Sourcing furniture becomes problematic when you cannot distinguish between specific raw materials and general weaving styles. This confusion often leads to procurement errors and unexpected durability issues in high-traffic commercial environments.

A rattan chair is a furniture item made from the solid, fibrous stalks of the rattan palm, a climbing vine native to tropical regions. Unlike wicker, which describes the weaving technique, rattan identifies the specific durable material used to create the chair’s structural frame.

I. Defining the Modern Rattan Chair

A rattan chair is characterized by its solid internal core and its construction from the flexible yet incredibly strong stems of the Calameae family palms. This specific category of furniture relies on the natural properties of the vine to provide structural integrity that hollow materials simply cannot match in a professional setting. You will find that the highest quality iterations utilize the full thickness of the vine to ensure long-term stability for end-users.

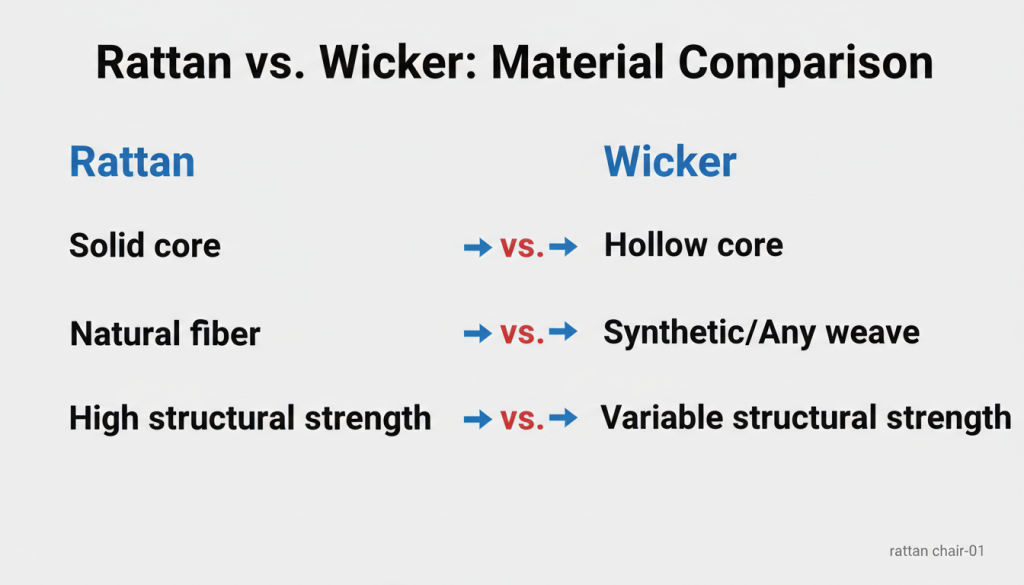

Material vs. Technique

The primary difference lies in the fact that rattan is a tangible plant species, while other terms often used in the industry refer strictly to the method of interlocking fibers. You should understand that a chair can be made of rattan and woven in a wicker style, but not all wicker items are composed of natural rattan. This distinction is vital when reviewing manufacturer specifications for large-scale hospitality projects.

The Solid Core Advantage

Unlike bamboo or certain synthetic tubes, the rattan used in your furniture has a completely solid center that prevents snapping under concentrated pressure. This dense cellular structure allows the material to be steamed and bent into ergonomic shapes without losing its inherent tensile strength. Professionals choose this material because it offers a unique combination of lightweight portability and heavy-duty load-bearing capacity.

The following data summarizes the core technical definitions required for accurate product sourcing and cataloging.

| Attribute | Technical Specification | Procurement Relevance |

|---|---|---|

| Primary Material | Solid-core Calameae palm vine | Determines structural weight limits |

| Internal Structure | Non-hollow fibrous vascular bundles | Prevents splintering and catastrophic failure |

| Flexibility | High-tensile steaming capability | Allows for complex ergonomic curves |

| Weight Class | Lightweight high-density fiber | Reduces international shipping costs |

Check the details.

It gets better.

II. Rattan Chair vs Wicker Methods

A rattan chair differs from wicker furniture because the former identifies a botanical species while the latter describes an ancient manufacturing process involving the interlacing of pliable branches. In the global B2B market, suppliers often use these terms interchangeably, which creates significant “grey areas” regarding the actual material composition of the goods you receive. You must specify natural rattan if you require the specific durability and aesthetic of the solid tropical vine.

The Weaving Process

Wicker is a process that can utilize various materials including willow, reed, bamboo, or even high-density polyethylene plastics to create a finished surface. When you order a wicker-style item, you are requesting a specific visual texture rather than a guaranteed botanical ingredient. This nuance is why many outdoor sets are marketed as wicker but are actually made of plastic fibers wrapped around aluminum frames.

Synthetic Wicker Differences

Synthetic wicker is engineered to withstand direct rain and heavy ultraviolet exposure, whereas natural rattan is better suited for protected or indoor environments. You will notice that synthetic versions often lack the organic variations in color and the tactile warmth provided by authentic palm fibers. Choosing between them requires a deep understanding of the intended final placement and the maintenance capabilities of your client.

Compare the differences between buyer expectations and factory realities to avoid common miscommunications.

| Feature | Buyer Expectation (Natural) | Factory Reality (Wicker Style) |

|---|---|---|

| Material | 100% Solid Natural Rattan | May include paper, plastic, or willow |

| Durability | Decades of indoor use | Variable based on the weave material |

| Texture | Organic, slightly irregular | Uniform and often perfectly smooth |

| Price | Premium for hand-harvested vine | Mass-produced options available |

Think about that.

Let’s move on.

III. Origins of Your Rattan Chair

The material for a rattan chair originates primarily from the dense tropical rainforests of Southeast Asia, where the vines can grow several hundred meters in length. These palms are a vital part of the local ecosystem, relying on larger trees for support as they climb toward the forest canopy. You will find that the specific region of origin significantly impacts the thickness, color, and grain density of the rattan available for furniture production.

The Rattan Palm Source

Over 600 species of the rattan palm exist, but only a small fraction are suitable for high-end furniture manufacturing due to specific diameter requirements. The harvesting process is labor-intensive, requiring skilled workers to navigate the jungle and extract the vines without damaging the surrounding flora. This difficulty is one of the factors that contributes to the prestige and cost of authentic rattan furniture in the Western market.

Regional Harvesting Cycles

Harvesting cycles must be carefully managed to ensure the long-term viability of the vine populations and the health of the rainforest. You should seek suppliers who adhere to strictly monitored harvesting schedules that allow the palms to regenerate every five to seven years. Understanding these cycles helps you explain lead times and price fluctuations to your customers who value ethical sourcing and environmental transparency.

This table provides a breakdown of the botanical and regional factors influencing the raw material supply.

| Factor | Description | Impact on Inventory |

|---|---|---|

| Botanical Species | Calamus rotang and related vines | Affects the diameter of the chair legs |

| Harvest Region | Indonesia, Philippines, and Vietnam | Determines the base color and oil content |

| Growth Rate | 1-3 meters per year | Sets the limits for annual production volume |

| Extraction Method | Manual cutting and pulling | Influences the initial raw material cost |

Keep reading.

Here is the truth.

IV. Building a Quality Rattan Chair

Manufacturing a rattan chair requires a sophisticated blend of traditional hand-weaving and modern factory precision to meet international safety and aesthetic standards. In our Shandong-based facilities, we employ advanced steaming chambers to soften the fibers before they are bent around custom-made jigs. This process ensures that every unit maintains dimensional consistency while preserving the unique character of the natural material.

Modern Factory Procedures

Modern production lines utilize CNC cutting for auxiliary wooden components and automated sanding stations to ensure a splinter-free finish. You benefit from these technological investments through lower defect rates and more reliable shipping schedules compared to smaller, less-equipped workshops. These Buying Tips help you identify which factory features correlate most strongly with long-term product success.

Skilled Weaving Techniques

Despite the presence of machinery, the actual weaving of the seat and back remains a highly skilled manual task that defines the chair’s final quality. Our artisans, typically aged 25 to 35, undergo rigorous training to ensure the tension of the weave is uniform across the entire surface. This human element is what gives the furniture its soul and makes it a standout piece in any high-end residential collection.

Review the production milestones that ensure your furniture meets global retail standards.

| Stage | Activity | Quality Metric |

|---|---|---|

| Preparation | Steam bending of main poles | Symmetry of the primary frame |

| Assembly | Fastening joints with glue and nails | Structural rigidity under 150kg |

| Weaving | Hand-interlacing the skin or core | Uniformity of the pattern tension |

| Finishing | Application of water-based sealants | Smoothness and UV resistance level |

That is a fact.

Wait, there is more.

V. Rattan Chair Lifespan Metrics

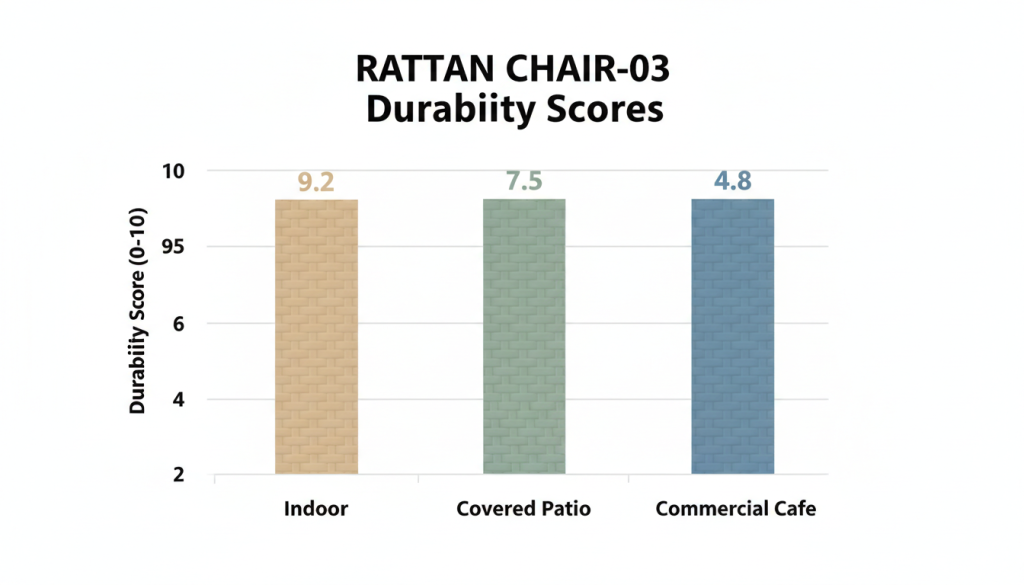

A rattan chair is engineered to last for decades when placed in the appropriate environment and subjected to regular, professional-grade maintenance. The natural durability of the fiber is comparable to many hardwoods, but its unique flexibility allows it to absorb shocks that might cause solid wood to crack. You should educate your clients on the difference between “weather-resistant” and “weather-proof” to manage their expectations regarding the product’s lifespan.

Environmental Resistance

While the material is naturally resistant to insects and mold, prolonged exposure to direct rain or intense desert heat can eventually dry out the fibers. You will see the best results when the furniture is used in semi-outdoor spaces like sunrooms or covered verandas where air circulates freely. Protecting the fibers from extreme moisture fluctuations prevents the “unconfirmed grey areas” of structural degradation that often plague inferior products.

Load Bearing Capacity

The solid core of the vine provides an exceptional strength-to-weight ratio, allowing a relatively light chair to support significant commercial loads. In laboratory tests, our frames consistently outperform hollow plastic alternatives in terms of fatigue resistance over thousands of sit-cycles. This reliability is why many boutique hotels choose this material for their high-traffic lounge and dining areas.

The following comparison helps you choose the right material based on the specific needs of your project.

| Metric | Natural Rattan (Option A) | Plastic Wicker (Option B) |

|---|---|---|

| Expected Lifespan | 20+ years (Indoors) | 5-10 years (Outdoors) |

| Load Capacity | High (Solid fiber) | Medium (Synthetic tube) |

| Repairability | Possible with skilled artisans | Difficult to impossible |

| Aesthetics | Premium natural patina | Uniform industrial look |

Look at the data.

It makes sense.

VI. Structural Joints in a Rattan Chair

The structural joints of a rattan chair are the most critical points of failure and require specialized binding techniques to ensure the frame remains stable. We utilize “wrap-around” bindings made from the outer skin of the rattan vine to hide mechanical fasteners and provide additional friction at the connection points. You can inspect these joints to verify the craftsmanship; they should be tight, smooth, and free from any protruding hardware or gaps.

Traditional Binding Methods

Traditional methods involve soaking the rattan peel until it is highly pliable and then tightly winding it around the primary joints while it is wet. As the peel dries, it shrinks and creates a powerful mechanical bond that prevents the chair from wobbling even after years of use. This time-tested approach is still the gold standard for high-quality Outdoor Furniture because it combines beauty with immense functional strength.

Reinforcement Strategies

In modern manufacturing, we often supplement these traditional wraps with high-strength wood glue and recessed steel screws for added safety in commercial settings. You will find that this hybrid approach satisfies both the aesthetic demands of interior designers and the safety requirements of corporate procurement officers. Ensuring that these reinforcements are invisible to the end-user is a hallmark of a professional-grade factory.

This table outlines the various joint types and their specific roles in the furniture’s overall stability.

| Joint Type | Mechanical Fastener | Binding Material | Primary Function |

|---|---|---|---|

| Leg-to-Seat | Internal steel screw | Rattan skin wrap | Prevents horizontal shearing |

| Backrest Arch | Glue and dowel | Decorative peel | Maintains the curved profile |

| Cross-Bracing | Heavy-duty nail | Full-round binding | Eliminates frame twisting |

| Armrest Pivot | Hidden bolt | Seamless resin finish | Supports downward arm pressure |

Check the joints.

You will see.

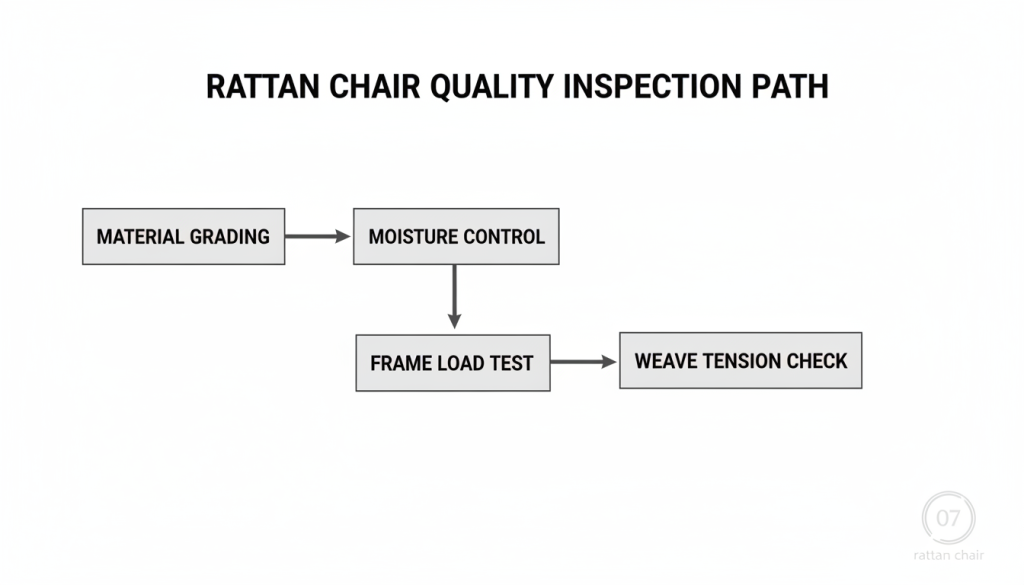

VII. Rattan Chair Inspection Protocols

Every rattan chair must pass through a multi-stage inspection process before it is cleared for container loading and international dispatch. Our quality control team monitors moisture content levels in the raw material to ensure that the wood will not warp or crack when it reaches different climates. You receive a full set of shipment photo records, which provides transparency and reduces the risks associated with unconfirmed material quality.

Material Grading Systems

Rattan is graded into three primary categories (A, B, and C) based on its diameter consistency, surface blemishes, and overall structural density. We exclusively use Grade A material for export orders, ensuring that the furniture you sell reflects the high standards of your brand. You should always ask for a grading report to confirm that the supplier is not mixing lower-quality vines into your production batch.

Moisture Level Testing

Maintaining a moisture content between 8% and 12% is essential for preventing mold growth during the weeks of sea transit in humid shipping containers. We use digital moisture meters at every stage of production to verify that the drying process has been completed successfully. This technical step is often overlooked by smaller workshops, but it is vital for ensuring that your products arrive in pristine condition.

The following quality control steps are standard for every production run in our Shandong facility.

| Inspection Stage | Tool Used | Target Metric |

|---|---|---|

| Raw Material | Digital Moisture Meter | <12% Moisture content |

| Frame Assembly | Calibrated Weight Test | Zero deflection at 120kg |

| Surface Finish | Tactile Glove Test | Zero splinters or rough spots |

| Final Packing | Drop Test Standards | Zero damage to internal contents |

This is the standard.

Don’t skip it.

VIII. Environmental Impact of Material

The sustainability of the rattan chair is one of its most compelling selling points for the modern, eco-conscious consumer and corporate buyer. Because rattan grows significantly faster than most hardwoods and requires a standing forest to thrive, it provides a powerful economic incentive against deforestation. You can market these items as “forest-friendly” products that contribute to the preservation of tropical biodiversity and local communities.

Renewable Resource Cycles

A rattan vine can reach maturity in as little as five to seven years, which is a fraction of the time required for oak or teak trees to grow. This rapid renewal rate allows for a continuous harvest that does not deplete the land’s natural resources when managed correctly. You should highlight this characteristic when competing against synthetic furniture options that rely on petroleum-based manufacturing processes.

Carbon Footprint Data

The production of natural fiber furniture generally involves much lower energy consumption than the manufacturing of metal or plastic alternatives. Most of the work is performed by hand or with low-power machinery, and the material itself sequers carbon throughout its long lifespan. By choosing these products, you are supporting a circular economy that prioritizes biological materials over non-renewable industrial outputs.

The table below summarizes the ecological benefits of choosing natural fibers for your furniture collections.

| Eco-Benefit | Natural Rattan | Metal/Plastic |

|---|---|---|

| Renewable Period | 5-7 Years | Non-renewable |

| Deforestation Role | Prevents (Needs trees) | Neutral or Negative |

| End-of-Life | Biodegradable | Landfill or Recycling |

| Processing Energy | Low (Manual) | High (Industrial) |

Save the planet.

It matters now.

IX. Commercial Value of Rattan Seating

The commercial appeal of a rattan chair lies in its ability to create an instantly recognizable atmosphere of relaxed luxury and organic warmth. High-end cafes and boutique hotels often utilize these chairs to soften the hard lines of modern industrial architecture and create a more inviting guest experience. You will find that the lightweight nature of the material also makes it practical for staff who must rearrange floor plans frequently for events.

Hospitality Interior Trends

Current interior trends emphasize biophilic design, which seeks to integrate natural elements into urban spaces to improve well-being and comfort. Natural fibers are the perfect medium for this trend, offering a tactile connection to the outdoors that synthetic materials cannot replicate. You can leverage this trend by including various Wooden Home Accessories to complement the larger seating pieces in your showroom.

Stacking and Storage Benefits

Many of our commercial designs are engineered to be stackable, allowing business owners to save valuable space during cleaning or off-season storage. This functional feature does not compromise the chair’s elegance, as the tapering legs and curved backs are designed to nest perfectly together. You should consider stackability a “must-have” feature when sourcing for the hospitality sector to ensure operational efficiency for your clients.

Consider these factors when deciding between indoor and semi-outdoor placements for your commercial project.

| Requirement | Indoor Lounge | Covered Terrace |

|---|---|---|

| UV Exposure | Minimal (Window filtered) | Moderate (Indirect sun) |

| Humidity Levels | Controlled (HVAC) | Fluctuating (Natural) |

| Cleaning Frequency | Weekly dusting | Daily wipe-down |

| Aesthetic Goal | Warmth and texture | Indoor-outdoor flow |

Focus on usage.

It drives sales.

X. Maintenance for Natural Fibers

Caring for a rattan chair is surprisingly simple and requires no specialized chemicals to maintain its structural integrity and original color. Regular dusting with a soft brush and an occasional wipe-down with a damp cloth is usually sufficient to remove surface debris and keep the fibers hydrated. You should advise your customers to avoid placing the furniture directly next to high-heat sources like radiators, as this can cause the material to become brittle.

Routine Cleaning Guide

For deeper cleaning, a solution of mild dish soap and warm water can be used to scrub the weave gently without soaking the core of the vine. It is important to let the furniture dry completely in a shaded, well-ventilated area before sitting on it again to prevent the weave from stretching. You will find that a light application of lemon oil or furniture wax once a year can restore the natural luster and provide an extra layer of protection.

Long Term Protection Tips

If the furniture is used in a very dry climate, a light misting of water every few months can help the fibers maintain their natural elasticity. Conversely, in very humid environments, ensuring proper air circulation is the best way to prevent surface mildew from forming on the organic material. Following these simple steps ensures that the investment your clients make today will continue to provide value for a generation or more.

The final summary table provides a quick-reference guide for the long-term maintenance of natural fiber furniture.

| Task | Frequency | Recommended Method |

|---|---|---|

| Dusting | Weekly | Soft brush or vacuum attachment |

| Deep Cleaning | Bi-annually | Damp cloth with mild soap |

| Conditioning | Annually | Natural furniture oil or wax |

| Protection | Seasonal | Move away from direct heat/rain |

Simple steps work.

The results last.

Frequently Asked Questions

- Can I use a rattan chair outdoors if it rains occasionally?

While the material is naturally resilient, you should not leave natural rattan in direct rain; instead, keep it under a covered patio or move it indoors during storms to prevent fiber rot. - What’s the best way to tell if a chair is real rattan or just synthetic wicker?

You can identify real rattan by looking at the cross-section of the frame poles; if it is solid all the way through rather than a hollow tube, it is authentic natural fiber. - How do I know if the quality of the weaving is high enough for a hotel?

You should check the tension of the weave by pressing firmly on the seat; there should be minimal “give,” and the bindings around the joints should be tight and immovable.

Closing Note

EverWoody provides high-quality manufacturing solutions for importers seeking stable, factory-direct furniture. We specialize in precision-crafted wooden and natural fiber items that meet rigorous international standards for safety and design. To discuss your next project or request a custom quotation, please contact us today and experience our commitment to manufacturing excellence.