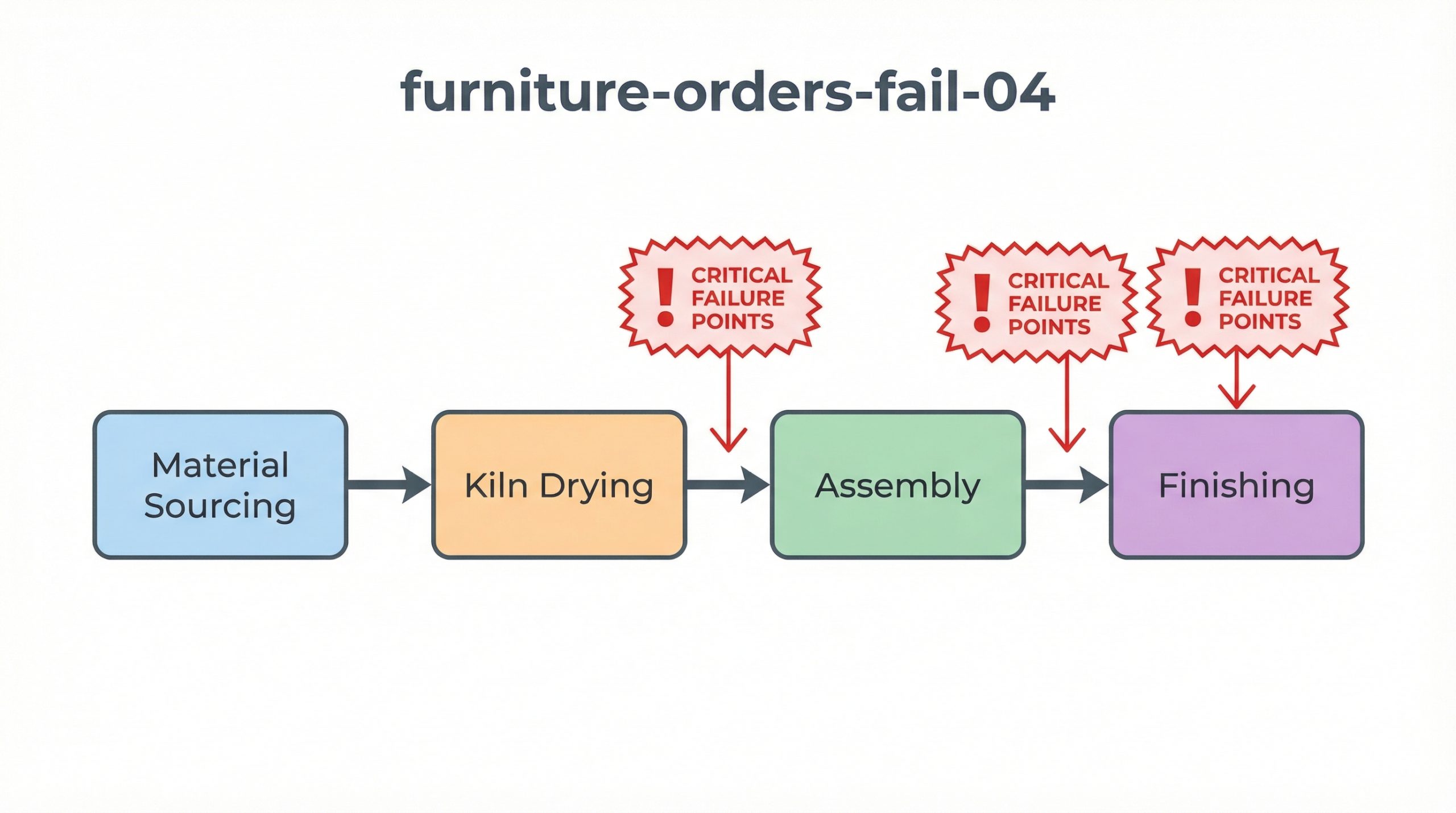

Furniture orders fail because of a critical misalignment between a buyer’s technical specifications and a factory’s internal production thresholds. Imagine the financial stress of unsealing a container only to discover warped table tops, delaminating veneers, or structural joints that fail basic stress tests. These scenarios represent significant capital loss and project delays that most procurement teams are ill-equipped to resolve post-shipment. The industry judges production success not by the beauty of a sample, but by the factory’s ability to adhere to standardized manufacturing rules and rigorous quality control (QC) protocols that identify failure points before goods leave the floor.

I. WHY YOUR FURNITURE ORDERS FAIL TODAY

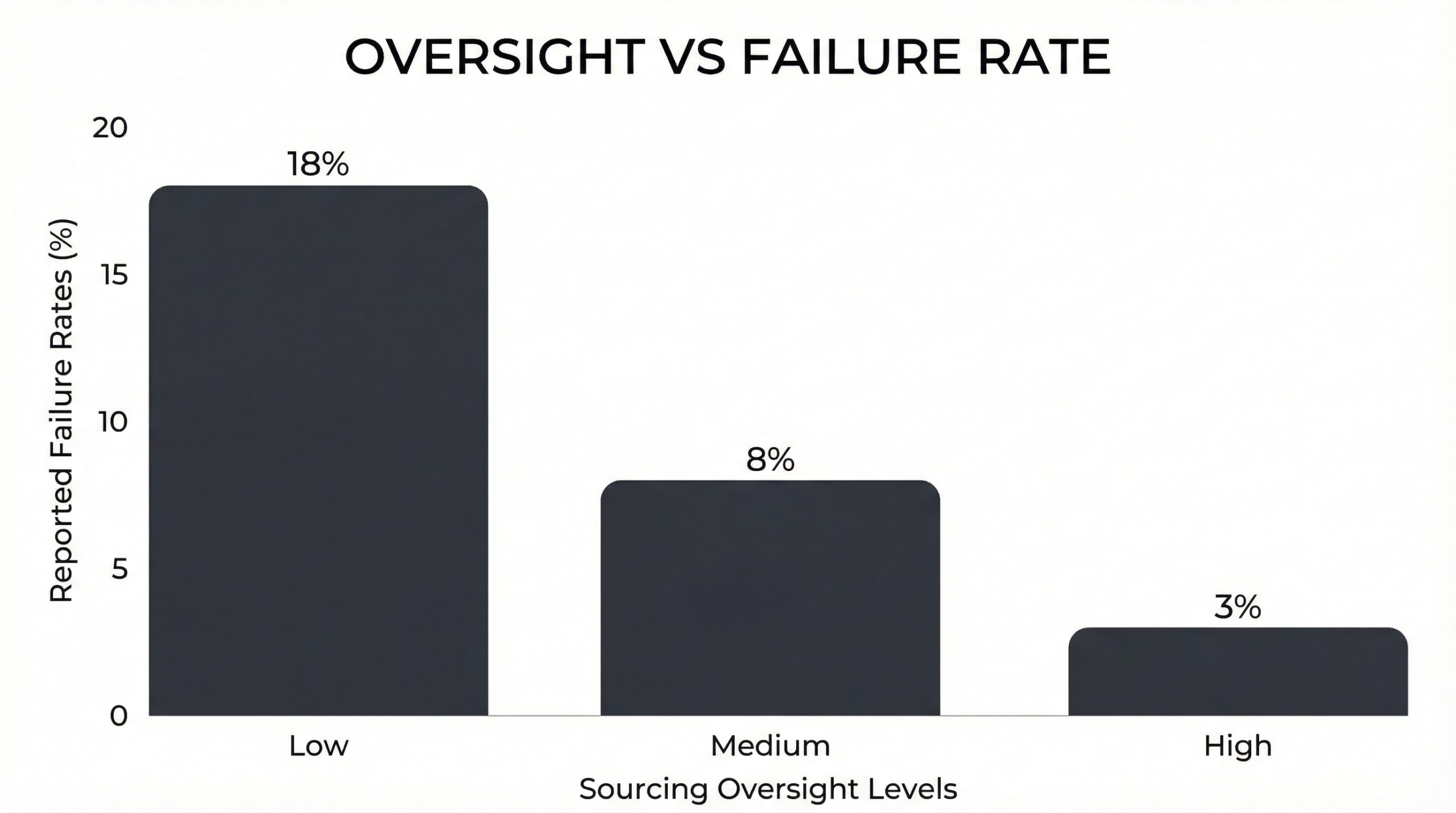

Inadequate oversight of the production floor is the primary reason furniture orders fail in the B2B sector. When buyers rely solely on email updates rather than physical audits, they lose visibility into the nuanced decisions made by factory floor managers. This lack of transparency allows for deviations in material density and assembly speed that ultimately compromise the final product’s integrity.

Is your oversight level sufficient?

Look at the data.

- Professional on-site auditing reduces defect rates by up to 15%.

- Third-party inspections act as an objective filter between production and shipping. These measures ensure that “standard” quality matches the buyer’s actual contract requirements.

Key Takeaway

The following table analyzes how oversight levels directly correlate to the probability of delivery success.

| Oversight Type | Impact on Failure Rate | Primary Benefit |

|---|---|---|

| Self-Inspection | High (15-20%) | Low cost but biased reporting |

| Remote Reporting | Moderate (8-12%) | Better than nothing; relies on trust |

| On-site Auditing | Low (<3%) | Real-time correction of assembly errors |

II. THE HIDDEN COST OF MATERIAL SUBSTITUTION

Substitution of core materials is a frequent catalyst when furniture orders fail during international sourcing. Factories often feel pressured to maintain margins amidst rising raw material costs, leading them to use unseasoned wood or lower-density fiberboards without informing the client. This objective reality means that what appears to be solid wood in a photo may actually be a compromised composite that will fail under environmental stress.

How does moisture content impact longevity?

It’s a simple rule of physics.

- Wood with a moisture content above 12% is prone to warping in dry climates.

- Inconsistent seasoning leads to internal cracks that emerge months after delivery. Buyers must demand kiln-drying certificates to judge the true stability of their timber.

Key Takeaway

This comparison highlights the material risks that lead to structural failure in wooden furniture.

| Material Component | Standard Rule | Failure Consequence |

|---|---|---|

| Timber Moisture | 8% – 12% | Warping, splitting, and joint separation |

| Adhesive Grade | E0 or E1 Standard | Formaldehyde off-gassing and delamination |

| Veneer Thickness | Min 0.6mm | Peeling and inability to sand/repair |

III. WHEN BULK FURNITURE ORDERS FAIL QUALITY

Batch inconsistency is the silent killer that ensures bulk furniture orders fail even after a successful prototyping phase. While a “Golden Sample” is often handcrafted by senior artisans, the mass production run is handled by general labor where speed is prioritized over precision. This transition from sample to scale is where the majority of dimensional and finishing errors occur.

Are hardware tolerances clearly defined?

Precision matters most here.

- Misaligned hinges cause drawer faces to rub and chip over time.

- Low-grade steel hardware leads to oxidation and structural weakness in humid environments. Standardized hardware testing is the only way to judge long-term durability in high-use settings.

Key Takeaway

The data below shows the common quality deviations found during mass production inspections.

| Quality Metric | Tolerance Level | Impact of Deviation |

|---|---|---|

| Dimensional Accuracy | +/- 1mm | Assembly failure for flat-pack goods |

| Finish Uniformity | Delta E < 2.0 | Visually mismatched sets in a single room |

| Hardware Load | 50kg per hinge | Premature breakage and safety liability |

IV. EVALUATING REGIONAL SUPPLY CHAIN RISKS

A lack of geographical intelligence causes many furniture orders fail, especially when buyers do not understand the manufacturing ecosystem of hubs like Shandong. Regional variations in labor skill and timber sourcing play a massive role in whether a factory can actually meet the complexity of your design. Deciding to source from a specialized region requires an understanding of their local standard operating procedures.

Does the regional climate affect the wood?

Climate is a factor.

- Factories in high-humidity regions often struggle with finish adhesion.

- Transitioning wood from a humid factory to a dry destination causes immediate shrinkage. Regional experts adjust kiln-drying times to compensate for these environmental shifts.

Key Takeaway

This analysis outlines the regional factors that buyers must judge before placing large-scale orders.

| Regional Factor | Advantage | Potential Failure Point |

|---|---|---|

| Timber Proximity | Lower material costs | Variable wood grades if not graded on-site |

| Specialized Labor | High craftsmanship | Labor shortages during peak agricultural seasons |

| Logistics Hubs | Faster export times | Port congestion in major shipping corridors |

V. WHY CUSTOM FURNITURE ORDERS FAIL TESTING

Aesthetics often override structural engineering, which is why custom furniture orders fail safety compliance audits. When a design is “bespoke,” it hasn’t been through the years of refinement that standard catalog items have endured. Buyers often decide on a visual style without realizing they have sacrificed the necessary support structures required for commercial use.

Have load-bearing tests been performed?

Safety is non-negotiable.

- Chairs must withstand static and dynamic weight tests to prevent collapse.

- Cantilevered designs often fail if the internal steel reinforcement is omitted. Requesting a BIFMA-standard test report is the only way to judge structural safety.

Key Takeaway

Custom designs require specific testing thresholds to avoid post-purchase failure.

| Test Category | Industry Standard | Failure Result |

|---|---|---|

| Static Weight | 150kg+ for seating | Frame fracture or leg collapse |

| Finish Rub Test | 50,000+ Martindale | Surface wear and pigment transfer |

| Stability Test | Non-tip at 10-degree incline | Liability risks in commercial environments |

VI. JUDGING LOGISTICAL GAPS AND DAMAGE RISK

International shipping and poor container loading are common reasons furniture orders fail at the destination port. Even the highest quality dining table is worthless if it arrives with “crushed-corner syndrome” due to inadequate carton ply or lack of internal foam protection. Buyers must decide on a packaging specification that anticipates the rough handling of ocean freight.

Is packaging drop-test certified?

Think of the journey.

- Standard 5-ply cartons often fail when stacked ten units high.

- Edge protectors are the difference between a pristine product and a 100% loss. Judging the packaging quality is just as important as judging the furniture itself.

Key Takeaway

The table below provides a logistical checklist for mitigating damage during long-distance transit.

| Logistic Phase | Hazard | Mitigation Strategy |

|---|---|---|

| Container Loading | Over-stacking/Crushing | Enforce “No Stacking” rules for heavy pallets |

| Sea Transit | Humidity/Container Rain | Use industrial-grade silica gel and moisture barriers |

| Last-Mile Delivery | Vibration/Impact | Honeycomb cardboard and 360-degree foam wrap |

Utility is the judge of success, and many office furniture orders fail when technical integrations like power modules and cable management are treated as afterthoughts. In a professional environment, furniture must facilitate technology, not hinder it. Deciding on the wrong desk height or non-adjustable features leads to immediate user dissatisfaction and costly replacements.

Are power modules compatible with your market?

Voltage is only the start.

- Plug configurations and safety certifications vary significantly by country.

- Integrated USB ports often fail if the transformer is of low quality. Verify that all electronic components hold UL, CE, or SAA certifications before shipping.

Key Takeaway

The following utility metrics define whether an office furniture order is a success or a failure.

| Utility Feature | Requirement | Common Failure Cause |

|---|---|---|

| Cable Management | Integrated hidden trays | Messy wiring that creates trip hazards |

| Height Adjustability | Smooth motor movement | Motor burnout due to low weight capacity |

| Surface Durability | Scratch-resistant laminate | Cheap veneers that chip under heavy laptop use |

VIII. DECIDING BETWEEN RESIDENTIAL DESIGN RISKS

Strategic procurement teams recognize that residential furniture orders fail when the factory uses “showcase” materials that lack daily durability. A soft-wood frame might look excellent in a catalog, but it will dent and scratch within weeks of domestic use. Buyers must judge the material hardness and finish resilience against the intended lifecycle of the product.

Is the wood finish durable enough for daily use?

Consider the spills.

- Acidic liquids like lemon or wine will eat through low-grade lacquers.

- Heat resistance is critical for dining surfaces to prevent permanent white rings. Always specify a high-grade polyurethane (PU) or UV finish for high-traffic surfaces.

Key Takeaway

This table analyzes the material risks specific to residential furniture procurement.

| Residential Component | Ideal Spec | Risk of Failure |

|---|---|---|

| Wood Hardness | Janka Scale > 1000 | Soft woods (Pine/Fir) dent too easily |

| Fabric Durability | 30,000+ Rubs | Pilling and thinning after 6 months |

| Joint Construction | Mortise & Tenon | Glued butt-joints fail under lateral pressure |

IX. WHY HIGH-VOLUME FURNITURE ORDERS FAIL

Operational strain is the primary reason high-volume furniture orders fail during a factory’s peak season. When a facility is pushed beyond its capacity, the Quality Management System (QMS) is the first thing to be compromised to meet deadlines. Deciding to scale requires evaluating the factory’s true throughput and their ratio of QC inspectors to production workers.

Is the factory QC staff-to-worker ratio high?

Numbers tell the truth.

- A ratio of 1:10 is the industry gold standard for high-end furniture.

- Anything over 1:30 suggests that the factory is “self-policing” rather than auditing. High-volume success depends on a factory’s ability to replicate quality across every single container.

Key Takeaway

Evaluating factory capacity helps buyers decide if a supplier can handle rapid scaling without failure.

| Scaling Metric | Success Indicator | Failure Warning |

|---|---|---|

| Lead Time Consistency | +/- 5 days | Delays that suggest material shortages |

| Sub-supplier Audit | Direct factory control | Outsourcing components to unknown workshops |

| Automation Level | High CNC utilization | Over-reliance on manual, variable labor |

X. HOW TO ENSURE FURNITURE ORDERS FAIL NEVER

To ensure your furniture orders fail never, you must move from a transactional mindset to an auditing mindset. This means treating every production milestone as an industry-governed checkpoint that requires validation. By implementing an “Evaluating-Judging-Deciding” framework, buyers can eliminate the variables that lead to warped wood, broken joints, and lost revenue.

Will you prioritize audit transparency?

Transparency is the solution.

- Unannounced factory visits keep the production team accountable.

- Shared QC reports allow for joint decision-making on rework before shipping. Investing in professional oversight is the most cost-effective way to secure your furniture supply chain.

Key Takeaway

This final table summarizes the strategic decisions needed to prevent order failure entirely.

| Action Step | Objective | Result |

|---|---|---|

| Pre-Production Meeting | Align specs with factory capabilities | Zero material substitutions |

| Mid-Line Inspection | Correct assembly errors early | Reduced rework costs at the end |

| Loading Supervision | Verify packaging and container seals | 100% damage-free delivery |

CONCLUSION

The industry has proved that failure is not a matter of bad luck, but of bad oversight. By understanding the real causes that other buyers miss—such as regional climate risks, material substitution, and the scaling limits of QC systems—you can transform your procurement process into a predictable, high-yield operation. We encourage you to explore our approach to see how we integrate these industry rules into every piece we manufacture in Shandong. Our vision is a supply chain where quality is a constant, and the stress of the “unsealed container” is a thing of the past.

FAQ

Can I rely on the factory’s own QC report?

Judgment: Generally, no. Reasoning: Factory-led reports are inherently biased toward meeting shipping deadlines rather than finding defects; third-party audits are required for objective validation.

Should I choose the lowest-cost factory if the sample is good?

Judgment: High risk. Reasoning: Low-cost providers often use “Golden Samples” to hide systemic production weaknesses that emerge only during high-volume runs.

Is kiln-drying really necessary for indoor furniture?

Judgment: Absolute necessity. Reasoning: Without kiln-drying, the wood’s internal moisture will inevitably react to your local HVAC systems, leading to irreversible warping or splitting.

Can packaging alone prevent all shipping damage?

Judgment: No, but it mitigates 90% of risks. Reasoning: While packaging can’t stop a container from falling off a ship, it can prevent the crushing and vibration damage that ruins 15-20% of poorly packed furniture.

Does a higher price always guarantee no failures?

Judgment: Not necessarily. Reasoning: Price reflects a factory’s overhead or branding, but only a rigorous Quality Management System (QMS) and active buyer oversight guarantee a defect-free order.