Importers reduce quality risk in furniture sourcing by implementing a comprehensive, multi-stage verification strategy that encompasses rigorous factory audits, systematic material testing, and independent third-party inspections throughout the production lifecycle. When you transition from local procurement to international sourcing, you often face the terrifying reality of receiving shipping containers filled with structural defects, incorrect finishes, or non-compliant materials that can instantly vaporize your profit margins. These inconsistencies do more than just cost money; they erode the trust of your retail partners and damage your brand’s reputation in a competitive marketplace where quality is the primary differentiator. By establishing a robust framework of quality control, you can proactively identify potential failures before they leave the factory floor, ensuring that every piece of furniture meets your exact specifications and regulatory requirements.

I. Establishing a Framework to Reduce Quality Risk Furniture Sourcing

The foundational step to reduce quality risk in furniture sourcing involves the creation of a detailed technical specification document that leaves no room for manufacturing ambiguity or material substitution. By defining every variable from timber moisture content to the specific tensile strength of joining hardware, you create a legally binding benchmark that the factory must adhere to throughout the production run. This framework acts as the “north star” for your quality inspectors, providing them with the objective criteria necessary to pass or fail a batch based on empirical data rather than subjective interpretation.

1. Defining Detailed Technical Specifications

The best part? When you provide a granular specification sheet, you eliminate the “cultural interpretation” gap that often leads to manufacturing errors in international sourcing. This document must serve as the ultimate authority for the factory’s production manager and your independent quality control team alike.

Look:

- Specified timber species and grade (e.g., Grade A Solid Oak).

- Moisture content range (typically 8% to 12% for temperate climates).

- Specific RAL or Pantone codes for lacquers and paints.

- Joinery requirements (e.g., mortise and tenon vs. dowel joints).

2. Setting Acceptable Quality Levels (AQL)

Think about it: no mass-production environment is perfect, which is why professional importers utilize ISO 2859-1 (AQL) standards to define the maximum number of defects allowed before a shipment is rejected. By establishing clear thresholds for critical, major, and minor defects, you provide the factory with a mathematical understanding of your quality expectations.

The result?

- Critical Defects: 0% tolerance (safety hazards or legal non-compliance).

- Major Defects: Typically 1.5% to 2.5% (functional failures or significant aesthetic issues).

- Minor Defects: Typically 4.0% (small blemishes that do not affect salability).

- Defined sample sizes based on the total lot size.

3. Establishing Communication Protocols

The reality is that most quality failures are actually communication failures, requiring you to set up a “double-check” system where all engineering changes are confirmed in writing. You must ensure that the factory understands that no deviation from the approved sample is permitted without a formal Change Request Order signed by your product development team.

Believe it or not:

- Weekly production status reports with photographic evidence.

- Direct access to the factory’s internal Quality Assurance manager.

- Standardized “Golden Samples” are kept at both the factory and your office.

- Clearly defined timelines for inspection bookings.

Key Takeaway: A successful sourcing strategy is built upon the rigidity of your initial specifications and the clarity of your quality thresholds. By removing subjectivity from the equation, you force the manufacturer to prioritize precision over speed, creating a transparent environment where quality is measured against documented facts.

| Element | Importance | Focus Area |

|---|---|---|

| Tech Specs | Critical | Material and construction detail |

| AQL Standards | High | Statistical rejection thresholds |

| Communication | Moderate | Real-time alignment and reporting |

Detailed specifications and statistical benchmarks provide the objective foundation necessary for consistent manufacturing outcomes.

II. Rigorous Supplier Audits to Reduce Quality Risk Furniture Sourcing

Conducting comprehensive supplier audits is a mandatory prerequisite to reduce quality risk in furniture sourcing by verifying a factory’s actual capacity and technical competence before a deposit is ever paid. You cannot rely on a factory’s website or digital catalog, as these often showcase products they are capable of copying rather than items they have the specialized machinery to produce consistently. A professional audit assesses the factory’s quality management system, their machinery maintenance logs, and their historical performance with other international clients in your specific category.

1. Technical Capability Assessments

The best part? A technical audit reveals whether a factory actually owns the CNC machines and kilns they claim to have, or if they are secretly outsourcing critical processes to smaller, unverified workshops. You need to know that the facility has the specialized equipment required for complex residential furniture production, such as multi-axis routers and climate-controlled finishing rooms.

Think about it:

- Verification of machinery age and maintenance records.

- Assessment of internal laboratory testing capabilities.

- Evaluation of workforce skill levels in specialized joinery.

- Review of existing quality control stations on the factory floor.

2. Quality Management System (QMS) Review

Look: a factory without a documented QMS is a factory where quality happens by accident rather than by design. You must verify that the supplier adheres to ISO 9001 standards or similar frameworks that mandate regular internal inspections and a systematic approach to handling defective components.

The truth is:

- Inspection of raw material quarantine areas.

- Review of “Non-Conformance Reports” from previous production runs.

- Evaluation of the factory’s “First-In, First-Out” (FIFO) material handling.

- Confirmation of systematic calibration for measuring tools.

3. Social and Environmental Compliance

The kicker? In today’s market, quality risk is inextricably linked to compliance risk, as a factory with poor labor standards is often a factory that takes shortcuts on material safety and finishing. You must ensure the facility meets international standards for worker safety and chemical management to prevent future legal or PR liabilities.

Consider this:

- Verification of FSC or PEFC certifications for timber sourcing.

- Audit of waste management systems for lacquers and solvents.

- Confirmation of fair labor practices and workplace safety.

- Review of fire safety and structural integrity of the facility.

Key Takeaway: The audit stage is your primary filter for risk, allowing you to bypass suppliers who lack the infrastructure to maintain consistency. A factory that passes a rigorous technical and social audit is significantly less likely to produce catastrophic quality failures during the peak production season.

| Audit Type | Objective | Key Metric |

|---|---|---|

| Technical | Capability | Machinery and tool accuracy |

| QMS | Consistency | ISO certification and records |

| Social | Compliance | Certification (FSC/BSCI) |

Proactive auditing filters out substandard manufacturers before they can introduce systemic defects into your inventory.

<p align=”center”><em>Modern factory floor utilizing automated machinery for consistency</em></p>

III. Material Selection and Verification Strategies

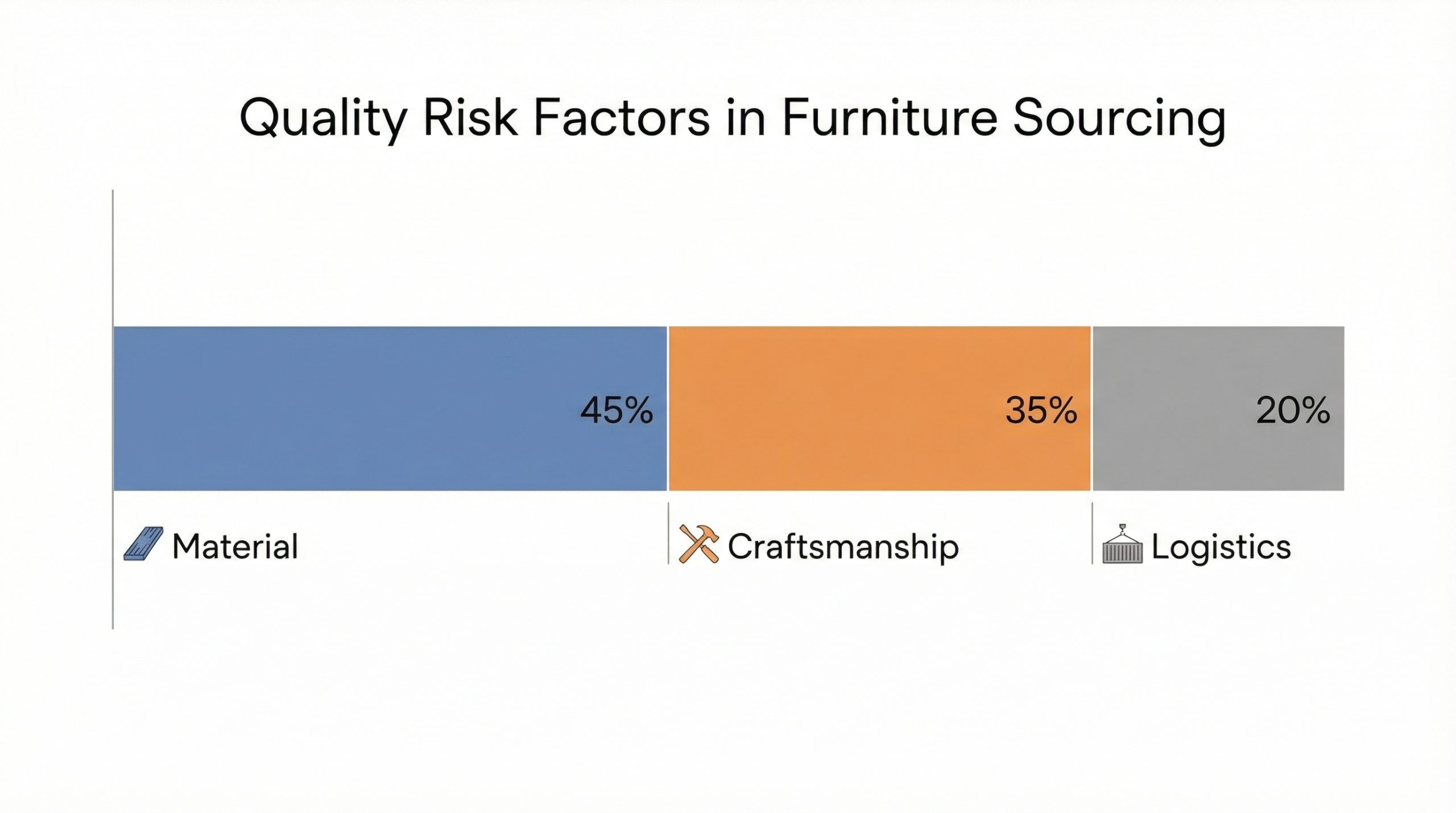

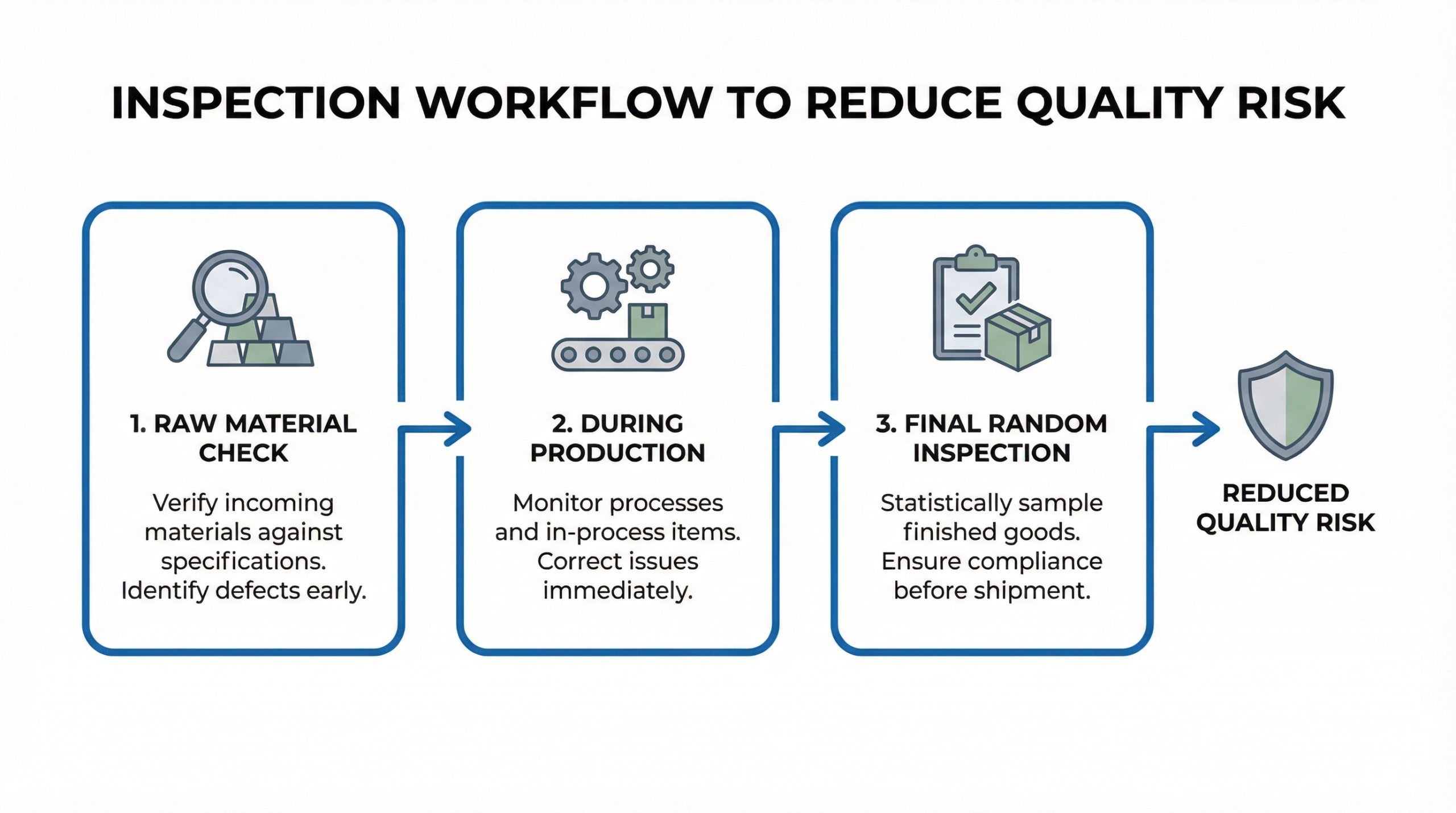

The most effective way to reduce quality risk in furniture sourcing is to exercise total control over the raw material supply chain, as the majority of furniture defects originate from substandard timber or hardware. You must realize that a factory may try to increase its margin by substituting expensive kiln-dried oak with cheaper, high-moisture alternatives that will inevitably warp or crack when they reach a drier climate. By mandating material certifications and conducting independent moisture tests on the raw planks, you eliminate the single most common cause of furniture failure.

1. Timber Moisture Content Management

The best part? When you enforce strict moisture content (MC) requirements, you prevent the structural warping and joint separation that plagues poorly made wooden furniture. You should require your QC team to use pin-type moisture meters on at least 10% of the raw timber stock before production begins to ensure it matches the destination environment.

Think about it:

- Requirement for 8-12% MC for products bound for North America.

- Documentation of kiln-drying cycles and certificates.

- Verification of moisture levels at multiple points on a single plank.

- Proper acclimatization of timber in the factory environment.

2. Hardware and Component Integrity

Look: a beautiful dining table is worthless if the extension slides fail or the leg bolts strip during assembly. You must specify the brand and grade of all hardware components, ensuring they have undergone salt spray testing and cycle testing to guarantee longevity in high-use environments.

The point?

- Specification of stainless steel vs. zinc-plated screws.

- Cycle testing requirements for drawer runners and hinges.

- Weight capacity verification for chairs and shelving units.

- Consistency in hardware finishes to match wood stains.

3. Finish and Coating Analysis

The best part? Advanced importers use “cross-hatch” adhesion tests to ensure that the lacquers and paints will not peel or flake over time due to poor surface preparation. You should also verify that all coatings are free from lead and Volatile Organic Compounds (VOCs) to meet international safety standards.

Consider this:

- Mandatory use of formaldehyde-free adhesives (E0 or E1 grade).

- Adhesion testing on finished surfaces using standardized tape.

- Verification of color consistency using light boxes.

- Scratch resistance testing using hardness pencils.

Key Takeaway: Quality in furniture is skin-deep if the underlying materials are compromised by moisture or low-grade components. By verifying the “ingredients” of your furniture before the assembly begins, you block defects at the source and ensure a durable final product.

| Material Category | Primary Risk | Verification Method |

|---|---|---|

| Wood | Warping/Cracking | Moisture meter testing |

| Hardware | Mechanical Failure | Salt spray & cycle testing |

| Finishes | Peeling/Toxicity | Adhesion & VOC testing |

Controlling material inputs is the most cost-effective method for preventing long-term structural failures.

IV. In-Process Monitoring to Reduce Quality Risk Furniture Sourcing

Implementing “During Production” (DUPRO) inspections is a critical tactic to reduce quality risk in furniture sourcing by catching errors while they are still reversible. You cannot afford to wait until 1,000 chairs are fully finished and packed to discover that the seat height is off by two centimeters or the stain color is slightly too red. By sending an inspector when the first 10-20% of the order is completed, you can identify systemic issues in the assembly or finishing lines and force the factory to make immediate corrections.

1. First-Article Inspection (FAI)

The best part? Performing a First-Article Inspection ensures that the factory has correctly translated your technical drawings into a physical product before they start mass production. This step is where you verify critical dimensions, joinery strength, and the “hand-feel” of the finish against your approved golden sample.

Look:

- Comparison of the first production unit to the golden sample.

- Verification of all internal joinery (e.g., hidden dowels).

- Check for the correct alignment of pre-drilled holes.

- Confirmation of correct labeling and branding placements.

2. Assembly Line Stability Checks

Think about it: factories often hire temporary labor during peak seasons, which can lead to a sudden drop in craftsmanship consistency on the assembly line. Your DUPRO inspection should monitor the actual workers to ensure they are using the correct amount of glue, the right torque on screws, and the proper sanding grits.

The result?

- Observation of gluing and clamping procedures.

- Monitoring of sanding quality between lacquer coats.

- Verification of jig and mold accuracy over repeated use.

- Identification of workers needing additional training.

3. Finishing Room Environmental Control

The kicker? Furniture finishes are highly sensitive to dust and humidity, meaning a poorly ventilated painting room can result in “orange peel” textures or trapped particles on your surfaces. You must verify that the factory maintains a clean, climate-controlled environment for all lacquering and drying processes.

Believe it or not:

- Check for dust-free drying areas.

- Measurement of ambient humidity in the finishing room.

- Verification of even coat application across different batches.

- Inspection for “runs” or “sags” in the liquid finish.

Key Takeaway: In-process monitoring transforms quality control from a “pass/fail” gate into a proactive management tool. By identifying defects during the manufacturing stage, you minimize waste and prevent the shipment delays that occur when a final batch is rejected.

| Inspection Stage | Primary Focus | Timing |

|---|---|---|

| First-Article | Design accuracy | First 1-5% completed |

| Assembly Line | Workmanship | 20-30% in progress |

| Finishing | Surface quality | Mid-way through coating |

Mid-production interventions allow for the correction of systemic errors before they affect the entire shipment.

V. Final Random Inspections to Reduce Quality Risk Furniture Sourcing

A Final Random Inspection (FRI) is your last line of defense to reduce quality risk in furniture sourcing before the goods are loaded onto a container, and your payment is released. At this stage, at least 80% of the production must be finished and packed, allowing an independent inspector to pull a statistically significant sample based on your AQL levels. This process involves a rigorous “out-of-box” audit where every aspect of the product, from its aesthetic appearance to its functional performance, is tested against the master specification.

1. Comprehensive Aesthetic Review

The best part? A professional inspector will examine each piece under high-intensity lighting to find subtle defects like wood grain mismatches, sanding marks, or inconsistent sheen levels that you might miss in a darker showroom. This ensures that the residential furniture you receive maintains a premium appearance across every single unit in the container.

Look:

- Check for color consistency across multiple units.

- Inspection for scratches, dents, or finish “clouding.”

- Verification of grain matching on visible surfaces.

- Check for proper cleaning and removal of factory dust.

2. Functional and Structural Testing

Think about it: furniture must be more than just beautiful; it must be structurally sound and safe for the end consumer to use. During the FRI, the inspector should perform “on-site” stress tests, such as sitting on chairs, opening and closing drawers 50 times, and checking the stability of tables on a flat surface.

The reality?

- Leveling test on a standardized flat marble floor.

- Stability test for tipping risks (especially for tall units).

- Functional check of all moving parts (hinges, slides, etc.).

- “Static Load” testing for seating and shelving.

3. Packaging and Labeling Verification

The kicker? You can have a perfect product, but if the packaging is weak or the barcode is incorrect, you will face massive losses due to shipping damage or retailer chargebacks. The FRI includes a thorough check of the carton strength, internal padding, and the accuracy of all shipping marks.

Consider this:

- Verification of carton burst strength (ECT rating).

- Check for correct UPC/EAN barcode scannability.

- Inspection of internal Styrofoam or EPE foam protection.

- Confirmation of assembly instructions and hardware packs.

Key Takeaway: The Final Random Inspection provides the mathematical confidence needed to authorize shipment. It is the only way to ensure that the quality of the mass-produced goods matches the quality of the samples you originally approved.

| FRI Component | Method | Goal |

|---|---|---|

| Visual Check | AQL Sampling | Aesthetic perfection |

| Functional Test | Stress/Cycle test | Structural reliability |

| Packaging | Drop/Marking test | Transit protection |

Final inspections act as a filter, ensuring that only compliant products reach the end consumer.

VI. Comprehensive Laboratory Testing Protocols

To truly reduce quality risk in furniture sourcing, you must supplement visual inspections with professional laboratory testing to verify invisible factors like chemical safety and structural durability. While an inspector can see a scratch, they cannot see the level of formaldehyde off-gassing or the specific alloy composition of a metal frame. By sending samples to accredited labs, you ensure your products comply with international regulations such as BIFMA for office furniture or ASTM standards for residential items.

1. Structural Durability and Safety

The best part? Lab testing simulates years of heavy use in just a few days, using mechanical arms to apply thousands of cycles of pressure to seats, backs, and drawer fronts. This prevents the “product fatigue” issues that lead to expensive returns and potential injury lawsuits six months after the sale.

Think about it:

- BIFMA X5.1 testing for office seating durability.

- Tip-over testing for dressers and chests (ASTM F2057).

- Backrest strength and durability cycling.

- Caster and base durability testing for mobile units.

2. Chemical and Environmental Safety

Look: many countries have strict laws regarding the chemicals used in furniture, particularly regarding fire retardants in upholstery and formaldehyde in engineered woods. Laboratory reports provide the legal proof you need to pass through customs and satisfy the requirements of major big-box retailers.

The point?

- Formaldehyde emission testing (CARB Phase 2 / EPA TSCA Title VI).

- Lead-in-surface-coating testing for child-safe furniture.

- Phthalate screening for plastic components and upholstery.

- Flammability testing (CAL TB 117-2013) for foam and fabrics.

3. Fabric and Upholstery Performance

The best part? If you are sourcing outdoor furniture , lab testing for UV resistance and water repellency is non-negotiable to prevent premature fading or mold growth. You should also verify the “Martindale” rub count of indoor fabrics to ensure they can withstand the friction of daily use.

Consider this:

- Martindale or Wyzenbeek abrasion testing for fabric wear.

- Colorfastness to light (UV aging) for outdoor textiles.

- Pilling resistance and seam strength analysis.

- Tear strength and tensile strength for leather products.

Key Takeaway: Laboratory testing provides a level of scientific certainty that manual inspection cannot match. It is an essential investment for any importer who wants to avoid the legal and financial catastrophe of a product recall.

| Test Category | Standard | Primary Benefit |

|---|---|---|

| Mechanical | BIFMA / ASTM | Prevents structural failure |

| Chemical | CARB / REACH | Ensures regulatory compliance |

| Textile | Martindale / UV | Guarantees surface longevity |

Scientific verification protects your brand from hidden liabilities and long-term durability issues.

VII. Logistics Management to Reduce Quality Risk Furniture Sourcing

Proper logistics oversight is a critical, yet often overlooked, phase to reduce quality risk in furniture sourcing by preventing damage during the high-stress environment of container loading and ocean transit. You must understand that even perfectly manufactured furniture can be ruined by improper stacking, excessive moisture inside the container, or rough handling during the drayage process. By mandating “Container Loading Supervision” (CLS), you ensure that the factory uses every cubic meter of space safely and that the goods are protected from the “container rain” caused by temperature fluctuations at sea.

1. Container Loading Supervision (CLS)

The best part? Having an inspector present during loading prevents the factory from “accidentally” sneaking in rejected cartons or stacking heavy items on top of fragile ones. They also verify that the container itself is clean, dry, and free from holes that could lead to water damage during the voyage.

Look:

- Verification of container number and seal integrity.

- Check for container “light leaks” and floor dryness.

- Monitoring of stacking patterns to prevent crushing.

- Photographic evidence of the fully loaded container before sealing.

2. Moisture and Humidity Protection

Think about it: ocean transit involves dramatic temperature shifts that cause moisture to condense on the ceiling of the container and drip onto your furniture, leading to mold and warped wood. You should require the use of high-capacity desiccant bags and ensure that the furniture is not loaded during heavy rain or high humidity.

The result?

- Placement of “dry bags” (desiccants) throughout the load.

- Use of moisture-barrier liners for sensitive wood items.

- Requirement for pallets to be heat-treated and dry (ISPM 15).

- Checking the moisture content of the container’s wooden floor.

3. Transit Packaging Performance

The kicker? Furniture is inherently bulky and heavy, meaning it is subject to extreme G-forces during shipping and handling. You must insist on ISTA-certified drop tests for all items, especially for “ready-to-assemble” office furniture that will be shipped individually via small parcel carriers.

Believe it or not:

- ISTA 1A or 3A drop testing for parcel-bound items.

- Vibration testing to simulate long-distance trucking.

- Compression testing for bottom-tier cartons in a stack.

- Verification of edge protectors and corner reinforcements.

Key Takeaway: Quality control does not end at the factory gate; it continues until the goods are safely inside your warehouse. Managing the logistics environment is the final step in ensuring that the quality you paid for is the quality your customers receive.

| Logistics Step | Risk Factor | Prevention Strategy |

|---|---|---|

| Loading | Crushing/Damage | CLS & stacking plan |

| Transit | Mold/Warpage | Desiccants & floor checks |

| Handling | Impact/Drop | ISTA 3A packaging |

Professional loading supervision ensures that manufacturing quality survives the rigors of international shipping.

VIII. Documentation Systems to Reduce Quality Risk Furniture Sourcing

The use of integrated documentation systems is a powerful way to reduce quality risk in furniture sourcing by creating a permanent, searchable record of every inspection, test, and production milestone. When you maintain a digital trail of “Quality Pass” certificates and laboratory reports, you create a culture of accountability that discourages the factory from attempting to cut corners. This documentation also serves as your primary evidence in the event of a quality dispute or an insurance claim, providing the “burden of proof” required to recover financial losses.

1. Standardized Inspection Reports

The best part? Modern inspection reports include hundreds of high-resolution photos and videos that allow you to “see” the production line from halfway across the world. These reports should be delivered within 24 hours of the inspection, giving you the real-time data needed to approve or hold a shipment.

Think about it:

- Visual evidence of every defect found during sampling.

- Measurement logs for all critical dimensions.

- Signed confirmation from the factory manager.

- Comparison photos of production vs. the golden sample.

2. Certification and Compliance Management

Look: as an importer, you are the “Manufacturer of Record” in your home country, meaning you are legally responsible for all safety certifications. You must maintain a centralized database of all FSC certificates, CARB reports, and BIFMA tests to quickly respond to audits from customs or consumer safety agencies.

The point?

- Tracking of expiration dates for factory certifications.

- Centralized storage of timber origin documentation.

- Accessibility of safety data sheets (SDS) for all finishes.

- Linking specific test reports to individual PO numbers.

3. Contractual Quality Clauses

The best part? Your purchase order (PO) should not just be a list of prices; it should be a legal contract that includes specific penalties for quality failures and late shipments. By clearly defining the financial consequences of a failed inspection, you give the factory a direct economic incentive to prioritize your quality standards.

Consider this:

- Clause for factory-paid re-inspections after a failure.

- Detailed “Chargeback” schedule for specific defect types.

- Definition of “Force Majeure” and its limits.

- Right to audit and inspect at any time without notice.

Key Takeaway: Documentation is the “memory” of your supply chain, preventing the repetition of past mistakes and providing the leverage needed to manage supplier performance. A robust data system transforms quality from a vague concept into a manageable business asset.

| Document Type | Value | User |

|---|---|---|

| QC Report | Operational | Sourcing / QA Team |

| Certificates | Legal | Customs / Retailers |

| Contracts | Financial | Finance / Management |

Systematic record-keeping creates the accountability necessary for long-term manufacturing excellence.

IX. Implementing Effective Corrective Action Plans

When an inspection fails, you must implement a formal Corrective Action Plan (CAP) to reduce quality risk in furniture sourcing and ensure that the root cause of the defect is permanently eliminated. Simply asking a factory to “do better next time” is a recipe for failure; you must require a detailed “8D” report that identifies exactly why the error occurred and what systemic changes have been made to the production process. This proactive approach turns a negative quality event into an opportunity for supplier development and long-term process improvement.

1. Root Cause Identification

The best part? Identifying the root cause—such as a worn-out router bit or an untrained worker—prevents you from wasting time on “band-aid” solutions that don’t solve the underlying problem. You should force the factory to use the “5 Whys” method to dig past the surface-level symptom and find the actual procedural failure.

Look:

- Analysis of machinery vs. human error.

- Evaluation of raw material batch consistency.

- Review of internal supervision and training logs.

- Check for environmental factors like sudden humidity spikes.

2. Rework Monitoring and Validation

Think about it: the “rework” process itself is often a high-risk activity where rushed repairs can lead to even worse quality issues like mismatched colors or weakened joints. You must send an inspector to verify that the rework was done correctly and that the repaired items now meet the original specification.

The result?

- Verification of the “fix” on a 100% inspection basis if needed.

- Ensuring that “repaired” units don’t show visible signs of mending.

- Testing the structural integrity of the reworked components.

- Confirmation that the factory didn’t just swap in old rejected stock.

3. Preventive Strategy Iteration

The kicker? A successful CAP ends with a change to the “Standard Operating Procedure” (SOP) to ensure the defect never happens again in future production runs. This might involve adding a new moisture-check station or upgrading the factory’s lighting system to better spot surface blemishes.

Believe it or not:

- Updating the technical specification sheet with new “lessons learned.”

- Mandating new testing equipment for the factory’s internal lab.

- Adjusting the AQL levels for the next three shipments.

- Reviewing the CAP results with the factory’s senior management.

Key Takeaway: Failures are inevitable in manufacturing, but repeating the same failure is a choice. By enforcing a strict Corrective Action Plan, you transform your suppliers into better partners and continuously “de-risk” your furniture sourcing operations.

| CAP Step | Activity | Outcome |

|---|---|---|

| Root Cause | 5 Whys Analysis | Identifies the true failure point |

| Rework | Supervised Repair | Salvages the current batch |

| Prevention | SOP Update | Blocks the defect in the future |

Corrective actions turn manufacturing failures into roadmap items for continuous quality improvement.

X. Strategic Partnership Development

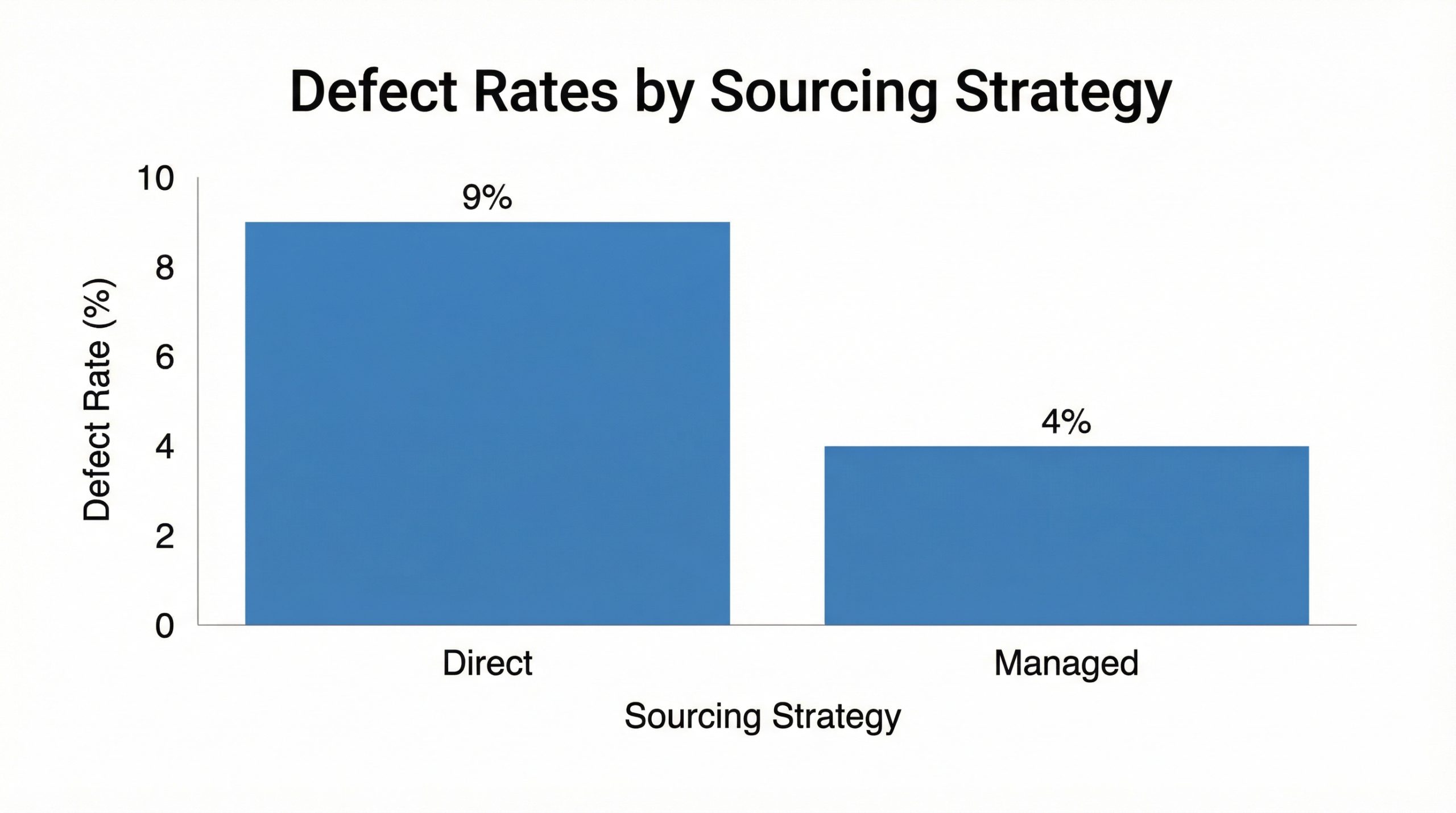

The ultimate way to reduce quality risk in furniture sourcing is to move away from transactional “order-by-order” relationships and toward strategic partnerships built on mutual trust and shared data. When a factory views you as a long-term partner rather than just another buyer, they are more likely to prioritize your orders, invest in specialized machinery for your designs, and be transparent about production challenges. This collaborative approach allows you to work together on “Design for Manufacturing” (DfM) initiatives, simplifying complex pieces to reduce the statistical probability of errors.

1. Collaborative Design Optimization

The best part? Involving the factory’s engineering team early in the design phase allows them to suggest minor changes that make the product easier to build without sacrificing its aesthetic appeal. This reduces quality risk by eliminating “over-engineered” components that are prone to breakage or assembly errors.

Look:

- Reviewing joinery types for production efficiency.

- Standardizing hardware across multiple product lines.

- Simplifying curves and angles to reduce CNC time.

- Optimizing material yields to reduce costs and waste.

2. Capacity Planning and Stability

Think about it: most quality spikes happen when a factory is over-capacity and starts rushing production or hiring unskilled subcontractors. By sharing your 12-month forecast and booking production slots in advance, you ensure your orders are produced during “steady-state” periods by the factory’s core workforce.

The result?

- Reduction in the use of temporary “peak-season” labor.

- Better pricing through guaranteed volume commitments.

- Early procurement of high-quality timber and hardware.

- Consistent quality through dedicated production lines.

3. Knowledge Transfer Initiatives

The kicker? Investing in your supplier’s team—such as bringing in a consultant to teach them advanced finishing techniques—can pay massive dividends in the form of reduced defect rates. When you treat your factory as an extension of your own company, their success becomes your success, creating a virtuous cycle of quality and reliability.

Consider this:

- Joint training sessions on international safety standards.

- Sharing market feedback and customer return data.

- Collaborative brainstorming on packaging improvements.

- Recognition and bonuses for factories hitting quality targets.

Key Takeaway: A partnership-based sourcing model is the most sustainable way to manage risk. When both parties are invested in each other’s success, quality stops being a battle of inspections and starts being a shared commitment to excellence.

| Partnership Level | Engagement | Focus |

|---|---|---|

| Transactional | Price-driven | Short-term margin |

| Collaborative | Design-driven | Process optimization |

| Strategic | Partnership-driven | Long-term growth & quality |

Strategic partnerships reduce risk by aligning the economic interests of the importer and the manufacturer.

FAQ

Can I rely solely on the factory’s internal quality control team?

No, you should never rely exclusively on a factory’s internal team because their primary loyalty is to the production schedule and the factory’s bottom line, not your quality standards. Independent third-party inspectors provide an unbiased perspective and are not under pressure to “pass” a shipment just to meet a container loading deadline.

What’s the best way to handle a failed final inspection?

The best way to handle a failure is to immediately halt the shipment and require the factory to submit a formal Root Cause Analysis and a Corrective Action Plan. You should then schedule a follow-up inspection (at the factory’s expense) once the rework is complete to ensure that all issues have been resolved to your satisfaction.

How do I know if a factory is being honest about their wood moisture content?

You should require your independent QC team to use their own calibrated, pin-type moisture meters to test at least 10-15 random planks from the production lot. If the factory’s readings consistently differ from your inspector’s readings, it is a sign that their equipment is either uncalibrated or they are intentionally providing false data.

Can I reduce my inspection frequency once a supplier becomes “reliable”?

While you can move from 100% inspection to “skipping” certain batches, it is dangerous to stop inspections entirely, as “quality fade” often occurs when a supplier feels unmonitored. The best practice is to move to a “Reduced Inspection” level under AQL standards, which maintains oversight while lowering your total quality control costs.

How do I know if my furniture is compliant with international safety laws?

The only way to ensure compliance is to require formal test reports from accredited third-party laboratories (like SGS, Intertek, or TÜV) for every new product and material change. Do not accept factory-issued “certificates of conformity” as legal proof; you must have the actual lab data showing the specific test results and the standards used.

Conclusion

Managing quality risk in furniture sourcing is an active, ongoing process that requires a disciplined blend of technical precision, statistical oversight, and strategic relationship management. By moving away from a “hope-for-the-best” mentality and adopting the rigorous frameworks outlined in this guide—from detailed specifications and DUPRO inspections to laboratory testing and logistics oversight—you can build a resilient supply chain that delivers consistent excellence. Quality is not an added expense; it is the most vital insurance policy your business can hold.

As you look to expand your furniture portfolio or optimize your current sourcing operations, we invite you to Home and explore our approach to manufacturing integrity.