Furniture sourcing from China requires a fundamental shift from simple purchasing to managing complex industrial ecosystems. Traditional buyers often face material substitutions and quality drift that occur when oversight is absent. These issues escalate into legal seizures or brand damage when products fail safety tests, making professional evaluation protocols essential for supply chain stability.

I. Landscape of Furniture Sourcing from China

The landscape of furniture sourcing from China is defined by specialized regional clusters that dictate manufacturing strengths and supply chain efficiency. Understanding whether a hub focuses on solid wood or upholstery is the first rule for professional procurement. Here is the kicker: proximity to specific ports determines your raw material access and total lead times.

Why do regional clusters dictate your quality?

Regional clusters allow factories to share specialized labor pools and material supply chains for hardware and finishing. This ecosystem reduces manufacturing variability compared to isolated facilities.

- Shandong: Premium solid wood furniture hub.

- Guangdong: Expertise in upholstery and modern metal designs.

- Zhejiang: Focus on office and outdoor category mass production.

Key Takeaway: Always align your product category with its corresponding industrial cluster to maximize technical expertise.

II. Risks in Furniture Sourcing from China

Risks in furniture sourcing from China primarily involve quality fade and unauthorized material substitutions during production cycles. Importers must recognize that legal liability for non-compliant goods rests entirely on their shoulders regardless of factory promises. But there is more.

Is “Quality Fade” an inevitable part of the process?

Quality fade refers to the incremental reduction in material grade over successive orders. Without strict oversight, premium timber is often replaced with lower-grade fillers to preserve factory margins.

- Material Substitution: Using MDF in place of specified solid wood.

- Chemical Drift: Switching to non-compliant glues or finishes.

- Structural Shortening: Reducing joinery complexity to speed up lines.

| Risk Factor | Severity | Mitigation Strategy |

|---|---|---|

| Material Substitution | High | Batch-level laboratory testing |

| Structural Failure | Critical | Static load and drop testing |

| Finish Defects | Medium | Standardized light-box color matching |

Key Takeaway: Implement a physical presence or third-party oversight to counteract the natural tendency toward quality fade.

III. Technical Material Standards and Safety

Technical material standards for wooden toys and furniture center on moisture content and chemical compliance. Professional buyers must specify kiln-drying parameters to prevent warping when goods are shipped to drier climates. Make no mistake: finishing chemicals are the ultimate hurdle for international market access.

What determines the durability of your timber?

Moisture content is the primary factor in the long-term structural integrity of wooden furniture. Proper kiln-drying to 8%–12% is required to ensure the wood does not crack or warp in the target market.

- Digital Moisture Metering: Standard verification tool.

- Kiln-Drying Logs: Essential documentation for batch audits.

- Acclimatization: Post-drying rest periods before machining.

| Specification | Standard | Verification |

|---|---|---|

| Timber Moisture | 8% – 12% | Meter Test |

| VOC Content | CARB / EPA | Lab Report |

| Hardware Finish | Salt Spray | Cycle Testing |

Key Takeaway: Specify technical parameters in the initial purchase agreement to ensure materials survive climate transitions.

IV. Logistics of Furniture Sourcing from China

Logistics of furniture sourcing from China depend on optimizing container utilization through strategic flat-pack designs. Shipping fully assembled pieces often results in excessive freight costs that erode potential profit margins. Here’s the deal: peak season bottlenecks can delay shipments by several weeks if not planned.

How does “Flat-Pack” design save your margins?

Knock-down (KD) designs maximize the cubic meter (CBM) efficiency of every shipping container. This approach significantly lowers the per-unit shipping cost despite requiring more detailed assembly instructions.

- CBM Optimization: Reducing empty space in sea containers.

- Packaging Strength: ISTA-standard drop tests for e-commerce.

- Hardware Kitting: Precise sorting to prevent assembly delays.

| Transit Mode | Best For | Risk Level |

|---|---|---|

| FCL (Full Container) | Bulk Orders | Low |

| LCL (Partial) | Small Batches | High Handling |

| Air Freight | Urgent Prototypes | High Cost |

Key Takeaway: Design products for modular assembly to reduce freight overhead and improve overall pricing competitiveness.

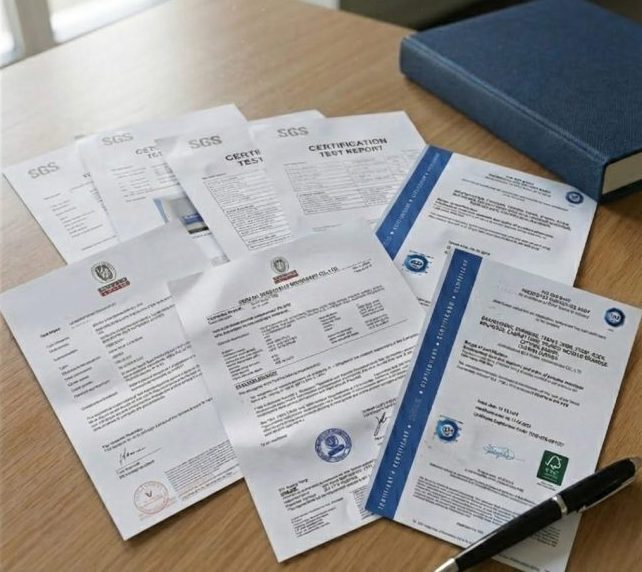

V. Third-Party Factory Audits and Verification

Third-party factory audits verify that a facility possesses the machinery and manpower claimed in their marketing materials. A physical walk-through is necessary to inspect the actual workshop floor and social compliance standards. But wait, there is more.

Does an ISO 9001 certificate guarantee quality?

ISO 9001 indicates a management system exists but does not guarantee the quality of a specific furniture piece. Buyers must verify actual machine calibration and worker safety protocols through independent on-site inspections.

- Bone Pile Inspection: Checking the scrap area for rejection rates.

- Machine Calibration: Verifying precision for CNC and saws.

- Labor Verification: Ensuring legal age and safety equipment usage.

| Audit Component | Focus | Red Flag |

|---|---|---|

| Technical Audit | Machinery | Poor maintenance |

| Social Audit | Labor Rights | Safety violations |

| Environmental | Chemicals | Improper waste disposal |

Key Takeaway: Never rely on digital brochures; always utilize independent audits to confirm manufacturing capabilities.

VI. Compliance in Furniture Sourcing from China

Compliance in furniture sourcing from China requires strict adherence to international timber legality and safety labeling regulations. Importers must secure chain-of-custody documentation to avoid customs penalties and environmental violations. Let that sink in: missing one tracking label can result in an entire shipment being destroyed.

Is your wood legally and sustainably harvested?

The Lacey Act and EUTR demand proof of legal timber origin to prevent the sale of illegally logged wood. Obtaining FSC certification is the industry standard for verifying sustainable and legal forest management.

- FSC Chain of Custody: Tracking wood from forest to factory.

- REACH/Prop 65: Chemical safety for paints and glues.

- Tracking Labels: Required for all kids and nursery products.

| Regulation | Region | Focus Area |

|---|---|---|

| FSC | Global | Timber Legality |

| ASTM F963 | USA | Safety Standards |

| EN 71-3 | EU | Heavy Metal Limits |

Key Takeaway: Compliance is a non-negotiable legal requirement that protects your brand from catastrophic financial penalties.

VII. Quality Control Methods and Last Defenses

Quality control methods provide a last line of defense before goods leave the factory floor and balance payments are made. Professionals utilize office furniture inspection protocols to ensure structural integrity and finish consistency. The bottom line is this: leverage disappears once the container seal is broken.

Why is pre-shipment inspection your last defense?

Pre-shipment inspections (PSI) confirm that the mass production units match the approved golden sample in every detail. Inspectors perform functional tests and visual checks to prevent defective goods from entering your warehouse.

- AQL Sampling: Standardized statistical quality checks.

- Functional Testing: Static load and hardware cycle tests.

- Visual Inspection: Checking for grain matching and finish burrs.

| Inspection Type | Timing | Main Goal |

|---|---|---|

| Initial (IPI) | 10% Production | Material verification |

| During (DUPRO) | 30% Production | Early defect detection |

| Pre-Ship (PSI) | 100% Production | Final quality gate |

Key Takeaway: Invest in pre-shipment inspections to secure your margins and reduce the rate of customer returns.

VIII. Sustainable Furniture Sourcing from China

Sustainable furniture sourcing from China involves selecting factories that prioritize low-VOC finishes and FSC-certified timber. Consumers now demand transparency regarding the environmental footprint of their home furnishings. It gets better: eco-friendly practices often align with higher long-term manufacturing efficiency.

How does eco-friendly manufacturing impact your brand?

Utilizing reclaimed wood or fast-growing species like bamboo can differentiate a brand in competitive Western markets. However, green claims must always be backed by third-party documentation to avoid greenwashing risks.

- Low-VOC Coatings: Healthier indoor air quality for users.

- Waste Management: Recycling wood dust and scrap into fuel.

- FSC-Certification: Mandatory proof of sustainable timber use.

| Eco Strategy | Brand Benefit | Cost Impact |

|---|---|---|

| FSC Timber | Regulatory Trust | Moderate |

| Water-based Paint | Consumer Health | Low |

| Recycled Material | Market Appeal | Variable |

Key Takeaway: Sustainability is no longer a niche preference but a core requirement for modern furniture brand resilience.

IX. The Lifecycle of Furniture Sourcing from China

The lifecycle of furniture sourcing from China spans from initial design prototyping to post-delivery warranty monitoring. Rushing the sampling phase often leads to systemic failures during mass production cycles. Believe it or not: the process only truly ends when the product performs in the end-user’s environment.

How long should the sampling process really take?

High-quality prototyping usually requires two to four weeks to ensure all structural and aesthetic details are refined. This approved sample becomes the “Golden Sample” that dictates the quality of all future production batches.

- Prototyping: Refining design and structural integrity.

- Production Run: Executing mass manufacturing protocols.

- Feedback Loop: Adjusting future runs based on warranty data.

| Phase | Duration | Output |

|---|---|---|

| Sourcing | 2-3 Weeks | Qualified Factory |

| Sampling | 4-6 Weeks | Golden Sample |

| Production | 45-60 Days | Export Cargo |

Key Takeaway: Respect the manufacturing timeline to ensure that quality is built into the product rather than rushed out.

X. Success Protocols for Professional Buyers

Success protocols for professional buyers involve drafting bilingual contracts that are enforceable under local Chinese law. Establishing a long-term partnership ensures that your orders receive priority during high-demand manufacturing windows. One last thing: solid wood dining table sourcing succeeds only when the relationship is built on mutual transparency.

Are your contracts enforceable in China?

Standard Western contracts are rarely effective unless they are drafted as NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreements. These documents must be stamped with the factory’s official “Chop” to be legally binding in a Chinese court.

- NNN Agreements: Protecting your intellectual property.

- Guanxi Building: Developing long-term factory relationships.

- Transparent Specs: Eliminating ambiguity in tech packs.

| Final Protocol | Requirement | Impact |

|---|---|---|

| Legal Security | Bilingual NNN | IP Protection |

| Technical Clarity | Complete Tech Pack | Lower Defects |

| Communication | Direct Management | Priority Status |

Key Takeaway: Professional success in the furniture sector depends on combining legal rigor with deep supplier relationships.

FAQ

Can I source custom furniture with low risk?

Risk is mitigated by implementing third-party inspections and detailed technical specifications from the very first order.

What’s the best way to verify a factory’s capacity?

Physical factory audits focusing on machinery maintenance and production logs provide the only reliable capacity data.

How can I avoid material substitutions?

Establish a batch-testing protocol for raw materials and perform random “bone pile” checks during the manufacturing process.

Should I use a trading company or a direct factory?

Direct factories offer more control over technical details, while reputable trading companies can provide broader category management and logistics support.

Is it possible to track timber origins easily?

Yes, by demanding FSC Chain of Custody documentation, you can verify the legal path of timber from forest to warehouse.

Strategic success in the global furniture market relies on moving beyond simple transactions to embrace rigorous manufacturing standards. By prioritizing compliance, technical transparency, and proactive quality control, importers can build resilient supply chains that stand the test of time. As you refine your procurement strategy, explore our approach to find a partner committed to manufacturing excellence and sustainable growth.