Outdoor assets often suffer from severe drying and structural cracking due to UV exposure and moisture loss. Neglected furniture devalues quickly, necessitating expensive replacements. High-performance teak oil provides the essential nourishment to preserve wood integrity.

Teak oil for outdoor furniture is a specialized wood treatment formulated with natural oils, UV inhibitors, and resins. It penetrates deep into hardwood pores to prevent cracking, reduce moisture absorption, and maintain a vibrant golden-brown finish. Professional application significantly extends the service life of commercial teak installations.

I. Role of Teak Oil for Outdoor Furniture

Teak oil for outdoor furniture serves as a critical replenishing agent that replaces the natural oils lost to environmental exposure and evaporation in dense hardwoods. By saturating the internal grain structure of the timber, you ensure that the wood remains flexible enough to expand and contract without developing the deep structural fissures that lead to asset failure. This preventative maintenance is essential for procurement managers who oversee high-value outdoor furniture installations in hospitality and residential sectors.

Preventing Deep Grain Cracking

The primary function of quality oil is to penetrate the tracheids of the wood to maintain internal moisture balance and prevent the brittleness that causes checking. When you apply these formulations, the resins bond with the cellulose fibers to create a resilient internal matrix that resists the drying effects of direct sunlight.

Factories recommend specific preventative measures:

- Scheduled saturation of end-grain sections where moisture loss is most rapid.

- Application during low-humidity windows to ensure maximum absorption depth.

- Multi-coat strategies for high-exposure horizontal surfaces like tabletops.

Essential Surface Nourishment

You must understand that teak is a living material that requires constant hydration to maintain its structural properties and visual appeal.

Think about this: If the wood fibers are allowed to dry out completely, the resulting cracks are often irreversible and will eventually compromise the safety of the furniture.

Moisture Barriers and Humidity Control

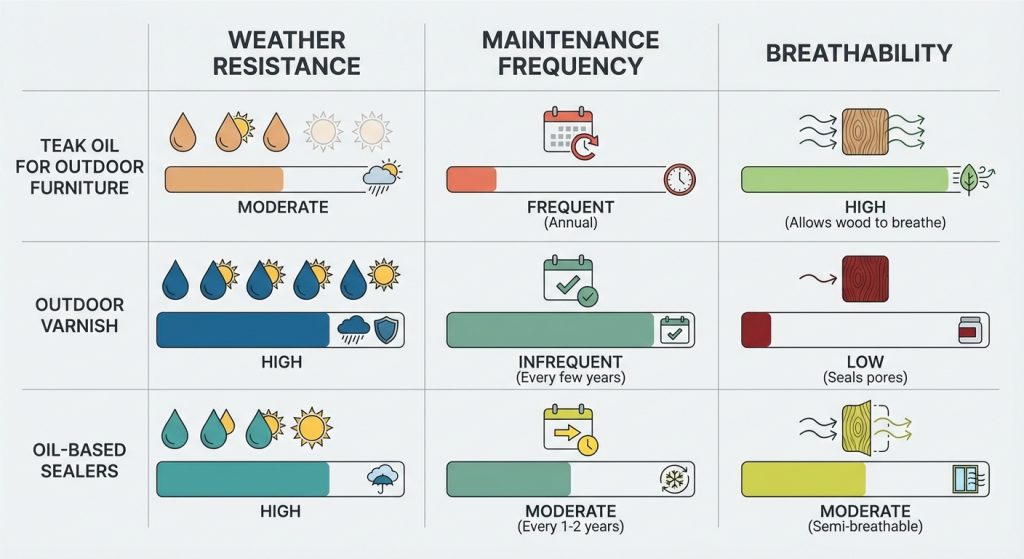

By creating a semi-permeable barrier, the oil allows the wood to breathe while simultaneously repelling liquid water that causes rot. This delicate balance is what separates professional-grade oils from cheap sealants that might trap moisture inside and cause internal decay.

Key Takeaway: Consistent oiling prevents the structural degradation of hardwood assets by maintaining internal fiber elasticity and moisture resistance.

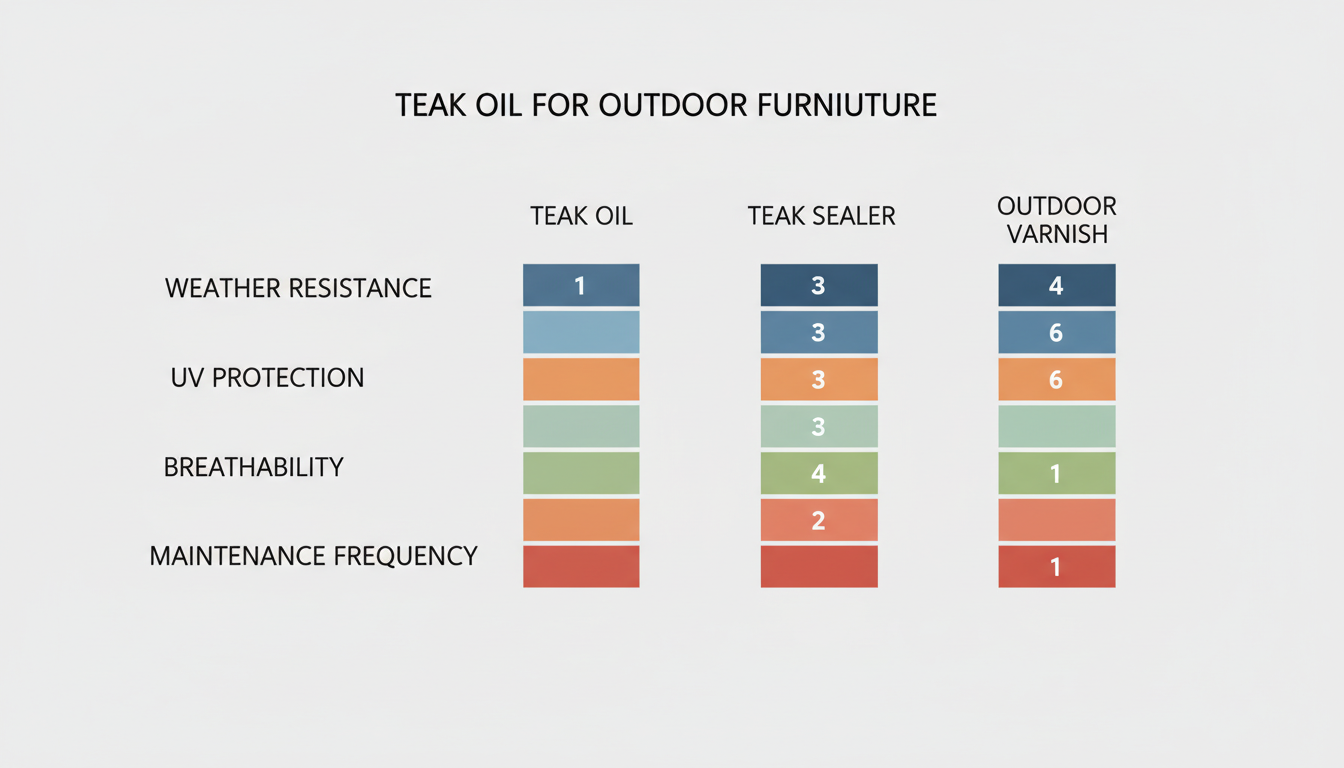

The following table compares different protective finishes for commercial wood applications:

| Finish Type | Depth of Penetration | Moisture Resistance | Breathability |

|---|---|---|---|

| Teak Oil | Deep | High (Hydrophobic) | High |

| Polyurethane | Surface Only | Absolute (Seal) | Low |

| Wood Wax | Moderate | Low | Moderate |

It gets better.

II. Blending Teak Oil for Outdoor Furniture

The chemical composition of teak oil for outdoor furniture involves a sophisticated blend of drying oils, such as Tung or linseed, combined with proprietary solvents that facilitate deep penetration into tight-grained hardwoods. These factory-blended solutions are engineered to carry UV inhibitors and mold retardants deep into the wood’s cellular structure, ensuring that the protection is not merely a surface-level film. As a procurement specialist, you should prioritize blends that offer high solids content for lasting durability in diverse climates.

Tung Oil vs. Linseed Oil Bases

Tung oil is generally preferred in high-end manufacturing because it offers superior water resistance and does not darken as significantly over time compared to linseed-based alternatives. When you choose a Tung-oil-rich blend, you are investing in a more durable polymer chain that withstands the rigors of commercial outdoor use.

Standard factory blending ratios include:

- High-solids Tung oil (40-60%) for maximum durability and water repellency.

- Aliphatic hydrocarbon solvents to ensure the oil reaches the heartwood.

- Metallic driers to catalyze the oxidation process and reduce curing time.

UV Inhibitors and Additive Science

Modern formulations incorporate micronized pigments and UV absorbers that act as a microscopic sunscreen for your timber assets.

The secret is here: These additives intercept harmful radiation before it can break down the lignin that holds wood fibers together, preventing the “silvering” effect.

Volatile Organic Compound (VOC) Standards

International compliance requires that industrial wood oils meet strict VOC limits to ensure safety for both the environment and the end-user. Leading factories now utilize low-odor, eco-friendly solvents that maintain high performance without the toxic off-gassing associated with traditional oil finishes.

Key Takeaway: High-quality oil blends utilize Tung oil and UV inhibitors to provide long-lasting internal protection and color stability.

The table below outlines the performance characteristics of common oil additives:

| Additive Category | Primary Function | Duration of Effect | Impact on Color |

|---|---|---|---|

| UV Absorbers | Prevent Lignin Decay | 12-18 Months | Minimal |

| Fungicides | Stop Mold Growth | 24 Months | None |

| Synthetic Resins | Increase Hardness | 12 Months | Slight Gloss |

Now, consider this.

III. Enhancing Teak Oil for Outdoor Furniture Results

Maximizing the effectiveness of teak oil for outdoor furniture requires an understanding of how temperature and wood density affect the absorption rate during the finishing process. You will achieve the best results when the oil is applied in thin, even layers that are allowed to soak into the grain before the excess is wiped away to prevent a tacky surface. This process enhances the natural figure of the wood, bringing out the rich, chatoyant qualities that make premium residential furniture so desirable for high-end clients.

Penetration Depth in Dense Hardwoods

The tight pores of Tectona grandis require low-viscosity oils that can travel deep into the grain to provide a reservoir of hydration. You can improve this penetration by applying the oil during the warmest part of the day when the wood pores are most open and receptive to treatment.

To optimize oil uptake, follow these factory protocols:

- Ensure the wood temperature is between 20°C and 30°C during application.

- Use lint-free applicators to avoid leaving debris in the wet oil film.

- Apply a second coat within 20 minutes while the first is still “open.”

Color Retention vs. Natural Weathering

While many designers appreciate the silver patina of aged teak, professional oiling allows you to maintain the original honey-gold hue for much longer. The pigments within the oil provide a sacrificial layer that protects the wood’s natural color from being bleached by the sun.

You see: The more frequently you maintain the oil layer, the less likely the wood is to develop the gray oxidation that signals moisture loss.

Protection Against Mold and Mildew

Premium teak oils contain zinc-based fungicides that prevent the growth of black spots which commonly plague outdoor furniture in humid environments. By creating an inhospitable surface for fungal spores, these oils keep your furniture looking clean and well-maintained without the need for harsh chemical scrubbing.

Key Takeaway: Proper application techniques and environmental timing are critical for ensuring deep oil penetration and long-term color retention.

Refer to this comparison of protection levels based on application frequency:

| Frequency | Color Retention | Structural Integrity | Mold Prevention |

|---|---|---|---|

| Bi-Annual | 95% | Excellent | High |

| Annual | 70% | Good | Moderate |

| Biennial | 40% | Fair | Low |

Believe it or not.

IV. Managing Teak’s Natural Aging and Patina

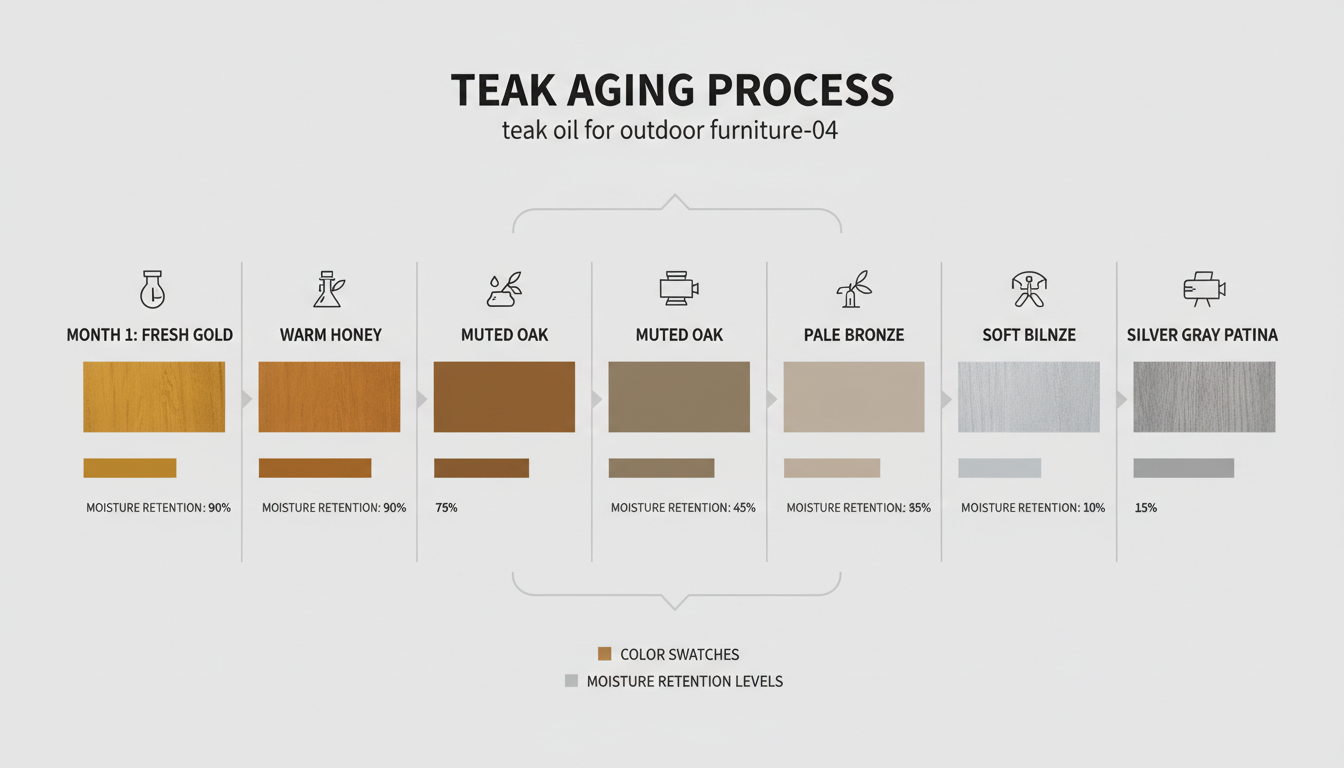

Managing the transition of teak oil for outdoor furniture as the wood ages is a primary concern for maintenance teams who want to preserve a specific aesthetic. If you choose not to oil regularly, the wood will naturally transition to a silver-gray color, but this must be managed carefully to ensure the graying is uniform and not blotchy. Strategic use of tinted oils can help bridge the gap between “new” and “weathered” looks, providing a controlled aging process that maintains the professional appearance of your inventory.

The 5-Month Silver-Gray Transition

Without the protection of UV-inhibiting oils, the surface lignin of teak begins to break down within 20 weeks of exposure to direct sunlight. You will notice the vibrant gold fading into a muted straw color before finally settling into the iconic silver patina that characterizes many luxury seaside resorts.

The aging process follows a predictable timeline:

- Month 1-2: Slight darkening and loss of surface oils.

- Month 3-4: Gradual fading of gold tones and appearance of silver flecks.

- Month 5+: Development of a full, protective silver-gray oxidation layer.

Using Graying Agents for Uniformity

If a weathered look is desired for a specific project, you can use specialized “weathered” oils that provide the gray aesthetic while still offering the protective benefits of deep hydration. These products ensure that the furniture looks mature and sophisticated from the day of installation without the vulnerability of untreated wood.

Here is the kicker: Using these agents allows you to skip the “ugly stage” of weathering where the wood looks unevenly stained and dirty.

Aesthetics in Commercial Landscapes

In high-end commercial settings, the consistency of the furniture’s appearance is vital for brand image and guest satisfaction. You must decide whether to maintain a constant oiled finish or commit to a fully weathered look, as switching between the two requires significant labor and sanding.

Key Takeaway: Teak aging can be managed through regular oiling for a golden look or specialized graying oils for a protected, weathered aesthetic.

The table below describes the maintenance requirements for different aesthetic stages:

| Aesthetic Goal | Required Product | Labor Intensity | Re-application Cycle |

|---|---|---|---|

| Golden Honey | High-UV Teak Oil | High | 6 Months |

| Weathered Gray | Graying Oil / Sealer | Moderate | 12 Months |

| Natural Silver | None (Cleaning only) | Low | 18 Months |

This is just the beginning.

V. Benefits of Teak Oil for Outdoor Furniture Care

The primary benefit of teak oil for outdoor furniture is the significant extension of the asset’s lifecycle, which directly reduces the long-term cost of ownership for commercial buyers. When you invest in a regular oiling program, you are effectively preventing the wood from becoming “spent,” a condition where it loses all natural resilience and begins to shatter under stress. For importers, recommending these care products alongside the furniture builds trust and ensures that the end-users are satisfied with the product’s longevity for years to come.

Extending Asset Lifecycle and Value

Furniture that is regularly treated with oil retains its structural value far longer than neglected pieces, making it a smarter investment for hotels and restaurants. You will find that well-oiled teak resists the loosening of joints and the warping of slats that often occur when wood is allowed to dry out and absorb moisture cyclically.

Consider these lifecycle benefits:

- Reduced frequency of structural repairs and hardware tightening.

- Higher resale or trade-in value for commercial furniture fleets.

- Elimination of splintering, which reduces liability in public spaces.

Enhancing Texture and Hand-Rubbed Finish

A well-oiled piece of teak has a tactile quality that synthetic finishes cannot replicate, offering a smooth, “silky” feel that enhances the user experience. This hand-rubbed finish is a hallmark of quality that your customers will appreciate every time they interact with the product.

Keep this in mind: The oil brings out the unique grain patterns of each piece, making the furniture feel like a custom, high-end installation rather than a mass-produced item.

Reducing Structural Maintenance Costs

By preventing cracks before they start, you avoid the need for expensive wood fillers, epoxy resins, and intensive sanding sessions. Proactive oiling is a low-cost, high-reward activity that can be performed by general maintenance staff without specialized training or equipment.

Key Takeaway: Regular oiling provides a high return on investment by preserving both the structural integrity and the premium aesthetic of teak furniture.

Compare the costs of proactive vs. reactive maintenance below:

| Maintenance Type | Annual Cost per Unit | Labor Hours | Replacement Risk |

|---|---|---|---|

| Proactive Oiling | Low | 1 hr | Near Zero |

| Reactive Sanding | Moderate | 4 hrs | Moderate |

| Total Refurbishment | High | 10+ hrs | High |

But wait, there’s more.

VI. Preparation for Outdoor Wood Treatments

Successful application of teak oil for outdoor furniture depends entirely on the quality of the surface preparation, as oil cannot penetrate through old sealants, dirt, or oxidized wood fibers. You must ensure that the timber is thoroughly cleaned and lightly sanded to open up the pores, allowing the oil to be drawn deep into the heartwood for maximum effect. For more information on sourcing high-quality timber that responds well to treatment, you can check our outdoor furniture buying guide section.

Degreasing and Sanding Requirements

If the wood has been previously treated or has accumulated oily residues from food and environment, a degreasing agent must be used before sanding. You should use a medium-grit sandpaper (around 120-150 grit) to remove the surface layer of dead wood cells, followed by a fine-grit (220) to create a smooth finish that is ready for oiling.

Preparation steps include:

- Removing all dust and debris using a vacuum or tack cloth.

- Ensuring the wood is completely dry for at least 48 hours after cleaning.

- Masking off any metal hardware or fabric cushions to prevent staining.

Removing Old Sealers and Debris

Attempting to oil over an existing varnish or film-forming sealer will result in a blotchy, sticky mess that will not dry properly. You must strip these old finishes back to the bare wood to ensure that the new oil can actually reach the fibers it is intended to nourish.

Don’t overlook this: Any remaining gray wood will turn dark brown or black when oiled, so it is vital to sand back to the original gold color for the best appearance.

Optimal Wood Moisture Content

For maximum absorption, the moisture content of the wood should be below 12% at the time of oil application. You can use a simple pin-type moisture meter to verify this, ensuring that the oil isn’t competing with water trapped inside the wood pores.

Key Takeaway: Thorough cleaning and sanding are non-negotiable steps for achieving a professional, long-lasting oil finish.

The following guide details the sanding process for different wood conditions:

| Wood Condition | Starting Grit | Finishing Grit | Estimated Time |

|---|---|---|---|

| New / Smooth | 180 | 220 | 15 min |

| Weathered / Gray | 80 | 150 | 45 min |

| Damaged / Cracked | 60 | 120 | 90 min |

Ready for the best part?

VII. Best Teak Oil for Outdoor Furniture Application

The industrial application of teak oil for outdoor furniture is most effective when performed in a controlled environment using a “wet-on-wet” technique to ensure total saturation of the wood fibers. You should apply the first coat generously, allow it to sit for approximately 15 to 20 minutes, and then apply a second coat to any areas that appear “thirsty” or dull. Following this rigorous factory-standard process ensures that every piece of furniture leaves the shop with a deep, resilient finish that can withstand the harshest outdoor conditions.

Brush vs. Wipe-On Techniques

While brushes are excellent for getting oil into deep crevices and intricate carvings, a wipe-on application with a lint-free cloth often results in a more even and professional-looking finish. You will find that wiping allows you to control the thickness of the oil more effectively, preventing the “pooling” that leads to sticky spots and uneven drying.

Key application methods include:

- Natural bristle brushes for heavy saturation of large surface areas.

- Foam applicators for precise work around hardware and joints.

- Microfiber cloths for the final “buffing” stage to remove excess oil.

Proper Curing and Drying Times

Teak oil does not simply “dry” like paint; it cures through a process of oxidation that can take anywhere from 24 to 72 hours depending on humidity and temperature. You must keep the furniture in a dust-free, covered area during this time to prevent environmental debris from becoming embedded in the curing oil film.

Listen closely: If you put the furniture into service too early, the oil may transfer to clothing or attract dirt that will be difficult to remove later.

Managing Over-Saturation Risks

Applying too much oil can be just as detrimental as applying too little, as it creates a thick, gummy surface that never quite hardens. You must be diligent about wiping away every drop of excess oil that hasn’t been absorbed within 30 minutes of application to maintain a clean, matte-to-satin finish.

Key Takeaway: A multi-step application with careful removal of excess oil ensures a beautiful, non-sticky, and durable finish.

Compare application methods for efficiency and quality:

| Method | Speed | Finish Quality | Waste Level |

|---|---|---|---|

| Wipe-On | Medium | Very High | Low |

| Brush-On | Fast | Moderate | High |

| Spray (Industrial) | Very Fast | High | Very High |

That’s not all.

VIII. Storage of Teak Oil for Outdoor Furniture

Safe storage and inventory management of teak oil for outdoor furniture are critical for maintaining the efficacy of the product and ensuring factory safety standards are met. You must store these oil blends in a temperature-controlled environment, as extreme heat can cause the volatile solvents to expand or the oil to begin polymerizing inside the container. Furthermore, understanding the shelf life of your bulk oil inventory allows you to optimize procurement cycles and ensure that you are always using fresh, high-performance materials for your finishing operations.

Spontaneous Combustion Risk Control

One of the most dangerous aspects of working with drying oils like teak oil is the risk of spontaneous combustion from oil-soaked rags. You must ensure that all applicators and cloths are submerged in water-filled metal containers or spread out flat to dry individually before disposal.

Safety protocols for your facility:

- Use only FM-approved oily waste cans for temporary rag storage.

- Train all staff on the exothermic reaction properties of drying oils.

- Keep fire suppression systems updated in all finishing and storage areas.

Temperature-Controlled Storage Units

To prevent the separation of additives and resins, bulk oil should be stored between 15°C and 25°C in a dark, well-ventilated space. You will find that maintaining a stable environment extends the usable life of the product and ensures consistent viscosity during the application process.

The truth is: Frequent temperature swings can cause the oil to become cloudy or develop “skin” inside the drum, rendering it difficult to use.

Shelf Life of Factory-Sealed Blends

While most unopened teak oils have a shelf life of 2-3 years, once a container is opened, the clock starts ticking due to oxygen exposure. You should use “bloxygen” or similar inert gas blankets to displace oxygen in partially used containers to keep the remaining oil fresh for future use.

Key Takeaway: Proper storage and strict fire safety protocols are essential when managing bulk wood finishing supplies.

Check the storage requirements for different oil volumes:

| Container Size | Storage Requirement | Venting Needs | Typical Shelf Life |

|---|---|---|---|

| 1L Tins | Cool, Dark Shelf | Low | 2 Years |

| 20L Pails | Grounded Pallets | Moderate | 1.5 Years |

| 200L Drums | Climate Controlled | High | 1 Year |

You won’t believe this.

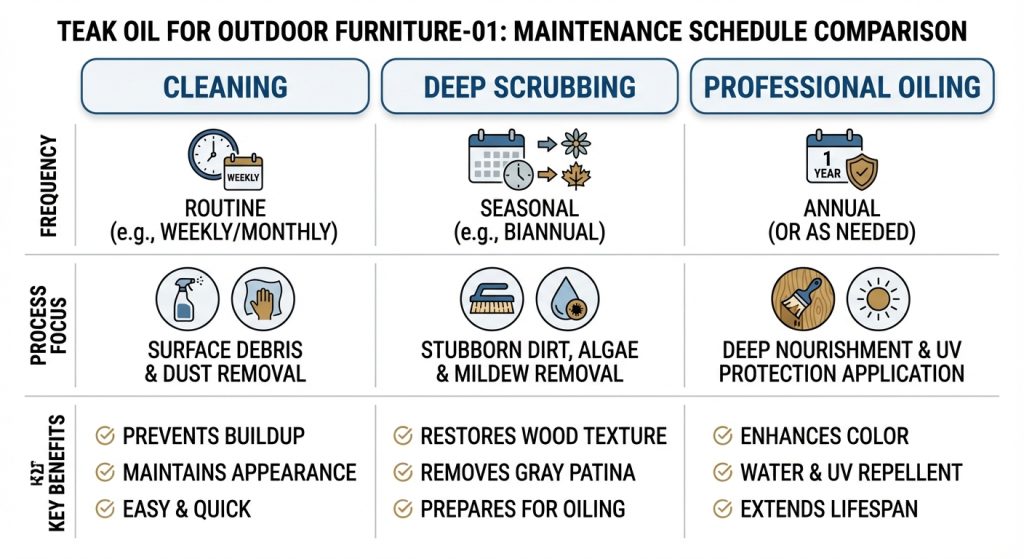

IX. Maintenance Cycles for Outdoor Furniture

Establishing a consistent maintenance cycle for teak oil for outdoor furniture is the only way to ensure the long-term survival of wood assets in high-traffic commercial environments. You should base your schedule on the local climate and the level of direct UV exposure the furniture receives, with most experts recommending a refresh every 6 to 12 months. By monitoring the wood for signs of “thirst,” such as water no longer beading on the surface, you can intervene before structural damage begins. You can read more about our factory’s durability standards on our outdoor furniture page.

Seasonal Application Schedules

In regions with harsh winters or intense summer sun, you should schedule your major maintenance sessions just before the onset of the most stressful season. This ensures that the wood is fully hydrated and protected when it needs it most, reducing the likelihood of seasonal cracking or warping.

Recommended maintenance windows:

- Spring: Prepare for high UV exposure and summer humidity.

- Autumn: Seal out winter moisture and prevent freeze-thaw damage.

- Monthly: Quick inspections of high-wear areas like armrests and seats.

Signs of Oil Depletion in Wood

You can easily identify when your furniture needs attention by performing the “water drop test” on a horizontal surface. If the water soaks into the grain rather than forming distinct beads, it is a clear sign that the protective oil layer has worn thin and needs to be replenished.

Check this out: Dull, grayish patches or a “furry” texture on the wood surface are also early warning signs of UV degradation that should be addressed immediately.

High-Traffic vs. Low-Traffic Factors

Furniture in heavy-use areas, such as poolside lounges or restaurant terraces, will require more frequent oiling due to the abrasive effects of sunblock, food oils, and constant cleaning. You should adjust your maintenance budget and labor allocation to account for these high-wear zones to ensure a uniform appearance across your entire property.

Key Takeaway: Maintenance cycles must be customized to local environmental stressors and the intensity of furniture use.

Use this decision matrix for scheduling your maintenance:

| Environment | UV Exposure | Humidity | Recommended Frequency |

|---|---|---|---|

| Tropical | High | High | Every 4-5 Months |

| Arid | Very High | Low | Every 6 Months |

| Temperate | Moderate | Moderate | Every 9-12 Months |

And the best part?

X. Selecting Teak Oil for Outdoor Furniture

Selecting the right teak oil for outdoor furniture involves evaluating supplier consistency and ensuring the product meets international safety and performance standards. You should look for manufacturers who provide detailed material safety data sheets (MSDS) and can demonstrate batch-to-batch uniformity in their formulations. Choosing a partner that understands the specific needs of the educational furniture or hospitality sectors ensures that you receive a product tailored for commercial-grade durability.

Evaluating Supplier Batch Consistency

A reliable factory partner will have rigorous quality control measures in place to ensure that every gallon of oil performs exactly like the last. You should ask for samples from different production runs to verify that the color, viscosity, and drying time remain within acceptable tolerances for your operations.

Supplier evaluation criteria:

- Documented QC processes for raw material sourcing (Tung oil purity).

- Capacity for large-volume orders with stable lead times.

- Technical support for application troubleshooting and custom blending.

Marine-Grade vs. Residential Blends

For extreme environments, you should specify “marine-grade” oils which typically contain higher concentrations of resins and biocides compared to consumer-level products. These professional formulations are designed for the deck of a yacht, making them more than capable of handling the demands of a luxury hotel terrace.

Here is the deal: Investing in premium oil upfront reduces the long-term labor costs of more frequent reapplications.

Compliance with International Standards

Ensure that your selected oil complies with REACH or similar environmental regulations if you are exporting furniture to the EU or North American markets. This not only protects the environment but also shields your brand from potential legal and compliance issues related to hazardous materials.

Key Takeaway: Prioritize suppliers who offer certified, consistent, and high-performance formulations tailored for commercial outdoor use.

The checklist below helps in evaluating a potential oil supplier:

| Evaluation Metric | Requirement | Importance |

|---|---|---|

| VOC Compliance | Meets Regional Standards | Mandatory |

| Solid Content | >40% for Durability | High |

| UV Protection | Tested Micronized Pigments | High |

Reader FAQ

What is the difference between teak oil and a teak sealer?

Teak oil penetrates the wood to replace natural oils lost to evaporation, while a sealer creates a more permanent surface barrier that locks in color and blocks moisture. Oils provide a traditional hand-rubbed look, whereas sealers are often preferred for long-term color retention with less frequent reapplication.

Can I apply teak oil to furniture that has already turned gray?

Yes, but the gray patina (weathered surface) must be removed first using a teak cleaner or light sanding. Applying oil directly over gray wood will result in a dark, blotchy, and uneven finish as the oil reacts with surface oxidation and dirt.

Is teak oil safe for indoor use as well as outdoor?

Most teak oil formulations are safe for indoor use, provided there is adequate ventilation during the application and curing process. However, for indoor furniture not exposed to UV, a lighter furniture wax or mineral oil may be sufficient.

Closing note

Effective maintenance of hardwood assets requires a proactive approach to hydration and UV protection. By utilizing professional-grade teak oil, commercial operators can safeguard their investments against the harsh realities of outdoor exposure. Partner with a leading Shandong wood care factory for your bulk requirements by reaching out to our contact team. Our vision is to provide scientifically formulated solutions that enhance the natural beauty and longevity of premium timber.