Struggling with inconsistent quality or vague manufacturing specs? Poorly defined wooden bedroom furniture orders lead to costly delays and high return rates. We provide the technical clarity you need to secure premium manufacturing results.

Wooden bedroom furniture consists of beds, nightstands, and storage units crafted from solid timber or wood-based composites. For B2B production, specifying the species, moisture content, joinery methods, and finish types is essential to ensure durability, aesthetic consistency, and long-term structural integrity in commercial environments.

I. Defining Wooden Bedroom Furniture Standards

Wooden bedroom furniture standards serve as the technical blueprint that governs the structural integrity and aesthetic finish of every piece in a production run. By establishing clear definitions for material thickness and load-bearing capacities, you eliminate the gray areas that often lead to manufacturing defects. This comprehensive framework ensures that your wooden bedroom furniture meets the rigorous demands of retail and hospitality environments.

The Scope of Commercial Bedroom Sets

Commercial bedroom sets encompass a wide array of functional pieces including bed frames, headboards, nightstands, and large-scale wardrobes designed for heavy use. You must define the dimensions and weight limits for each item to ensure they fit the intended spatial layout and safety requirements. This phase involves mapping out the entire collection to maintain design continuity across diverse manufacturing lines.

Why Material Specification Matters

Here is the kicker: Without precise material specifications, factories may substitute cheaper woods that fail under stress. You need to dictate the exact density and fiber strength required for legs and support rails to prevent long-term sagging. High-quality production hinges on your ability to enforce these material rules from the very first prototype.

Standard Components in B2B Production

- Headboards must feature integrated mounting hardware for wall or frame attachment.

- Drawer boxes require specific bottom panel thicknesses to support weight without bowing.

- Support slats for bed frames should be spaced no more than three inches apart for mattress longevity.

Key Takeaway: Establishing rigid standards at the outset protects your brand from structural failures and ensures a uniform product experience for the end user.

| Standard Element | Requirement Specification | Compliance Metric |

|---|---|---|

| Frame Thickness | Minimum 25mm for primary rails | Caliper Measurement |

| Load Capacity | 250kg for standard bed frames | Stress Test Report |

| Surface Smoothness | Sanding to 220 grit minimum | Visual/Touch Audit |

| Edge Treatment | 2mm radius ease on all corners | Template Matching |

This table summarizes the core physical requirements that must be verified during the initial sampling phase of production.

II. Specifying Raw Wooden Bedroom Furniture

Specifying raw wooden bedroom furniture requires a deep understanding of timber grades and how natural characteristics affect the final appearance of the product. You must choose between clear-grade woods and those that allow for natural knots or mineral streaks based on the desired design aesthetic. High-quality wooden bedroom furniture starts with a strict selection process that filters out timber with structural flaws like heart-shake or excessive sapwood.

Selecting Primary Hardwood Stocks

Selecting the right hardwood stock involves evaluating the Janka hardness rating to ensure the surface resists dents and scratches in high-traffic areas. You should request samples of the products from the current inventory to verify the grain consistency and color range of the raw lumber. Establishing a baseline for acceptable grain patterns prevents wide variances that could look disjointed when the furniture is assembled in a room.

Grade Requirements for Visual Surfaces

The truth is, Visual surfaces demand a higher grade of timber than internal support structures or drawer bottoms. You must specify ‘Grade A’ for all exposed panels to ensure a premium look that justifies the investment in solid wood construction. If the factory uses lower-grade wood for hidden components, ensure it still meets the necessary density requirements for structural stability.

Certification and Origin Tracking

- Request FSC or PEFC documentation to verify the timber is harvested from legally managed forests.

- Require a Chain of Custody (CoC) certificate to track the wood from the forest floor to the factory.

- Ensure that all imported timber complies with the Lacey Act or EUTR regulations to avoid legal complications.

Key Takeaway: Clear grading and certification requirements ensure that your raw material inputs are both high-quality and legally compliant for global markets.

| Material Property | Hardwood (e.g., Oak) | Softwood (e.g., Pine) | Judgment |

|---|---|---|---|

| Surface Durability | Very High | Low to Moderate | Hardwood is superior for retail |

| Structural Stability | High | Moderate | Hardwood resists warping better |

| Cost Per Board Foot | Premium | Budget-Friendly | Softwood is better for internals |

| Finish Absorption | Even | Variable/Blotchy | Hardwood provides more luxury |

This comparison indicates that while hardwoods carry a higher cost, their performance metrics are essential for premium bedroom collections.

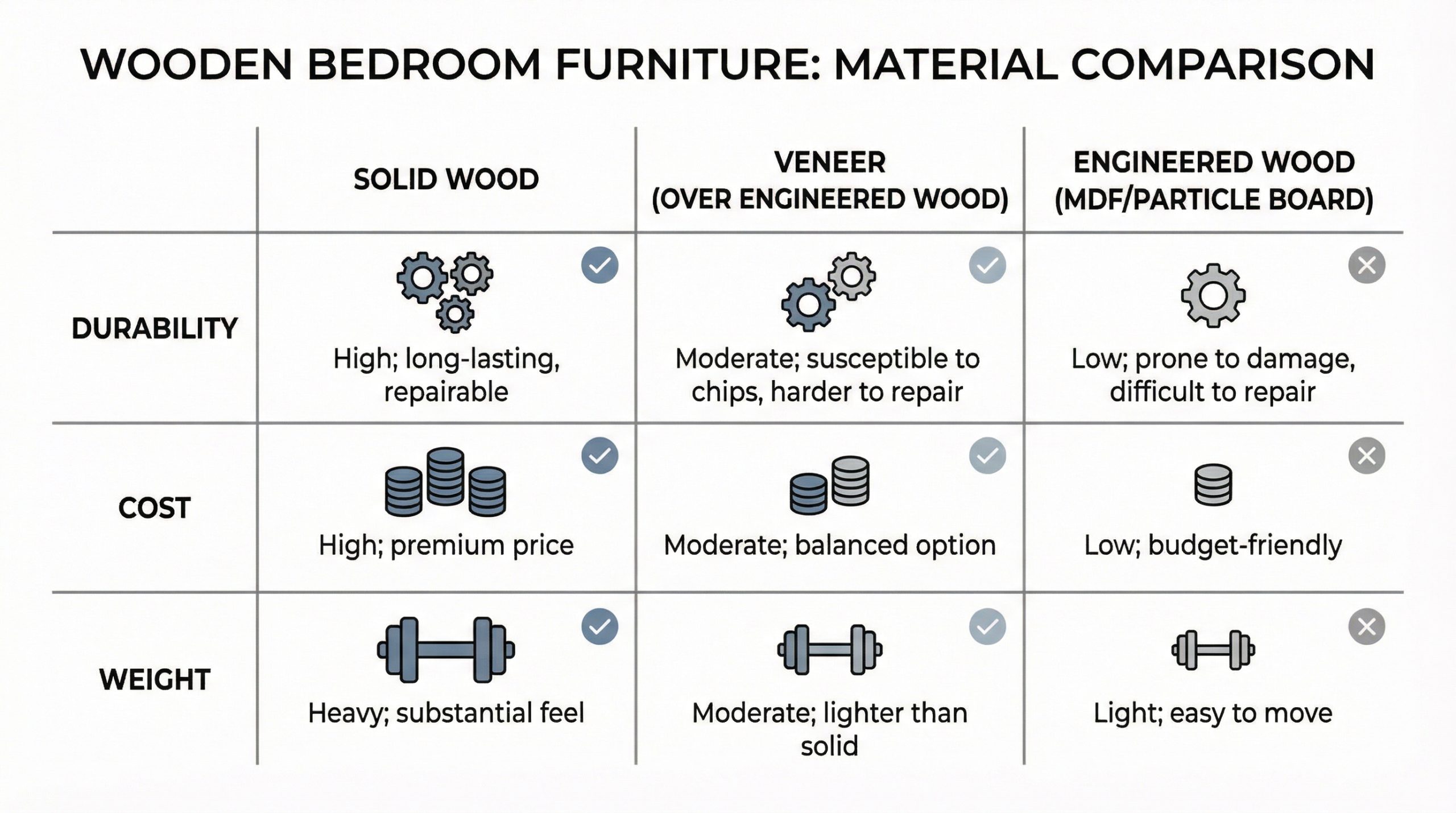

III. Wooden Bedroom Furniture: Solid vs. Veneer

Determining the balance between solid timber and veneer is the most critical decision for the cost and durability of your wooden bedroom furniture. Solid wood offers unmatched longevity and the ability to be refinished, while veneers provide a way to achieve exotic looks at a lower price point. Most professional-grade wooden bedroom furniture utilizes a hybrid approach where structural components are solid and large panels are veneered to minimize wood movement.

Performance Metrics for Solid Timber

Solid timber is prized for its substantial weight and the tactile quality it adds to high-touch surfaces like drawer fronts and tabletops. You should specify solid wood for any component that will experience significant wear or requires intricate carving. Because solid wood expands and contracts with the seasons, your production specs must include allowances for natural movement in the assembly.

The Utility of High-Quality Veneers

Think about this: Veneers are not just a cost-cutting measure; they offer superior stability for large surfaces like wardrobe doors and side panels. By using a stable core like plywood or MDF, you can prevent the large-scale warping that often plagues wide solid wood boards. Modern slicing techniques allow you to select specific grain patterns, such as book-matching, that are impossible to achieve with solid planks.

Hybrid Construction for Cost Control

- Use solid wood for the frame and legs to provide the primary structural support.

- Apply matching veneers to the side panels and internal shelves to reduce the overall weight and cost.

- Ensure the edge-banding on veneered panels is at least 2mm thick to prevent peeling and damage.

Key Takeaway: A strategic mix of solid wood and veneer maximizes the benefits of both materials, offering beauty, stability, and cost-efficiency.

| Construction Type | Durability | Repairability | Stability |

|---|---|---|---|

| Full Solid Wood | Maximum | High (Sandable) | Low (Moves) |

| Veneer over Plywood | High | Moderate | Very High |

| Veneer over MDF | Moderate | Low | Maximum |

| Solid Frame / Veneer Panel | High | Moderate | High |

This summary illustrates why the hybrid approach is favored in commercial furniture for balancing performance and reliability.

IV. Essential Wood Species for Procurement

Selecting the right wood species is a foundational step in defining the price, color, and marketability of your furniture line. Each species has unique grain characteristics and staining properties that will dictate the final look of your bedroom sets. Our about-us page highlights our extensive experience in selecting timber that meets both aesthetic and structural requirements for international clients.

Oak: The Industry Benchmark for Strength

Oak remains the most popular choice for heavy-duty furniture because of its open grain and exceptional resistance to physical impact. You can choose between White Oak for a more modern, neutral tone or Red Oak for a traditional, warm appearance. Its ability to take stains evenly makes it a versatile option for brands that offer multiple colorways in the same collection.

Maple and Cherry: High-End Aesthetics

Look no further: Maple and Cherry are the go-to choices for designers seeking a smooth, closed-grain finish that feels sophisticated to the touch. Maple is incredibly hard and provides a bright canvas for light finishes, while Cherry is famous for its natural darkening over time. Specifying these woods signals a commitment to premium quality and timeless design to your customers.

Walnut and Exotic Species Selection

- Walnut is highly sought after for mid-century modern designs due to its rich chocolate tones.

- Exotic species like Teak or Rosewood require careful sourcing to ensure environmental sustainability and legal compliance.

- Consider Ash as a cost-effective alternative to Oak when you need a similar grain pattern at a lower price.

Key Takeaway: The choice of species defines the character of the furniture and must be aligned with your target market’s preferences and budget.

| Wood Species | Janka Hardness | Primary Use | Color Range |

|---|---|---|---|

| White Oak | 1,360 lbf | Frames & Tops | Light Tan to Brown |

| Hard Maple | 1,450 lbf | High-Wear Units | Creamy White |

| Black Walnut | 1,010 lbf | Luxury Accents | Deep Brown |

| Yellow Pine | 690 lbf | Internal Bracing | Yellowish White |

This table provides a snapshot of how different species contribute to the structural and visual goals of your production.

V. Joinery in Wooden Bedroom Furniture Production

The quality of joinery in wooden bedroom furniture determines whether a piece will last for decades or wobble after just a few months of use. You should always specify mechanical joints over simple butt joints that rely solely on glue for their strength. Robust wooden bedroom furniture requires time-tested techniques like dovetails and mortise-and-tenon connections to withstand the stresses of shipping and daily operation.

Dovetail and Mortise Joinery Techniques

Dovetail joints are the gold standard for drawer construction because their interlocking shape prevents the drawer front from pulling away over time. For the main frame of beds and cabinets, mortise-and-tenon joints provide the surface area needed for a permanent, rock-solid bond. You must insist on these techniques in your technical drawings to ensure the factory allocates the necessary CNC time for precision cutting.

Corner Block Reinforcement Standards

But wait, there’s more. Even the best joints can benefit from secondary reinforcement, especially in heavy items like dressers and bed frames. You should require corner blocks that are both glued and screwed into the frame to provide maximum lateral stability. These small additions are a low-cost way to drastically reduce the number of structural failures in the field.

Hardware Integration and Pre-Drilling

- Specify pre-drilled holes for all handles and knobs to ensure perfectly centered alignment across the batch.

- Use high-quality European-style hinges and soft-close drawer slides for a premium user experience.

- Require threaded metal inserts for any component that must be assembled and disassembled by the end user.

Key Takeaway: Precision joinery and reinforced corners are the hallmarks of well-engineered furniture that can survive the rigors of the B2B supply chain.

| Joinery Method | Strength Level | Common Application | Quality Indicator |

|---|---|---|---|

| English Dovetail | Maximum | Drawer Fronts | Tight, gap-free pins |

| Mortise and Tenon | Very High | Bed Frames | Flush, square fit |

| Dowel Joint | Moderate | Shelf Supports | Glue squeeze-out |

| Cam-Lock | Low | RTA Furniture | Hidden by covers |

This judgment table highlights why traditional joinery methods remain the preferred choice for high-end furniture manufacturing.

VI. Finishing Wooden Bedroom Furniture

The finishing stage is where your wooden bedroom furniture receives its final protection against moisture, oils, and physical abrasions. A well-applied finish not only enhances the natural beauty of the wood grain but also seals the surface to prevent the timber from drying out. Consistent finishing processes are vital for wooden bedroom furniture to ensure that every piece in a set matches perfectly under different lighting conditions.

Protective Coatings and Gloss Levels

Protective coatings like catalyzed lacquer or polyurethane provide a hard shell that resists the chemicals found in household cleaners. You should define the gloss level—whether matte, satin, or high-gloss—in your specification documents to maintain brand consistency. Requesting a “wet film thickness” report from the factory can help you verify that the finish is thick enough to provide long-term protection.

Staining Consistency Across Batches

The reality is, Wood is a natural product that absorbs stain differently from board to board, creating potential color mismatches. You must require the factory to use a “control sample” for every batch to ensure the final color stays within an acceptable range. Multi-step staining processes, including toners and glazes, are often necessary to achieve a uniform look on different wood species.

Safety Compliance for Finishing Chemicals

- Ensure all finishes are low-VOC (Volatile Organic Compounds) to comply with air quality standards.

- Verify that the coatings are lead-free and safe for use in residential environments.

- Request documentation showing compliance with international standards like REACH or California Proposition 65.

Key Takeaway: A high-performance finish is essential for both the aesthetic appeal and the physical longevity of your wooden products.

| Finish Type | Durability | Repairability | Environmental Impact |

|---|---|---|---|

| Nitrocellulose | Low | High | High VOC |

| Catalyzed Lacquer | High | Moderate | Moderate VOC |

| Water-Based Poly | High | Moderate | Low VOC |

| Hardwax Oil | Moderate | Very High | Very Low VOC |

This table provides a summary of the trade-offs between different finishing technologies commonly used in the furniture industry.

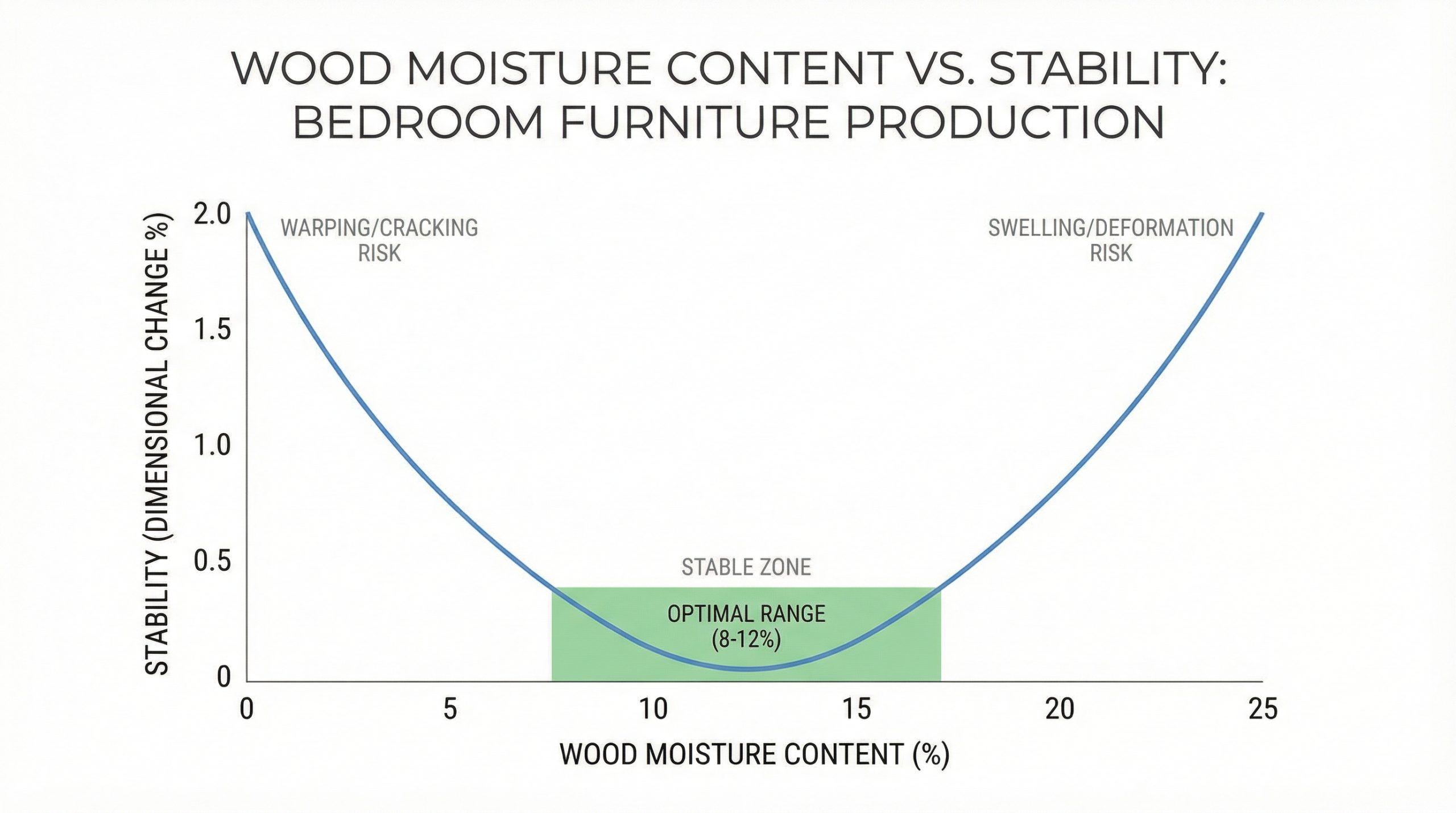

VII. Managing Wood Moisture and Stability

Managing moisture is the most technically challenging aspect of producing wooden furniture for a global market. Wood is hygroscopic, meaning it will always try to reach an equilibrium with the humidity of its surrounding environment. Our factory employs advanced climate control systems to ensure that timber is processed at the optimal moisture levels for its destination country.

The Science of Kiln Drying Processes

Kiln drying is the process of slowly removing moisture from green lumber to a target percentage, usually between 6% and 10%. You must specify the final moisture content (MC) based on whether the furniture will be sold in a desert climate or a humid coastal region. Proper drying prevents the internal stresses that cause wood to crack or split as it adjusts to its new home.

Equilibrium Moisture Content for Export

The secret is: If you ship furniture with a high moisture content to a dry climate, the wood will shrink, leading to loose joints and cracked panels. You need to ensure the factory monitors the Equilibrium Moisture Content (EMC) throughout the entire production cycle. This technical oversight is what separates world-class manufacturers from those who experience high failure rates in export markets.

Preventing Warping in Varied Climates

- Specify the use of “breadboard ends” on large tables to allow the wood to expand and contract without warping.

- Ensure that both sides of a panel are finished equally to prevent uneven moisture absorption.

- Request that all end-grain surfaces be sealed immediately after cutting to slow down moisture exchange.

Key Takeaway: Managing moisture content is a non-negotiable requirement for ensuring the structural stability of wooden products in international trade.

| Climate Zone | Target Moisture % | Risk of Neglect | Preventive Measure |

|---|---|---|---|

| Arid (e.g., Dubai) | 6% – 8% | Structural Cracking | Extra Kiln Time |

| Temperate (e.g., UK) | 8% – 11% | Joint Loosening | Climate Control |

| Tropical (e.g., SE Asia) | 12% – 15% | Mold / Swelling | Sealed Finishing |

| Generic Export | 8% – 10% | Variable Movement | Hybrid Construction |

The data above shows how specific your moisture requirements must be to match the local environment of your end-user.

VIII. QC for Wooden Bedroom Furniture

Quality control for wooden bedroom furniture must be proactive rather than reactive to catch issues before they are baked into the final product. You cannot rely on a final check alone; inspections must occur at every critical stage, from lumber selection to final assembly. Rigorous QC for wooden bedroom furniture ensures that your brand reputation remains intact and your warranty claims stay low.

First-Article Inspection Protocols

A first-article inspection (FAI) is conducted on the very first unit off the production line to verify that the factory has correctly interpreted your specifications. You should personally review this sample or hire a third-party inspector to check every dimension, joint, and finish detail. This is your last chance to make adjustments before the factory commits to a full-scale production run of hundreds of units.

In-Line Production Monitoring Steps

But that’s not all. In-line inspections allow you to see the “skeleton” of the furniture before the finish hides any potential defects. You should check the moisture content of the wood, the quality of the glue application, and the precision of the CNC cuts during this phase. Catching a mistake here can save you from having to reject an entire container of finished goods later.

Final Assembly and Hardware Testing

- Test every drawer for smooth operation and ensure the soft-close mechanisms are properly tensioned.

- Verify that all pieces in a set have consistent color and grain matching.

- Conduct a “drop test” on the packaging to ensure the furniture can survive the bumps of local delivery services.

Key Takeaway: A multi-stage quality control process is the only way to guarantee that your production meets the high standards of the B2B market.

| Inspection Phase | Critical Checkpoint | Target Result | Method |

|---|---|---|---|

| Raw Material | Moisture Content | 8% (+/- 2%) | Digital Meter |

| White Body | Joint Tightness | Zero Visible Gaps | Feeler Gauge |

| After Finishing | Color Matching | Delta E < 2.0 | Spectrometer |

| Final Packaging | Box Integrity | ISTA 3A Pass | Drop Testing |

This analytical guide emphasizes the importance of using objective measurements throughout the manufacturing process to ensure quality.

IX. Sustainable Sourcing Strategies

Sustainable sourcing is no longer an option but a requirement for modern B2B procurement in the furniture industry. You must ensure that your supply chain respects both environmental regulations and ethical labor practices to protect your brand from reputational risk. If you have questions about our compliance standards, please contact us to receive our latest sustainability report and factory audit results.

Environmental Compliance Certifications

Certifications such as FSC (Forest Stewardship Council) provide a transparent way to prove that your wood is sourced from responsibly managed forests. You should also look for factories that utilize renewable energy sources or have robust programs for recycling wood waste into briquettes or particleboard. These green credentials are increasingly important to eco-conscious consumers and corporate buyers.

Waste Reduction in Large Scale Orders

Think about it this way: Efficient manufacturing not only saves the planet but also saves you money by reducing material costs. You should work with factories that use advanced nesting software to maximize the yield from every board foot of lumber. By minimizing off-cuts and sawdust, you can lower the overall environmental footprint of your wooden bedroom furniture production.

Ethical Labor and Factory Standards

- Ensure the factory complies with local labor laws regarding wages, working hours, and safety.

- Verify that no child or forced labor is used anywhere in the supply chain.

- Look for BSCI or Sedex audits as a sign of the factory’s commitment to social responsibility.

Key Takeaway: Integrating sustainability into your procurement strategy builds long-term value and ensures your products meet the highest ethical standards.

| Sustainability Goal | Implementation Strategy | Expected Benefit |

|---|---|---|

| Carbon Reduction | Regional Timber Sourcing | Lower Logistics Cost |

| Zero Waste | Wood Chip Recycling | Secondary Revenue |

| Chemical Safety | Water-Based Finishes | Healthier Interiors |

| Social Impact | Fair Wage Audits | Stable Workforce |

This summary highlights how sustainable practices create a “win-win” scenario for the manufacturer, the buyer, and the environment.

X. Global Logistics and Bulk Shipping

Shipping bulk orders of furniture across the globe requires specialized packaging and careful container planning to avoid damage during transit. Because wooden furniture is heavy and often features delicate finished surfaces, standard shipping methods are usually insufficient. You must specify reinforced packaging materials and clear handling instructions to ensure your wooden bedroom furniture arrives in showroom condition.

Packaging Requirements for Ocean Freight

Ocean freight exposes furniture to high humidity and significant physical movement, necessitating a multi-layered packaging approach. You should require double-walled corrugated boxes, EPE foam edge protectors, and moisture-absorbing silica gel packs inside every carton. This level of protection is a small insurance policy against the thousands of dollars in losses that can occur from shipping damage.

Container Loading Optimization Plans

Here is the best part: Proper container loading is a science that maximizes the space you are paying for while preventing the load from shifting. You should request a “loading plan” that shows how different-sized boxes will be stacked to fill the container without crushing the bottom units. Efficient loading can reduce your per-unit shipping costs by as much as 15%, significantly improving your margins.

Damage Mitigation and Insurance Rules

- Use high-quality plastic strapping to secure heavy items to their pallets within the container.

- Photograph the container at various stages of loading to provide evidence in case of an insurance claim.

- Ensure your freight insurance covers “concealed damage” that might only be discovered when the customer unboxes the item.

Key Takeaway: Proactive logistics management and superior packaging are essential for maintaining the value of your furniture throughout the global supply chain.

| Shipping Factor | LCL (Less than Container) | FCL (Full Container Load) | Judgment |

|---|---|---|---|

| Risk of Damage | High | Low | FCL is safer for wood |

| Cost Per Unit | High | Low | FCL is more economical |

| Handling Points | Multiple | Two (Load/Unload) | FCL reduces handling |

| Speed | Slower (Consolidation) | Faster | FCL is more predictable |

This comparison clearly shows that for large-scale B2B orders, FCL shipping is the most reliable and cost-effective method available.

FAQ

Can I mix different wood species in a single bedroom set?

Yes, you can utilize a hybrid approach where secondary woods like Poplar are used for internal structures to reduce costs while maintaining high-end species like Oak for all visible surfaces.

What’s the best way to verify factory capacity for a large order?

The most reliable method is to request a recent production schedule and conduct an on-site audit to see the number of active CNC machines and finishing lines currently in operation.

How do I know if the moisture content is stable before shipping?

You should require a documented moisture report using a calibrated pin-less meter for 10% of the items in each batch, ensuring they fall within your specified 8-12% range.

Final check

Specifying wooden bedroom furniture requires technical precision and a commitment to quality standards across every production stage. By mastering material selection, joinery, and moisture management, you can build a resilient brand with superior products. As your manufacturing partner, we invite you to contact us to discuss your next production run and elevate your furniture procurement strategy.