High return rates due to material failure destroy furniture margins. Sourcing inferior substrates leads to structural warping and surface degradation. Our guide provides the technical framework to mitigate these procurement risks immediately.

To choose a long-lasting outdoor furniture material, prioritize Grade A teak for wood, powder-coated aluminum for metal, and High-Density Polyethylene (HDPE) for wicker. These materials withstand UV exposure, moisture, and temperature fluctuations, ensuring a product lifespan of 10+ years in commercial environments.

I. Assessing GRC as an Outdoor Furniture Material

Glass Fiber Reinforced Concrete (GRC) is a premier outdoor furniture material specifically engineered to overcome the brittleness and extreme weight of traditional pre-cast concrete. By embedding alkali-resistant glass fibers into a high-strength cement matrix, manufacturers achieve a composite with exceptional tensile strength and durability. This material is particularly effective for heavy-use items like coffee tables and fire pits because it resists the thermal expansion cycles that typically cause cracking in standard masonry products.

Structural Integrity and Fiber Reinforcement

The durability of GRC depends entirely on the ratio of glass fibers to cement and the specific application of protective sealants. A high-quality GRC component should contain approximately 3% to 5% fiber content to ensure flexibility under load. Without this reinforcement, the material remains susceptible to impact damage during logistics and consumer use.

Porosity Management and Stain Resistance

Since concrete is naturally porous, a water-based or solvent-based sealer must be applied to the surface during the finishing stage. This treatment prevents the absorption of oils and environmental pollutants that lead to permanent discoloration. Buyers must verify that the factory uses a UV-stable sealer to prevent the yellowing of the finish over time.

Weight Management for Logistics

GRC is significantly lighter than solid stone or traditional concrete, which reduces shipping costs and handling risks. The hollow-core construction allows for large-scale designs that remain manageable for white-glove delivery services.

- Fiber content should meet ISO standards for structural composites.

- Surface sealers must be tested against salt spray and acid rain.

- Internal structural ribbing is required for large spans to prevent sagging.

The following table summarizes the technical performance of GRC in various environmental conditions.

| Property | Metric/Value | Risk Mitigation Strategy |

|---|---|---|

| Compressive Strength | 40-60 MPa | High-density cement casting |

| UV Resistance | Excellent | UV-stable topical sealants |

| Moisture Absorption | < 5% | Multi-layer waterproofing |

| Maintenance Level | Low | Annual resealing recommended |

Consider this:The cost of GRC is higher than plastic, but the reduction in breakage claims makes it a more profitable long-term asset.

Key Takeaway: GRC offers a stone-like aesthetic with superior strength-to-weight ratios, provided the factory maintains strict fiber-to-cement ratios and sealing protocols.

II. Metal Sourcing Risks for Professional Buyers

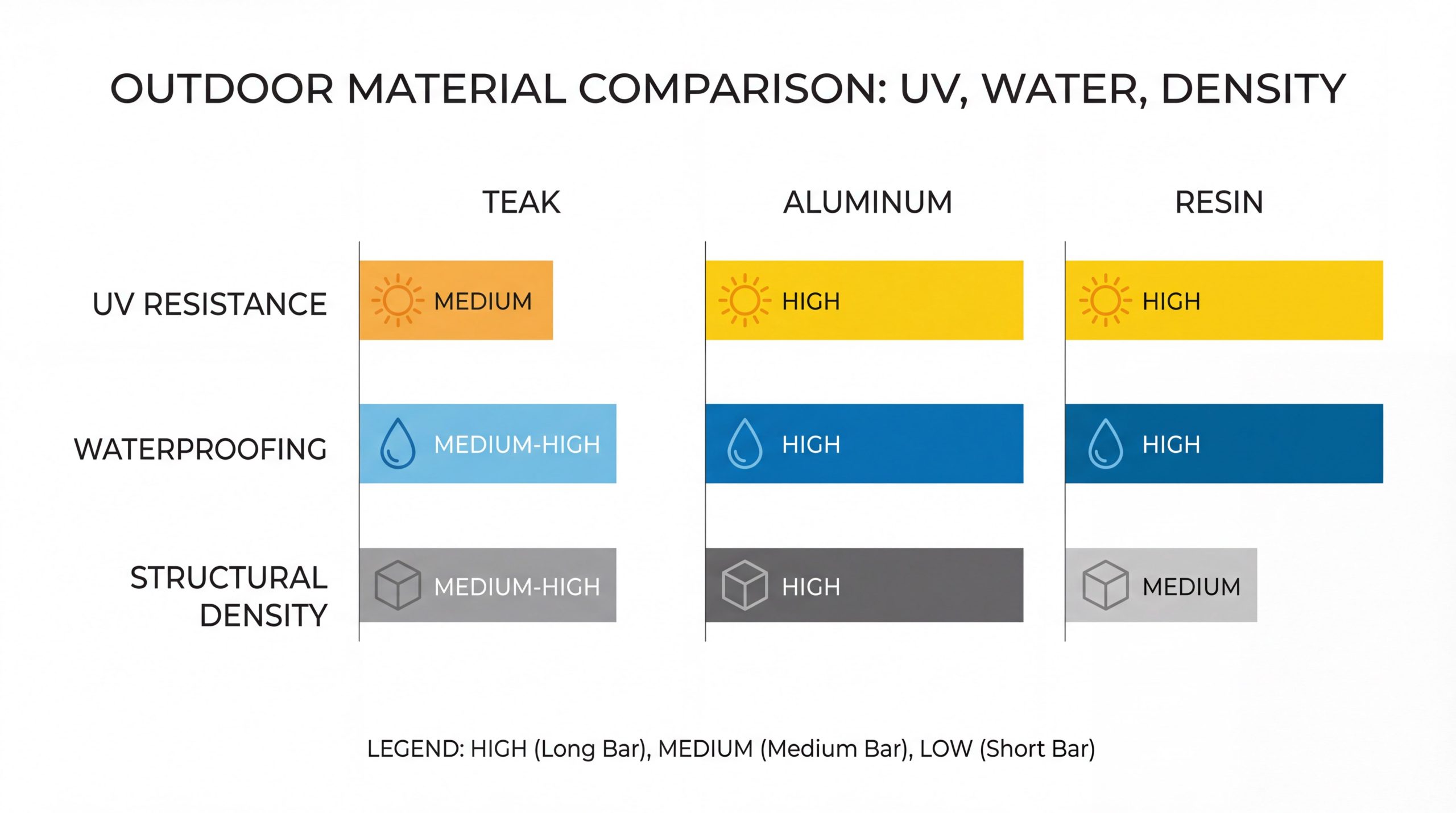

Selecting a metal outdoor furniture material involves balancing the electrochemical properties of different alloys against the intended climate zone. Aluminum is the industry standard for general use due to its self-passivating nature, which creates a thin oxide layer that prevents deep corrosion. However, for coastal environments, the presence of chlorides in the air requires the use of 316-grade stainless steel or specialized marine-grade coatings to prevent pitting.

Aluminum Alloy Selection and Wall Thickness

For commercial-grade furniture, the aluminum must be of a high-grade alloy like 6063-T5 to ensure structural rigidity and weldability. The wall thickness of the tubing is a critical quality metric, with 1.5mm to 2.0mm being the minimum standard for contract-grade seating. Thinner walls often lead to structural failure at the joints under repetitive loading.

Stainless Steel and Corrosion Resistance

Stainless steel offers superior density and impact resistance compared to aluminum but requires careful grade selection. Grade 304 is suitable for inland use, whereas Grade 316 is mandatory for any project within five miles of the ocean. Failure to specify the correct grade will lead to “tea staining” or surface rust within months of installation.

Powder Coating and Pre-treatment

The longevity of any metal frame is determined by the quality of the powder coating and the chemical pre-treatment process. A multi-stage wash, including phosphate conversion coating, is necessary to ensure the powder adheres properly to the substrate.

- Chrome-free pre-treatment is now the standard for eco-compliance.

- Minimum coating thickness should be 60-80 microns.

- Welds must be ground smooth to prevent “holidays” in the coating layer.

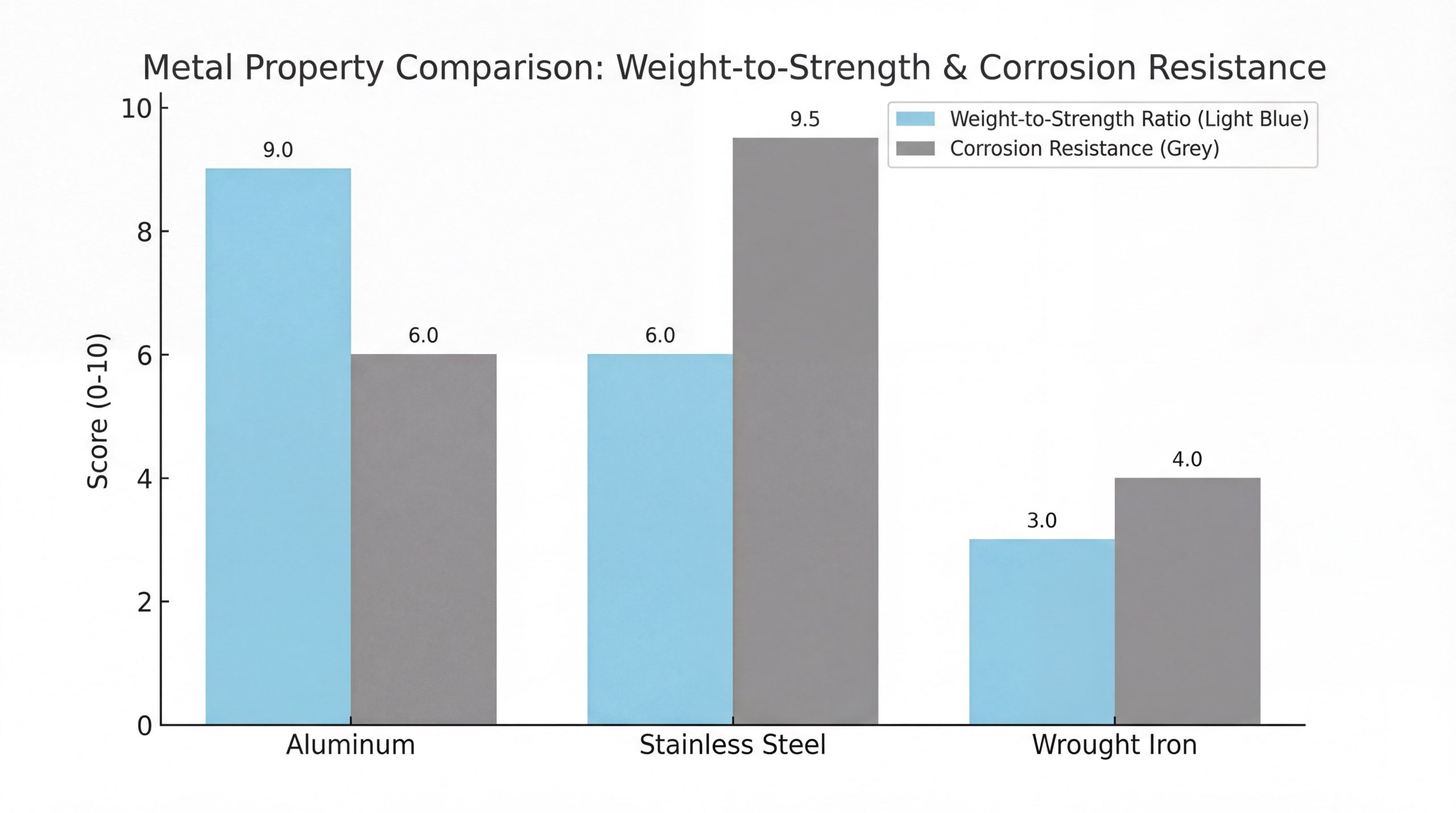

Use the decision matrix below to choose between the two most common metal framing options.

| Feature | Powder-Coated Aluminum | Stainless Steel (Grade 316) | Winner |

|---|---|---|---|

| Weight | Low (Easy to move) | High (Wind resistant) | Aluminum for ease |

| Rust Risk | Very Low | None (if 316) | Tie |

| Cost | Mid-Range | High | Aluminum for ROI |

| Best For | Residential Patios | Coastal & Commercial | Stainless for durability |

Think about this:If you source steel frames without a zinc-rich primer, the product will likely fail in humid environments before the first season ends.

Key Takeaway: Metal frames must be matched to the local climate, with aluminum serving as the best all-around performer and stainless steel reserved for high-salinity areas.

III. Outdoor Furniture Material Performance Metrics

Understanding the objective performance of an outdoor furniture material requires a data-driven approach to physical properties. Density, tensile strength, and thermal conductivity are not just engineering terms; they dictate how the product feels to the end-user and how it survives seasonal storage. For instance, high-density materials provide better wind resistance but can increase shipping costs significantly.

Weight-to-Strength Ratios

Aluminum currently dominates the market because it provides the best weight-to-strength ratio among common metals. This allows for the creation of intricate, lightweight designs that do not sacrifice the structural integrity required for heavy use. In contrast, wrought iron offers high strength but is prone to oxidation and is difficult to transport.

UV Stability and Chemical Degradation

UV radiation is the primary cause of material failure in polymers and fabric coatings. Sourcing materials with integrated UV inhibitors, rather than just topical treatments, ensures that the structural bonds of the material do not break down over time. This is especially important for Residential Furniture which may be left exposed to the sun year-round.

Thermal Conductivity and User Comfort

Metal furniture can become uncomfortably hot in direct sunlight, whereas wood and GRC maintain a more stable temperature. This factor influences the choice of material for seating surfaces versus structural frames.

- High thermal mass materials like stone retain heat longer.

- Low-density plastics may warp under high-temperature fluctuations.

- Marine-grade finishes are required for any material used near pool chemicals.

The following table compares the physical properties of the top three material categories.

| Material Group | Density (kg/m³) | UV Stability | Maintenance |

|---|---|---|---|

| Hardwoods | 650 – 900 | High (Natural) | Moderate |

| Light Metals | 2,700 (Alum) | Excellent | Low |

| Synthetic Polymers | 940 – 960 (HDPE) | High (with additive) | Very Low |

Here is the bottom line:Always request technical data sheets (TDS) from your supplier to verify that material properties meet your specific project requirements.

Key Takeaway: Performance metrics like density and UV stability are the most reliable predictors of long-term product success and customer satisfaction.

IV. Resin Wicker as an Outdoor Furniture Material

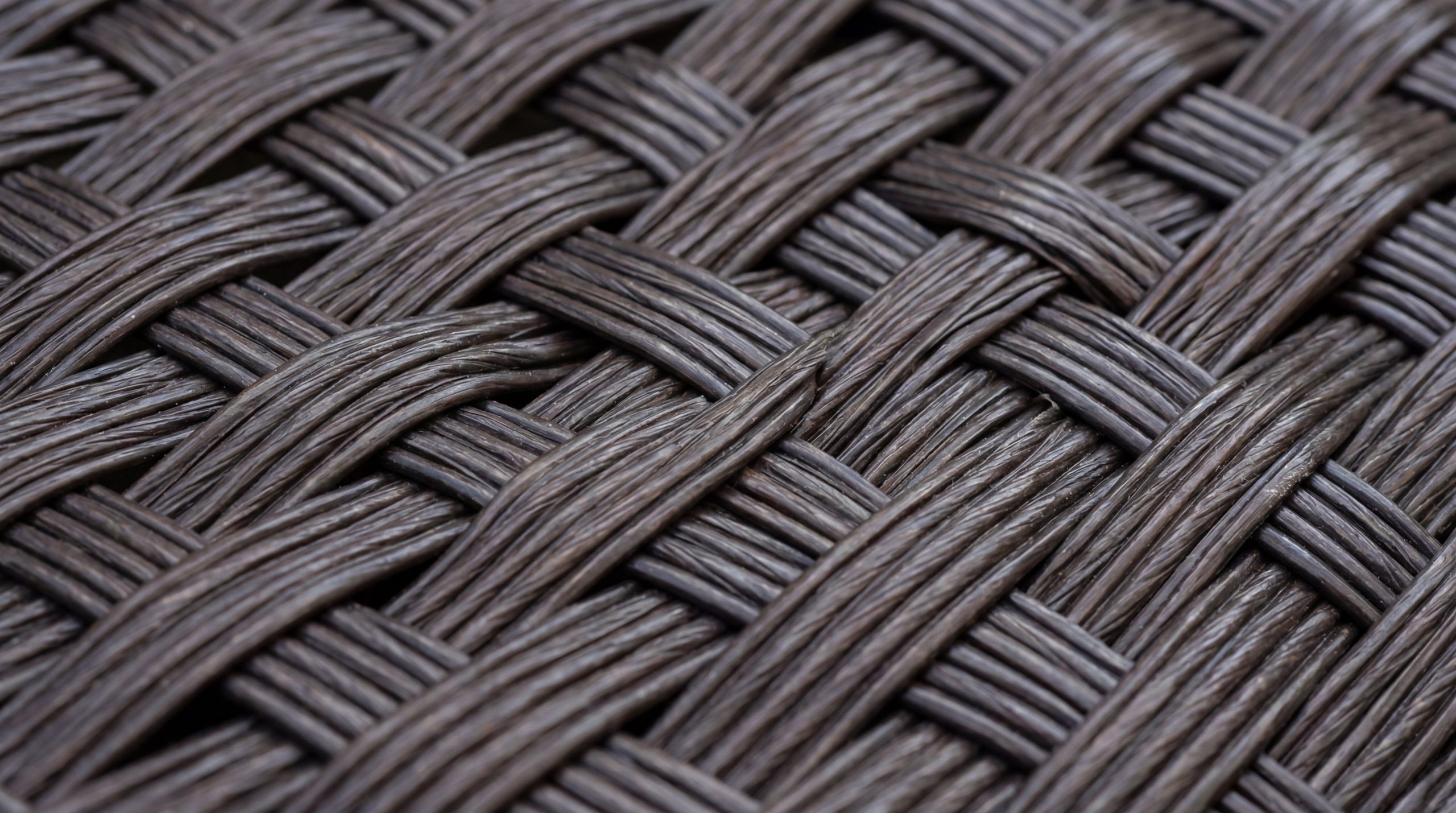

Resin wicker is a highly durable outdoor furniture material that has largely replaced natural rattan in international markets due to its superior weather resistance. High-quality synthetic wicker is extruded from High-Density Polyethylene (HDPE), which is a non-toxic, recyclable thermoplastic. Unlike PVC-based wicker, which becomes brittle and cracks when exposed to UV light, HDPE remains flexible and retains its color even in extreme temperature ranges.

HDPE vs. PVC Identification

The primary risk in sourcing wicker furniture is the substitution of cheap PVC for HDPE. PVC feels harder to the touch and has a distinct chemical odor, whereas HDPE is more supple and “waxy” in texture. From a factory perspective, HDPE is preferred for Residential Furniture because it significantly reduces after-sales claims related to unraveling and breaking.

Weave Tension and Structural Support

The longevity of a wicker piece is as much about the weaving technique as the material itself. Each strand must be woven with consistent tension over a powder-coated aluminum frame. If the tension is too loose, the wicker will sag over time; if it is too tight, the structural integrity of the individual strands may be compromised.

Color Fastness and Pigmentation

High-quality resin wicker is solution-dyed, meaning the color is consistent through the entire thickness of the strand. This ensures that scratches and minor abrasions do not reveal a different color underneath.

- Check for a minimum of 3,000 hours of UV testing.

- Ensure the frame is aluminum to prevent internal rust from staining the wicker.

- Look for hand-woven patterns which offer better durability than machine-woven alternatives.

Refer to this decision matrix when choosing between synthetic wicker grades.

| Criteria | HDPE Resin Wicker | PVC Synthetic Wicker | Winner |

|---|---|---|---|

| Environmental Impact | Recyclable/Eco-friendly | Toxic/Non-recyclable | HDPE |

| UV Resistance | 10+ Years | 1-2 Years | HDPE |

| Flexibility | Remains supple | Becomes brittle | HDPE |

| Market Position | Professional/Premium | Budget/Disposable | HDPE |

Don’t forget:Low-quality wicker often uses fillers like calcium carbonate to reduce costs, which drastically lowers the material’s impact resistance.

Key Takeaway: HDPE resin wicker is the only viable option for long-lasting furniture, offering unmatched UV protection and structural flexibility.

V. Evaluating Plastic Grade Selection for Durability

Plastic is a versatile outdoor furniture material, but the quality spectrum between recycled “junk” plastic and virgin HDPE is vast. For items like chairs used in Kids & Nursery Furniture , the material must be free of harmful chemicals and strong enough to withstand rough handling. High-density polyethylene (HDPE) is the gold standard for plastic furniture because it does not absorb moisture and is resistant to most environmental chemicals.

Virgin HDPE vs. Recycled Content

While recycled plastic is environmentally friendly, it can contain impurities that affect the structural strength of the furniture. We recommend a blend of at least 50% virgin HDPE to ensure the material retains its impact strength and color consistency. Purely recycled plastic often suffers from “stress whitening” where the material turns white at points of high tension.

Injection Molding Quality Control

The manufacturing process for plastic furniture must be strictly monitored to prevent air bubbles (voids) and sink marks. These defects are not just aesthetic; they represent structural weak points that can lead to catastrophic failure. Modern factories use precision injection molding machines with automated cooling cycles to ensure every part is uniform.

Thermal Expansion and Contraction

Plastics have a high coefficient of thermal expansion, meaning they grow and shrink significantly with temperature changes. Furniture design must account for this by using flexible joints or slotted holes for fasteners to prevent the material from buckling.

- UV stabilizers must be added in the correct percentage (usually 2-3%).

- Anti-static additives prevent the build-up of dust and grime.

- Impact modifiers can be added to increase the material’s toughness in cold climates.

The table below outlines the differences in plastic grades used for outdoor applications.

| Grade | UV Resistance | Load Capacity | Risk Level |

|---|---|---|---|

| Virgin HDPE | Highest | High | Low |

| Polypropylene (PP) | Moderate | Medium | Medium |

| Recycled PE | Variable | Low-Medium | High |

| PVC | Low | Medium | High |

Think about this:Using the wrong grade of plastic in a cold climate will result in the furniture becoming as brittle as glass during the winter months.

Key Takeaway: Virgin HDPE with added UV stabilizers is the only way to guarantee the safety and longevity of plastic outdoor furniture components.

VI. Selecting Textile Outdoor Furniture Material

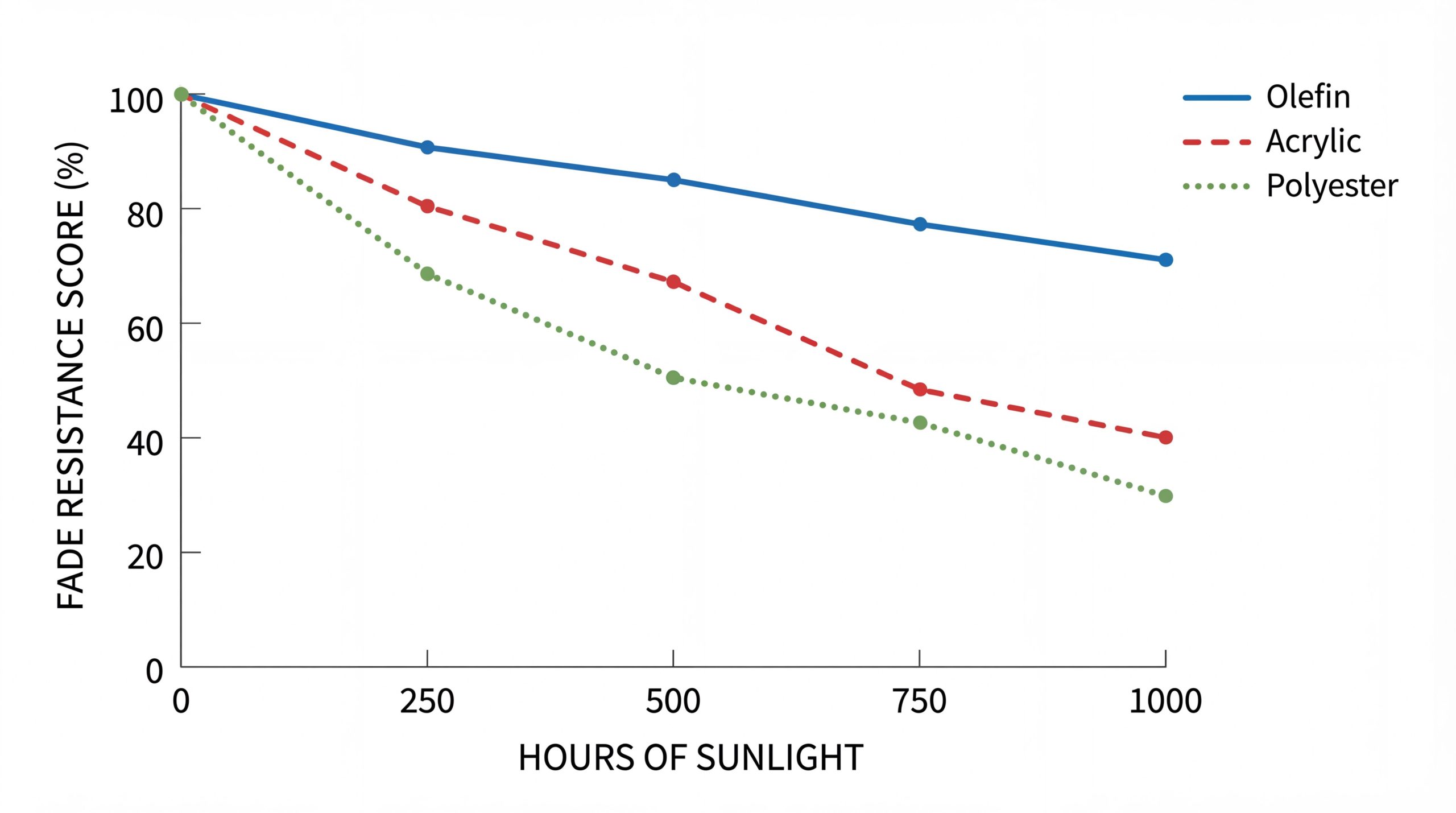

The choice of fabric as an outdoor furniture material is often the deciding factor in how long a set remains attractive. Conventional indoor fabrics like cotton or standard polyester will fade and rot within a single season of outdoor exposure. To manage this risk, buyers must specify solution-dyed synthetics like Olefin or Acrylic, which are engineered to resist UV degradation and moisture absorption.

Solution-Dyeing vs. Piece-Dyeing

In piece-dying, the color is applied only to the surface of the finished fabric, making it prone to rapid fading. Solution-dyeing involves adding the pigment to the liquid polymer before the fibers are extruded, ensuring the color is locked into the very core of the material. This process is essential for fabrics used in Outdoor Furniture applications.

Moisture Management and Mold Prevention

Outdoor fabrics should be hydrophobic or treated with a Durable Water Repellent (DWR) coating. This prevents water from soaking into the cushion core, which is the primary cause of mold and mildew growth. Additionally, using open-cell foam or reticulated foam inside the cushions allows water to drain through quickly.

Abrasion Resistance and Durability

Fabric durability is measured using the Martindale or Wyzenbeek test. For commercial outdoor use, a fabric should withstand at least 15,000 to 30,000 double rubs to ensure it does not pill or tear under frequent use.

- Solution-dyed acrylic is the premium choice for color fastness.

- Olefin provides excellent value and is highly resistant to staining.

- Breathable weaves are necessary to prevent heat build-up for the user.

The following summary table helps in selecting the right textile for your project budget.

| Fabric Type | UV Resistance (Hrs) | Water Resistance | Price Point |

|---|---|---|---|

| Acrylic (Sol-Dyed) | 1,500+ | High | Premium |

| Olefin (Sol-Dyed) | 1,000+ | Medium | Mid-Range |

| Polyester (Ctd) | 200 – 400 | Low | Budget |

Here is the bottom line:Sourcing cheap polyester cushions for a high-end furniture set will lead to customer dissatisfaction as soon as the first sign of fading appears.

Key Takeaway: Solution-dyed fabrics like Olefin and Acrylic are non-negotiable for any outdoor furniture intended to last more than one season.

VII. Hardwood Selection for High-End Projects

Wood remains a classic outdoor furniture material, but the distinction between hardwood and softwood is critical for longevity. Grade A Teak is the undisputed leader in this category due to its exceptionally high natural oil content and silica, which act as a natural defense against rot and insects. When sourcing for Outdoor Furniture , buyers must prioritize FSC-certified hardwoods to ensure both quality and environmental compliance.

The Superiority of Teak

Teak (Tectona grandis) is unique because it does not require artificial preservatives to survive outdoors. Over time, it develops a beautiful silvery-gray patina, or it can be oiled to maintain its original golden-brown hue. Other hardwoods like Acacia and Eucalyptus are popular budget-friendly alternatives but require more frequent maintenance and have a higher risk of checking (small cracks).

Moisture Content and Kiln Drying

The most common cause of warping and joint failure in wooden furniture is improper seasoning. Every piece of wood used in our factory is kiln-dried to a moisture content of 8% to 12%. This ensures that the wood has reached its equilibrium moisture content, minimizing the movement that occurs when the product is shipped to different climates.

FSC Certification and Sourcing Ethics

Sourcing wood responsibly is a major risk management factor for modern retailers. Using FSC-certified wood ensures that the material comes from managed forests, preventing legal risks associated with the Lacey Act in the US or EUTR in the EU.

- Grade A teak is cut from the heartwood of mature trees.

- Avoid “sapwood” as it lacks the natural oils found in heartwood.

- Mortise and tenon joinery is essential for long-term structural stability.

Use this decision matrix to determine if premium teak is worth the investment for your project.

| Feature | Grade A Teak | Economic Pine/Fir | Winner |

|---|---|---|---|

| Lifespan | 25+ Years | 3-5 Years | Teak |

| Pest Resistance | Naturally Immune | Requires Treatment | Teak |

| Stability | Very High | High Warp Risk | Teak |

| Initial Cost | High | Low | Pine (Budget only) |

Think about this:The labor cost to maintain a cheap wood set over five years often exceeds the initial cost of a premium teak set.

Key Takeaway: Grade A teak is the most durable wooden outdoor furniture material, offering a lifespan that justifies its higher initial procurement cost.

VIII. Testing Every Outdoor Furniture Material

Quality assurance for an outdoor furniture material is not a single event but a continuous process that begins with raw material inspection. At EverWoody, we implement rigorous testing protocols to ensure that every component meets international standards like EN581 for outdoor furniture safety. For clients in the Educational Furniture sector, these tests are even more stringent to ensure the safety of children.

Salt Spray and Corrosion Testing

Metal components undergo salt spray testing (ISO 9227) to simulate years of coastal exposure in a few hundred hours. This reveals any weaknesses in the powder coating or the underlying alloy. We only pass materials that show zero signs of corrosion after 500 hours of continuous exposure.

Structural Loading and Fatigue Tests

Every furniture design is subjected to static load and fatigue testing. This involves applying thousands of cycles of weight to the seating surfaces and backrests to ensure the joints and materials do not fatigue. This is a critical step in reducing the risk of product liability claims.

Chemical and Finish Safety

All finishes, including paints and oils, are tested for lead and phthalate content. For products destined for the EU or US markets, compliance with REACH and CPSIA is mandatory. We provide full documentation for every batch of Educational Furniture we produce.

- Moisture meters are used on 100% of wood components before assembly.

- Cross-hatch adhesion tests ensure powder coating won’t peel.

- UV weatherometer testing verifies the longevity of fabrics and plastics.

The following table summarizes our standard quality control checklist for all outdoor orders.

| Procedure | Standard | Pass Criteria |

|---|---|---|

| Salt Spray Test | ISO 9227 | No rust @ 500 hours |

| Moisture Check | Internal SOP | 8% – 12% MC |

| Coating Adhesion | ASTM D3359 | 4B – 5B Rating |

| Load Testing | EN 581 | 110kg – 160kg capacity |

Don’t forget:A factory that cannot provide recent test reports is a high-risk partner that could cost you your reputation.

Key Takeaway: Rigorous technical testing is the only way to transform an “aesthetic” material choice into a reliable, long-term business asset.

IX. Logistics and Packaging Safety Standards

Even the highest quality outdoor furniture material can be compromised by poor logistics and packaging. Damage during maritime transit or “last-mile” delivery is one of the biggest hidden costs in the furniture industry. To protect your investment, we utilize ISTA-3A certified packaging standards, which include drop tests and vibration simulations.

Humidity Control in Containers

Wooden and metal furniture is highly sensitive to the “container rain” phenomenon, where moisture condenses on the ceiling of the shipping container and drips onto the product. We use high-capacity desiccant bags and VCI (Vapor Corrosion Inhibitor) bags for metal parts to prevent rust and mold growth during long voyages.

Edge Protection and Internal Bracing

Flat-pack furniture requires specialized internal protection to prevent the corners from crushing. We use high-density foam inserts and reinforced cardboard edge protectors to ensure the product arrives in pristine condition. This is especially important for delicate Wooden Home Accessories that may have intricate details.

Carton Strength and Stackability

Our shipping cartons are made from heavy-duty 5-ply or 7-ply corrugated cardboard. Each carton is marked with clear handling instructions and stacking limits to prevent structural collapse in the warehouse.

- Double-wall cartons are used for all items over 20kg.

- Polybags must have suffocation warnings for the US/UK markets.

- All hardware is vacuum-sealed to prevent loss and oxidation.

This table outlines the packaging tiers available for different sales channels.

| Channel Type | Protection Level | Packing Density | Cost Impact |

|---|---|---|---|

| E-commerce (Mail Order) | Highest (ISTA-3A) | Low | High |

| Traditional Retail | Medium | High | Low |

| Project/Bulk | Low (Bulk Pallet) | Very High | Lowest |

Think about this:Investing 2% more in packaging can reduce your damage-related return rate by up to 15%, directly increasing your bottom line.

Key Takeaway: Logistics planning and robust packaging are essential components of the material selection process for international furniture sourcing.

X. Sustainable Outdoor Furniture Material Trends

The future of outdoor furniture material is increasingly focused on sustainability and circular economy principles. Global retailers are now demanding materials that are not only durable but also have a low carbon footprint. From recycled ocean plastics to fast-growing timber alternatives, the industry is shifting toward materials that offer long-term ecological and economic value.

Recycled Ocean Plastics

Manufacturers are now able to transform discarded fishing nets and ocean-bound plastic into high-performance HDPE furniture. This material offers the same durability as virgin HDPE while providing a compelling marketing story for eco-conscious consumers. We are seeing a major uptick in this material for Wooden Home Accessories and decorative accents.

Thermally Modified Timber (TMT)

Thermal modification is a process that uses heat and steam to change the cellular structure of sustainable softwoods like pine, making them as durable as tropical hardwoods. This eliminates the need for chemical preservatives and allows for the use of locally sourced, fast-growing timber.

Bio-Based Resins and Coatings

The industry is moving away from solvent-based finishes toward bio-based resins derived from plants. These coatings offer excellent UV protection while significantly reducing Volatile Organic Compound (VOC) emissions during the manufacturing process.

- Recycled aluminum requires 95% less energy to produce than virgin aluminum.

- Look for Global Recycled Standard (GRS) certification.

- Bio-based coatings must still meet traditional durability benchmarks.

The following table compares the sustainability profile of emerging materials.

| Emerging Material | Main Advantage | Durability Rank | ROI Potential |

|---|---|---|---|

| Ocean Plastic HDPE | Eco-Impact | High | High |

| Thermally Modified Wood | No Chemicals | Moderate-High | Medium |

| Recycled Aluminum | Low Energy | Highest | Highest |

Consider this:Sustainability is no longer a niche market; it is becoming a mandatory requirement for large-scale institutional and government contracts.

Key Takeaway: Sustainable material sourcing is the next frontier in furniture procurement, offering a path to both brand loyalty and environmental responsibility.

FAQ about Outdoor Furniture Material

What is the best outdoor furniture material for salt air?

Aluminum or Grade 316 stainless steel are the best choices for coastal environments. These materials naturally resist the corrosive effects of salt spray and moisture, provided they are finished with marine-grade powder coatings.

Which outdoor furniture material is most mold-resistant?

Synthetic materials like HDPE resin wicker and aluminum are naturally mold-resistant because they do not absorb moisture. For fabrics, solution-dyed acrylic treated with a water-repellent coating is the most effective at preventing fungal growth.

How can you tell if an outdoor furniture material is high quality?

Verify the technical specifications, such as the alloy grade for metal, the moisture content for wood, and the UV rating for plastics. A reputable factory should provide test reports from independent laboratories like SGS or Intertek.

Final check

Selecting the right outdoor furniture material is a strategic decision that balances durability, maintenance, and environmental risk. By prioritizing high-performance substrates like Grade A teak, aluminum, and HDPE, you can significantly reduce return rates and build a more profitable brand. If you are ready to secure high-quality products, feel free to contact us for a custom quote.