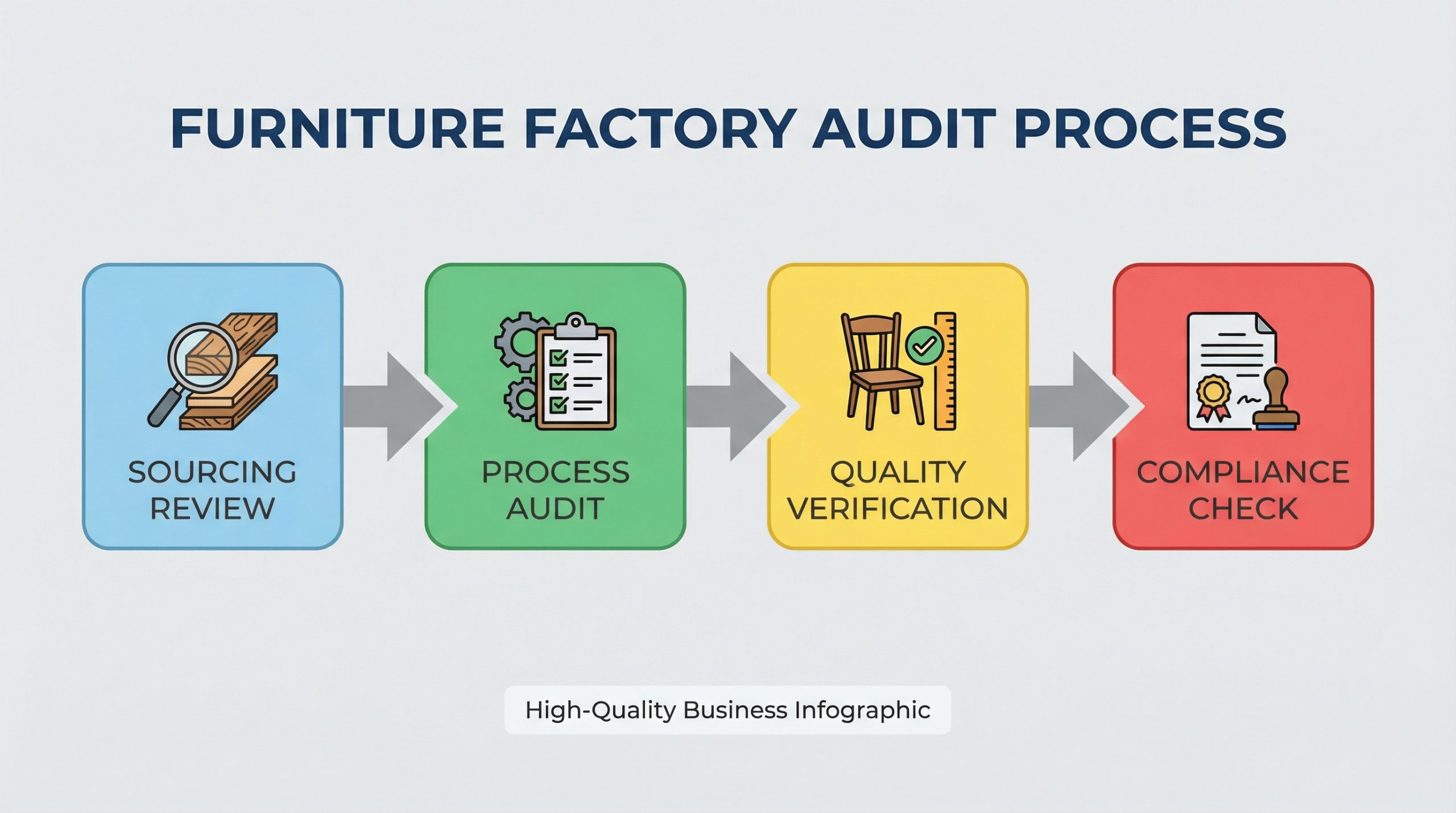

Buyers evaluate furniture manufacturers by conducting on-site audits of timber moisture, structural joinery precision, and safety compliance reports. Relying on digital catalogs alone risks receiving shipments with warped wood or unstable joints that can devastate your brand reputation and result in expensive recalls. Professional sourcing relies on a standardized assessment of the production floor to verify that a manufacturer’s claims match their operational reality.

I. Auditing Raw Material Integrity

You assess material quality by testing moisture levels and verifying the authenticity of wood species entering the workshop. To effectively evaluate furniture manufacturers, you should start by confirming that solid timber is not being substituted with cheaper veneers or composite materials. Simply put, the durability of your final product depends entirely on the grade of timber used at the start.

Verifying Moisture Content

You must ensure the factory uses calibrated moisture meters to check every batch of raw lumber for residential furniture . Think about this:

- Wood with high moisture content will eventually crack or warp.

- Calibrated pin-type meters should show a range of 8% to 12%.

- Consistent logs prevent future structural failures in dry retail environments.

Key Takeaway: Authentic material sourcing and moisture control prevent structural failures and ensure long-term product value.

| Material Factor | Standard Requirement | Quality Impact |

|---|---|---|

| Moisture Content | 8% – 12% | Structural Stability |

| Wood Grade | Species Match | Product Longevity |

| Certification | FSC / PEFC | Market Compliance |

Establishing the integrity of raw materials provides a baseline for evaluating the secondary stages of furniture manufacturing.

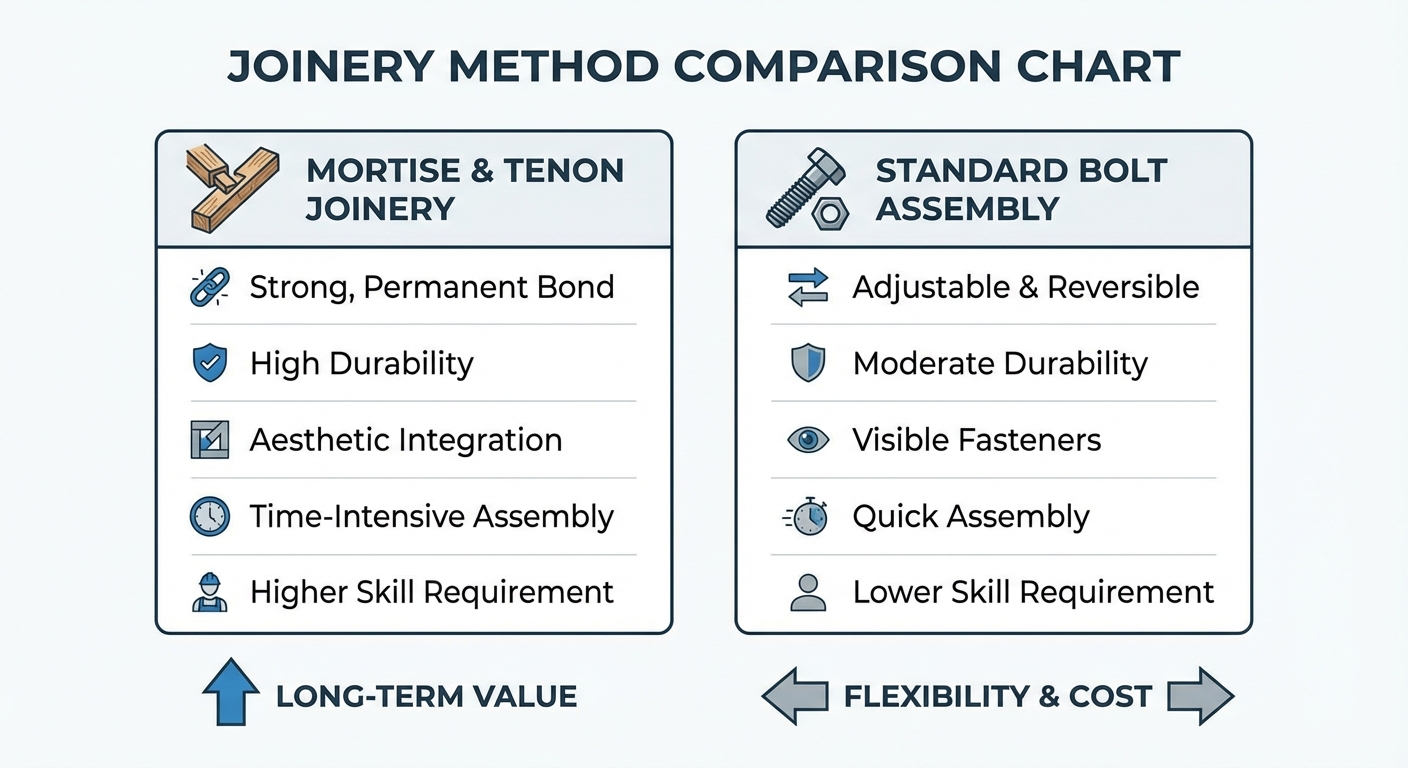

II. Evaluate Furniture Manufacturers on Joinery

You evaluate furniture manufacturers on structural engineering by inspecting the precision of their cutting and grooving equipment. Modern buyers look for factories that utilize CNC machinery to ensure every component fits perfectly during final assembly without wobbling. Hand-cut joints often introduce human error that leads to unstable units for the end-user.

Testing Joint Stability

You should inspect the tightness of mortise and tenon joints to ensure they are free from excessive gaps or loose connections. Here is the thing:

- CNC precision guarantees the consistent tolerances required for commercial orders.

- Tight joints should hold together even before the application of industrial glue.

- Machine-led joinery is the foundation of furniture safety and professional craftsmanship.

Key Takeaway: Machine-led precision joinery provides the consistent results required for maintaining high-volume quality across diverse categories.

| Engineering Check | Factory Requirement | Expected Outcome |

|---|---|---|

| Cutting Method | CNC Precision | Uniform Components |

| Joinery Style | Mortise & Tenon | Superior Strength |

| Tolerance | < 0.5mm Deviation | Perfect Assembly |

Once the structural frame is verified, your next audit point focuses on the surface finishes and chemical safety protocols.

III. Evaluate Furniture Manufacturers’ Finishing

You check finishing protocols by analyzing the consistency and safety of the surface coating processes for outdoor furniture . It is essential to verify that the factory performs multi-stage hand sanding before applying the final coat to eliminate rough textures or bubbles. High-quality finishes require climate-controlled spray booths to prevent dust particles from ruining the final sheen.

Sanding Consistency

You should look for smooth edges and a consistent sheen across different batches of furniture. The best part?

- Multi-stage sanding ensures a professional feel that reflects attention to detail.

- Even color application prevents noticeable variations between separate production units.

- Smooth surfaces are easier to maintain and more attractive to retail consumers.

Key Takeaway: A multi-stage sanding and painting process is necessary to achieve both regulatory safety compliance and premium aesthetic appeal.

| Finish Component | Audit Standard | Goal |

|---|---|---|

| Coating Type | Water-based / Eco-friendly | User Safety |

| Texture | Even & Hand-sanded | Aesthetic Appeal |

| Application | Controlled Spray Booth | Clean Finish |

Surface appearance must be backed by official documentation to ensure the products meet global safety standards.

IV. Assessing Global Safety Compliance

You assess compliance by reviewing the manufacturer’s ability to provide updated safety reports for their specific materials. To thoroughly evaluate furniture manufacturers, you need to confirm they hold valid certifications like EN71 or ASTM F963 for mechanical safety. These documents must be batch-specific and verified against independent laboratory databases to be truly reliable for customs clearance.

Verification of Certification

You must request updated test reports that cover heavy metals and paint safety for every product line. But wait, there’s more:

- Regulatory compliance is non-negotiable for entering European and American markets.

- Certification prevents costly import rejections at international borders.

- Verified safety reports protect your business from legal liabilities and consumer injury claims.

Key Takeaway: Regulatory compliance is a non-negotiable requirement for entering Western markets and protecting your brand from safety litigation.

| Compliance Type | Target Market | Core Focus |

|---|---|---|

| EN71 / ASTM | EU / USA | Mechanical Safety |

| FSC Chain | Global | Wood Sustainability |

| CARB Phase 2 | USA | Low Formaldehyde |

Compliance documents prove safety, but technical capacity determines if a factory can actually deliver your order on time.

V. Evaluate Furniture Manufacturers’ Capacity

You evaluate furniture manufacturers on capacity by reviewing their machinery inventory and total production floor space. You should confirm that the facility has enough automated systems to handle your specific order volume without compromising lead times. A workshop with only manual tools will struggle to maintain quality consistency during peak ordering seasons.

Assessing Scalability

You should verify the presence of specialized machines and the total square footage of the manufacturing area. Simply put:

- Higher machine counts translate to faster lead times and lower human error.

- Large floor space allows for a more efficient and organized production workflow.

- Scalability ensures the manufacturer can grow with your business over long-term contracts.

Key Takeaway: Capacity assessment allows you to predict a manufacturer’s performance during peak seasons and their ability to fulfill large contracts.

| Capacity Metric | Target Value | Benefit |

|---|---|---|

| Machine Units | 25+ Specialized Units | Faster Lead Times |

| Floor Space | 3,000m² Minimum | Efficient Workflow |

| Monthly Output | 10-20 Containers | Scalability |

Technical capacity must be paired with protective engineering to ensure the furniture reaches its destination in perfect condition.

VI. How to Evaluate Furniture Manufacturers’ Packaging

You evaluate furniture manufacturers on packaging by inspecting their specialized areas for transit protection and carton density. You must ensure they use custom foam inserts and moisture-resistant materials to protect goods during long-distance maritime transport. Even the highest quality furniture is worthless if it arrives at your warehouse with crushed corners or surface scratches.

Shipping Protection

You should request a “drop test” report to verify that the packaging can survive global logistics. Look at this:

- Custom foam inserts prevent shifting and internal damage during heavy handling.

- Double-wall corrugated boxes provide the external strength needed for container stacking.

- Moisture-resistant wrapping is essential for protecting wood during long-distance sea freight.

Key Takeaway: Professional packaging is an engineering task that prevents post-sale returns and protects your overall profit margins.

| Packaging Step | Material Used | Protection Goal |

|---|---|---|

| Edge Protection | Custom Foam | Prevent Scratches |

| Inner Barrier | Moisture Film | Mold Prevention |

| External Shell | Double-Wall Box | Impact Resistance |

Reliable packaging is the result of a disciplined quality control unit monitoring every stage of the manufacturing process.

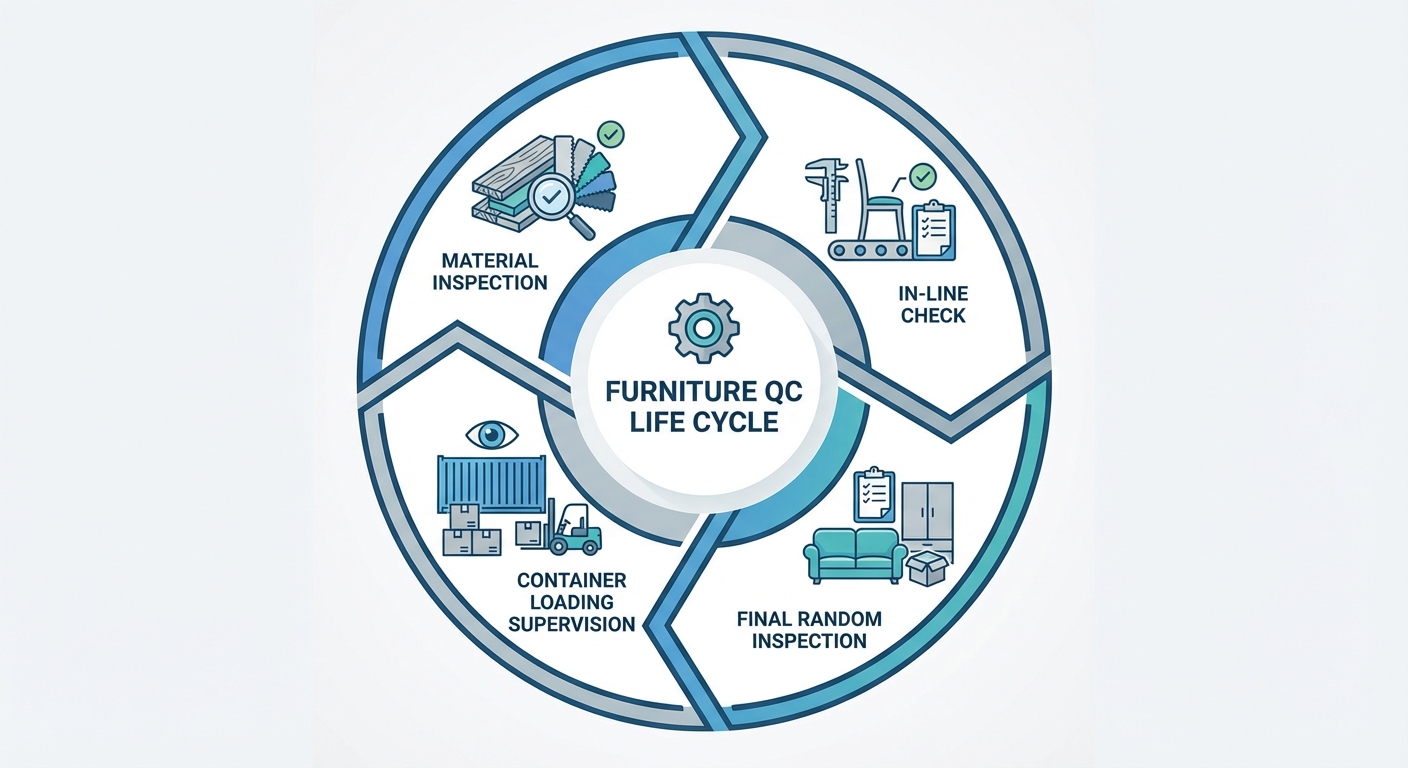

VII. Auditing Quality Control Procedures

You audit QC procedures by checking the frequency of in-line inspections and the availability of archived shipment photos. When you evaluate furniture manufacturers, a dedicated quality control team usually indicates a factory that prioritizes error prevention over raw speed. You should ask for dimensional check records and batch logs that are systematically updated for every order.

Reviewing QC Logs

You must verify that inspections occur during raw material intake, mid-production, and final packaging. The result?

- Transparent logs provide the data you need to trust a supplier’s consistency.

- In-line checks prevent small defects from turning into large-scale production failures.

- Pre-shipment photos act as your eyes on the ground before the container leaves.

Key Takeaway: A disciplined quality control unit acts as your eyes on the ground, ensuring every unit meets your specific quality threshold.

| QC Stage | Checkpoint | Documentation |

|---|---|---|

| In-Line | Joint Stability | Live Photos |

| Pre-Shipment | Finish & Appearance | QC Report |

| Loading | Container Integrity | Loading Log |

Quality control also extends to the ethical environment of the factory, which impacts long-term workforce stability.

VIII. Evaluate Furniture Manufacturers on Ethics

You evaluate ethical standards by auditing worker safety equipment and labor conditions for kids furniture . You need to observe the factory environment to ensure it aligns with global social audit requirements and safe labor practices. Unethical manufacturing poses a significant risk to your brand’s reputation in the eyes of modern, conscious consumers.

Workplace Safety

You should check for proper protective gear and ensure the facility maintains a clean and organized production floor. Consider this:

- Proper worker safety equipment reduces the risk of production delays caused by accidents.

- Clean workshops often correlate with higher precision and lower defect rates.

- Ethical labor practices are essential for building stable, long-term partnerships.

Key Takeaway: Ethical manufacturing practices are essential for building long-term partnerships and maintaining a positive public image for your brand.

| Ethics Audit | Requirement | Impact |

|---|---|---|

| Worker Safety | PPE & Guards | Reduced Liability |

| Facility | Organized & Clean | Higher Efficiency |

| Labor | Age & Hours Verified | Brand Reputation |

A safe workspace is only part of the facility; the way they store their raw materials is equally telling of their expertise.

IX. Evaluate Furniture Manufacturers’ Storage

You evaluate furniture manufacturers on storage by verifying climate controls and ground-clearance racking for raw materials. Experienced buyers examine how timber is stored to prevent mold or structural warping before it even reaches the assembly line. Wood stored in humid or outdoor conditions will inevitably crack once it reaches a dry retail environment.

Wood Stability

You should confirm that wood is stored off the ground in a climate-controlled area with batch tags for easy tracking. The catch?

- Elevation prevents ground moisture from seeping into the raw planks.

- Climate locking maintains the stability of the natural timber throughout the seasons.

- Batch tags ensure that the right wood grade is used for the correct project.

Key Takeaway: Proper storage facilities are a silent but powerful indicator of a factory’s expertise in handling natural wooden materials.

| Storage Factor | Factory Standard | Purpose |

|---|---|---|

| Elevation | Racked Off-Ground | Moisture Control |

| Environment | Climate-Locked | Material Stability |

| Inventory | Batch Tagged | Tracking Accuracy |

The final piece of the evaluation puzzle is how the manufacturer supports you after the products leave their warehouse.

X. Reviewing After-Sales Responsiveness

You gauge responsiveness by testing the resolution timeframes for quality issues and the willingness to provide compensation plans. To fully evaluate furniture manufacturers, you should look for partners who offer a defined 3-day resolution window for any production concerns. The relationship truly begins when the goods arrive, and your supplier must be ready to provide technical support.

Support Availability

You should verify that the manufacturer offers a transparent policy for handling damaged or defective goods. You know the feeling:

- A 6-hour inquiry response time indicates a manufacturer committed to communication.

- Pre-defined compensation plans minimize your financial risk during unexpected issues.

- Weekly progress updates maintain total transparency over your order lifecycle.

Key Takeaway: Selecting a manufacturing partner with strong after-sales responsiveness ensures your long-term business success and operational stability.

| Service | Metric | Assurance |

|---|---|---|

| Inquiry | 6-hour Response | Communication |

| Issue Fix | 3-day Resolution | Risk Reduction |

| Updates | Weekly Progress | Transparency |

Conclusion

Selecting the right production partner requires moving beyond the surface of a digital catalog and into the heart of the workshop. When you explore our approach , you will find that a factory’s true value lies in its machines, its people, and its internal quality systems. By following these industry norms to evaluate furniture manufacturers, you secure a supply chain that is both resilient and reliable. Our brand stance is that precision in manufacturing is the only path to building furniture that defines environments and comforts lives.

Frequently Asked Questions

Can I request a factory tour before placing an order?

Yes, professional buyers often conduct on-site or virtual tours to verify the machinery and storage conditions mentioned in the factory’s profile.

What is the best way to verify wood moisture content?

The most reliable method is to observe the factory’s QC team using a calibrated pin-type moisture meter on raw planks and semi-finished parts.

Can I check the packaging density myself?

You should request a “drop test” report or video where a fully packed carton is dropped from a specific height to ensure the foam protection holds.

How do I know if the paint is truly eco-friendly?

You should ask for the manufacturer’s latest VOC (Volatile Organic Compound) test report and check for international certifications like EN71-3 or ASTM safety reports.

What happens if I find defects after the container arrives?

A reliable manufacturer will have a pre-defined compensation plan and should offer a resolution or replacement within a few working days.