Buyers evaluate furniture manufacturers by conducting on-site technical audits and tiered quality inspections to ensure that production aligns with global safety and durability standards. If you overlook factory-level verification, you risk significant financial losses from product recalls and structural failures that damage your brand’s market standing. A systematic evaluation approach solves these inconsistencies by identifying defects before the goods leave the assembly line.

I. How to evaluate furniture manufacturers effectively?

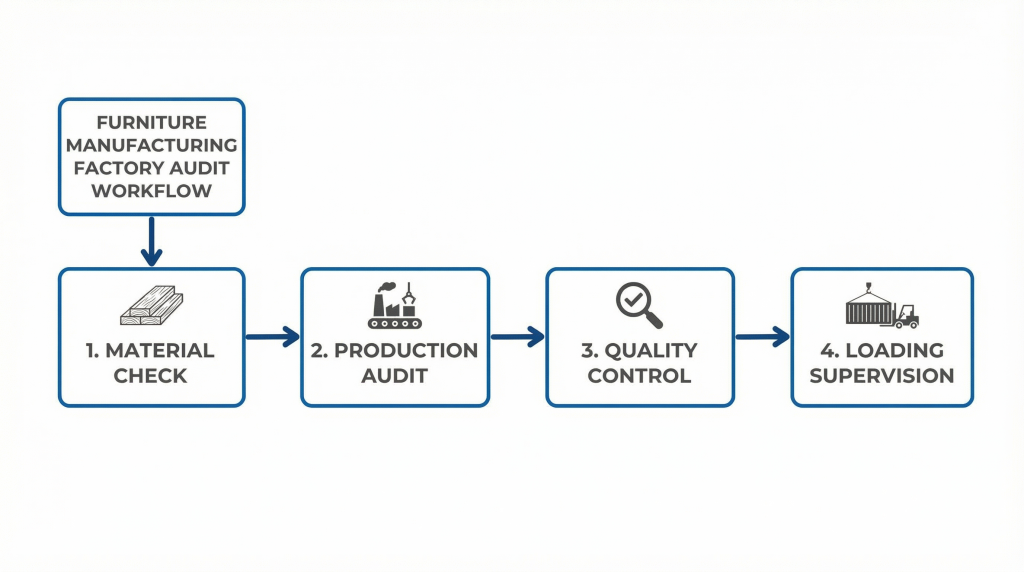

To evaluate furniture manufacturers effectively, you should implement a multi-stage inspection framework that covers everything from raw material verification to final container loading. This process ensures that the factory has the technical capability to meet your specific design requirements and lead times without compromising safety. By focusing on the factory floor, you gain visibility into the actual manufacturing conditions that influence the final product’s quality.

Identifying systemic factory risks?

Are you aware of how hidden manufacturing flaws can lead to catastrophic product failures? These risks often stem from inadequate joint strength, toxic chemical off-gassing, or general structural instability. Keep this in mind: a factory’s past performance is no guarantee of future quality without rigorous oversight.

- Inadequate joint strength

- Toxic chemical off-gassing

- Structural instability

The following data summarizes the essential stages of a professional factory-level technical audit.

| Audit Stage | Focus Area | Success Metric |

|---|---|---|

| Technical Audit | Machinery & Workflow | Production efficiency |

| Quality System | QC Protocols | Low defect rates |

| Compliance | Safety Standards | Certification validity |

II. How to evaluate furniture manufacturers’ materials?

To evaluate furniture manufacturers’ materials, you must assess the authenticity of wood species and moisture content to prevent future warping or cracking in your residential furniture . Evaluating furniture manufacturers at the source includes checking for FSC certifications and the presence of harmful VOCs in paints or adhesives. This foundational step ensures that the materials used match your specifications and meet environmental regulations.

Validating wood moisture and origin?

How do you confirm that the timber used in your order is actually the solid hardwood you paid for? You should utilize digital moisture meters to target an 8-12% range and verify the FSC Chain of Custody certificates. The best part? Catching material defects at the warehouse stage prevents you from wasting time on a doomed production run.

- Moisture meter testing (8-10% target)

- FSC Chain of Custody verification

- Visual inspection for knots and cracks

Reviewing these material benchmarks is the only way to guarantee the longevity of wood products post-sale.

| Material Check | Requirement | Evaluation Method |

|---|---|---|

| Wood Moisture | 8% – 12% | Digital Moisture Meter |

| Certification | FSC / PEFC | Certificate Verification |

| Surface Finish | Low-VOC / LFGB | Lab Chemical Analysis |

III. Evaluate furniture manufacturers via prototyping?

You should evaluate furniture manufacturers through First Article Inspections (FAI) because samples serve as the benchmark for all subsequent units in kids furniture orders. Inspecting the initial prototype allows you to correct aesthetic discrepancies and structural weaknesses before the factory commits to high-volume manufacturing. This stage provides the ultimate proof of a manufacturer’s ability to translate technical drawings into physical reality.

Confirming structural integrity early?

What happens if your sample fails a basic stability or weight-bearing test? You must subject the prototype to static load testing and joint stress analysis to identify potential failure points. Think about it: it is much cheaper to fix a design flaw in a single sample than in a thousand finished units.

- Static load testing

- Joint stress analysis

- Finish adhesion (3M tape test)

Comparing the physical sample to the master specification ensures that the factory can replicate your design consistently.

| Prototype Test | Standard | Pass Criteria |

|---|---|---|

| Stability | EN 1022 | No tip-over under load |

| Strength | EN 1728 | No fracture after cycles |

| Dimensions | ± 2mm | Matches technical drawing |

IV. Evaluate furniture manufacturers during production?

Evaluating furniture manufacturers during production (DPI) allows you to catch errors when the first 10% to 20% of the order is completed. This proactive step helps you identify recurring defects in the assembly line or finishing booth that could affect the entire batch if left unaddressed. By intervening mid-stream, you ensure the production schedule stays on track and quality remains uniform across all components.

Monitoring batch consistency in-line?

Can you afford to wait until the end of production to discover that every chair has an uneven leg? Professional inspectors perform workmanship checks and assembly audits to ensure every component fits flush and tight. Here is the kicker: spotting a finishing error during DPI can save you weeks of rework and thousands of dollars in wasted materials.

- Inline workmanship check

- Assembly process audit

- Color matching against master sample

Analyzing production flow in real-time gives you the leverage to demand immediate corrections before mass assembly finishes.

| DPI Checkpoint | Focus Area | Goal |

|---|---|---|

| Workmanship | Sanding/Joints | Zero visible burrs or gaps |

| Component Fit | Mortise/Tenon | Flush and tight connections |

| Schedule | Output Rate | Align with delivery deadline |

V. Evaluate furniture manufacturers at final QC?

You should evaluate furniture manufacturers at final QC using Pre-Shipment Inspections (PSI) to verify the quality of the finished goods before they are packed. This evaluation typically follows AQL standards, where a statistically significant sample is drawn to check for functional, aesthetic, and safety defects. Only after passing this final gate should you authorize the balance payment and release the shipment.

Applying AQL standards to finished goods?

How many defects are you willing to accept in a shipment of five hundred tables? Most buyers follow a strict limit where 0% critical defects are allowed, while minor aesthetic issues have a slightly higher tolerance. In other words: AQL sampling provides a scientifically valid snapshot of your shipment’s quality without the cost of a 100% inspection.

- Critical: 0% allowed

- Major: 2.5% limit

- Minor: 4.0% limit

The final quality control report serves as your last line of defense against sub-standard product delivery.

| Defect Category | Example | Action |

|---|---|---|

| Critical | Sharp edges / Lead paint | Immediate Rejection |

| Major | Cracked wood / Wrong color | Rework required |

| Minor | Acceptable within the limit | Acceptable within limit |

VI. Inspection of factory loading safety protocols?

Evaluating the loading safety protocols is essential to ensure that your products are not damaged by moisture, pests, or improper stacking during transit. Container Loading Supervision (CLS) involves verifying the container’s condition and monitoring the placement of cartons to maximize space while protecting fragile items. This final check prevents last-mile damage that can occur even if the products were manufactured perfectly.

Supervising container loading protocols?

Do you know if the factory is loading your furniture into a container with a leaking roof or holes? You must verify container integrity and stacking patterns to ensure heavy items remain on the bottom to avoid crushing cartons. Keep this in mind: poor stacking in a container is one of the leading causes of transit damage for large wooden furniture items.

- Container integrity check

- Loading pattern verification

- Seal number recording

A technical analysis of the loading process ensures that the shipping environment remains secure throughout the journey.

| Loading Check | Requirement | Purpose |

|---|---|---|

| Container | Dry and Odorless | Prevent mold and smells |

| Stacking | Heavy items on bottom | Avoid crushing cartons |

| Quantities | Accurate carton count | Ensure no missing items |

VII. Evaluate furniture manufacturers’ lab compliance?

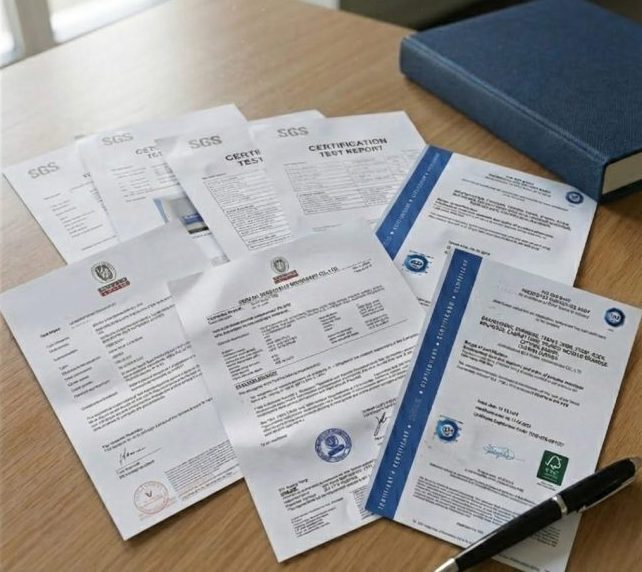

To evaluate furniture manufacturers for global market access, you must assess their adherence to laboratory testing for mechanical safety and chemical emissions. You should verify that their products, especially those for office furniture applications, meet BIFMA or EN standards for durability and CARB Phase 2 for formaldehyde. These tests provide an unbiased verification of the manufacturer’s claims and satisfy consumer safety agencies.

Navigating EN and ASTM safety requirements?

Is your supplier able to provide valid test reports that satisfy customs and consumer safety agencies? You must verify compliance with standards like EN 1728 for seating durability or ASTM F963 for children’s furniture safety. The best part? Verified lab reports act as an insurance policy against government fines and mandatory product recalls.

- BIFMA (Office sustainability)

- EN 71 (Child safety)

- CAL TB 117 (Flammability)

Reviewing these certifications allows you to filter out manufacturers who cannot legally sell into your target jurisdiction.

| Safety Standard | Target Market | Product Type |

|---|---|---|

| EN 1728 | Europe | Seating Durability |

| ASTM F963 | USA | Children’s Furniture |

| CARB P2 | USA | Formaldehyde Emissions |

VIII. Assessing factory transparency and social ethics?

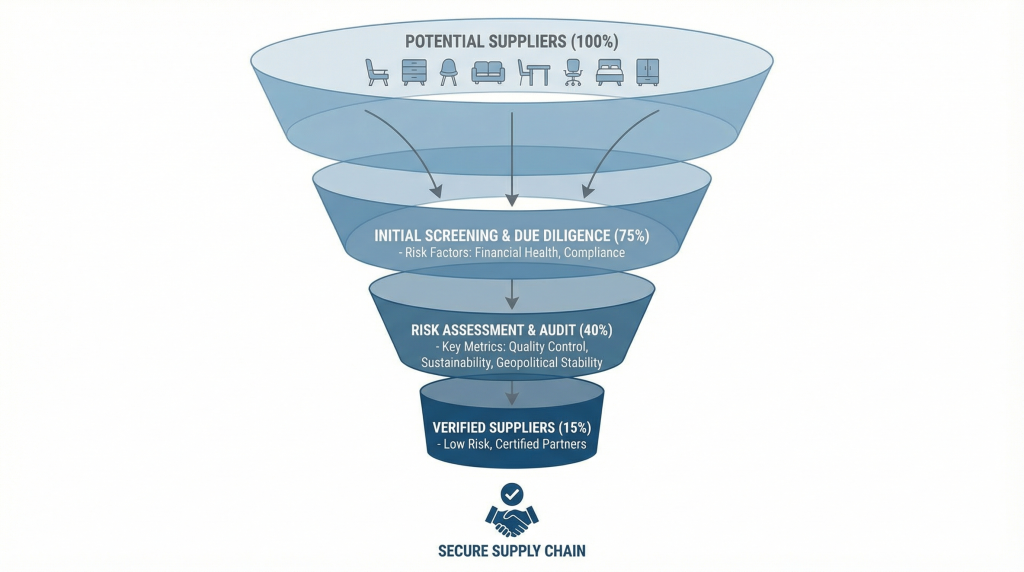

You should evaluate transparency to ensure that your supply chain is free from ethical violations and hidden sub-contracting. A transparent manufacturer allows for social audits and provides clear documentation of their Tier-2 suppliers for hardware and textiles. This level of openness is critical for maintaining your brand’s reputation and meeting the growing consumer demand for ethically sourced goods.

Conducting social and environmental audits?

Are you certain that your factory is following fair labor practices and proper waste disposal methods? You should check for SA8000 social compliance and ISO 14001 environmental impact certifications to mitigate supply chain risks. Think about it: a lack of transparency often hides poor management practices that eventually manifest as quality issues.

- Social compliance (SA8000)

- Environmental impact (ISO 14001)

- Sub-contractor disclosure

Evaluating transparency requires looking beyond the production line to the management systems that govern the entire facility.

| Audit Type | Focus | Outcome |

|---|---|---|

| Social | Labor rights/Safety | Ethical sourcing score |

| Technical | Machinery/Capacity | Production capability |

| ESG | Sustainability | Brand alignment |

IX. Evaluating factory scaling and machine capacity?

To evaluate manufacturers on scaling capacity, you must analyze their machinery, workforce size, and production lead times during peak seasons. You need to know if the factory can handle a sudden increase in order volume without sacrificing the quality standards established during the sample phase. This evaluation helps you determine if the manufacturer is a suitable long-term partner for your growth strategy.

Testing production limits for bulk orders?

Can your manufacturer maintain a 30-day lead time when you triple your monthly order volume? You should analyze machine uptime and the availability of skilled labor to prevent bottlenecks during high-demand periods. Here is the kicker: many factories over-promise their capacity, leading to late shipments and rushed, lower-quality workmanship.

- Machine uptime analysis

- Skilled labor availability

- Warehouse storage capacity

Performing a capacity audit ensures that your business growth is supported by a factory that can scale output reliably.

| Capacity Metric | Evaluation Point | Risk Factor |

|---|---|---|

| CNC Hours | Machine availability | Production bottlenecks |

| Staff Count | Trained QC team | Inspection oversight |

| Lead Time | Average vs. Peak | Late delivery impact |

X. Managing long-term factory partnership risks?

To evaluate manufacturers for long-term success, you must build a relationship based on continuous improvement and shared quality goals. This involves regular factory audits and the implementation of a Corrective Action Plan (CAP) whenever defects are detected during the inspection process. By treating the factory as a strategic partner, you can drive down defect rates and improve production efficiency over time.

Building strategic factory relationships?

How do you ensure that your manufacturer remains committed to your quality standards over several years? You should conduct periodic re-audits and maintain a transparent feedback loop regarding product performance and consumer returns. In other words, treating a manufacturer as a partner rather than a vendor creates mutual accountability for product excellence.

- Periodic re-audits

- Corrective Action Plans (CAP)

- Shared quality KPIs

The following matrix highlights how to track improvement across a long-term manufacturing partnership.

| Partnership Metric | Tracking Method | Long-term Goal |

|---|---|---|

| Defect Trend | Monthly QC Reports | Continuous reduction |

| Lead Time Accuracy | Shipping Logs | 95% on-time delivery |

| Innovation Rate | New Prototype Speed | Faster market entry |

FAQ

Can I skip the during-production inspection if the sample was perfect?

No, because mass production introduces variables like machine wear and different wood batches. You must verify consistency throughout the entire run to avoid batch-wide failures.

What’s the best way to handle a failed final inspection?

Issue a formal rejection report immediately and require the factory to perform 100% sorting at their expense. You should never release the final payment until a re-inspection proves the issues are resolved.

How do I know if a factory is sub-contracting my order?

Perform unannounced visits and check if the machinery on-site matches the production requirements of your specific items. You should also look for inconsistencies in labeling and packaging that suggest external handling.

Can I rely on the factory’s internal QC reports?

No, as factory reports are often biased; you should always use an independent third-party inspector to verify the results. Trust but verify remains the standard industry rule for global sourcing.

How do I know if a manufacturer is truly FSC certified?

Ask for their specific FSC Chain of Custody (CoC) number and verify it directly on the official FSC public database. A simple logo on a website is not valid proof of current certification.

To optimize your supply chain through factory-level oversight and technical audits, you can explore our approach to quality control and manufacturing excellence. Our commitment to transparency and rigorous inspection standards ensures that your brand is protected at every stage of the production cycle.