular level, moisture enters wood through capillary action within the tubular cell structures. These cells, originally designed to transport nutrients, act like sponges when exposed to liquid water or high vapor pressure. End-grain surfaces are particularly vulnerable, as they expose the open ends of these capillaries to the environment.

Identifying Common Moisture Damage

Manufacturers often look for “checking,” which refers to the small hairline cracks that appear as the surface dries faster than the core. If left unaddressed, these cracks expand into deep splits that allow water to bypass surface treatments entirely. Fungal decay becomes a significant risk once the internal moisture content exceeds 20% for extended periods.

Wood Species and Permeability

The natural density and oil content of a wood species determine its inherent resistance to water penetration. To ensure longevity, our Shandong factory prioritizes materials with closed-pore structures or high natural extractive levels. Selecting the right timber is the first line of defense in the manufacturing process.

The following list highlights critical wood characteristics considered during material selection:

- Lignin Content: Higher lignin levels provide better structural “glue” between cells.

- Natural Oils: Species like teak possess internal oils that repel liquid water naturally.

- Pore Size: Tight-grained hardwoods limit the rate of capillary suction.

- Heartwood vs. Sapwood: Heartwood is significantly more resistant to decay and moisture.

Key Takeaway: Selecting species with low permeability and high natural oil content is the foundational step in professional waterproofing.

| Moisture Factor | High Density (Teak) | Medium Density (Acacia) | Low Density (Pine) |

|---|---|---|---|

| Porosity | Very Low | Moderate | High |

| Absorption Rate | Minimal | Controlled | Rapid |

| Rot Resistance | Excellent | Good (Treated) | Poor |

| Cellular Stability | Exceptional structural integrity over long cycles. | Requires industrial sealing for outdoor use. | Susceptible to rapid warping without film. |

| End-Grain Seal | Recommended to prevent micro-cracking. | Essential for preventing water traps. | Mandatory for all outdoor applications. |

| Vapor Diffusion | Slow and controlled release. | Moderate moisture exchange rates. | Rapid fluctuation leads to checking. |

| Finish Adhesion | High due to stable moisture levels. | Requires specific primers for oils. | Subject to peeling from internal pressure. |

| Swelling Factor | Minimal dimensional changes observed. | Predictable movement within set tolerances. | High risk of joint failure from expansion. |

| Natural Defenses | High concentration of protective extractives. | Moderate fungal resistance in heartwood. | Requires chemical impregnation for survival. |

| Target Application | Premium luxury outdoor installations. | High-volume commercial patio furniture. | Economy-tier or temporary garden items. |

Here is the bottom line.

II. Coating Failure in Wooden Outdoor Furniture

Even the most expensive wooden outdoor furniture can fail if the surface coating is not chemically compatible with the wood’s natural movement. Most consumer-grade sealants fail because they create a brittle shell that cannot accommodate the expansion of wood fibers. Understanding why these films break down is critical for developing superior industrial protection systems.

Limitations of Standard Surface Sealing

Retail varnishes often sit on top of the wood rather than integrating with the internal fiber network. While this creates an initial waterproof barrier, it prevents the wood from “breathing,” leading to vapor entrapment. Once internal pressure builds, the coating loses its mechanical bond and begins to flake or peel.

Thermal Expansion and Finish Cracking

Wooden furniture is dimensionally unstable and reacts to temperature shifts by expanding and contracting. Brittle coatings like standard lacquers develop microscopic cracks during these thermal cycles, creating entry points for liquid water. This trapped moisture then accelerates rot beneath the visible surface of the finish.

Comparison of Coating Systems

Modern industrial finishes prioritize elasticity and molecular bonding over simple thickness. By using penetrating oils or flexible acrylic-urethane hybrids, we ensure the finish moves in tandem with the timber. This approach prevents the catastrophic delamination common in low-tier wooden outdoor furniture products.

Our factory utilizes specific coating technologies to ensure maximum adhesion:

- Penetrating Oils: These saturate the fibers and provide internal water repellency.

- Microporous Films: These allow vapor to escape while blocking liquid droplets.

- UV Blockers: Additives that prevent the sun from destroying the bond.

- Fungicidal Primers: Base layers that stop mold growth at the wood-finish interface.

Key Takeaway: Effective protection requires flexible, breathable coatings that bond at a molecular level rather than just sitting on the surface.

| Coating Type | Surface Film (Varnish) | Penetrating Oil | Professional Hybrid |

|---|---|---|---|

| Bonding Style | Mechanical Overlap | Molecular Saturation | Chemical Integration |

| Flexibility | Low (Brittle) | High (Elastic) | Maximum (Adaptive) |

| Breathability | Poor (Traps Vapor) | Excellent (Diffusive) | Controlled (Balanced) |

| Maintenance | Sanding required for repair. | Simple re-application steps. | Annual buff and top-coat. |

| UV Resistance | High initially, then degrades. | Moderate (Needs pigments). | Excellent (Triple-shield). |

| Water Repellency | Absolute until cracked. | High (Water beads). | Permanent hydrophobic barrier. |

| Finish Texture | Smooth, plastic feel. | Natural wood grain texture. | Satin or matte professional. |

| Peeling Risk | Significant after 12 months. | Zero (Fades gradually). | Negligible with proper prep. |

| Eco-Compliance | High VOC (Solvent based). | Low VOC (Natural bases). | Zero VOC (Water based). |

| Application Time | 24-48 hours per coat. | 12-24 hours per coat. | 2-4 hours (Industrial dry). |

This is where the magic happens.

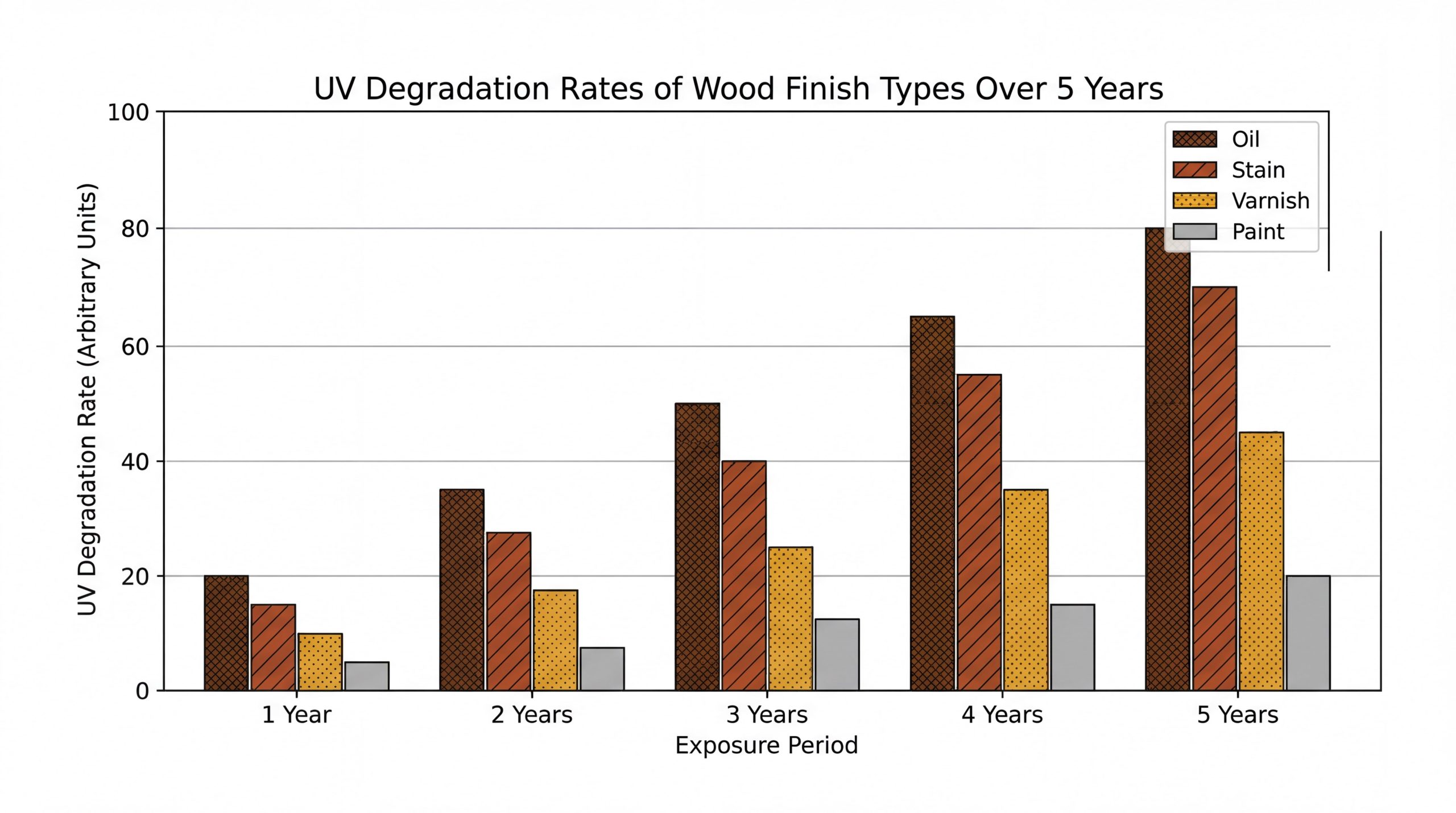

III. UV Entry in Wooden Outdoor Furniture

Solar radiation is arguably the most destructive force acting upon wooden outdoor furniture over long-term exposure. Ultraviolet (UV) light penetrates the surface and acts as a catalyst for photochemical reactions that destroy the wood’s structural integrity. Without professional UV shielding, the very “glue” holding the wood together begins to dissolve.

Photochemical Lignin Breakdown

UV rays target lignin, the organic polymer responsible for the rigidity and strength of wood cells. As lignin degrades, the surface fibers become loose and brittle, leading to the “silver-gray” appearance of weathered wood. This process, known as photo-oxidation, makes the wood more porous and susceptible to further moisture damage.

Solar Energy and Pigment Fading

Natural wood pigments are highly sensitive to high-frequency solar energy, which breaks their chemical bonds and causes rapid bleaching. Industrial-grade stains utilize iron oxide pigments that act as tiny umbrellas, physically blocking UV rays from reaching the wood. Clear coats without these additives offer almost no protection against solar-induced color loss.

UV Shielding Technologies

Manufacturers incorporate UV absorbers (UVAs) and hindered amine light stabilizers (HALS) into their finishing systems. These chemicals absorb solar energy and dissipate it as harmless heat before it can damage the wood fibers. This engineering step is what separates professional furniture from standard DIY projects.

To combat UV degradation, we implement the following factory standards:

- Iron Oxide Pigmentation: Provides deep-color retention and physical solar blocking.

- HALS Technology: Extends the life of the clear coat by neutralizing free radicals.

- Reflective Topcoats: Deflect infrared heat to keep the wood surface cool.

- Multi-Layer Stacks: Multiple applications to ensure no “holidays” or thin spots exist.

Key Takeaway: UV protection must be chemical and physical, using stabilizers and pigments to prevent the structural breakdown of lignin.

| UV Protectant | Clear Sealer | Semi-Transparent Stain | Solid Opaque Stain |

|---|---|---|---|

| Blocking Method | Chemical UV Absorber | Pigment + Chemical | Total Physical Barrier |

| Color Retention | 3 – 6 Months | 18 – 24 Months | 36 – 60 Months |

| Lignin Shield | Low | High | Absolute |

| Application | High-maintenance luxury. | Standard commercial grade. | Industrial heavy-duty use. |

| Appearance | Original wood look. | Enhanced grain visibility. | Painted appearance. |

| Maintenance | Quarterly inspections. | Annual re-coat recommended. | Multi-year service life. |

| Cost Factor | Medium (Frequent upkeep). | Low (Best value). | High (Initial material). |

| Film Thickness | Thin (1-2 mils). | Medium (2-3 mils). | Thick (4-5 mils). |

| Weathering | Rapid graying of fibers. | Controlled patina development. | No visible wood aging. |

| Heat Absorption | Low (Natural temperature). | Moderate (Pigment based). | High (Depending on color). |

Think about that for a second.

IV. Engineering Better Wooden Outdoor Furniture

The longevity of wooden outdoor furniture is decided at the drafting stage, long before any timber is cut. “Design for Durability” is an engineering philosophy that addresses moisture and UV risks through geometry and material science. By eliminating design flaws that trap water, we significantly reduce the burden on the chemical finishing system.

The Design for Durability Model

Engineers focus on “shedding geometry,” which ensures that liquid water cannot pool on any surface. This includes introducing slight slopes to table tops and using slatted designs for seating areas to promote airflow and drainage. Rounded or “radiused” edges are also vital, as finishes tend to thin out and fail first on sharp corners.

Material Selection and Grain Orientation

The orientation of the wood grain affects how the furniture expands and contracts in different humidity levels. Quarter-sawn timber is often preferred for outdoor use because it is more dimensionally stable than flat-sawn alternatives. Our factory carefully selects “heartwood” sections to ensure the highest natural resistance to decay-causing organisms.

Precision Engineering Standards

Using advanced CNC machinery allows for tighter tolerances in joints, preventing gaps where moisture can accumulate. These precision fittings, combined with marine-grade adhesives, create a structural unit that resists the mechanical stress of moisture cycling. Engineering every detail ensures that the wooden furniture manufacturing process results in a world-class product.

Our engineering team prioritizes these structural features for maximum durability:

- Slatted Surfaces: Prevents standing water and allows for rapid drying.

- Chamfered Edges: Improves coating thickness and reduces edge peeling.

- Venting Holes: Ensures internal cavities do not trap humid air.

- Isolator Feet: Keeps the wood end-grain away from moist ground contact.

Key Takeaway: Durability begins with smart geometry that prevents water pooling and utilizes the most stable grain orientations.

| Design Feature | Standard Construction | Engineered Durability | Impact on Life |

|---|---|---|---|

| Table Surface | Solid Panel (Flat) | Slatted (1° Slope) | Eliminates pooling. |

| Edge Profile | Sharp 90° Corner | 3mm Radius Round | Prevents finish failure. |

| Joint Type | Basic Butt Joint | Precision Mortise/Tenon | Maximizes glue bond. |

| Hardware | Zinc-Plated Steel | 316 Stainless Steel | Zero corrosion risk. |

| End-Grain | Exposed to Ground | Raised on Glides | Prevents bottom rot. |

| Fastening | External Screws | Hidden / Plugged Joins | No water entry points. |

| Airflow | Closed Structures | Ventilated Geometry | Rapid drying cycles. |

| Tolerance | +/- 2.0 mm | +/- 0.5 mm | Structural rigidity. |

| Adhesives | D3 Standard Glue | D4 Marine-Grade | Waterproof bonding. |

| Timber Grade | Mixed (Sap/Heart) | 100% Heartwood | Natural rot resistance. |

Do you see the difference?

V. Precise Moisture Control for Wooden Outdoor Furniture

The stability of wooden outdoor furniture is fundamentally linked to the moisture content of the raw timber during production. If the wood is too wet or too dry when it is manufactured, it will suffer from “climatic shock” when placed in its final environment. Precise moisture control is the invisible thread that holds a high-quality piece together through the seasons.

Industrial Kiln Drying Stability

Kiln drying is a controlled process that removes “bound water” from the wood cells to reach a target Moisture Content (MC). This process stabilizes the cellular structure, reducing the wood’s tendency to shrink or swell by up to 80%. Our factory utilizes computer-controlled kilns to ensure every board in a production run is uniform.

Equilibrium Moisture Content Targets

Every geographic region has an Equilibrium Moisture Content (EMC)—the state where wood neither gains nor loses water. For outdoor furniture, we typically target an MC of 10% to 12%, which is a safe median for most temperate climates. Manufacturers who ignore these targets often face issues with warping and joint failure within weeks of delivery.

Moisture Verification Processes

Quality control starts with digital moisture meters that verify the state of every raw plank before it enters the CNC machines. We also monitor the humidity levels within the factory to prevent the wood from re-absorbing moisture during the machining phase. This level of furniture quality control is essential for international shipping stability.

We maintain strict moisture standards across these critical production stages:

- Raw Receipt: Initial testing to ensure the timber matches the manifest.

- Post-Kiln: Verification that the drying cycle reached the core.

- Post-Machining: Ensuring the wood remains stable after cutting.

- Pre-Finishing: The surface must be dry enough for optimal coating adhesion.

Key Takeaway: Controlling the moisture content to match the destination climate is the only way to prevent warping and cracking.

| Climate Zone | Avg. Humidity | Target MC Range | Structural Risk |

|---|---|---|---|

| Arid / Desert | < 25% | 6% – 8% | Excessive Checking |

| Temperate | 40% – 60% | 10% – 12% | Standard Movement |

| Tropical | > 80% | 14% – 16% | Mold / Fungal Rot |

| Manufacturing | Controlled | 10% +/- 2% | Stability Baseline |

| Shipping | Variable | Sealed Wrap | Container Sweat |

| Storage | 50% | 10% – 12% | Inventory Quality |

| Installation | Outdoor | Acclimatized | Natural Expansion |

| Coating Prep | Low | < 12% | Optimal Bond Strength |

| Joint Fitment | Specific | Tight Tolerance | Interference Fitting |

| End-Use | Dynamic | Seasonal Flux | Stress Resistance |

It’s a game changer for longevity.

VI. Protecting Wooden Outdoor Furniture Joints

The joints are the most vulnerable points in any piece of wooden outdoor furniture, as they act as natural reservoirs for water. When moisture enters a joint, it causes the wood to swell, putting immense pressure on the fasteners and the adhesive bond. Protecting these connections requires a combination of precision machining and advanced chemical bonding.

Humidity Impact on Structural Joints

As wood moves through its expansion cycles, it can actually “pull” fasteners out of their holes if the design is inadequate. Traditional glue-only joints often fail in outdoor settings because standard PVAc glues are not waterproof and will soften under constant rain. This leads to “wobbling” furniture that eventually collapses under load.

CNC Machining and Adhesive Quality

To counter these forces, we use CNC-machined mortise and tenon joints which provide a massive surface area for adhesive bonding. We exclusively use D4-rated waterproof adhesives that are chemically engineered to withstand prolonged water immersion. The precision of the fit ensures that the glue line is consistent and strong across the entire connection.

Fastener Selection and Corrosion

In coastal or high-humidity environments, even the joints themselves can be compromised by the corrosion of internal hardware. We utilize 304 or 316-grade stainless steel fasteners to ensure that rust never compromises the structural integrity of the frame. These fasteners are often recessed and plugged with matching wood to create a seamless, water-tight seal.

Our factory standard for joints includes the following protective measures:

- Interference Fitting: Precision joints that stay together even without glue.

- D4 Adhesives: Highest international rating for waterproof wood bonding.

- Hidden Fasteners: Reduces the number of entry points for liquid water.

- Epoxy Sealing: Used in high-stress areas to provide an absolute moisture barrier.

Key Takeaway: Precision machining and D4-rated adhesives are required to prevent joint failure caused by moisture-induced expansion.

| Joint Quality | Residential DIY | Commercial Grade | Industrial Factory |

|---|---|---|---|

| Fitting Method | Hand-cut / Loose | Machine-cut | CNC High-Precision |

| Adhesive Class | D2 (Interior) | D3 (Water-Resistant) | D4 (Waterproof) |

| Fastener Type | Zinc-Plated Steel | Galvanized Steel | 316 Stainless Steel |

| Joint Geometry | Butt / Screw | Dowel / Pocket | Mortise & Tenon |

| Water Traps | High (Open gaps) | Moderate | Zero (Tight seal) |

| Shear Strength | Low | Moderate | Exceptional |

| Lifecycle | 1 – 2 Years | 3 – 5 Years | 10+ Years |

| Repairability | Poor (Replace item) | Moderate | Simple disassembly |

| Expansion Gap | Not considered | Minimal | Engineered tolerance |

| Cost Basis | Economy | Standard | Premium |

Make no mistake, joints are the soul of the furniture.

VII. Drainage Design for Wooden Outdoor Furniture

Effective drainage is the most overlooked aspect of waterproofing wooden outdoor furniture in the consumer market. Liquid water is only dangerous to wood when it is allowed to remain in contact with the fibers for extended periods. By engineering surfaces that facilitate rapid runoff, we reduce the hydrostatic pressure that forces water into the wood’s pores.

Hydrostatic Pressure and Rot

Standing water on a flat table creates hydrostatic pressure, which pushes moisture through microscopic cracks in the finish. This “puddling” also acts as a magnifying glass for UV rays, accelerating the chemical breakdown of the coating directly underneath the water. Rapid drainage is the most effective way to break this destructive cycle.

Geometric Solutions for Water Shedding

Professional designs incorporate “shedding geometry,” such as chamfered edges and sloped slats that guide water away from critical joints. By ensuring that every horizontal surface has a path for water to exit, we significantly increase the “dry-time” of the furniture. The faster a piece dries after a rain event, the lower the risk of fungal infestation.

Advanced Drainage Engineering

At our facility, we use CNC technology to carve subtle drainage channels into the undersides of chairs and tables. These channels prevent water from “wicking” around the edges and soaking into the underside, which is often less protected than the top. This holistic approach to water management ensures every square inch of the wooden outdoor furniture stays as dry as possible.

Our drainage-first design philosophy includes these specific factory features:

- V-Groove Slats: Directs water into channels for immediate runoff.

- Drip Edges: Prevents water from following the surface to the underside.

- Splayed Legs: Ensures water runs down the leg rather than pooling at the seat.

- Non-Porous Footers: High-density plastic glides that stop ground-wicking.

Key Takeaway: Engineering shedding geometry and drip edges reduces the hydrostatic pressure that causes finishes to fail.

| Drainage Logic | Poor (Flat Panel) | Good (Simple Slats) | Best (Engineered Slopes) |

|---|---|---|---|

| Water Path | Pooling / Stagnant | Vertical Drainage | Active Shedding |

| Drying Time | 24+ Hours | 4 – 8 Hours | < 2 Hours |

| Fungal Risk | High | Moderate | Minimal |

| Finish Wear | Accelerated | Standard | Prolonged |

| Surface Slope | 0 Degrees | 0.5 Degrees | 1.5+ Degrees |

| Wicking Action | Severe | Moderate | Controlled |

| Underside Care | Neglected | Standard Finish | Drip-Edge Carving |

| User Comfort | Wet Seats | Rapid Dry | Dry-Touch Design |

| Cleaning Ease | Traps Dirt | Easy Rinse | Self-Cleaning Flow |

| Aesthetic | Modern Solid | Traditional Garden | Precision Industrial |

It’s all about the flow.

VIII. Testing Quality of Professional Furniture

To ensure that our waterproofing strategies are effective, every production model must undergo rigorous industrial testing. We do not rely on guesswork; instead, we use scientific simulations to predict how the furniture will behave over a decade of use. Testing verifies that the combination of wood species, joinery, and coating is optimized for the elements.

Accelerated Weathering Simulations

High-end factories utilize QUV machines that subject wood samples to cycles of intense UV radiation and high-pressure moisture. One week in a QUV lab can simulate six months of real-world exposure, allowing us to identify failure points before mass production. This testing helps us refine the chemical composition of our UV stabilizers and water repellents.

Eight-Step Factory Quality Control

Quality control is integrated into every phase of the manufacturing process, from raw material inspection to final packaging. We perform “cross-hatch adhesion tests” on finished surfaces to ensure the coating is physically bonded to the wood fibers. A “salt spray test” is also conducted on all stainless steel hardware to guarantee zero corrosion in coastal environments.

Performance Verification Standards

Before any batch is cleared for shipping, we perform a final moisture check and a structural load test. These metrics ensure that the furniture is not only waterproof but also safe and durable for long-term commercial use. This rigorous furniture quality control protocol is why professional buyers trust factory-direct suppliers.

Our standard testing suite includes these essential factory evaluations:

- ASTM D3359 Adhesion: Verifies that the finish will not peel or flake.

- Static Load Testing: Ensures joints can handle 200kg+ of constant pressure.

- Moisture Delta Test: Measures how much the wood expands after 24h immersion.

- UV Exposure Cycle: Simulates multi-year solar damage in a controlled lab.

Key Takeaway: Industrial testing labs provide the data necessary to guarantee a 10-year lifespan in harsh outdoor environments.

| Quality Test | DIY Standard | Factory Standard | Acceptable Metric |

|---|---|---|---|

| Moisture Check | Visual only | Digital Meter | 10% +/- 2% |

| Finish Adhesion | Fingernail test | ASTM Cross-Hatch | Grade 4B or higher |

| Hardware Rust | None | 240h Salt Spray | No visible oxidation |

| Joint Strength | Weight test | Static Load Sim | > 200kg per seat |

| UV Resistance | None | QUV Lab Cycle | No fading @ 500h |

| Water Beading | Initial only | 48h Immersion | < 3% weight gain |

| Packaging | Standard box | ISTA Drop Test | Damage-free @ 60cm |

| Chemical Resist | None | Solvent Rub Test | No finish softening |

| Surface Rough | Sanded by hand | RA Meter Check | < 15 microns |

| Eco-Compliance | Unknown | VOC Emissions | E1 / FSC Certified |

The data doesn’t lie.

IX. Advanced Industrial Coating Systems

Professional waterproofing requires a multi-stage coating system rather than a single “one-and-done” application. Industrial systems are designed with specialized layers that each perform a specific protective function. This layered defense ensures that even if the topcoat is scratched, the wood remains protected from the inside out.

Multi-Stage Chemical Barriers

The first layer is typically a deep-penetrating preservative that contains fungicides and insecticides to prevent biological attack. This is followed by a UV-blocking primer that creates a strong chemical bond between the wood and the topcoat. Finally, two or more layers of high-build topcoat are applied to provide the primary barrier against liquid water.

Water-Based vs. Traditional Oil

While traditional oils are popular for their natural look, modern water-based acrylic-urethane hybrids offer superior durability and environmental safety. These “microporous” coatings allow water vapor to escape from the wood while blocking liquid droplets from entering. They are also non-flammable and have significantly lower VOC levels, making them safer for both workers and consumers.

Application Technology and Consistency

Factories use high-pressure, low-volume (HVLP) spray systems to ensure a perfectly uniform coating thickness across the entire piece. Automated spray booths maintain a dust-free environment, which is critical for achieving a professional, furniture-grade finish. This consistency is impossible to replicate with hand-brushing in a non-controlled environment.

Our industrial coating process involves these critical steps:

- Vacuum Impregnation: Forces preservatives deep into the cellular structure.

- Electrostatic Spraying: Ensures wrap-around coverage on complex chair slats.

- UV Curing: Uses high-intensity lamps to dry the finish instantly for hardness.

- Fine-Grit Scuffing: Light sanding between coats to maximize mechanical inter-layer bonding.

Key Takeaway: Multi-layer industrial coating systems provide redundant protection that single-coat DIY solutions cannot match.

| Coating Layer | Function | Primary Component | Effectiveness |

|---|---|---|---|

| Preservative | Biocide / Fungicide | Borates / Zinc | Prevents internal rot. |

| Sealing Primer | Adhesion / Tannin Block | Acrylic Resin | Stops bleed-through. |

| UV Shield | Solar Protection | Iron Oxide / HALS | Prevents graying. |

| Topcoat 1 | Waterproof Barrier | Poly-Urethane | Liquid repulsion. |

| Topcoat 2 | Abrasion Resistance | Nano-Ceramic | Scratch protection. |

| Maintenance Oil | Refreshing Layer | Linseed / Tung | Restores luster. |

| Edge Sealer | End-Grain Guard | Wax / Epoxy | Blocks high-suction. |

| Joint Filler | Gap Protection | D4 Sealant | Prevents water traps. |

| Eco-Barrier | Safety Compliance | Water-Based | Low VOC emissions. |

| Final Wax | Shipping Protection | Carnauba | Buffs to high sheen. |

You get what you pay for in protection.

X. Maintaining Your Outdoor Wooden Investment

Even the best-engineered wooden furniture requires a basic maintenance schedule to preserve its waterproofing and aesthetic appeal. Maintenance is not about fixing a failure; it is about extending the life of the protective barriers before they become compromised. A proactive approach saves significant time and money over the lifespan of the furniture.

Strategic Resealing and Maintenance

Furniture exposed to direct sun and rain should be inspected every six months for signs of finish thinning. A simple “bead test”—where water is dropped on the surface—will indicate if the waterproof barrier is still active. If the water stops beading and begins to darken the wood, it is time to apply a maintenance coat of professional oil or sealer.

Off-Season Storage Protocol

The most effective way to protect outdoor wood is to reduce its total exposure time to the elements during extreme seasons. We recommend storing furniture in a cool, well-ventilated space like a shed or garage during the winter months. Avoid using non-breathable plastic covers, as they can trap moisture and create a “greenhouse effect” that promotes rapid mold growth.

Cleaning and Care Tips

Regular cleaning with mild, non-detergent soap prevents the buildup of organic matter that can trap moisture against the wood. Avoid using high-pressure power washers, as these can strip away the protective finish and drive water deep into the grain. For further details on long-term care, refer to our guide on how to care for and maintain your wooden furniture .

Follow these expert maintenance steps to maximize your furniture’s life:

- Bi-Annual Cleaning: Removes dirt, pollen, and fungal spores.

- Hardware Tightening: Checks for fastener loosening due to seasonal movement.

- Spot Sanding: Addresses minor scratches before they allow water entry.

- Breathable Covers: Protects from UV during periods of non-use.

Key Takeaway: Proactive maintenance and proper off-season storage are essential to preserving the industrial-grade protection of your wood furniture.

| Exposure Level | Cleaning Frequency | Re-sealing Interval | Storage Recommendation |

|---|---|---|---|

| Full Sun / Rain | Monthly | 12 Months | Indoor Winter Storage |

| Partial Shade | Quarterly | 18 – 24 Months | Breathable Covers |

| Fully Covered | Bi-Annually | 3 – 4 Years | Leave in Place |

| Coastal Area | Weekly (Rinse Salt) | 6 – 12 Months | Maximum Protection |

| Arid / Dry | Monthly (Dusting) | 12 Months | UV Protection Priority |

| High Humidity | Bi-Weekly | 12 Months | Mold Monitoring |

| Commercial Use | Weekly | 12 Months | Heavy Duty Coatings |

| Residential Use | Quarterly | 24 Months | Standard Care |

| Public Parks | Monthly | 12 Months | Anti-Graffiti Coatings |

| Poolside | Weekly (Rinse Chlorine) | 12 Months | Chemical Resistance |

It really is that simple.

FAQ: Professional Wood Waterproofing

1. Does all wooden outdoor furniture require annual resealing?

Not necessarily. While high-exposure items in full sun usually need attention every 12 months, furniture kept under covered patios or in shaded areas can often go 2-3 years before requiring a maintenance coat. Always use the “bead test” to determine the actual state of the waterproof barrier.

2. Is oil or a water-based finish better for outdoor wood?

For commercial and high-durability applications, water-based acrylic-urethane hybrids are superior due to their high UV resistance and elasticity. Traditional oils offer a more “natural” feel and are easier for consumers to re-apply, but they require more frequent maintenance to prevent the wood from graying.

3. Why is end-grain protection so important?

End-grain acts like a bundle of straws, drawing moisture deep into the wood through capillary action much faster than the side-grain. If the ends of table legs or slats are not sealed with wax or epoxy, they will rot from the bottom up, even if the rest of the piece is perfectly finished.

Closing Note

As a leading Shandong-based manufacturer, Everwoody is dedicated to producing resilient, high-performance wooden solutions for global markets. Our engineering-first approach ensures that every piece of furniture we ship is optimized for durability, stability, and aesthetic excellence. If you are looking for a reliable manufacturing partner for your next project, please contact us to discuss your specific requirements.