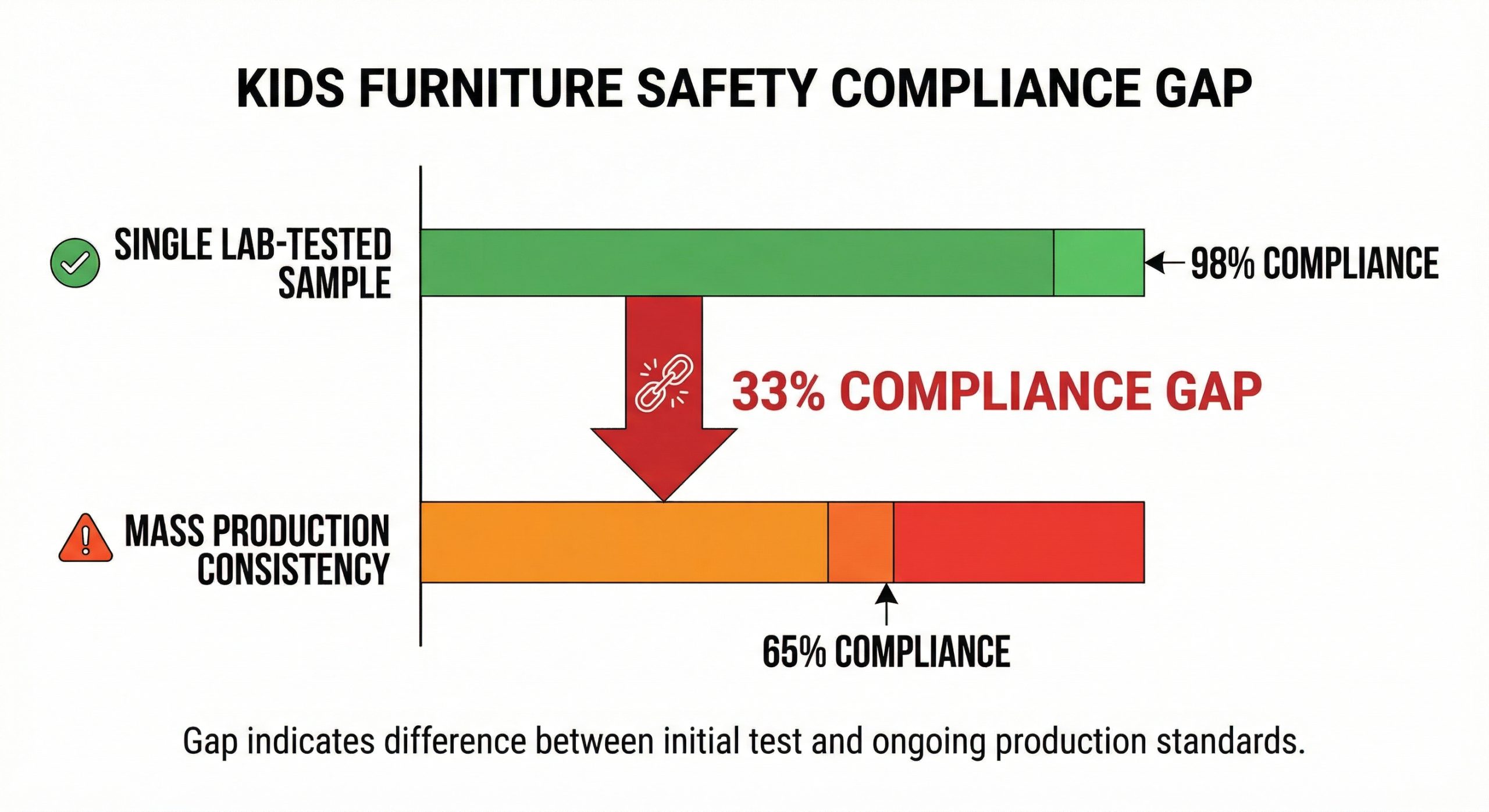

In the global furniture supply chain, a “passed” test report from an accredited laboratory is often viewed as the finish line. For many importers and brands, securing a Children’s Product Certificate (CPC) feels like the ultimate insurance policy against liability. However, from our perspective on the factory floor in Shandong, we know a hard truth: Safety certifications do not prevent defects; they only document a single moment of success.

A lab test proves that one specific sample, often handcrafted by a factory’s best engineers, met the requirements of the law. It does not guarantee that the 5,000th unit coming off the high-speed CNC line six months later will be identical. Real safety is a living process, not a static document.

I. Why Paper Compliance Fails Kids Furniture Safety

The “Certification Paradox” is a phenomenon where a brand believes they are protected by a stack of paperwork while their actual product risk remains high. This occurs because of the fundamental disconnect between laboratory environments and mass production realities.

The Certification Paradox

When an importer receives a test report from a body like SGS or Intertek, they see a “Pass” grade. What they don’t see are the variables that change daily in a manufacturing environment:

- Tool Wear: A drill bit that is sharp on Monday may be dull by Friday, leading to slightly oversized pilot holes that compromise screw withdrawal strength.

- Moisture Content: Wood is a biological material. A change in seasonal humidity in Shandong can affect the dimensional stability of a crib rail, potentially leading to cracks or gaps that exceed the 6cm safety limit.

- Material Drift: A hardware supplier might change their zinc plating process without notice, introducing trace amounts of lead that weren’t present in the initial test sample.

Why Lab Testing Isn’t Enough

Lab testing is reactive. It tells you what was true about a sample, not what is true about your inventory. To bridge this gap, manufacturers must move toward active risk management.

Table 1: The Compliance Gap – Lab vs. Factory Floor

| Feature | Lab Testing (Snapshot) | Factory QC (Continuous) |

|---|---|---|

| Scope | One specific sample (Golden Sample) | Every batch and production run |

| Focus | Regulatory “Pass/Fail” | Process stability and variance |

| Timing | Once per year or per design change | Daily, hourly, and at every station |

| Goal | Legal market entry | Consumer safety and brand protection |

II. CPSIA Mandates for Kids Furniture Safety

The Consumer Product Safety Improvement Act (CPSIA) is the bedrock of children’s product regulation in the United States. For any professional sourcing from Everwoody Products , understanding these mandates is non-negotiable.

Durable Infant Product Standards

The CPSIA distinguishes between general-use furniture and “durable infant or toddler products.” The latter includes items like cribs, high chairs, and toddler beds. These are subject to much stricter scrutiny because they are intended for use by children aged 12 and under, who are most vulnerable to structural failures.

Mandatory Safety Specification Lists

The CPSC enforces safety through the 16 CFR (Code of Federal Regulations). These regulations often incorporate ASTM (American Society for Testing and Materials) standards by reference. Key regulations include:

- 16 CFR Part 1219: Safety Standard for Full-Size Baby Cribs.

- 16 CFR Part 1217: Safety Standard for Toddler Beds.

- 16 CFR Part 1222: Safety Standard for Bedside Sleepers.

The Importer’s Legal Responsibility

Under US law, the Importer of Record is legally responsible for ensuring that products manufactured overseas comply with all safety standards. If a factory in China fails to follow the 16 CFR requirements, it is the US brand that faces the fines, recalls, and lawsuits. This is why choosing a partner that understands the technical nuances of CPSIA is critical for long-term viability.

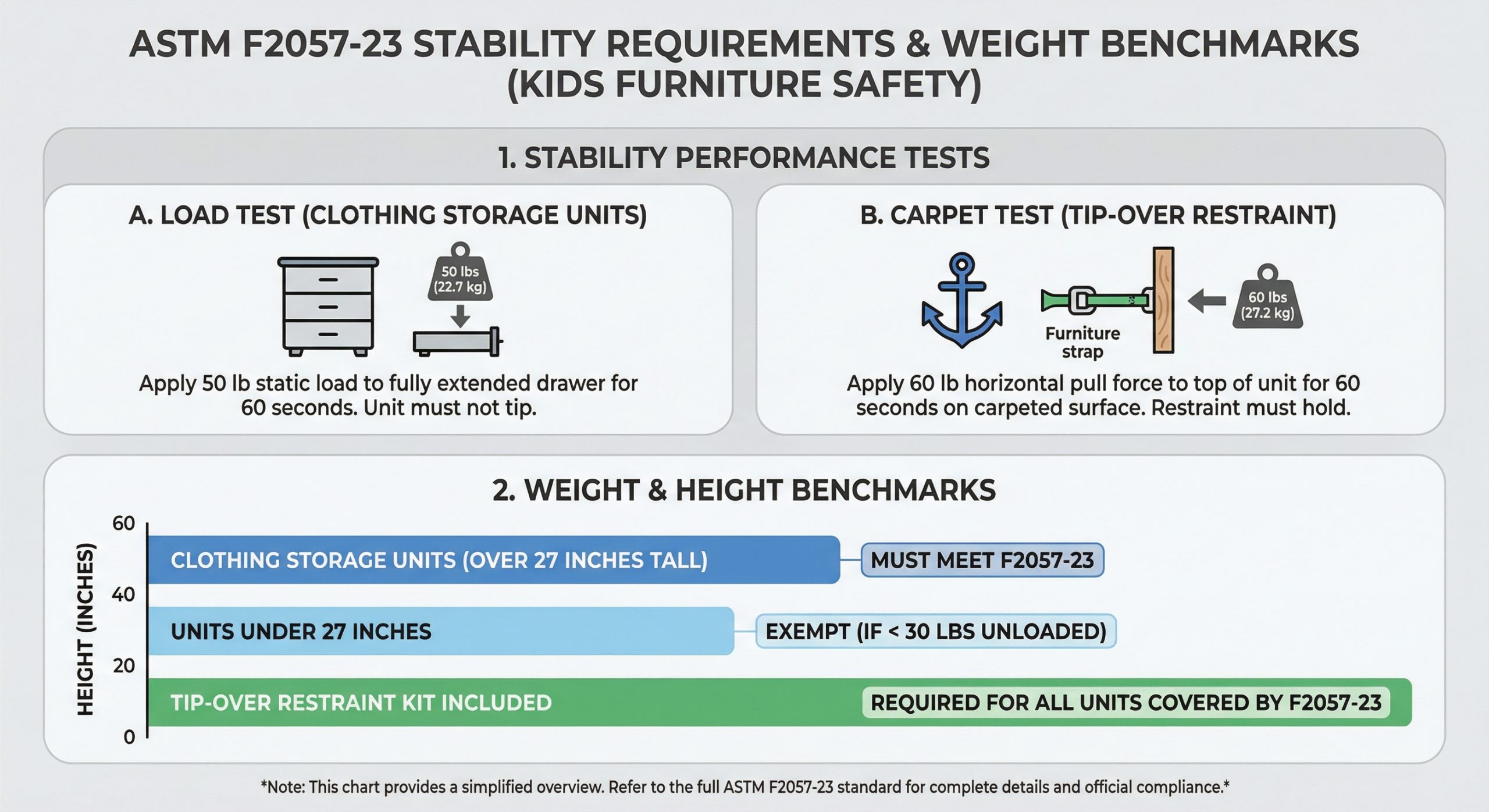

III. ASTM F2057-23 and Kids Furniture Safety

The most significant recent change in the industry is the enactment of the STURDY Act and the subsequent update to ASTM F2057-23. This standard specifically targets furniture tip-overs, which have historically been a leading cause of injury in children’s bedrooms.

Preventing Furniture Tip-Overs

ASTM F2057-23 applies to Clothing Storage Units (CSUs) like dressers and bureaus. The new standard is significantly more rigorous than previous iterations, requiring units to remain stable under three specific conditions:

- Test 1: Stability with all drawers open.

- Test 2: Stability with drawers open and a 60lb weight applied to simulate a child climbing.

- Test 3: Stability on a carpeted surface (simulated by a specific test apparatus).

ASTM F2057-23 Compliance Steps

To meet these standards, we implement several engineering solutions at the factory level:

- Interlock Systems: Mechanical devices that prevent more than one drawer from being opened at a time, keeping the center of gravity over the base.

- Weighted Bases: Adding density to the rear or bottom of the unit to counteract forward-leaning forces.

- Anti-Tip Kits: Every unit must include a permanent tip-over restraint that meets ASTM F3096.

Labeling for Stability Awareness

Compliance isn’t just about physics; it’s about education. Permanent warning labels must be attached to the unit in a location visible during use. These labels use standardized icons to warn against placing heavy items (like TVs) on top of the furniture and to emphasize the importance of using wall anchors.

IV. Chemical Hazards in Kids Furniture Safety

While structural safety is visible, chemical safety is invisible and often more dangerous. Kids’ furniture must be free from toxic substances that could be ingested or inhaled.

Lead and Phthalate Restrictions

- Lead-in-Paint (16 CFR Part 1303): The limit for lead in surface coatings is 90 ppm (parts per million). We verify this by testing not just the liquid paint, but the dried film on the finished product.

- Phthalates (16 CFR Part 1307): Certain plasticizers used in vinyl or plastic components are restricted to 0.1%.

Formaldehyde Emission Standards

Most kids’ furniture uses composite wood like MDF or Plywood. These materials are governed by TSCA Title VI (and California’s CARB ATCM).

“Formaldehyde is a known carcinogen. Ensuring that composite wood materials meet the strict emission limits of 0.05 to 0.11 ppm (depending on the material) is the baseline for indoor air quality in a nursery.”

Toxic Substance Control Act (TSCA)

Beyond formaldehyde, the TSCA regulates persistent, bioaccumulative, and toxic (PBT) chemicals. This includes restrictions on flame retardants like decaBDE, which was once common in upholstered furniture but is now prohibited due to its neurotoxic effects on developing children.

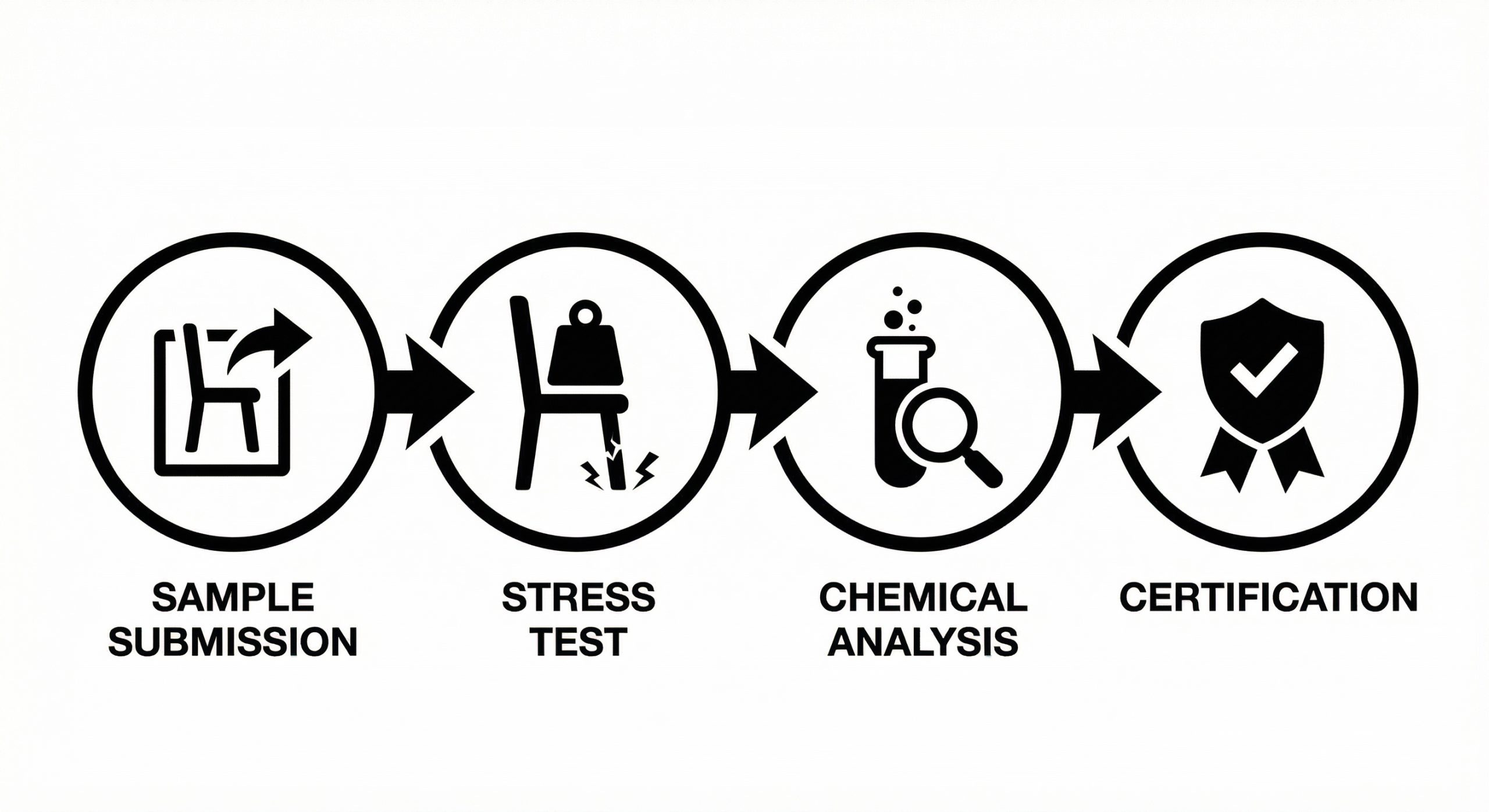

V. Lab Testing Roles in Kids Furniture Safety

To be legally valid in the US, testing must be performed by a CPSC-Accepted Third-Party Laboratory. Standard ISO certifications are not enough for children’s products.

Selecting CPSC-Accepted Laboratories

Brands should work with established names like QIMA, UL, or V-Trust. These labs are audited by the CPSC to ensure their testing equipment and methodologies are calibrated specifically to the 16 CFR standards.

Small Parts and Physical Testing

Mechanical evaluations involve “use and abuse” simulations:

- Tension Test: Pulling on small components (like drawer pulls) with up to 15 lbs of force to ensure they don’t break off and become choking hazards.

- Drop Test: Dropping the product or its components to ensure structural integrity remains intact.

- Sharp Edge/Point Test: Using specialized gauges to ensure no accessible edge can cut a child’s skin.

Flammability Testing Protocols

Upholstered seating for children must meet 16 CFR Part 1640, which largely adopts the California TB 117-2013 standard. This focuses on smolder resistance, ensuring that a lit cigarette or small open flame won’t cause the furniture to ignite rapidly.

VI. The Importance of CPC Documentation

The Children’s Product Certificate (CPC) is the “Passport” for your furniture. Without it, your shipment can be seized by US Customs.

Drafting the Children’s Product Certificate

A valid CPC must include:

- Product Identification: Detailed description of the item.

- Citation of Regulations: A list of every 16 CFR regulation the product is certified for.

- Importer Information: Name, address, and phone number of the US-based entity.

- Manufacturer Information: Name and location of the factory (e.g., Everwoody’s Shandong facility).

- Date and Place of Manufacture: Specifically when the batch was produced.

- Testing Date and Location: Link to the specific third-party lab report.

Supporting Evidence Requirements

The CPC is just a summary. You must maintain the full test reports as supporting evidence. If the CPSC requests a “compliance folder,” you have typically 24-48 hours to provide the complete chain of testing data.

Records Retention Best Practices

Legally, compliance records must be kept for five years. In our factory, we maintain digital and physical archives of every batch’s testing history to ensure our clients are always prepared for an audit.

VII. Tracking Labels and Product Recalls

If a defect is discovered after the product reaches the consumer, the ability to conduct a “targeted recall” instead of a “mass recall” can save a company millions of dollars.

Mandatory Tracking Label Information

Every children’s product must have a permanent tracking label. This is not a sticker; it is usually laser-engraved or stamped into the wood. It must contain:

- The Manufacturer’s name.

- The location of production (City/Province).

- The date of production.

- Cohort Information: The specific batch or run number.

Durable Product Registration Cards

For durable infant products like cribs, a postage-paid registration card must be attached to the product. This allows the manufacturer to contact the buyer directly in the event of a safety recall, bypassing the limitations of retailer data.

Source Identification Systems

By using sophisticated manufacturing codes, we can isolate exactly which shift produced a unit and which batch of raw timber was used. If a structural failure is traced back to a specific pallet of lumber, only the units built from that pallet need to be recalled.

VIII. Beyond Testing: Factory-Level Verification

This is where real safety happens. In our facility, we operate a three-stage quality control system that goes far beyond what a lab can see. For more details on our process, visit Everwoody Quality Control .

Material Inspection and Verification

Safety begins at the gate. Before a single board is cut, we verify the moisture content and chemical composition of the incoming materials. We don’t just trust the supplier’s invoice; we conduct our own spot checks to ensure the wood matches the samples we sent for initial certification.

In-Line Quality Control Audits

During assembly, inspectors at Everwoody’s Factory check critical safety points:

- Joint Tightness: Ensuring mortise and tenon joints are within 0.1mm tolerances.

- Fastener Torque: Using calibrated drivers to ensure screws are tight but not over-stressed.

- Gaps and Openings: Using “torso probes” and “head probes” to ensure no part of the crib could trap a child’s limb or head.

Pre-Shipment Inspection Protocols

The final check occurs in the Furniture Plant Packaging Department . We verify that the instructions are present (and in the correct language), that the hardware kits are complete, and that the shipping cartons are robust enough to prevent damage during transit.

IX. State Laws Impacting Kids Furniture Safety

While federal law sets the floor, state laws often set the ceiling. For brands selling across the US, California’s regulations are the most critical to follow. Learn more about our compliance philosophy at About Us .

California Proposition 65 Warnings

Prop 65 requires businesses to provide warnings to Californians about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm. Even if a product is “safe” under federal law, it may still require a Prop 65 warning if it contains certain chemicals above the “Safe Harbor” levels.

Law Labels for Upholstered Goods

For chairs or mattresses, “Law Labels” (the “Do Not Remove” tags) are required by many states (including PA, OH, and MA). These labels must disclose the exact percentage of filling materials and confirm whether the material is “New” or “Second-hand.”

Technical Bulletin 117-2013 Standards

TB 117-2013 has become the de facto national standard for furniture flammability. Because no brand wants to manage two different inventories (one for California and one for the rest of the US), we manufacture all our upholstered items to meet this standard by default.

X. Implementing a Kids Furniture Safety Strategy

The most successful brands don’t treat safety as a hurdle to clear at the end of the project. They treat it as a design requirement.

Designing for Compliance First

We encourage our clients to integrate ASTM and CPSIA requirements at the CAD stage. By analyzing the center of gravity in a digital model, we can predict whether a dresser will pass the F2057-23 tip-over test before we ever cut a piece of wood.

Supplier Compliance Agreements

A strong B2B relationship is built on accountability. We provide our clients with binding agreements that guarantee material transparency. If we change a glue or a finish, we notify the client and provide new chemical test results before production begins.

Continuous Improvement Cycles

Safety is an iterative process. We use data from lab failures (which happen to even the best factories during R&D), customer feedback, and return rates to refine our manufacturing.

The Path Forward for B2B Furniture Buyers:

- Audit the Factory, Not the Paper: Visit the facility (or use a third-party auditor) to see if the QC processes described on the website actually happen on the floor.

- Verify Batch-Testing: Ask for test reports for your specific production run, not just the “Golden Sample” report from three years ago.

- Focus on Engineering: Choose designs that are inherently stable, rather than relying on add-on safety kits.

At Everwoody , we believe that a safe product is the result of a culture of precision. Certifications get you into the market; factory-level vigilance keeps you there. For brands looking to build a legacy of safety, the work starts on the workshop floor in Shandong.