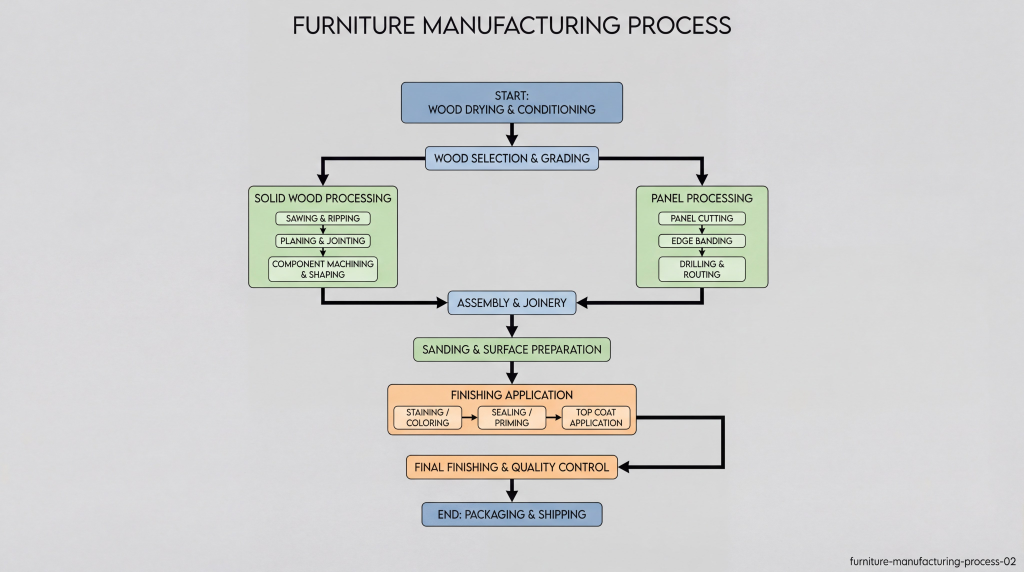

The furniture manufacturing process for bulk orders is a sophisticated technical orchestration that converts industrial-grade raw materials into precision-engineered assets through a sequence of CAD-driven machining and rigorous quality auditing. Many professional procurement officers face the recurring challenge of receiving batches that look acceptable on the surface but fail structurally under the stress of high-traffic commercial use or variable climate conditions. This happens because high-volume production requires a fundamental shift from artisanal craft to automated consistency, where even a minor deviation in moisture content or joinery tolerances can compromise thousands of units. By mastering the technical benchmarks of this workflow, you can move beyond aesthetic selection and perform deep-vein audits of a partner’s engineering capacity to ensure long-term durability and brand protection.

I. Scalable Furniture Manufacturing Process

The scalability of a furniture manufacturing process is determined by the factory’s ability to maintain tight tolerances across several thousand units using synchronized ERP systems and automated machining centers. Large-scale procurement demands a transition from manual variability to machine-led reliability, ensuring that the structural integrity of the first unit is identical to that of the ten-thousandth unit. To achieve this, modern facilities integrate real-time tracking of raw material throughput and machine uptime to mitigate the risks of bottlenecking during peak production cycles.

Managing Industrial Throughput Capacity

How do you verify if a facility can truly handle your volume without sacrificing the specialized residential solutions required for high-end markets? Here is the kicker: you must look past the floor space and analyze the integration between their procurement software and the actual output of the assembly lines.

- Automated material flow systems reduce human handling errors.

- Real-time ERP monitoring prevents unpredicted lead time extensions.

- Multi-shift operational capacity ensures deadline compliance for seasonal launches.

| Throughput Metric | Industrial Benchmark | Impact on Buyer Risk |

|---|---|---|

| Machine Uptime | > 95% | Prevents sudden production halts |

| Error Rate | < 0.5% | Minimizes batch inconsistencies |

| Daily Unit Capacity | 500+ Units | Supports rapid market scaling |

The synchronization of hardware and software within the facility provides a transparent window into the actual production velocity you can expect.

II. Design Engineering in Furniture Manufacturing Process

The engineering phase of the furniture manufacturing process acts as the blueprint for cost-efficiency and physical longevity by utilizing advanced CAD/CAM software to optimize material yield and joint strength. Successful bulk procurement relies on Design for Manufacturing and Assembly (DFMA) principles, which ensure that every component is engineered for maximum container loading and intuitive end-user assembly. Without this rigorous technical foundation, complex designs often suffer from high reject rates and excessive material waste that inflate the total cost of ownership.

Auditing CAD and CAM Technical Integration

Have you considered how a lack of digital precision in the early design stages could lead to catastrophic failures in the final assembly? Think about it: when you provide a concept, the engineering team must translate that vision into a machine-readable format that accounts for every millimeter of tolerance.

- Advanced CAD modeling identifies structural weak points before a single cut is made.

- CAM software optimizes the tool path for CNC machines to minimize lumber waste.

- Digital twin simulations allow you to visualize the stresses placed on joints during use.

| Design Feature | Technical Requirement | Strategic Benefit |

|---|---|---|

| Tolerance Level | +/- 0.5mm | Ensures perfect part interchangeability |

| Joint Optimization | Finite Element Analysis | Maximizes the weight-bearing capacity |

| Material Yield | > 85% | Lowers environmental impact and waste costs |

The bridge between conceptual design and physical reality is built on the accuracy of the underlying engineering data.

III. Materials in Furniture Manufacturing Process

Selecting the core lumber for a furniture manufacturing process is a critical decision point where you must balance aesthetic requirements with the technical necessity of moisture stabilization and FSC certification. High-volume production requires a reliable supply chain of raw timber that has been kiln-dried to specific thresholds to prevent the warping or checking that often occurs when wood moves between different global climates. Professional buyers must demand transparent documentation of the sourcing and seasoning of every board to mitigate the risk of post-production structural failures.

Verification of Wood Grading Standards

What steps are you taking to ensure that the timber in your order hasn’t been improperly seasoned or sourced from non-compliant forests? Make no mistake: the durability of your product line is entirely dependent on the moisture content and the grade of the lumber selected at the very start.

- Kiln-drying to 8-12% moisture content prevents the wood from shrinking or expanding.

- FSC certification ensures your supply chain meets global environmental compliance standards.

- Visual grading protocols filter out knots or cracks that could compromise structural integrity.

| Material Variable | Optimal Range | Operational Importance |

|---|---|---|

| Moisture Content | 8% – 12% | Critical for dimensional stability |

| Grading Class | FAS or Superior | Ensures surface clarity and strength |

| Certification | FSC / PEFC | Protects brand reputation and customs entry |

Strict adherence to material grading protocols serves as your primary insurance policy against environmental degradation of the finished goods.

IV. Precision CNC Machining for Large Volumes

Precision CNC (Computer Numerical Control) machining is the technological heartbeat of the modern furniture manufacturing process, offering a level of repeatability that manual routing simply cannot match. By utilizing multi-axis milling machines, factories can execute complex joinery and intricate silhouettes with sub-millimeter accuracy, which is essential for “knock-down” furniture that must be assembled by the end consumer. As you evaluate production partners, the sophistication and maintenance of their CNC fleet should be a primary indicator of their technical maturity and ability to deliver consistent quality at scale.

Evaluating Automated Routing Efficiency

Are you aware that even a slight misalignment in a borehole can render an entire batch of flat-pack furniture useless? Bottom line: the transition to fully automated cutting reduces human error to nearly zero, which is why you should prioritize facilities with multi-axis CNC capabilities.

- Multi-axis machines allow for complex geometries in a single setup.

- Laser-guided precision ensures every tenon and mortise fits perfectly.

- High-speed routing reduces the “per-unit” production time significantly.

| Machine Capability | Technical Specification | Production Outcome |

|---|---|---|

| Axis Count | 3-Axis to 5-Axis | Enables complex and curved designs |

| Spindle Speed | 18,000+ RPM | Produces smoother cuts and reduces sanding |

| Repetition Accuracy | < 0.1mm | Guarantees identical parts across batches |

Investing in automated precision is the only way to eliminate the “craftsmanship gap” that plagues high-volume manual production.

V. Structural Integrity During Batch Assembly

The assembly stage is where the individual components of the furniture manufacturing process are unified, requiring a technical focus on adhesive performance and the mechanical strength of specialized joinery. For bulk buyers, this phase must include rigorous “pre-fit” testing of the first article to ensure that the tolerances established in the engineering phase are being realized on the factory floor. Whether the product is fully assembled or ready-to-assemble, the application of pressure and the quality of the fastening hardware will determine the long-term safety and weight capacity of the piece.

Auditing Joint Strength and Hardware

How can you be certain that the joints in your furniture won’t loosen after six months of heavy commercial use? As it turns out, the choice between mortise-and-tenon or cam-lock joinery depends entirely on your intended weight-bearing requirements and the final destination of the product.

- Mortise-and-tenon joints provide the highest level of structural rigidity for solid wood.

- High-grade adhesives must be applied in climate-controlled environments for maximum bond.

- Industrial hardware should be tested for rust resistance and cycle durability.

| Assembly Factor | Industry Standard | Longevity Impact |

|---|---|---|

| Joinery Method | Mortise & Tenon | Superior resistance to racking forces |

| Adhesive Grade | Type II or III Water Resistant | Prevents delamination in humid climates |

| Fastener Torque | Calibrated Pneumatic | Ensures consistent structural tension |

The mechanical marriage of components is the final test of the factory’s ability to execute a sound engineering plan.

VI. Surface Durability in the Manufacturing Process

Finishing in the furniture manufacturing process is not merely an aesthetic choice but a technical barrier designed to protect the substrate from moisture, UV radiation, and daily abrasion. In a bulk production environment, consistent color and texture can only be achieved through automated spray booths or UV-curing lines that eliminate the airborne contaminants found in traditional open-air workshops. You should verify that the coatings used are not only durable but also compliant with international safety standards such as REACH or Prop 65, ensuring your inventory is safe for global distribution.

Compliance in Surface Treatment Systems

Do you know if your current finishing process is actually providing durable outdoor collections that can withstand 2,000 hours of direct salt-spray and UV exposure? Here is the deal: if the finish fails, the entire piece is compromised, which is why automated application and controlled curing are non-negotiable for bulk orders.

- UV-curing technology allows for an instant, hardened finish that is scratch-resistant.

- Electrostatic spray booths ensure an even coating on all 360 degrees of a component.

- Low-VOC coatings meet the strictest environmental regulations for indoor air quality.

| Coating Attribute | Technical Metric | Distribution Benefit |

|---|---|---|

| UV Resistance | ASTM G154 Standards | Prevents fading in sun-exposed areas |

| Hardness Rating | 2H – 4H Pencil Test | Minimizes shipping and handling damage |

| VOC Content | < 50g/L | Ensures compliance with health regulations |

A superior finish acts as a defensive shield, extending the lifespan of your products and reducing customer returns.

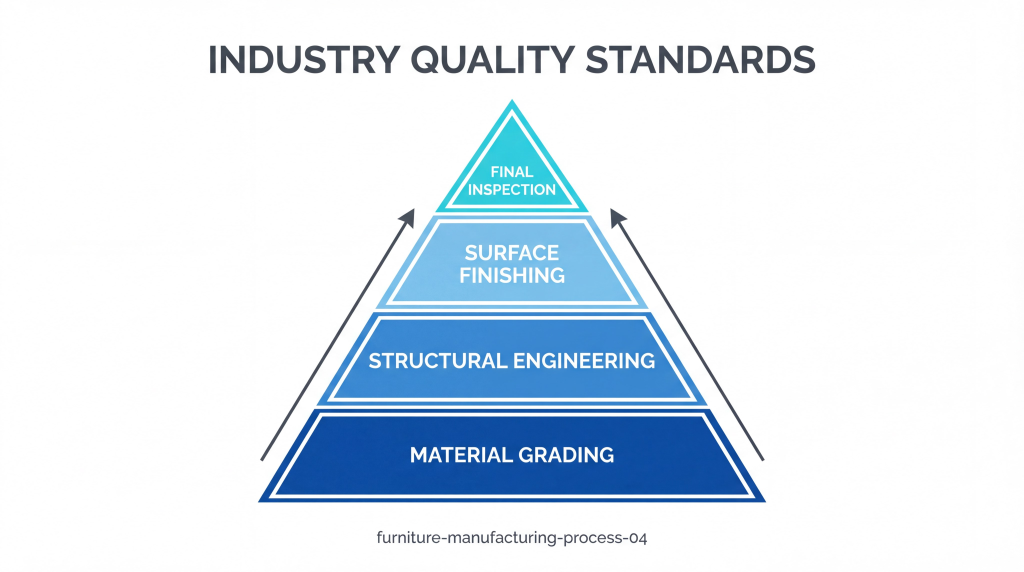

VII. Quality Control Protocols and Gate Checks

A robust quality control system within the furniture manufacturing process acts as the buyer’s internal audit, identifying defects at the source before they are packed into a container. Gate checks must occur at every critical transition—from moisture testing raw lumber to stress-testing the finished assembly—to ensure that the final shipment matches the approved master sample. By requiring a “First Article Inspection” and randomized “AQL” (Acceptable Quality Limit) testing, you can maintain control over the production standards without being physically present on the factory floor every day.

Implementing Multi-Stage Gate Checks

What is your strategy for catching a structural defect before it costs you thousands in logistics and replacement fees? Believe it or not, the most effective factories use a “stop-gate” methodology where a batch cannot move from cutting to finishing until it passes a 100% inspection of critical dimensions.

- Incoming material inspection rejects lumber with irregular moisture or grain defects.

- In-process monitoring ensures that CNC boreholes remain within a 0.1mm tolerance.

- Final batch testing includes load-bearing and drop tests to simulate real-world usage.

| QC Checkpoint | Method of Verification | Prevention Goal |

|---|---|---|

| Raw Material | Digital Moisture Meter | Eliminates warping and structural cracks |

| Assembly | First Article Inspection | Corrects fit issues before mass production |

| Final Audit | Randomized AQL Sampling | Prevents defective batches from shipping |

The presence of a structured quality pyramid is the ultimate indicator of a manufacturer’s commitment to your brand’s reputation.

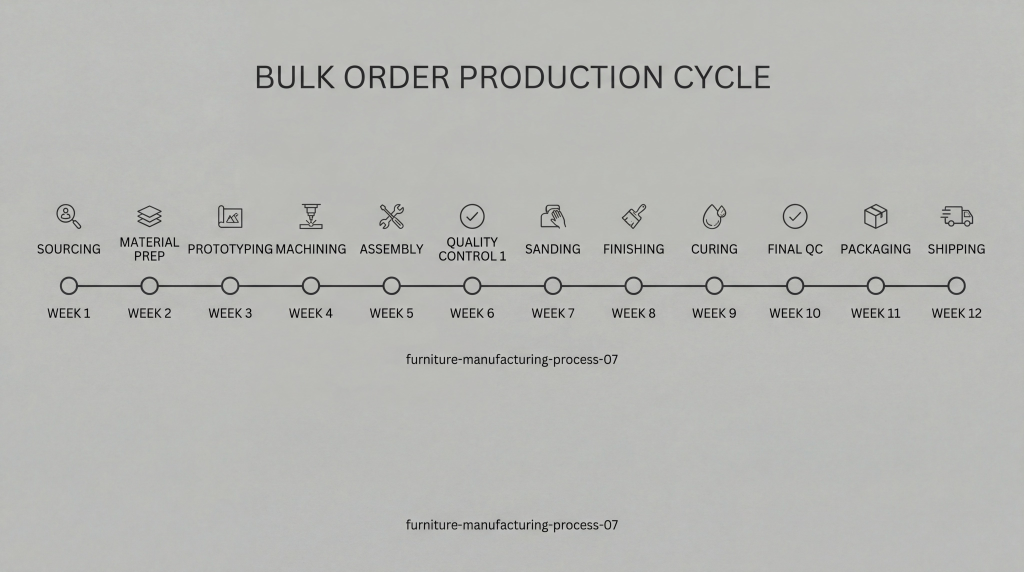

VIII. Prototyping in the Furniture Manufacturing Process

The prototyping phase of the furniture manufacturing process is the essential bridge between digital engineering and mass production, allowing you to test the physical reality of a design before committing to a full-scale run. A high-tier factory in a hub like Qingdao should be able to deliver a production-grade sample within 14 days, providing a tangible model that can be subjected to “torture tests” to identify any unforeseen structural flaws. For bulk buyers, the prototype is the final opportunity to refine dimensions, hardware choices, and assembly instructions to ensure a seamless market entry.

Stress Testing the Physical Sample

Could you be overlooking a critical design flaw that only reveals itself during a 100kg load-bearing test? Think about it: the prototype is not just for looking at; it is a sacrificial unit meant to be pushed to its absolute breaking point to verify the safety margins.

- Load-bearing tests simulate years of heavy usage in a compressed timeframe.

- Assembly trials verify that a layperson can put the piece together without specialized tools.

- Finish testing ensures the stain and lacquer are applied exactly as specified in the tech pack.

| Prototyping Stage | Purpose | Buyer Action |

|---|---|---|

| White Sample | Dimensional Verification | Approve the basic form and fit |

| Production Sample | Final Material/Finish Check | Signature approval for mass production |

| Torture Testing | Structural Safety Validation | Review the failure points and adjust |

A successful prototype acts as the “North Star” for the entire production team, ensuring everyone is aligned on the final expectations.

IX. Packaging Rules for International Logistics

Packaging is the final, and often most overlooked, technical step in the furniture manufacturing process, specifically designed to protect finished surfaces during the rigors of transoceanic shipping and “last-mile” delivery. Professional bulk buyers must insist on packaging that meets ISTA (International Safe Transit Association) standards, utilizing high-density foam, honeycomb cardboard, and corner protectors to minimize “shipping rash.” The packaging must also be engineered for maximum “cube utilization,” allowing you to fit more units into a container and significantly reducing the landed cost per item.

Engineering for Container Optimization

How much money are you losing every year by shipping “dead air” inside your furniture cartons? Make no mistake: the way a product is packed is just as important as how it is built, especially when you are calculating the logistics of thousands of units.

- ISTA 3A or 6B drop-test certification ensures the box can survive a 1-meter fall.

- Internal honeycomb structures provide 10x the crushing resistance of standard bubble wrap.

- Flat-pack engineering minimizes carton volume, doubling the capacity of a 40HC container.

| Packaging Component | Material Standard | Risk Mitigated |

|---|---|---|

| Outer Carton | 5-Ply or 7-Ply Corrugated | Prevents puncturing and moisture ingress |

| Internal Padding | High-Density EPE Foam | Eliminates surface scratching and denting |

| Box Integrity | 200lb Burst Strength | Protects the contents during stacking |

The goal of engineered packaging is to ensure that the quality achieved in the factory is the same quality that arrives at your customer’s door.

X. Regional Strength in the Manufacturing Process

The geographic location of a furniture manufacturing process plays a vital role in its efficiency, particularly in export hubs like Qingdao, Shandong, where a 20-year history of international trade has built a robust ecosystem of specialized suppliers. This proximity to major deep-water ports and a vast pool of skilled labor allows for predictable delivery schedules and rapid responses to custom design requests. When you partner with a facility in this region, you are not just buying a product; you are tapping into a specialized industrial cluster that understands the compliance, quality, and logistical requirements of the global market.

Leveraging Export Hub Infrastructure

Have you explored how a manufacturer’s proximity to a major port can save you weeks in transshipment delays? The reality is that the best furniture is made where the infrastructure is most mature, allowing for a seamless transition from the assembly line to the container ship.

- Direct access to Qingdao Port reduces domestic transport costs and lead times.

- Local access to FSC-certified wood and high-grade hardware simplifies the supply chain.

- A concentration of technical talent ensures your designs are handled by experts.

| Regional Advantage | Technical Benefit | Business Outcome |

|---|---|---|

| Port Proximity | < 50km from Qingdao Port | Predictable delivery and lower drayage |

| Supplier Density | 500+ Local Component Providers | Rapid sourcing of specialized hardware |

| Export Experience | 20+ Years of EU/US Compliance | Seamless customs and regulatory entry |

Selecting the right region is the final strategic decision that ensures your technical manufacturing process is supported by world-class logistics.

Summary of the Technical Workflow

Navigating the complexities of high-volume furniture procurement requires a shift in perspective—from seeing furniture as a finished object to seeing it as the result of a rigorous, repeatable technical system. By auditing the engineering, material stabilization, and automated precision of your manufacturing partner, you can mitigate the inherent risks of global sourcing.

If you are ready to elevate your procurement standards and discuss high-capacity production requirements, our technical support team is available to provide detailed engineering consultations. To understand how we apply these standards across our entire catalog, we invite you to explore our approach and see how our Shandong facility can secure your supply chain for the long term.

Frequently Asked Questions

Can I visit the factory to perform a mid-production technical audit?

Yes. We recommend this because it allows you to verify that the moisture stabilization and CNC tolerances are being strictly maintained according to your specifications.

What’s the best way to ensure consistent color across a batch of 5,000 chairs?

Automated spray booths. This is essential because manual application cannot maintain identical thickness and tint levels across a large volume of units.

How do I know if the hardware used is durable enough for commercial traffic?

Cycle-test documentation. You should always demand a 50,000-cycle test report for any hinges, sliders, or moving parts to verify they won’t fail in high-use environments.

Can I request a production-grade sample before committing to the full order?

Yes. This is the standard procedure because it serves as the physical “master sample” that both parties use to benchmark the final production quality.

What’s the best method for reducing shipping damage on flat-pack furniture?

ISTA-6 packaging standards. Using 7-ply corrugated boxes and internal honeycomb protection is the most effective way to ensure the product survives international transit.